2

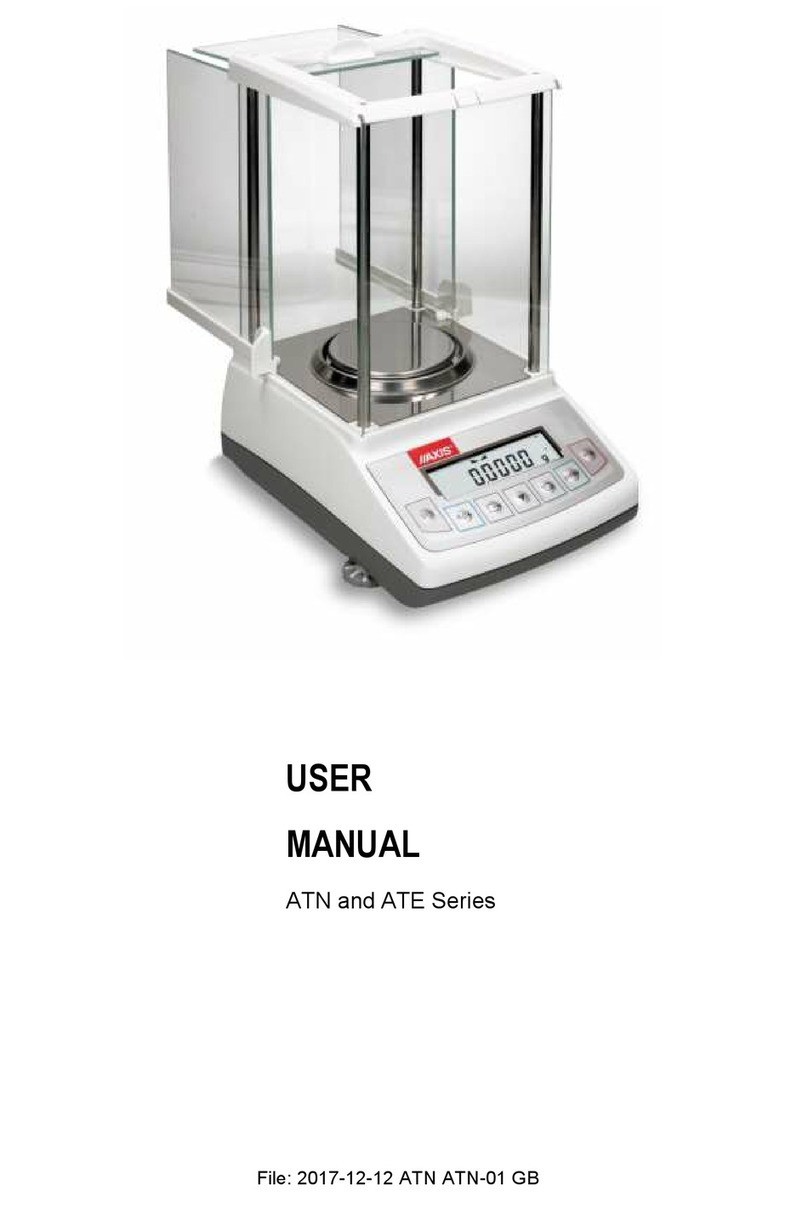

INSTRUCTION MANUAL

_____________________________________________________________________________________________________________________

Table of contents:

1. General description ................................................................................................................................................................ 3

2. Completation .......................................................................................................................................................................... 4

3. echnical data ........................................................................................................................................................................ 4

4. Safety principles ..................................................................................................................................................................... 5

5. Principles of used balance treatment ..................................................................................................................................... 5

6. Balance keys and indicators .................................................................................................................................................. 6

7. Balance preparation to work .................................................................................................................................................. 7

8. Balance start .......................................................................................................................................................................... 8

9. Operation principles ............................................................................................................................................................... 9

10. Balance test .................................................................................................................................................................... 10

11. Balance adjustment ........................................................................................................................................................ 10

12. Connection with computer, printer or label printer .......................................................................................................... 10

13. Basic function.................................................................................................................................................................. 14

13.1 Normal weighing ............................................................................................................................................................. 14

13.2 Weighing with tare .......................................................................................................................................................... 15

13.3 Increased readability ....................................................................................................................................................... 15

14. Special functions describtion .......................................................................................................................................... 16

14.1 Menu customization function (ACtIV and dEFAUL) ........................................................................................................ 17

14.2 Autozeroing function (AutoZE) ....................................................................................................................................... 18

14.3 Pieces counting (PCS) ................................................................................................................................................... 19

14.4 Printer cooperation settings (PrInt) ................................................................................................................................ 20

14.5 Serial port parameters setting (Port) .............................................................................................................................. 21

14.6 Constant tare (tArE) ........................................................................................................................................................ 22

14.7 Average calculation function (AVErAG) ......................................................................................................................... 24

14.8 Recipe weighing function (RECIPE) .............................................................................................................................. 25

14.9 Percentage weighing function (PErC) ............................................................................................................................ 26

14.10 Anti-disturbance filter function (FILtEr) ..................................................................................................................... 27

14.11 Function for maximum value indication (UP) ............................................................................................................. 28

14.12 Force measuring function (nEWto) ........................................................................................................................... 29

14.13 Function for weighing large animals (LOC) ............................................................................................................... 30

14.14 Checkweighing function (thr) ..................................................................................................................................... 31

14.15 otal weight function (totAL) ...................................................................................................................................... 34

14.16 Function for setting date and time (dAtE) .................................................................................................................. 36

14.17 Function for selecting label number (LAbEL) ............................................................................................................ 37

14.18 External calibration (CALIb) ....................................................................................................................................... 38

14.19 Setting time of stabilization function (Stb) ................................................................................................................. 39

14.20 Entering reference zero function (Zero) ..................................................................................................................... 40

14.21 Automatic switching off the scale function (AutoOF) ................................................................................................. 41

14.22 Density determining function (dEnSIt) ....................................................................................................................... 42

14.23 Statistical calculations function (StAt) ............................................................................................................................. 44

15. Maintenance and small repairs ................................................................................................................................................ 46

Declaration of Conformity ............................................................................................................................................................... 47

Appendix A ..................................................................................................................................................................................... 48