2INSTRUCTION MANUAL

_____________________________________________________________________________________________________________________

Table of contents:

1. General description.......................................................................................................................................... 4

2. Certificates:...................................................................................................................................................... 4

3. Meters.............................................................................................................................................................. 5

4. Completation.................................................................................................................................................... 7

5. Technical data.................................................................................................................................................. 7

6. Security rules ................................................................................................................................................. 10

7. Scale external outputs.................................................................................................................................... 11

7.1 Connecting a computer, printer or label printer.............................................................................................. 13

7.2 Detailed LonG protocol description................................................................................................................ 14

7.3 Detailed EPL protocol description.................................................................................................................. 16

8. Balance preparation to work .......................................................................................................................... 17

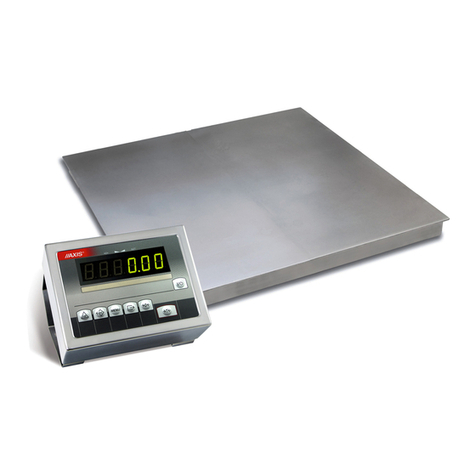

8.1 Preparing platform, pallet and skid scales ..................................................................................................... 17

8.2 Preparing overrun scales ............................................................................................................................... 18

8.3 Preparing foundation scales........................................................................................................................... 19

8.3.1 Preparing foundation............................................................................................................................. 19

8.3.2 Scale installation ................................................................................................................................... 21

9. Balance test........................................................................................................................................................ 22

10. Accumulator change (ME-01 option).............................................................................................................. 23

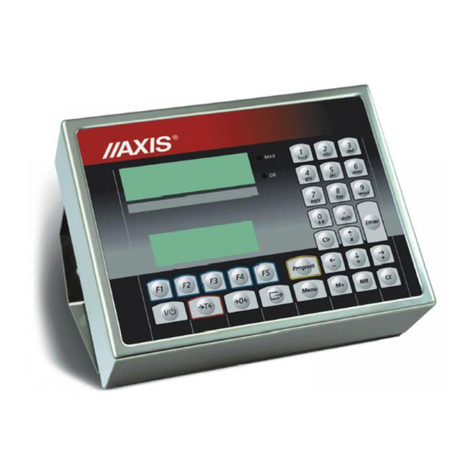

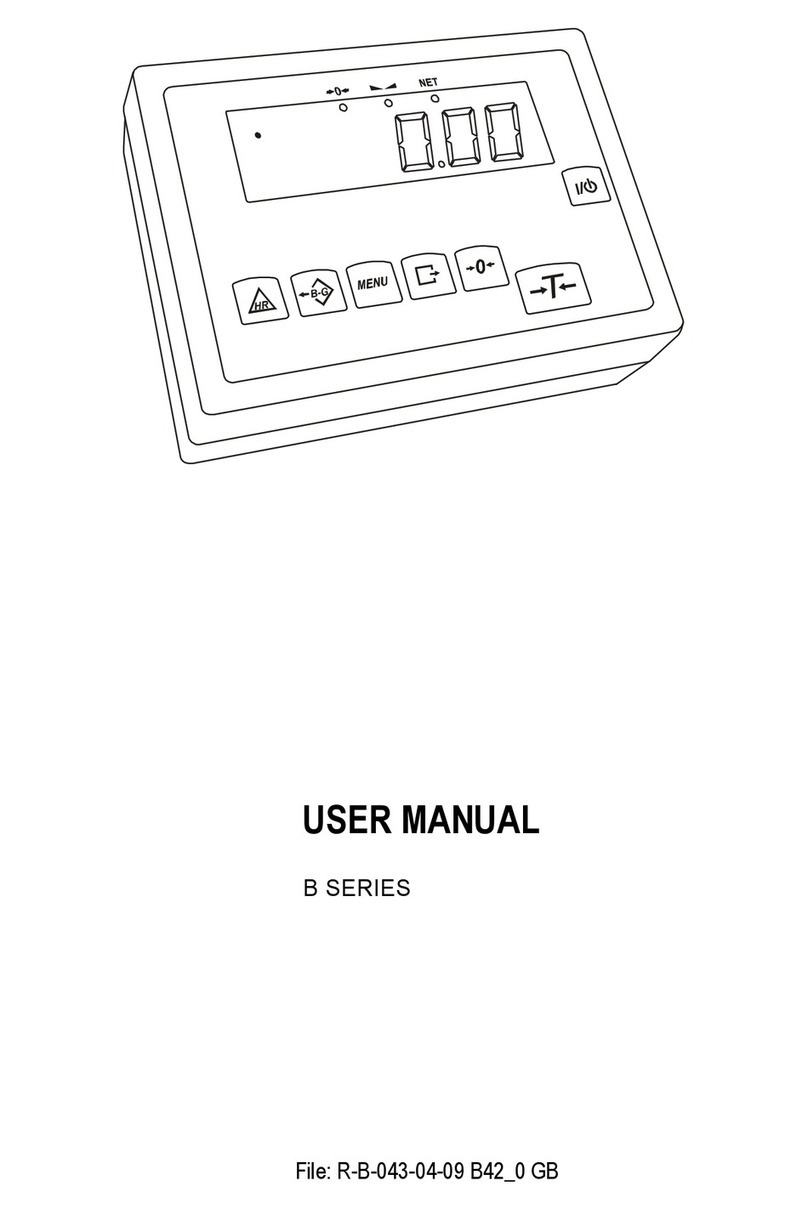

11. Scale with ME-01 meter keys and indicators ................................................................................................. 24

12. Operation principles ....................................................................................................................................... 26

13. Start-up .......................................................................................................................................................... 27

14. Weighing with tare.......................................................................................................................................... 28

15. Scale menu.................................................................................................................................................... 29

16. Menu navigation rules.................................................................................................................................... 30

17. Scale setup (SEtUP)...................................................................................................................................... 35

17.1 Scale calibration (CALIb)........................................................................................................................... 37

17.2 Autozeroing function (AutoZEr) ................................................................................................................ 38

17.3 Weight unit selection (UnIt)........................................................................................................................ 39

17.4 Serial port parameters setting (SErIAL).................................................................................................... 40

17.5 Printout configuration (PrInt).................................................................................................................... 41

17.6 Setting backlight function (b_LIGHt) .......................................................................................................... 43

17.7 Analog out configuration (AnALoG)........................................................................................................... 44

17.8 Entering reference zero value (ZErO)........................................................................................................ 45

18. Special functions description.......................................................................................................................... 46

18.1 Products and users database (Prod i USEr).............................................................................................. 47

18.2 Pieces counting function (PCS) ................................................................................................................ 51

18.3 Percentage weighing function (PErC)....................................................................................................... 52

18.4 Label choosing function (LAbEL)............................................................................................................... 53