TECH ICAL A D MOTIO DOCUME TATIO

___________________________________________________________________________________________________

3

1. Introduction

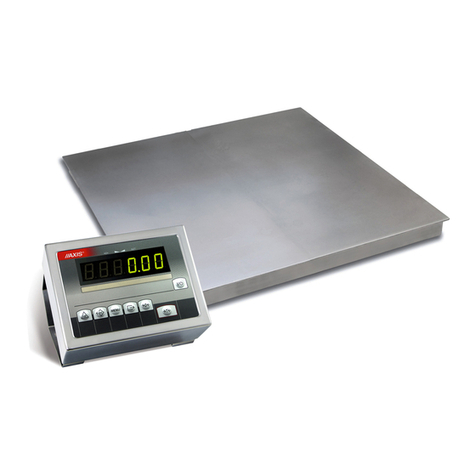

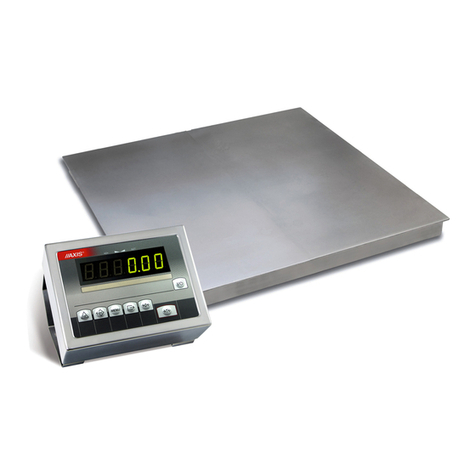

Balance meter SE-12 is suitable for connecting platform with weight sensors and

performs all basic balance functions. Moreover, it is possible to perform data exchange

between SE-12 module and computer through the multi-station S485. If the module is

equipped with auxiliary S232C ports, it is also possible to read bar codes with the

handheld scanner and printing weight slips or self-adhesive labels. The module is

delivered separately or as part of ready balance (according to order).

2. Certificates

SE-12 meters have the test certificate no. PL CB 1, issued by Central Office Of

Measures in Warsaw (Notified Unit No. 1440).

Meters SE-01/N/18 and SE-01/N/25 have IP65 protection grade, confirmed by test

performed in esearch Laboratory of Electrotechnical Institute, accredited by PCA.

Meter can be used for constructing balance according to standard PN-EN 45501

Specification for metrological aspects of non-automatic weighing instruments, issued in

December 1999, harmonized with the 90/384/EEC council directive, changed by

93/68/EEC council directive).

Balances classification (PKWiU code) 29.24.23.

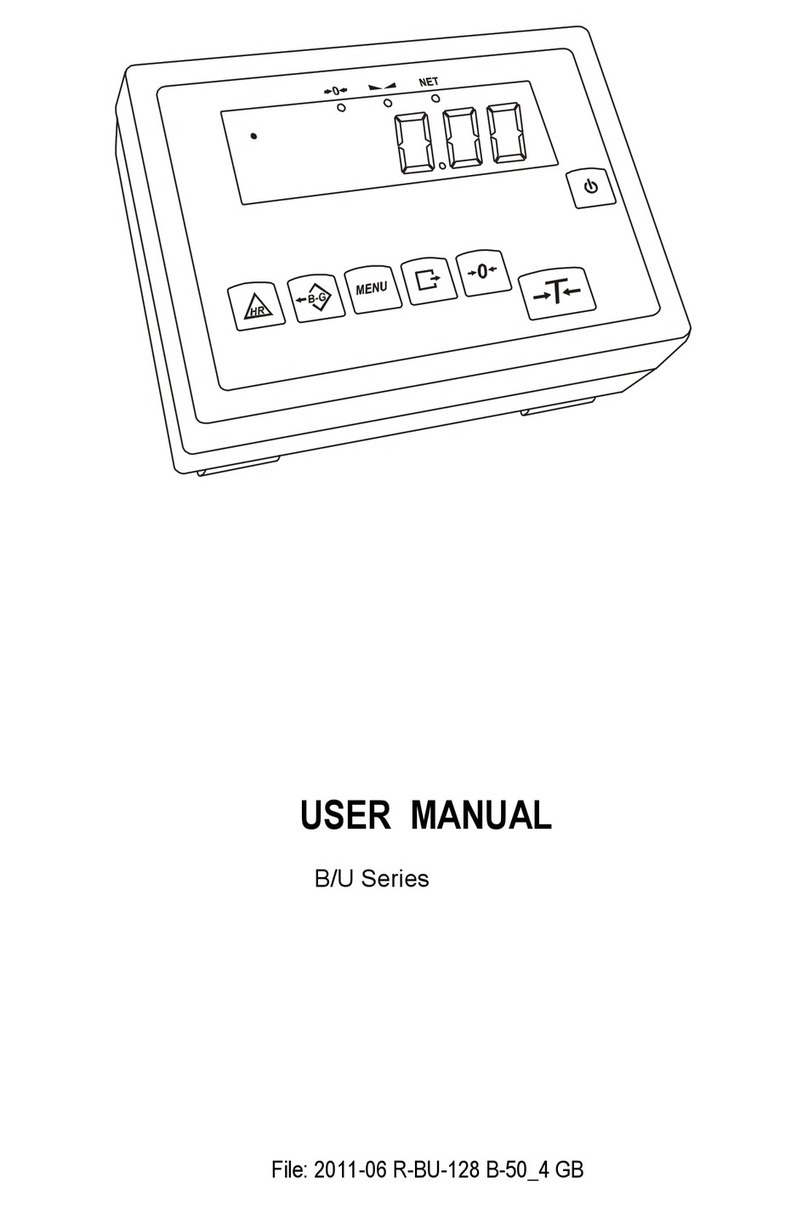

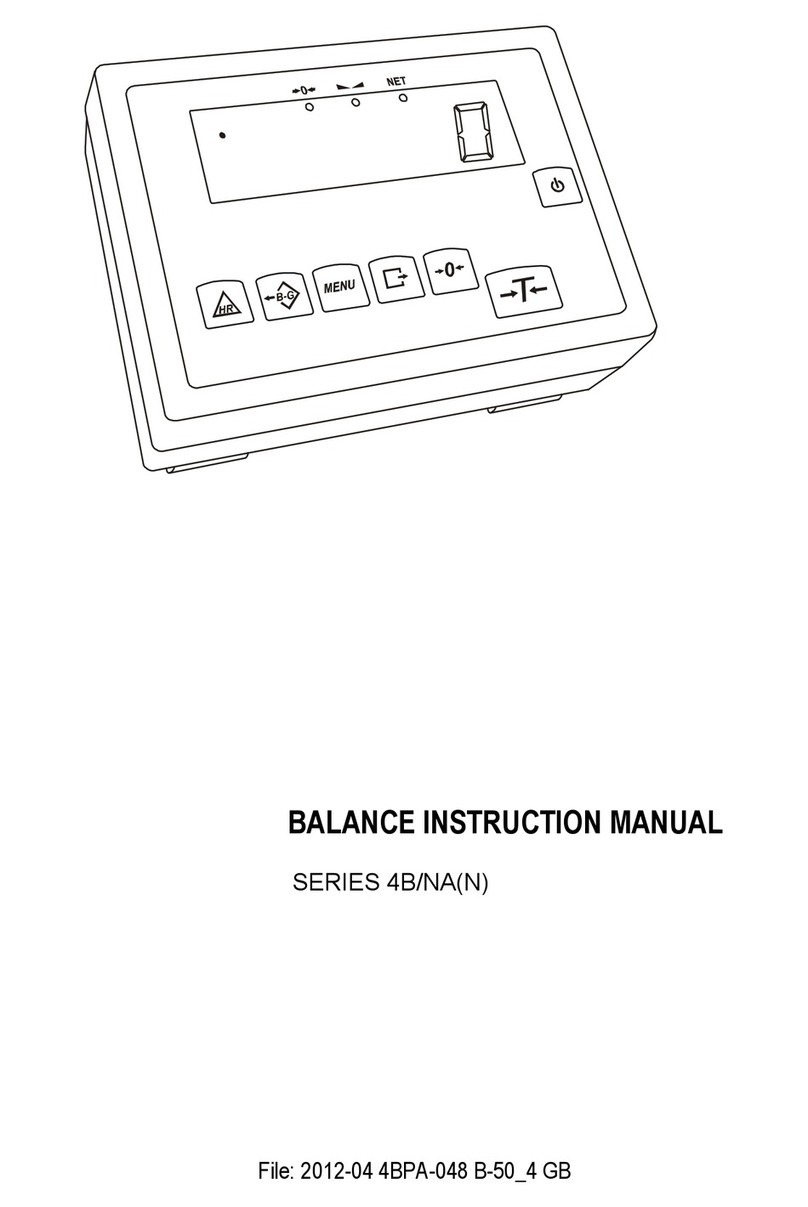

3. Balance keys and indicators

Keys

I/ ,

→

T

←

,

→

0←

and

Menu

perform the basic weighing functions. Key (Print)

sends the result to the computer. Key F recalls list of special functions.

Operation of F1÷F5 keys depends on their configuration, made dynamically by the

computer. Description of functions performed by those keys is shown in the bottom text

line. Alphanumeric keys and ENTE are activated automatically after selecting