2INSTRUCTION MANUAL

_____________________________________________________________________________________________________________________

Table of contents:

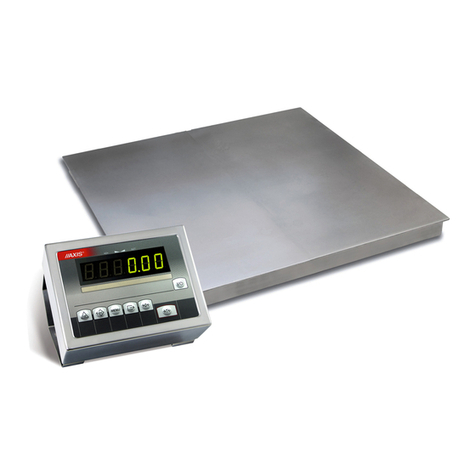

1. General description........................................................................................................ 4

2. Meters ........................................................................................................................... 5

3. Completation ................................................................................................................. 7

4. Technical data ............................................................................................................... 7

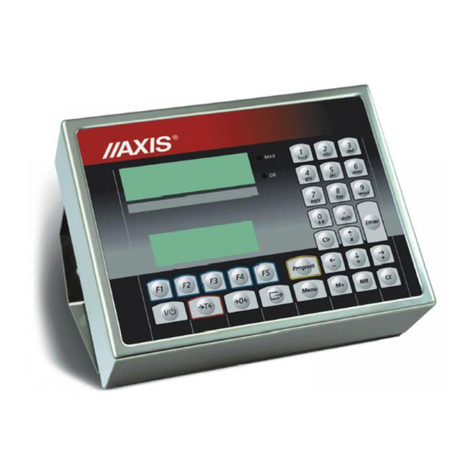

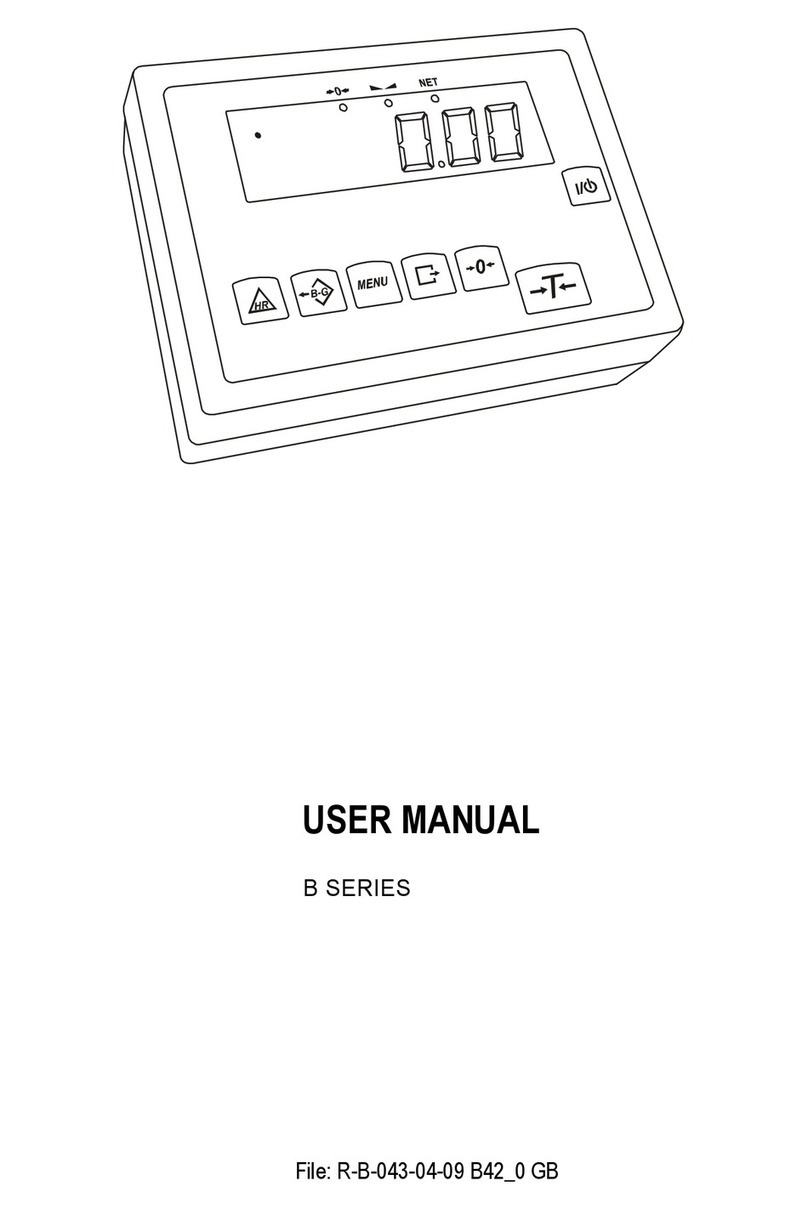

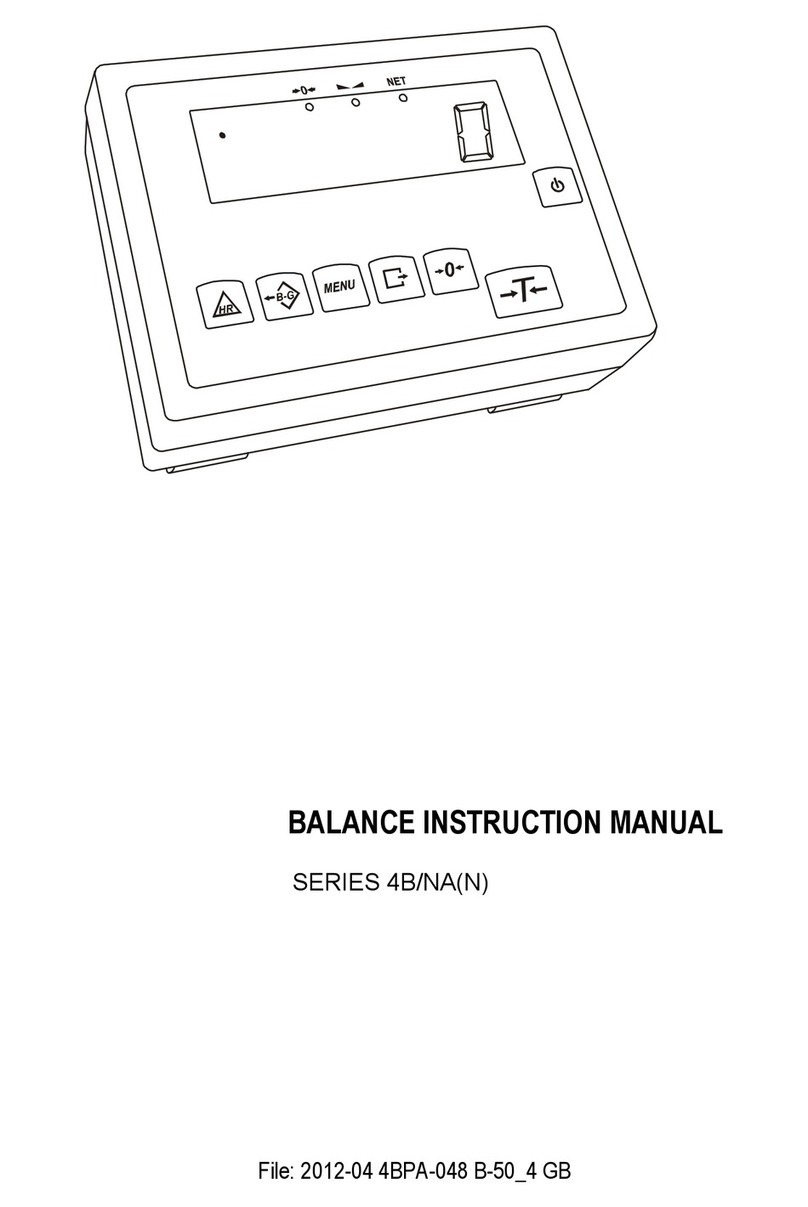

5. Meter ME-01 balance keys and indicators ................................................................... 10

6. Scale external outputs ................................................................................................. 12

7. Safety principles .......................................................................................................... 14

8. Balance preparation to work ........................................................................................ 15

8.1 Preparing platform, pallet and skid scales ................................................................... 15

8.2 Preparing overrun scales............................................................................................. 16

8.3 Preparing foundation scales ........................................................................................ 17

8.3.1 Preparing foundation......................................................................................17

8.3.2 Scale installation............................................................................................19

9. Balance start................................................................................................................ 21

10. Operation principles ................................................................................................. 22

11. Balance test ............................................................................................................. 23

12. Accumulator change (ME-01 option) ........................................................................ 23

13. Connection with computer, printer or label printer .................................................... 24

14. Basic function........................................................................................................... 28

14.1 Normal weighing ................................................................................................... 28

14.2 Weighing with tare ................................................................................................ 29

14.3 Increased readability............................................................................................. 29

15. Special function description...................................................................................... 30

15.1 Menu customization function (ACtIV and dEFAUL) .................................................... 31

15.2 Autotare function (AutotAr) ........................................................................................ 32

15.3 Pieces counting (PCS)............................................................................................... 33

15.4 Function for changing mass unit (UnIt) ....................................................................... 34

15.5 Percentage weighing function (PErC)........................................................................ 35

15.6 Recipe weighing function (RECIPE) .......................................................................... 36

15.7 Function for calibration with external weight (CALIb).................................................. 37

15.8 Label choosing function (LAbEL)................................................................................ 39

15.9 Serial port parameters setting (SErIAL) ..................................................................... 40