2BD/T USER MANUAL

_____________________________________________________________________________________________________________________

Table of contents:

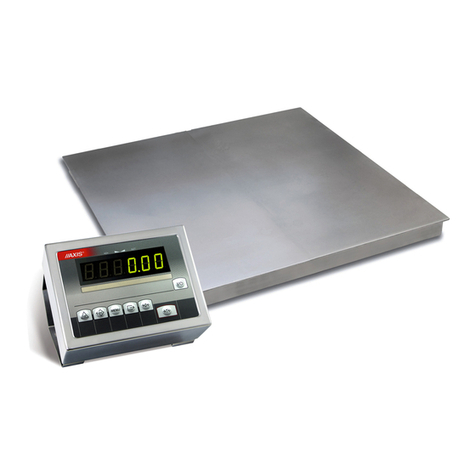

1. General description.................................................................................................................................................................................... 3

2. Set.............................................................................................................................................................................................................. 3

3. Technical data............................................................................................................................................................................................ 4

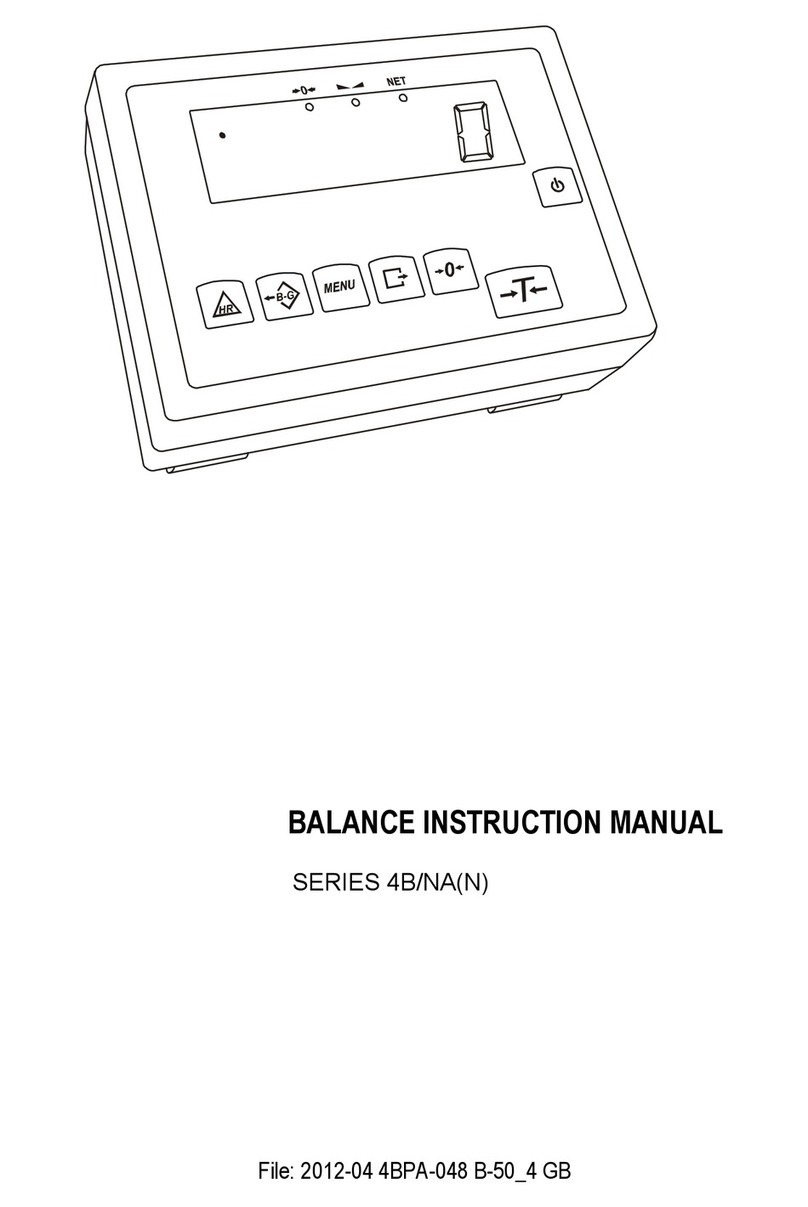

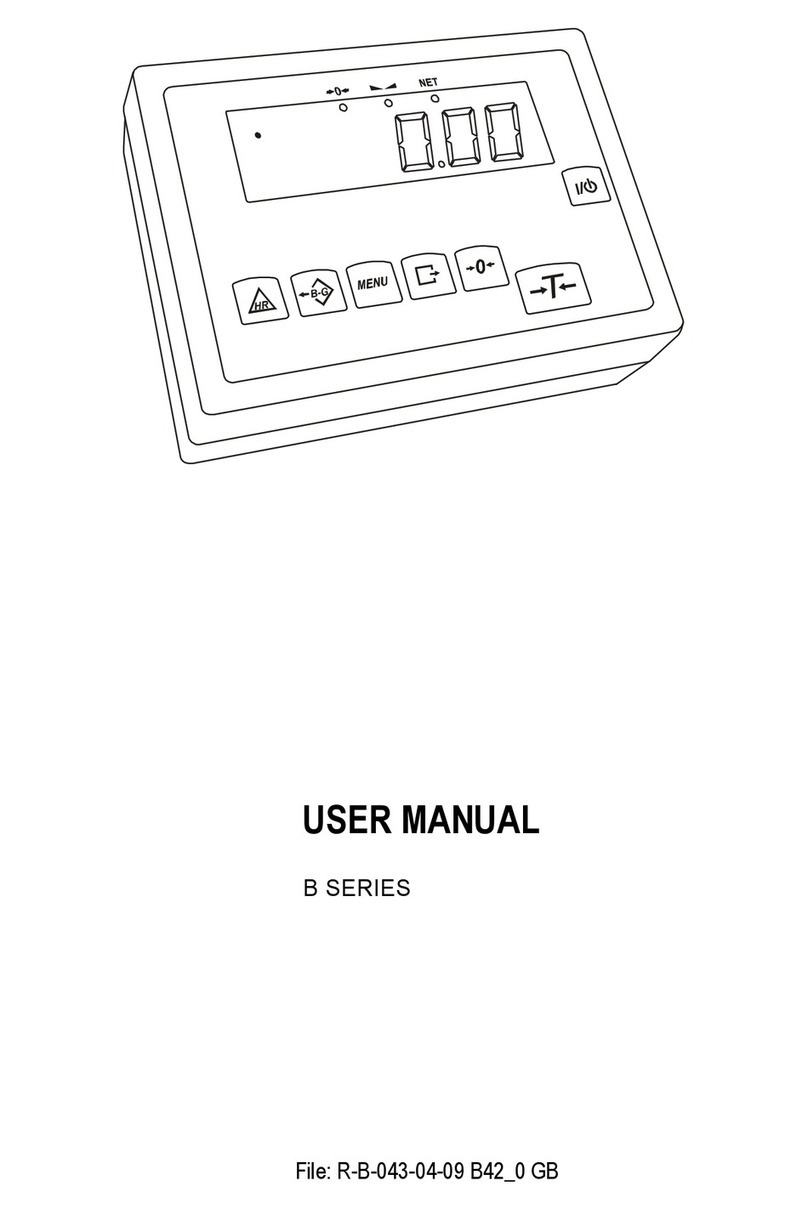

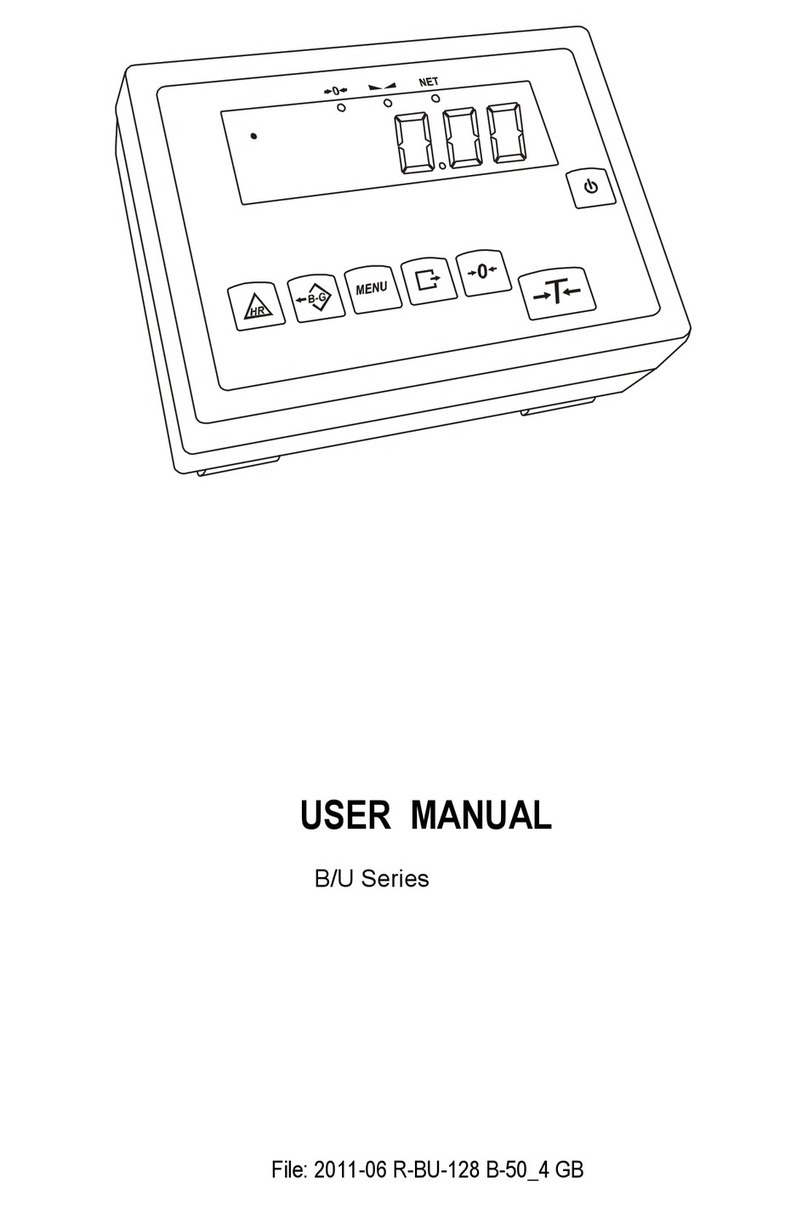

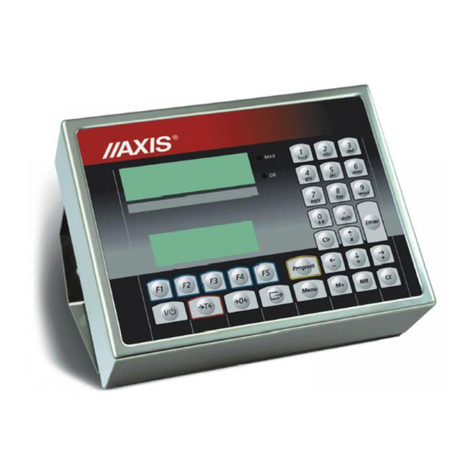

4. Keys and indicators ................................................................................................................................................................................... 5

5. Security rules ............................................................................................................................................................................................. 6

6. Environment protection.............................................................................................................................................................................. 6

7. Preparing working environment................................................................................................................................................................. 7

8. Preparing scale to work ............................................................................................................................................................................. 7

9. General operation principles...................................................................................................................................................................... 8

10. Operation rules during work with accumulators (batteries) ....................................................................................................................... 9

11. Scale checking........................................................................................................................................................................................... 9

12. Scale calibration (CAL) ............................................................................................................................................................................ 10

13. Connecting a computer, printer or label printer ....................................................................................................................................... 11

13.1 Detailed LonG protocol description..................................................................................................................................................... 12

13.2 Detailed EPL protocol description....................................................................................................................................................... 14

14. Start-up .................................................................................................................................................................................................... 15

15. Weighing with tare ................................................................................................................................................................................... 16

16. Scale menu.............................................................................................................................................................................................. 17

17. Menu navigation rules.............................................................................................................................................................................. 18

18. Scale setup (SEtUP)................................................................................................................................................................................ 23

18.1 Scale calibration (CALIb) .................................................................................................................................................................... 25

18.2 Autozeroing function (AutoZEr) ......................................................................................................................................................... 26

18.3 Weight unit selection (UnIt)................................................................................................................................................................. 27

18.4 Serial port parameters setting (SErIAL)............................................................................................................................................. 28

18.5 Printout configuration (PrInt)............................................................................................................................................................. 29

18.6 Setting backlight function (b_LIGHt) ................................................................................................................................................... 31

18.7 Analog out configuration (AnALoG) .................................................................................................................................................... 32

18.8 Entering reference zero value (ZErO)................................................................................................................................................. 33

19. Special functions description .............................................................................................................................................................. 34

19.1 Products and users database (Prod i USEr)....................................................................................................................................... 35

19.2 Pieces counting function (PCS) ......................................................................................................................................................... 39

19.3 Percentage weighing function (PErC)................................................................................................................................................ 40

19.4 Label choosing function (LAbEL)........................................................................................................................................................ 41

19.5 Weighing animals function (LOC) ....................................................................................................................................................... 42

19.6 Maximum value indication function (UP) ............................................................................................................................................ 43

19.7 Force measuring function (nEWton) .................................................................................................................................................. 44

19.8 Total weight function (totAL) ............................................................................................................................................................... 45

19.9 Checkweighing function (thr) .............................................................................................................................................................. 47

19.10 Setting date and time function (dAtE) ............................................................................................................................................ 50

19.11 Radio communication channel choice function (rF CHn)............................................................................................................... 51

19.12 Charging accumulators function (bAttErY)- option ........................................................................................................................ 52

19.13 Automatic switching off the scale function (AutoOFF) ................................................................................................................... 53

19.14 Statistical calculations function (StAt)............................................................................................................................................ 54

19.15 Paperweight calculation (PAP) ...................................................................................................................................................... 57

Maintenance and repairs of small defects.............................................................................................................................................................. 58

Declaration of Conformity....................................................................................................................................................................................... 59