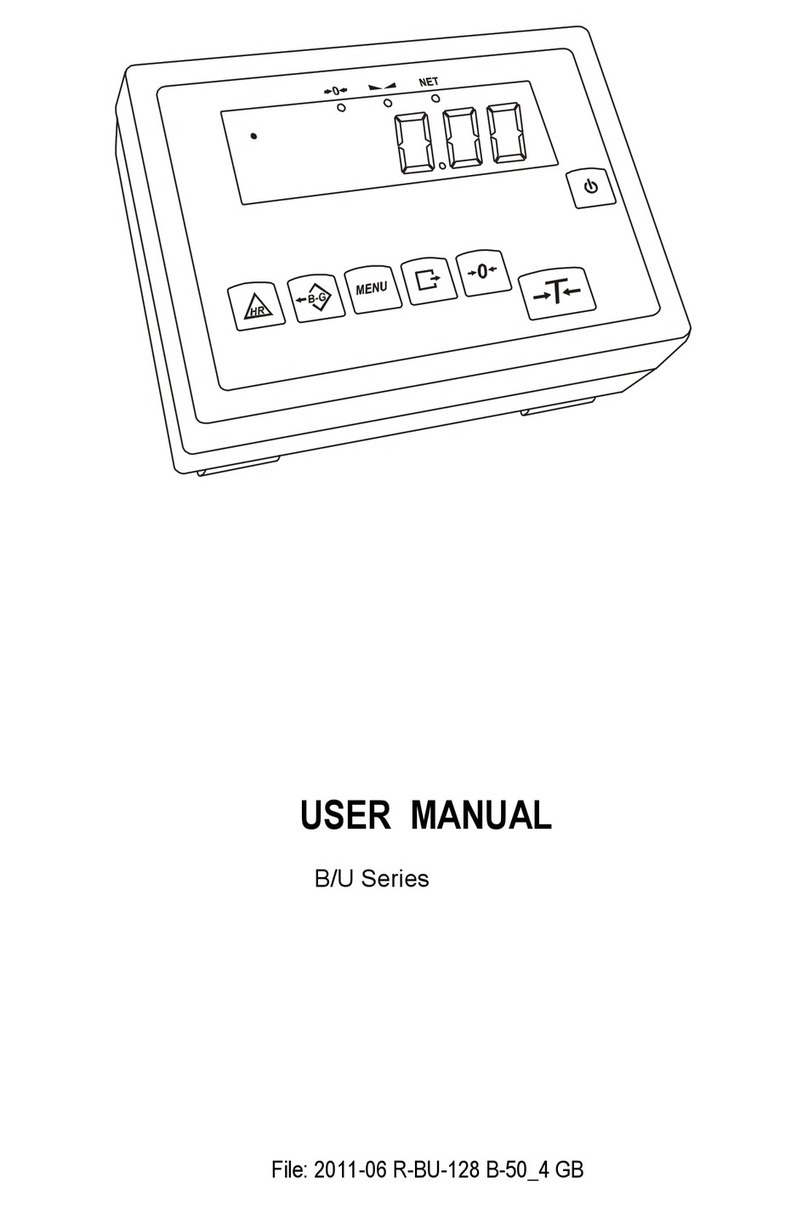

2USER MANUAL

____________________________________________________________________________________________________________________

Contents:

1. General description................................................................................................................................ 3

2. Completeness........................................................................................................................................ 3

3. Safety rules............................................................................................................................................ 4

4. Technical data ....................................................................................................................................... 5

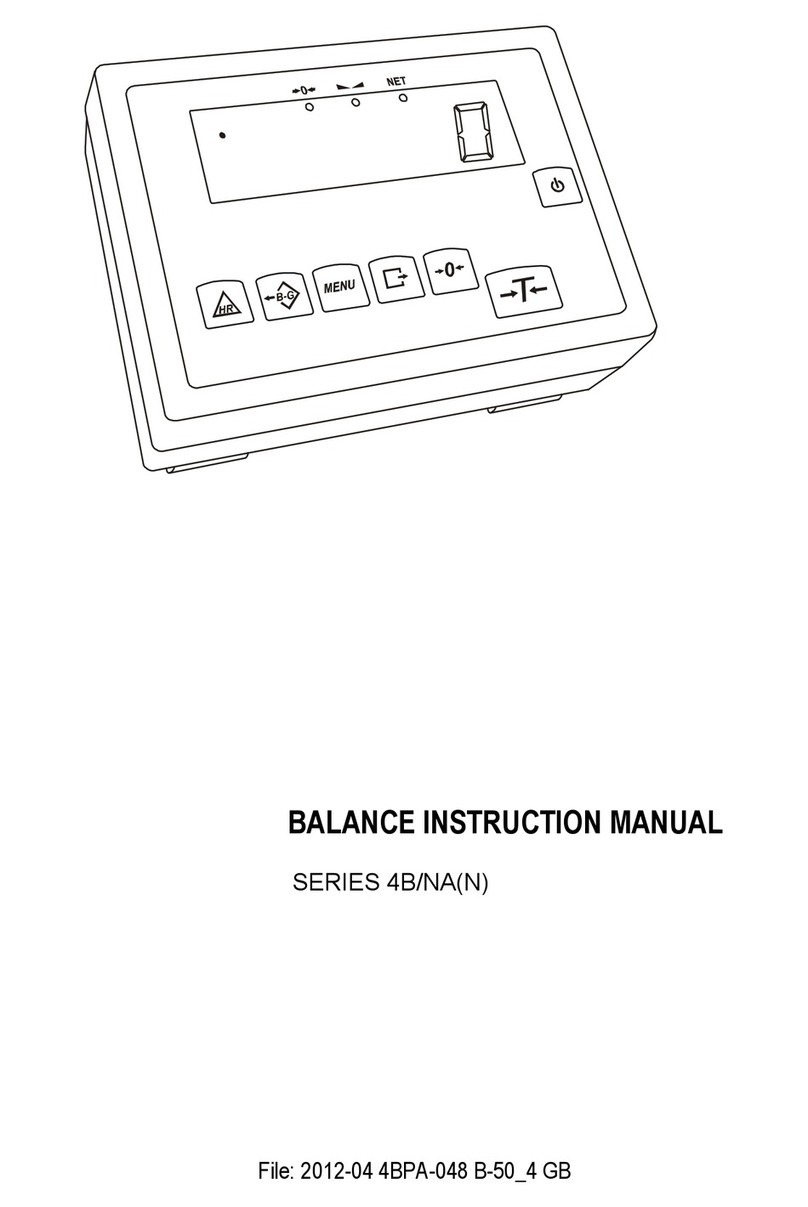

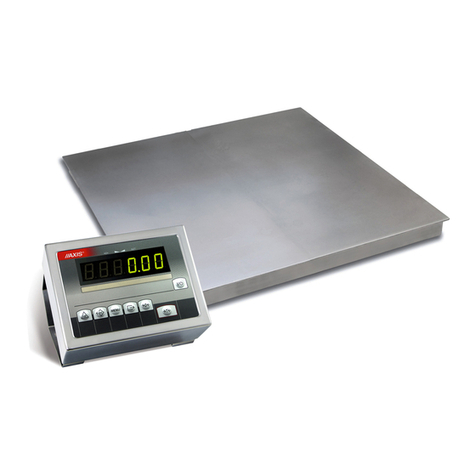

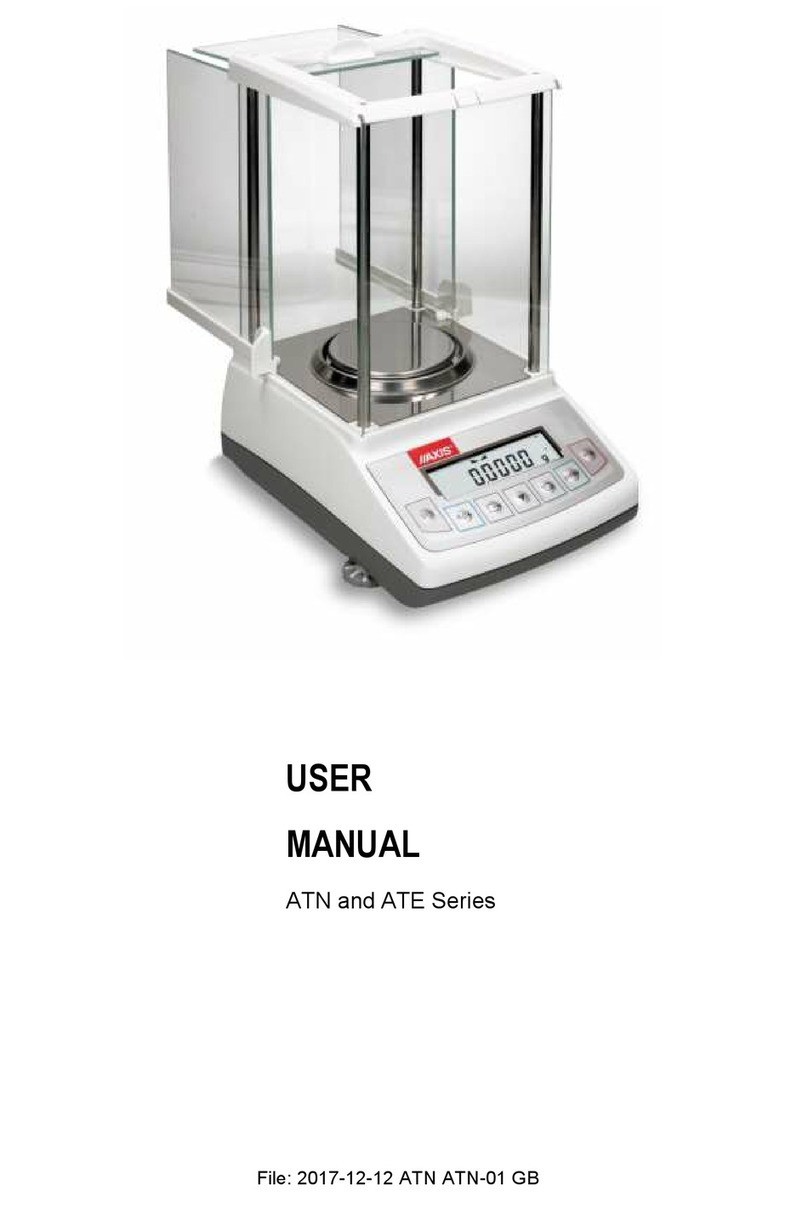

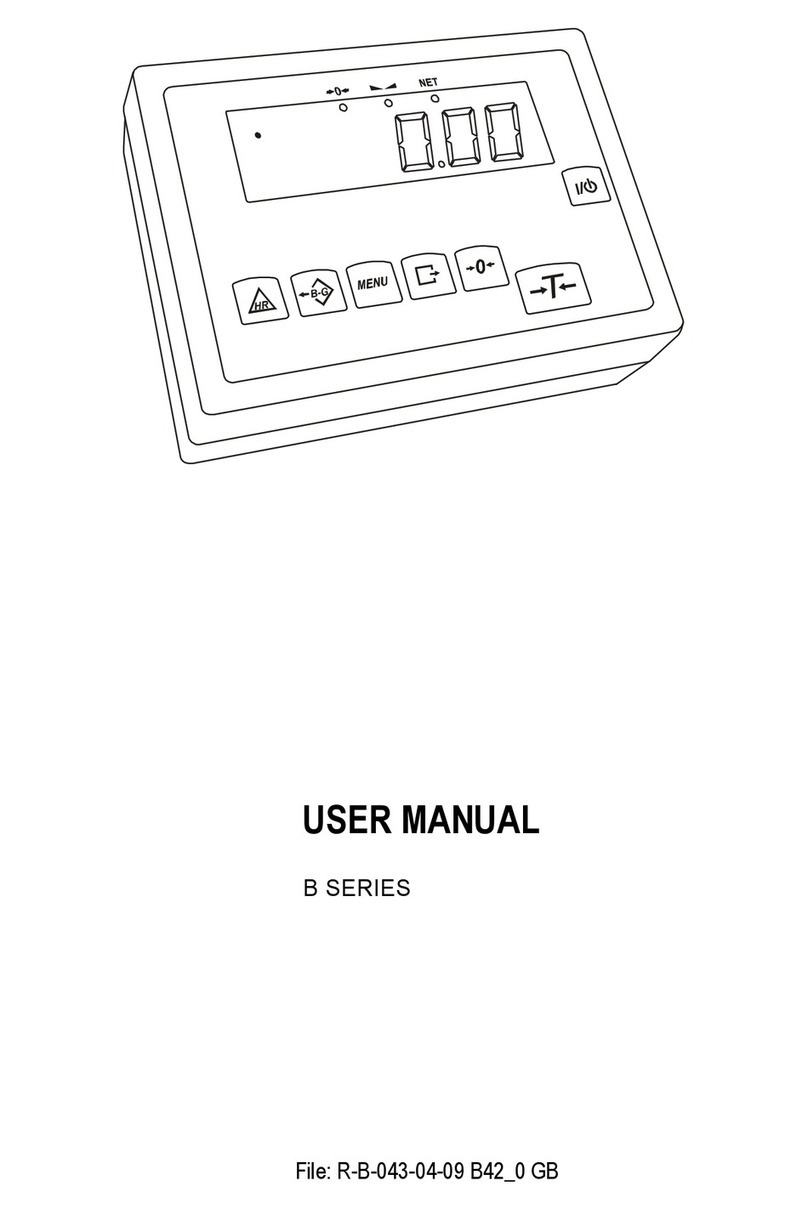

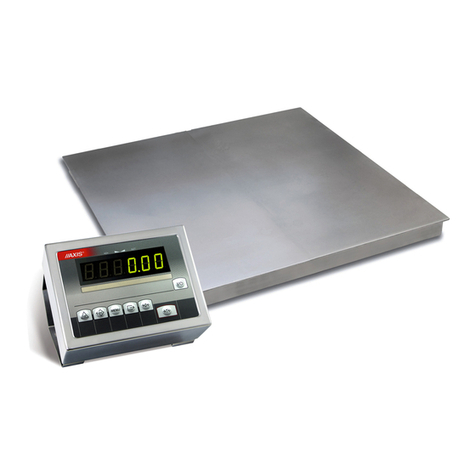

5. General balance description .................................................................................................................. 6

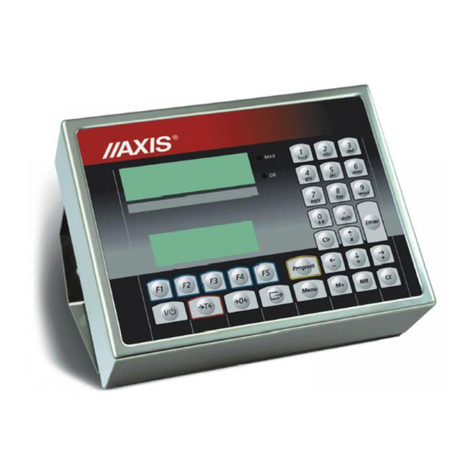

6. Keys and indicators ............................................................................................................................... 7

7. Preparing working environment ............................................................................................................. 8

8. Preparing balance to work ..................................................................................................................... 9

9. General operation principles................................................................................................................ 10

10. Start-up.............................................................................................................................................. 11

11. Internal calibration ............................................................................................................................. 11

12. Checking the balance ........................................................................................................................ 13

13. Connecting the balance to computer or printer.................................................................................. 13

14. Basic balance functions..................................................................................................................... 15

14.1 Simple weighing............................................................................................................................... 15

14.2 Weighing with tare ........................................................................................................................... 16

15. Special functions................................................................................................................................ 17

15.1 Menu customization function (ACtIV)............................................................................................... 18

15.2 Autozeroing function (AutOtAr)....................................................................................................... 19

15.3 Pieces counting function (PCS) ....................................................................................................... 20

15.4 Function for changing weighing units grams/carats/pounds (UnIt) .................................................. 21

15.5 Percent function (PErCEnt).............................................................................................................. 22

15.6 Function for calibration with external weight / calibration options (CALIbr)...................................... 23

15.7 Function for setting serial ports mode and parameters (Port).......................................................... 27

15.8 Printout configuration (PrInt)............................................................................................................ 28

15.9 Backlighting setting (b_LIGHt) ......................................................................................................... 30

15.10 Weigh summation (rECIPE)........................................................................................................... 31

15.11 Function for weighing animals (LOC)............................................................................................. 32

15.12 Tare memorizing function (tArE) .................................................................................................... 33

15.13 Force measurement function (nEWton) ......................................................................................... 33

15.14 Function for maximum value indication (UP) ................................................................................. 35

15.15 Anti-disturbance filter function (FILtEr) ......................................................................................... 36

15.16 Date and time setting (dAtE).......................................................................................................... 37

15.17 Treshold comparison function (thr) ................................................................................................ 39

15.18 Total weight function (totAL) .......................................................................................................... 42

15.19 Density determination (dEnSity) .................................................................................................... 44

15.19.1 Solids density determination....................................................................................................... 44

15.19.2 Liquid density determination ....................................................................................................... 46

15.20 Statistical calculations function (StAt) ............................................................................................ 48

15.21 Printout language selection (LAnGUAG) ....................................................................................... 51

15.22 Paperweight calculation (PAPEr)................................................................................................... 52

16. Troubleshooting and maintenance................................................................................................... 53

Declaration of Conformity...................................................................................................................... 54