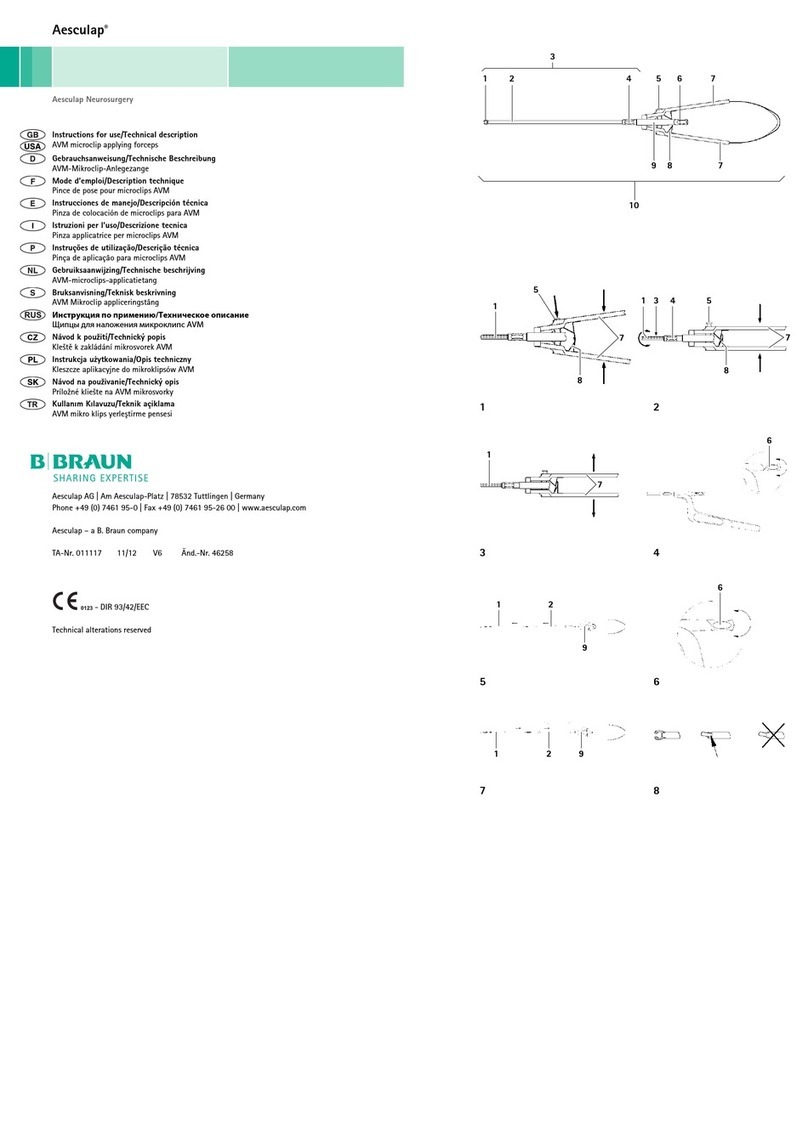

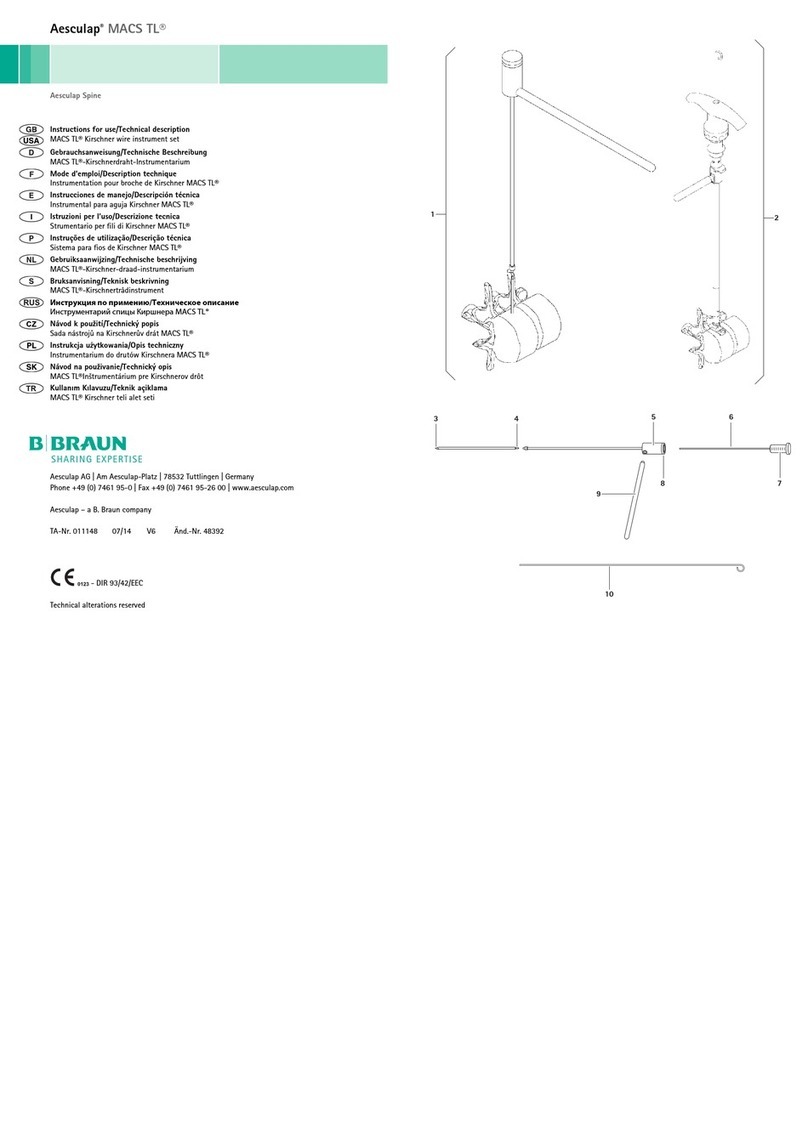

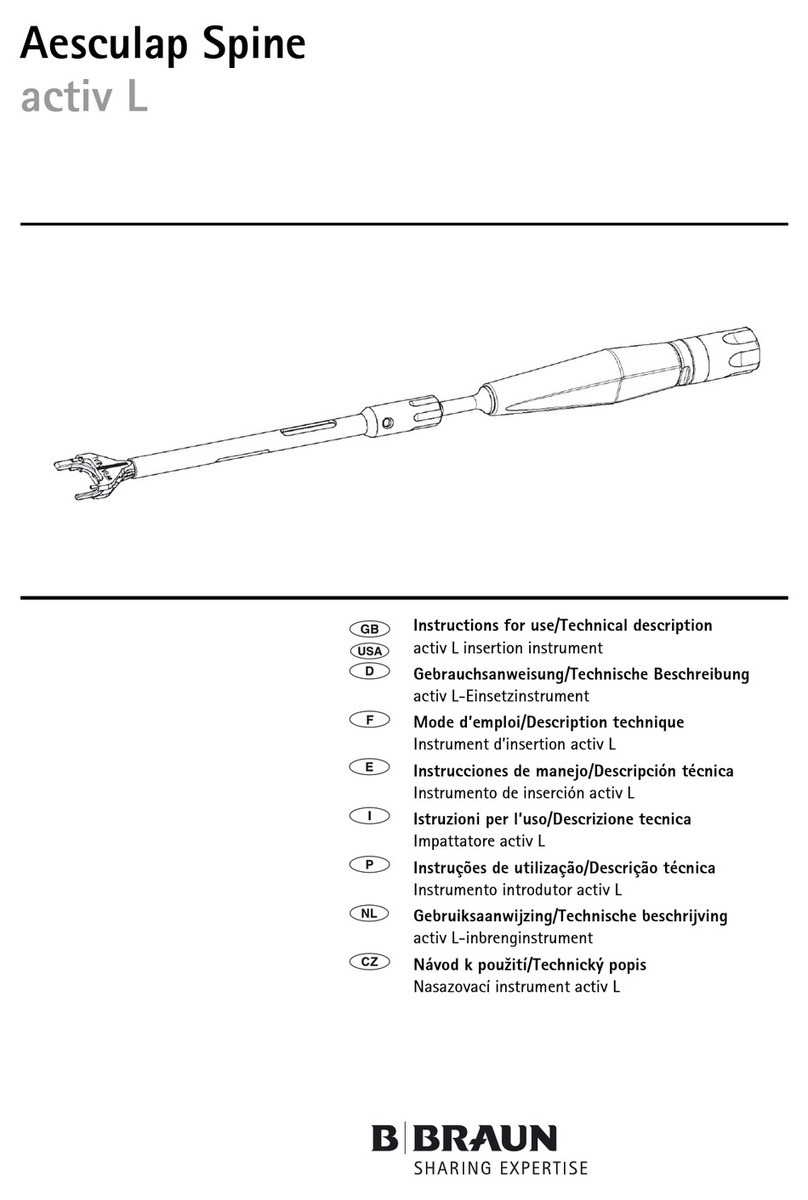

Legend

1Adjustment knob

2Handle stems

3Jaw part mounting (on handle)

4Jaw part with notched rod

Intended use

The micro-instruments are intended for use in neurosurgery, and

are specially designed for use in tight spaces. They can be applied

to the cutting, grasping, dissecting, etc. of vessels and tissues.

Available sizes

The micro-instruments are available as complete instruments or as

separate, combinable components. Various jaw parts (e.g., straight

scissors, curved scissors, and forceps) can be used with the suitable

handles.

Complete information about products currently available can be

found in AESCULAP brochure C 74511.

Safe handling and preparation

CAUTION

Federal law restricts this device to sell by or on order of a phy-

sician!

ØRead the instructions for use and keep them in a safe place.

ØUse the instrument only in accordance with professional stan-

dards and practices, see Applications.

ØClean the new instrument either manually or mechanically

prior to the initial sterilization.

ØStore the new or unused instrument in a dry, clean and safe

place.

ØInspect the instrument after each cleaning and disinfecting

cycle to be sure it is clean, functioning properly, not damaged,

has e.g. intact insulation and does not have any loose, bent,

broken, cracked, worn, or fractured components.

ØDo not use the instrument if it is damaged or defective. Re-

place damaged parts immediately with original spare parts.

ØSet aside the instrument immediately if it is damaged.

ØPrior to each use, inspect the instrument for: loose, bent, bro-

ken, cracked, worn, or fractured components.

Safe operation

Disassembling

ØTurn the adjustment knob 1at 180° until it engages (i.e., clicks

into place).

ØHold the handle stems 2in one hand and at the same hold the

jaw part with notched rod 4in the other hand.

ØPull the jaw part mounting 3and jaw part with notched rod 4

apart.

ØTurn the adjustment knob 1back to its original position.

Assembling

ØEnsure that the bridge of the jaw part with notched rod 4and

the groove in the jaw part mounting 3are in the same axis

when the handle stems are in closed position.

ØPush the jaw part mounting 3and jaw part with notched rod 4

together until the notched rod engages with an audible click.

Check functionality:

ØPush the handle stems 2all the way together.

Check to ensure that the jaw part functions properly.

Care and handling

ØClean the entire handle with the cleaning brush provided (see

Manual cleaning/Disinfecting).

ØThe jaw part with notched rod can be cleaned either manually

or mechanically.

After each use

ØClean the contaminated instrument as soon as possible.

ØLeave hinged instruments open at a 90° angle.

ØWhen carrying out mechanical cleaning, avoid watermarks by

placing instruments in wire baskets suitable for cleaning.

ØDisassemble the instrument, see Disassembling.

ØRemove debris from the instrument while it is dry.

ØIf the instrument is cleaned while wet, use an active cleaning

disinfectant. Prior to mechanical cleaning and disinfecting,

rinse the instrument thoroughly in clear running water.

ØIf ultrasound is needed, carry out the procedure according to

the user instructions provided by the manufacturer of the de-

vice:

– as an effective mechanical supplement to manual cleaning.

– for initial cleaning of instruments with dried debris on

them prior to mechanical cleaning.

ØPerform manual or mechanical cleaning. Follow the manufac-

turer's instructions.

Manual cleaning, disinfecting

ØPlace the instrument in a suitable active cleaning and disin-

fectant solution in such a way that all surfaces, interior sur-

faces, lumen, and openings are covered. Follow the

disinfectant manufacturer's instructions.

ØAfter disinfecting chemically, always rinse the items thor-

oughly in plenty of clear running water. Follow the disinfec-

tant manufacturer's instructions.

ØRemove encrusted material with a soft nylon brush. Do not use

harsh cleaning agents or metal brushes.

ØClean lumina and channels with a soft round nylon brush.

Note

Use brushes that are an appropriate diameter for the lumen they

are being used to clean.

ØCarry out the final rinse in distilled or fully demineralized wa-

ter.

ØDry the instrument with a soft, absorbent, lint-free cloth.

ØDry lumen and channels with compressed air.

Mechanical cleaning, disinfecting

ØWhen choosing a program for mechanical cleaning, take into

account the materials in the instruments to be cleaned (e.g.

stainless instrument-grade steel, aluminum). Follow the in-

structions provided by the manufacturer of the device.

ØCarry out the final rinse in distilled or fully demineralized water.

ØBe sure the drying phase is sufficiently long.

ØRemove the instrument from the apparatus as soon as the pro-

gram is completed.

Control

ØAllow instruments to cool down to room temperature.

ØMoving parts such as hinges and latches should be sprayed

with a sterilizable and moisture-permeable lightweight ma-

chine oil (such as AESCULAP STERILIT Spray JG 600 or mainte-

nance oil JG 598).

ØInspect the instrument after each cleaning and disinfecting

cycle to be sure it is: clean, functioning properly, not damaged,

has intact insulation and does not have any loose, bent, bro-

ken, cracked, worn, or fractured components.

ØSet aside and replace the instrument if it is damaged or defec-

tive.

Storage

ØKeep instruments with fine working tips and/or microsurgical

instruments in appropriate storage units.

Sterilization method and parameters

ØSterilize with steam, taking note of the following:

The sterilization has to be done according to a validated steam

sterilization procedure (e.g. in a sterilizer in conformance with

EN 285/ANSI/AAMI/ISO 11134-1993, ANSI/AAMI ST46-1993,

and validated in conformance with EN 554/ISO 13683). In case

of application of the fractionated vacuum procedure the ste-

rilization has to be carried out for a minimum of 5 minutes at

134 °C and at 2 bar pressure.

Sterilization for the US-market:

• Sterilization of the device may be accomplished by steam or

ethylene oxide (EtO) gas.

• AESCULAP does not recommend the device be sterilized by

“Flash” or chemical sterilization.

• Surgical instruments may also be placed within an AESCULAP

rigid sterilization container (sterile container) for processing

under generally accepted hospital in-use conditions.

The recommended sterilization parameters are as follows:

Repairs

Repairs may be carried out only by persons authorized to do so by

AESCULAP. Only in this way will warranties and guarantees remain

valid.

ØIf any repairs are needed, please send the device to:

AESCULAP Technischer Service

Am Aesculap-Platz

78532 Tuttlingen/Germany

Phone: +49 (7461) 95 27 00

Fax: +49 (7461) 16 28 87

Or in the US:

AESCULAP Inc.

Attn. AESCULAP Technical Services

615 Lambert Pointe Drive

Hazelwood

MO, 63042-2609

AESCULAP Repair Hotline

Phone: +1 (800) 214-3392

Fax: +1 (314) 895-4420

Other service addresses can be obtained from the address indica-

ted above.

Distributor in the US

AESCULAP Inc.

3773 Corporate Parkway

Center Valley, PA, 18034

Sharp cutting edges and tips on the

instruments can cause injury to user and

patient!

ØHandle instruments with care.

WARNING

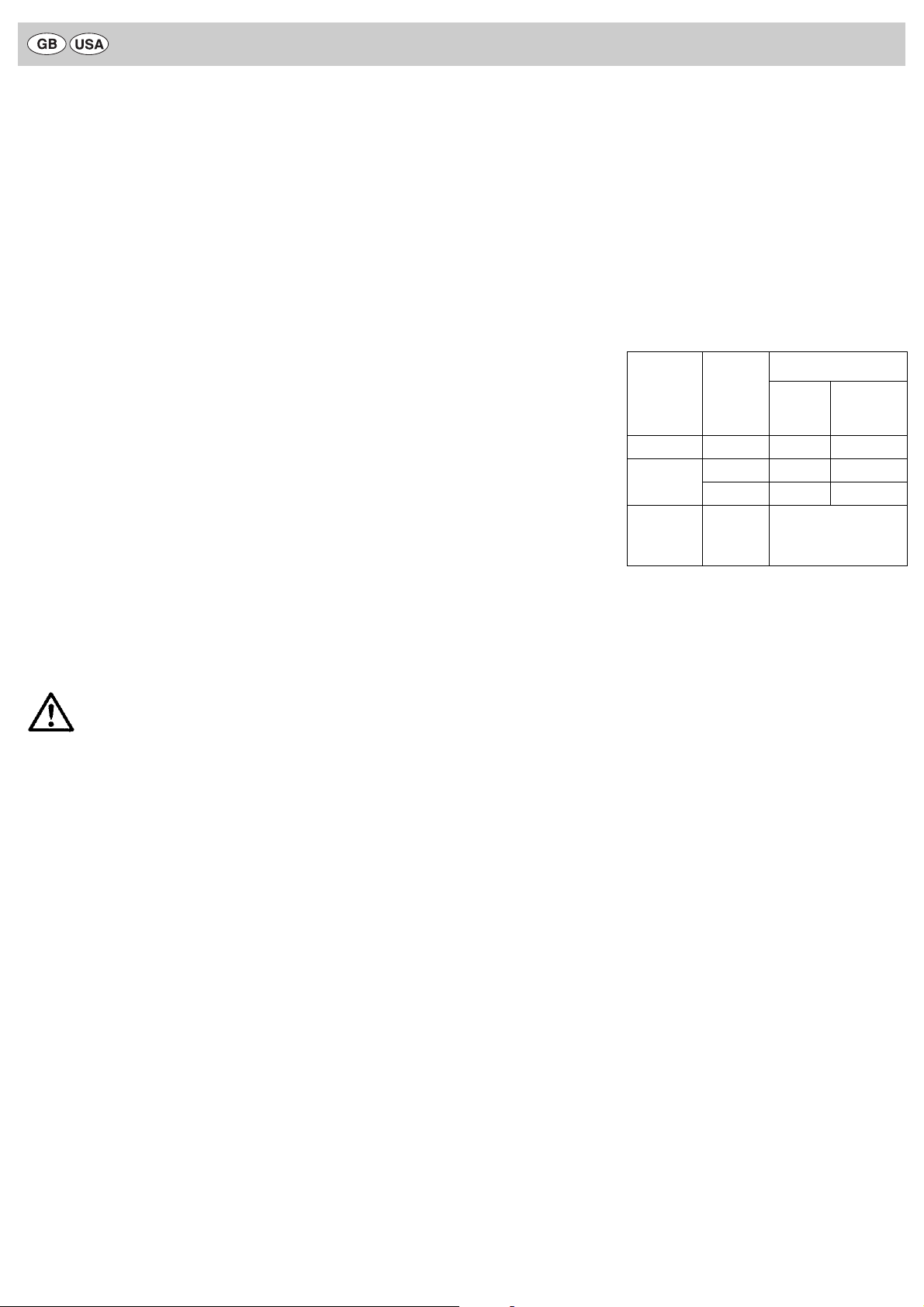

Sterilization

method Temp.

Minimum exposure time

Wrapped

In a sterile

container

system

Pre-vacuum 270—275 °F 4 min 4 min

Gravity 250—254 °F 15 min 40 min

270—275 °F 10 min 30 min

Ethylene

Oxide (EtO)

125—130 °F 105 min with 12 % EO,

88 % FREON;

45—75 % chamber humidity,

reaction of 6 hours

Micro-instruments