6/40

2.1 Introduction

Dear Beta Industries customer:

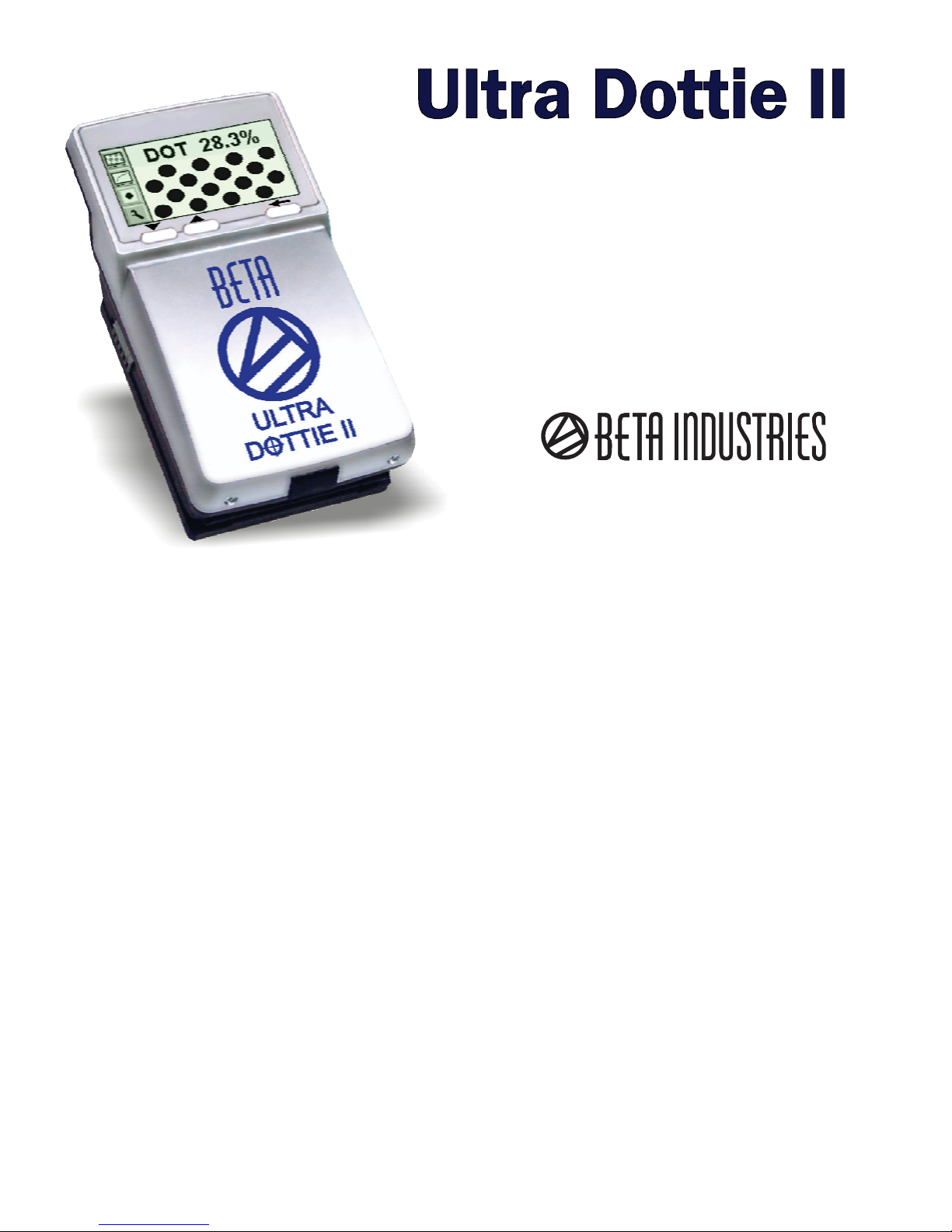

Congratulations! You have just acquired the portable plate measuring device

Ultra Dottie II made by Beta Industries. This device solves one of the most difficult

tasks in the printing industry – quick and accurate quality control of the

Computer-to-Plate (CtP) process. With the help of its built-in video camera the

Ultra Dottie II geometrically analyzes the dot area of any given test patches with

regular or stochastic screens. Where applicable the dot diameter, screen ruling,

the screen angle and the visual coverage are calculated and displayed. The

quality of the dot form of a screen type occasionally has to be assessed. This

can be done with the Ultra Dottie II at a resolution of 12,700 ppi (pixels per inch) or

6,350 ppi as a matter of choice. To avoid having to check each individual

measurement during the linearization of a CtP, the Ultra Dottie II offers the

possibility of measuring an entire curve with up to 100 sample points and then

transferring it to a host PC. Beta Industries also offers BetaTab software,

with which the data can be copied into a word processor, a spreadsheet or

another software program. The power-saving electronics and LED technology allow up

to 30,000 measurements for each set of batteries (2 ordinary commercial AA batteries), which

means that no limits are placed on mobility. With the icon-based, graphical user interface

Beta Industries is opening up new paths and offers the user a simple, easy to understand operating concept.