4

1. Installing the Internet connection

1.1. SIM card (data SIM card)

To be able to use the Dairy Feeder system you require an Internet connection between the PDA

and Dairy Feeder via a valid PDA data SIM card. Please acquire such a SIM card from your mobile

telephone operator. A simple data SIM card that provides you with a monthly volume of 10–20

MB is sufficient. Ask your mobile phone operator whether it is possible to combine your existing

contract with one that provides you with a data SIM card. Check the network coverage (GPRS or

3G) for the area in which you intend to use the Dairy Feeder system.

If you are a Vodafone customer, you can order the required SIM card directly by calling + 49 (0)

800-172 1234. This is then added to your existing contract. They will provide you with what is

called an Ultra Card, the data tariff of which is connected to your existing contract.

The tariff at Deutsche Telekom is called Mobile Connect Medium. If you are a Deutsche Telekom

customer, then call the following telephone number: +49 (0) 39 43 / 40 999 19

Data contracts can also be concluded with all other mobile telephone operators.

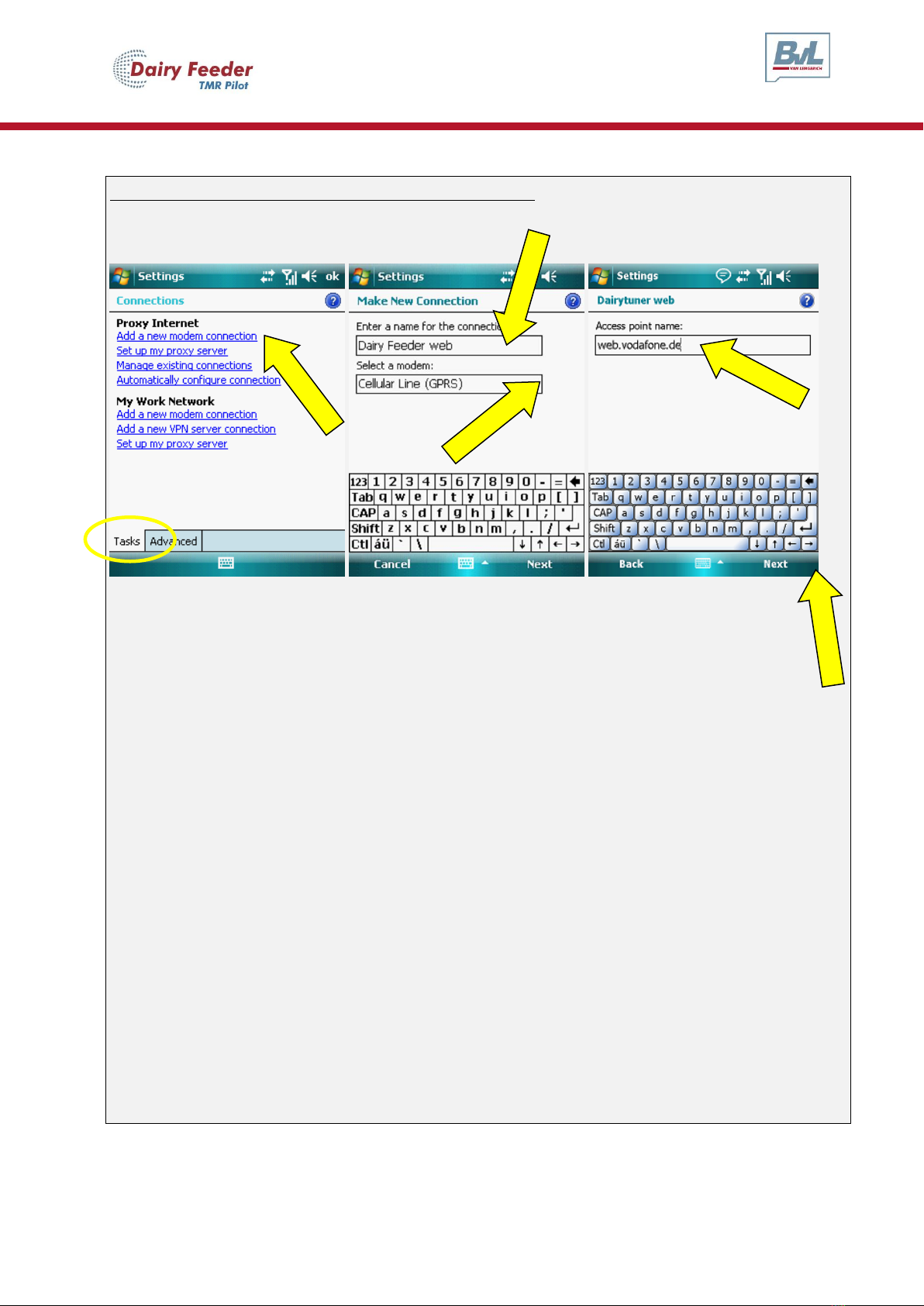

Insert the active data SIM card for your Dairy Feeder System into your PDA and activate the

internet connection of your PDA.

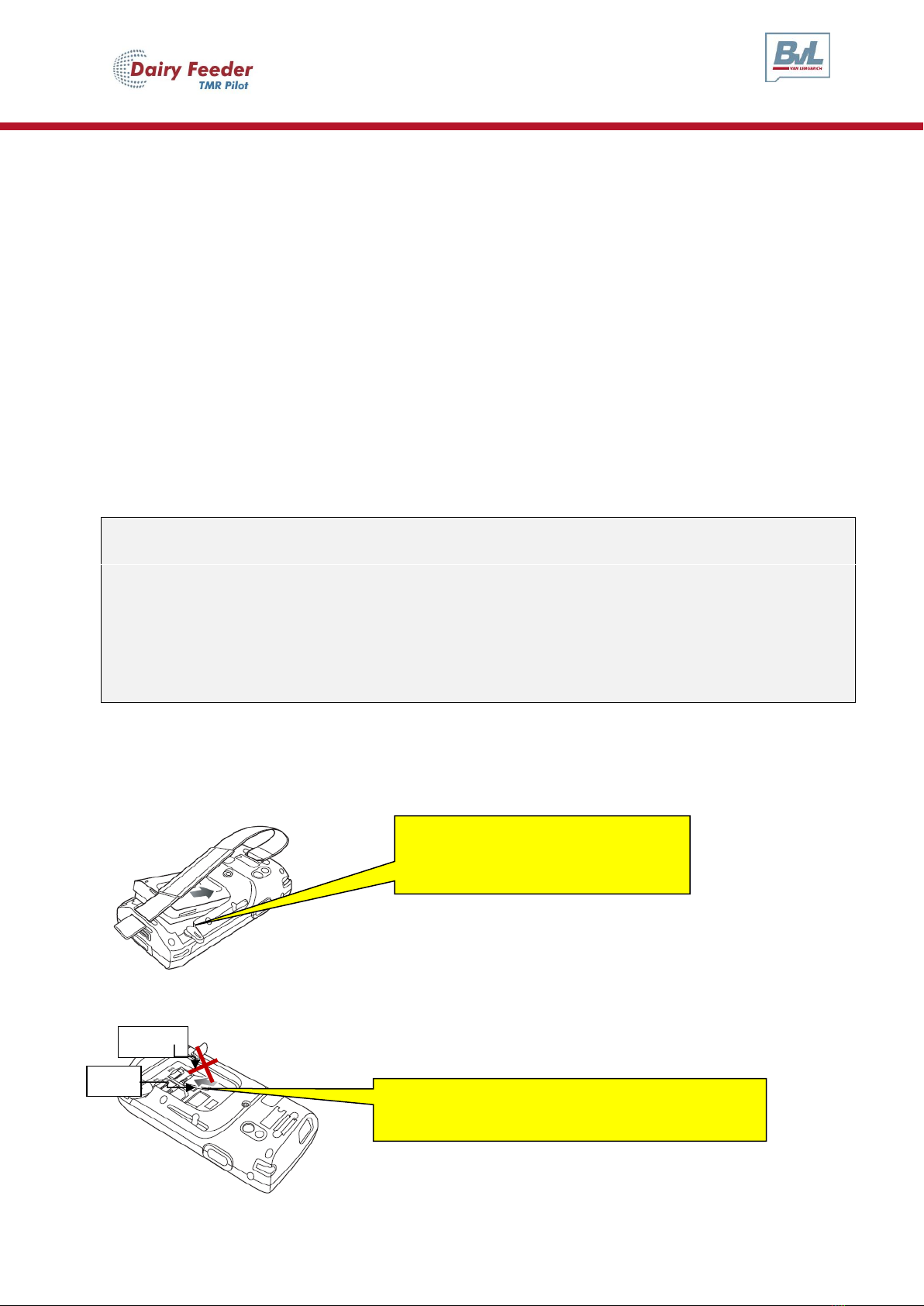

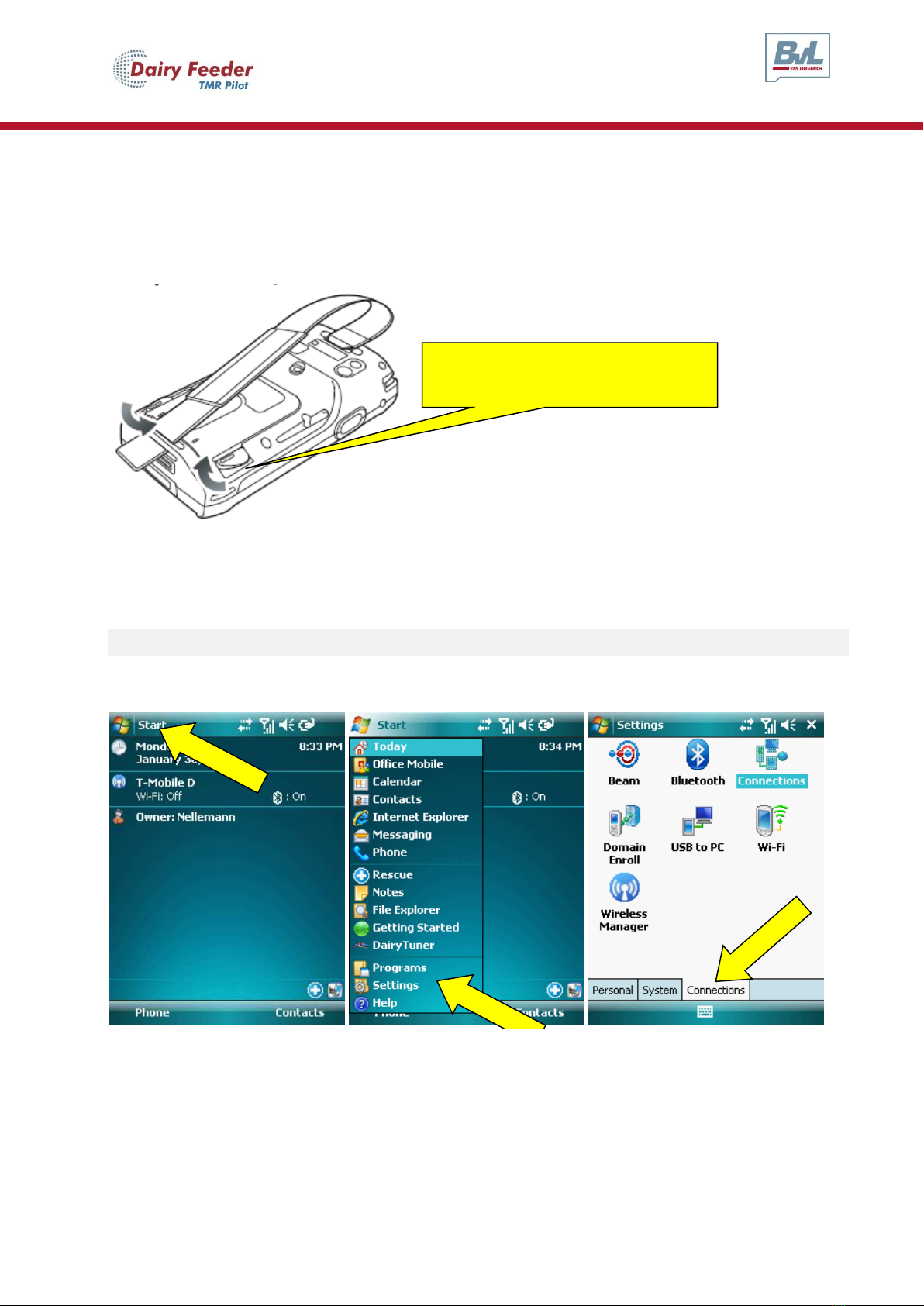

a. Remove the battery

b. Insert SIM card

Unlock by turning outwards and

insert battery

Insert the SIM card here (not into the SAM

compartment!)