Translation of the original assembly and operating manual

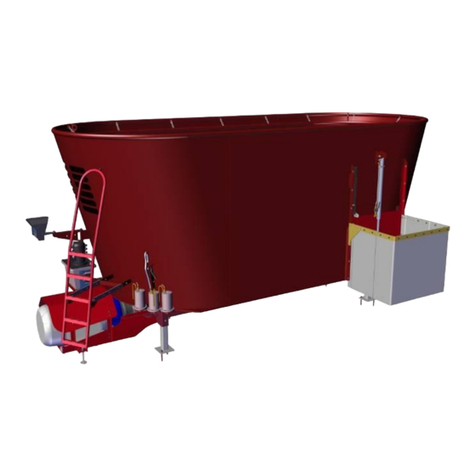

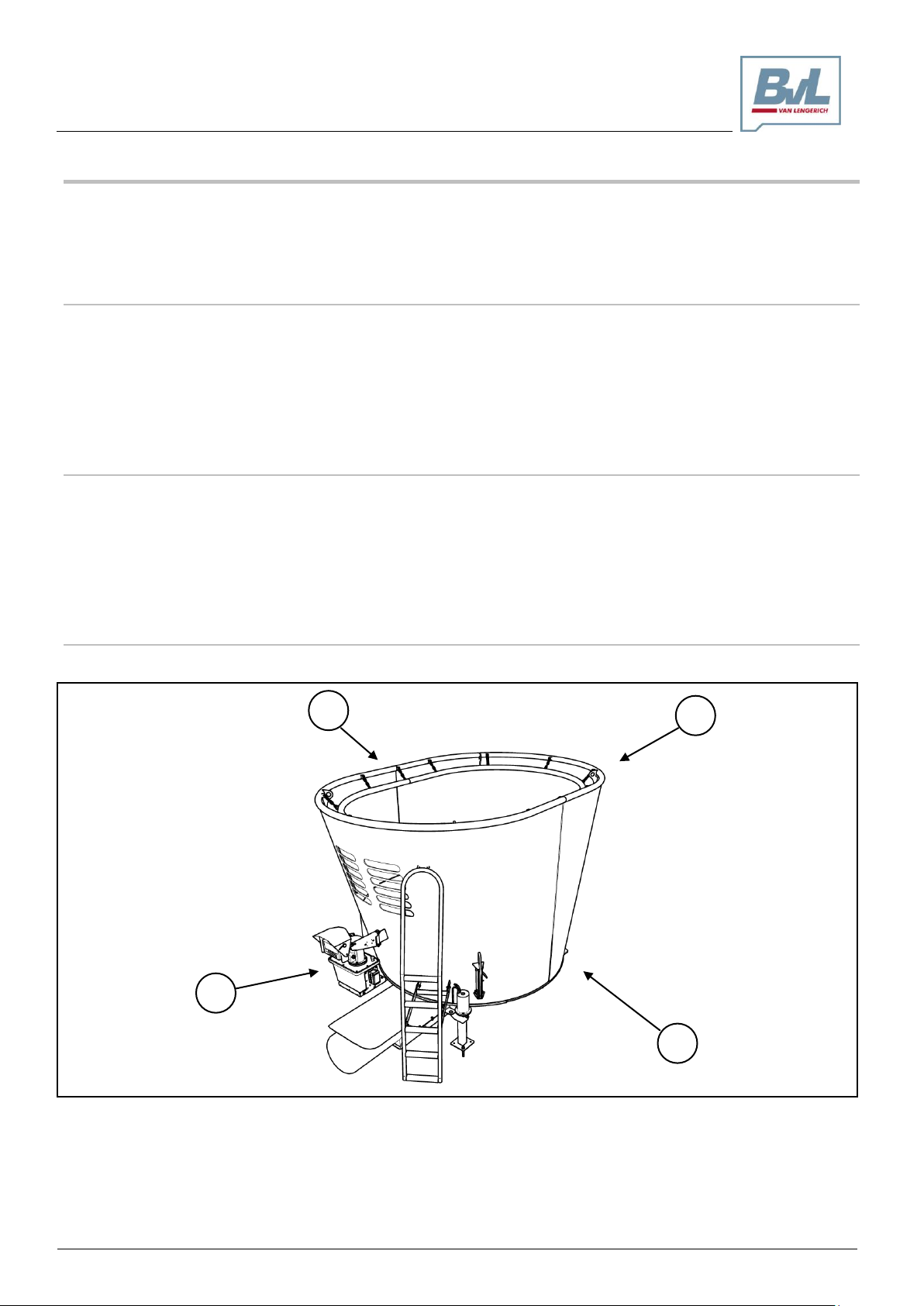

4.7 Discharge area (discharge opening) 36

4.8 Ladder and inspection window 37

4.9 Conveyor belt (optional) 37

4.10 Weighing system (optional) 38

4.11 Hydraulic unit (optional) 38

4.11.1 Electrohydraulic control block 39

4.12 Hydraulic hand pump (optional) 39

4.13 Safety devices and guards 40

4.13.1 Cover aprons 40

4.13.2 Block ball valve 40

4.13.3 Motor and main drive shaft protective plates 41

5Transport, setup, and initial commissioning 42

5.1 Scope of delivery as supplied 42

5.2 Loading and unloading the machine 43

5.3 Machine setup 43

5.4 Connecting the electrical system 45

5.5 Checking the machine for proper operation 45

6Use and operation 46

6.1 Operation of the machine 46

6.2 Filling the mixing hopper 47

6.2.1 Recommended order during filling 48

6.3 Discharging fodder 48

6.3.1 Removing clogs 50

7Cleaning, maintenance and repairs 51

7.1 Cleaning 52

7.2 Lubricating 52

7.2.1 The lubrication chart at a glance 52

7.2.2 Lubrication points –overview 53

7.3 Maintenance schedule –overview 54

7.4 Oil change in the gear unit 55

7.4.1 Gear unit ECS 1512 56

7.4.2 Gear unit PGA 1602 57

7.5 Replacing shear bolt of the shear bolt coupling 58

7.6 Entering the mixing hopper 59

7.7 Cutting blades of the mixing auger Fehler! Textmarke nicht definiert.

7.7.1 Sharpening cutting blades 62

7.7.2 Swiveling/replacing cutting blades 63

7.8 Hydraulic system 64

7.8.1 Checking the hydraulic oil level 65

7.8.2 Refilling hydraulic oil 66

7.8.3 Markings on hydraulic hose lines 66

7.8.4 Maintenance intervals 67

7.8.5 Inspection criteria for hydraulic hose lines 67

7.8.6 Installing and removing hydraulic hose lines 68

7.9 Conveyor belt (optional) 69

7.9.1 Belt connection 69

7.9.2 Tensioning/aligning the conveyor belt 69

7.10 Tightening torques for bolt joints 70