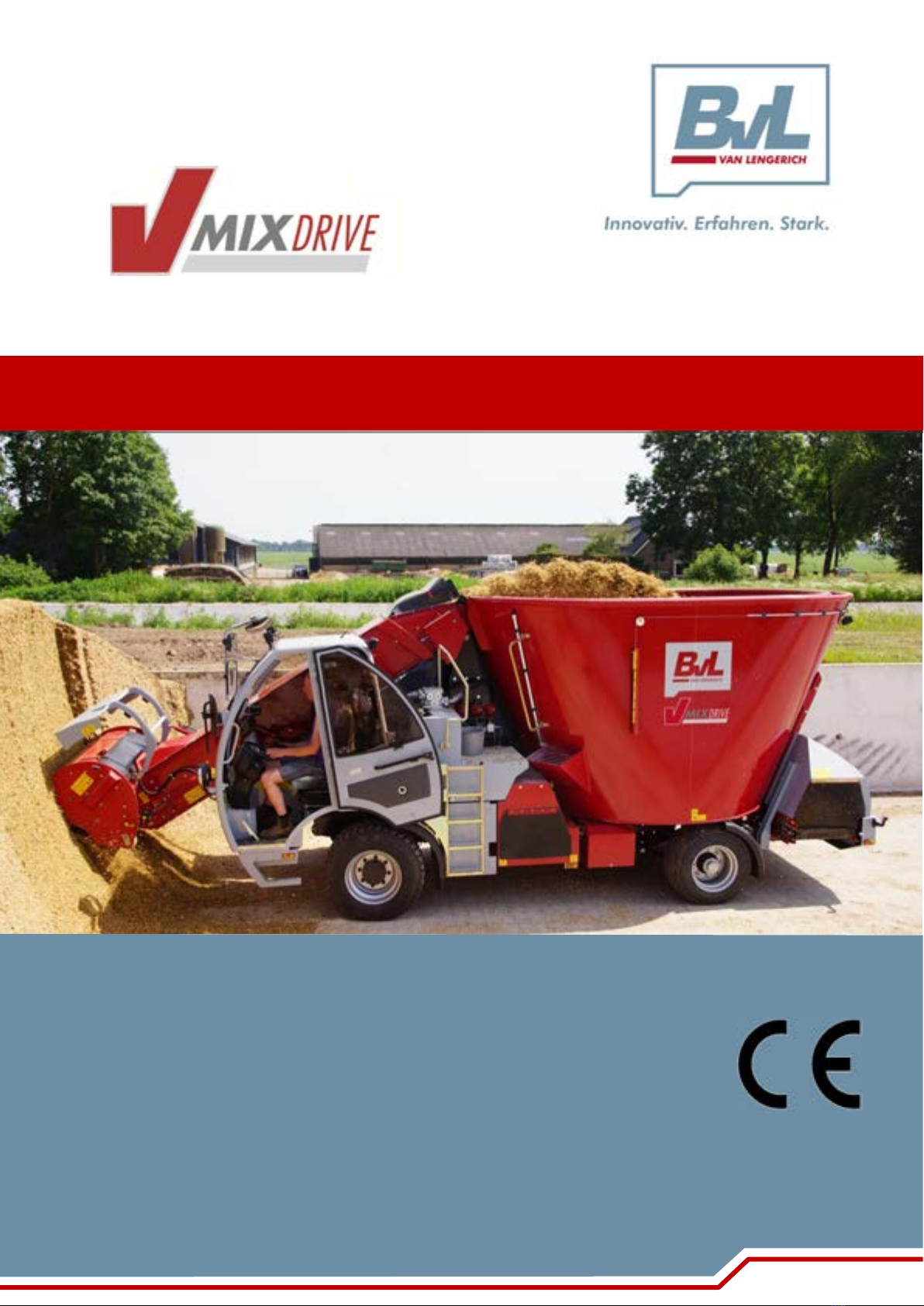

Self-Propelled Feeder Wagon

Translation of the Original Operating Manual

5.1.14.3.1Home screen 92

5.1.14.3.2Cross conveyor on 93

5.1.14.3.3Cleaning mode 94

5.1.14.3.4Error position of loading arm 95

5.1.14.3.5Error cross conveyor center position 96

5.1.14.4 Mode 3 –Transport 97

5.1.14.4.1Home screen 97

5.1.14.5 Mode 4 –Diagnostics and settings 98

5.1.14.5.1Home screen 98

5.2 Diesel engine 112

5.2.1 Starting the diesel engine 112

5.2.2 Warming up the diesel engine 114

5.2.3 Stalling the diesel engine 114

5.2.4 Venting after lack of diesel fuel 115

5.2.5 Starting the diesel engine with a jumper battery 116

5.2.6 Tow-starting the diesel engine 116

5.2.7 Shutting off the diesel engine 117

5.2.8 Operating the diesel engine in the winter 117

5.3 Drive mode 118

5.3.1 Driving forward 119

5.3.2 Driving in reverse 120

5.3.3 Decelerating and stopping the machine 121

5.3.4 Parking brake (hand brake) 122

5.3.5 Switching four-wheel drive on and off (optional) 123

5.3.6 Differential lock 123

5.3.7 Steering 124

5.3.7.1 Switching to four-wheel steering (optional) 124

5.3.7.2 Switching to two-wheel steering (optional) 124

5.4 Lighting and visibility 125

5.4.1 Switching the sidelight or headlight on and off 125

5.4.2 Turn-signal indicator, high beam, parking light and headlight flasher 126

5.4.3 Hazard warning flasher 127

5.4.4 Visibility 127

5.4.4.1 Windshield wipers 127

5.4.4.2 Mirrors 129

5.4.4.3 Rear view camera 130

5.5 Loading arm 131

5.5.1 Raising/lowering the loading arm 131

5.5.2 Setting the loading arm to the transport position 132

5.6 Profiled roller and elevator 133

5.6.1 Switching profiled roller and elevator on and off (mode 1) 133

5.6.2 Adjusting the drive speed of the profiled roller (mode 1) 134

5.6.3 Adjusting the belt speed of the elevator (mode 1) 134

5.6.4 Opening/closing the guard on the profiled roller (mode 1) 135

5.6.5 Reversing profiled roller and elevator (mode 1) 135

5.6.6 Opening and closing the dosing gate for the discharge opening (mode 2) 136

5.7 Cross conveyor 137

5.7.1 Switching the cross conveyor on and off (mode 2) 137

5.7.1.1 Adjusting the belt speed of the cross conveyor (mode 2) 138

5.7.2 Shifting the cross conveyor to the right or left (optional) (mode 2) 139

5.8 Mixing auger 140

5.8.1 Switching the mixing augers on and off (mode 1/2/3) 140

5.8.2 Adjusting the drive speed of the mixing auger (mode 1/2/3) 140