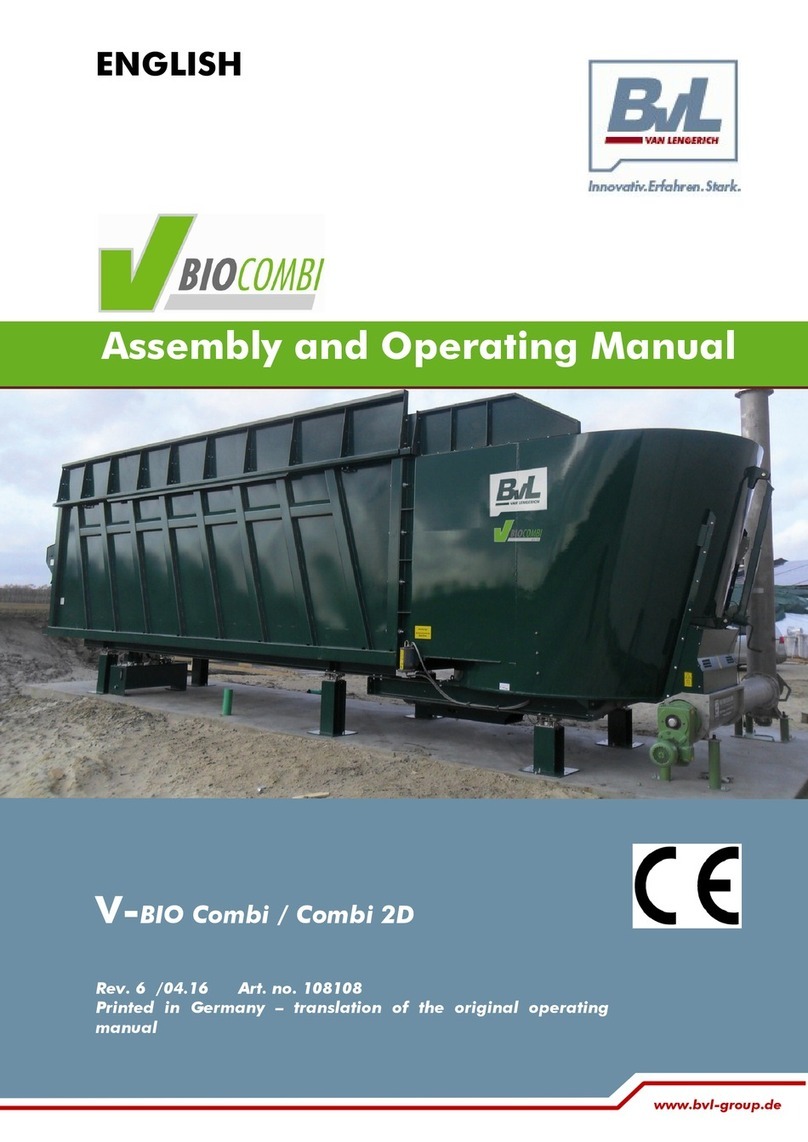

Translation of the original assembly and operating manual

2.2 Organizational measures

The assembly and operating manual:

must always be stored at the location of the machine,

must be freely accessible to operator and maintenance personnel at all times.

2.2.1 Responsibilities of the owner

The owner is required to:

observe all national, generally applicable regulations regarding safety and accident prevention as

well as environmental protection,

limit work with/on the machine to personnel who:

oare familiar with all general safety and accident-prevention regulations,

ohave been instructed in how to work with/on the machine,

ohave read and understood this operating manual.

keep all warnings attached to the machine legible at all times,

replace damaged warnings,

provide the necessary personnel protective equipment such as:

oSafety goggles,

oWork gloves,

oSafety shoes,

oProtective suit,

oSkin protection, etc.

2.2.2 Responsibilities of the operator

Before commencing work, all personnel designated to work with/on the machine are required to:

observe all national, generally applicable regulations regarding safety and accident prevention as

well as environmental protection,

read and observe chapter "Qualification of the personnel", starting on page 11 of this operating

manual,

read the chapter "Warnings and instructions", starting on page 20 of this operating manual and ob-

serve it while operating the machine,

become familiar with the machine,

read the chapters in this assembly and operating manual that are essential for the execution of the

work tasks they have been assigned.

If detecting that a fixture is no longer fully compliant with the safety regulations, the operator is required

to remedy this defect immediately. If the correction of a fault is not part of the operator's responsibilities

or the operator lacks the necessary expertise, the operator must report the defect to his supervisor or the

owner.