Cinderella Motion User manual

Other manuals for Motion

3

Table of contents

Languages:

Other Cinderella Toilet manuals

Cinderella

Cinderella Comfort User manual

Cinderella

Cinderella Urinal User manual

Cinderella

Cinderella COMFORT ANZ User manual

Cinderella

Cinderella COMFORT EU User manual

Cinderella

Cinderella TRAVEL User manual

Cinderella

Cinderella GAS North America User manual

Cinderella

Cinderella CINDERELLA GAS User manual

Cinderella

Cinderella Motion User manual

Cinderella

Cinderella Comfort User manual

Cinderella

Cinderella Urinal User manual

Cinderella

Cinderella FREEDOM User manual

Cinderella

Cinderella FREEDOM User manual

Cinderella

Cinderella CLASSIC User manual

Cinderella

Cinderella TRAVEL User manual

Cinderella

Cinderella Classic NA User manual

Cinderella

Cinderella Classic NA User manual

Cinderella

Cinderella Comfort NA User manual

Cinderella

Cinderella Motion User manual

Cinderella

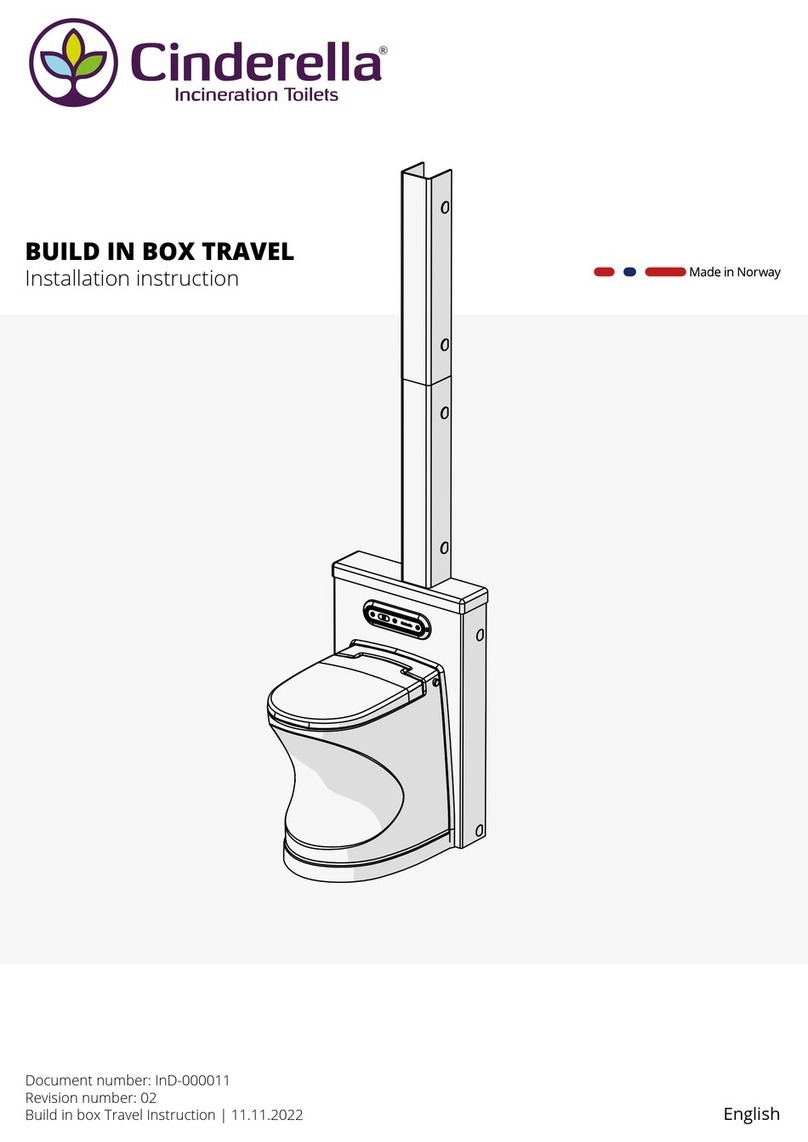

Cinderella BUILD IN BOX TRAVEL User manual

Cinderella

Cinderella CLASSIC Guide

Popular Toilet manuals by other brands

Signature Hardware

Signature Hardware EASTPOINTE 953755 manual

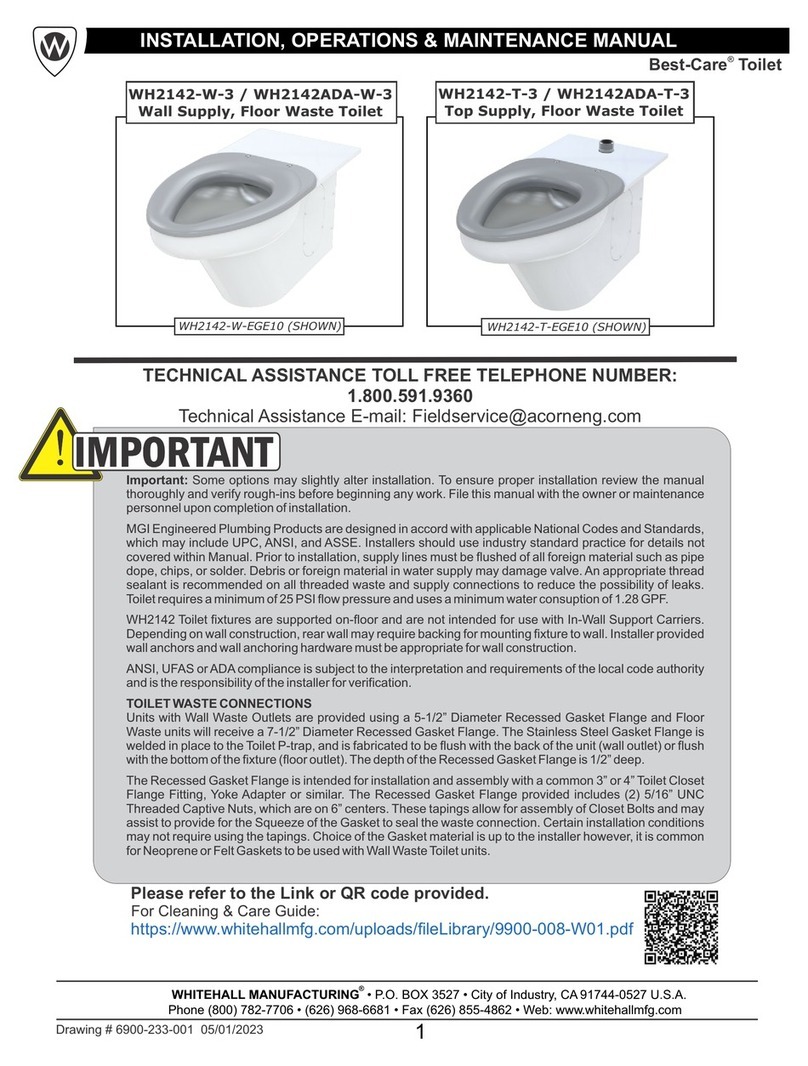

Whitehall

Whitehall WH2142-W-3 Installation, operation & maintenance manual

Danze

Danze Ziga Zaga DC031221 installation instructions

sanindusa

sanindusa CETUS 52 quick start guide

Sanela

Sanela Alessi SLP 25RZ Instructions for use

Kohler

Kohler K-3451 installation guide

BEMIS

BEMIS NextStep installation instructions

SFA-SANIFLO

SFA-SANIFLO SANICOMPACT Installation and maintenance instructions

Simas

Simas BORMIO Installation and maintenance instructions

Signature Hardware

Signature Hardware KEY WEST 948416 Install

Coway

Coway BIDETMEGA 200 user manual

SAT

SAT OptimFlush SATOFSHFS2 installation instructions