Content

Chapter One Safety............................................................................................................................................1

1.1 Instructions for Safe Use of Robots.....................................................................................................1

1.1.1 Safety Precautions during Adjustment, Operation, Maintenance, etc..................................... 1

1.1.2 Safety Countermeasures of Robot Body.................................................................................. 3

1.2 Robot Body Label Description............................................................................................................7

1.3 Shift, Transfer, and Sale of Robots......................................................................................................7

1.4 Abandonment of Robots...................................................................................................................... 8

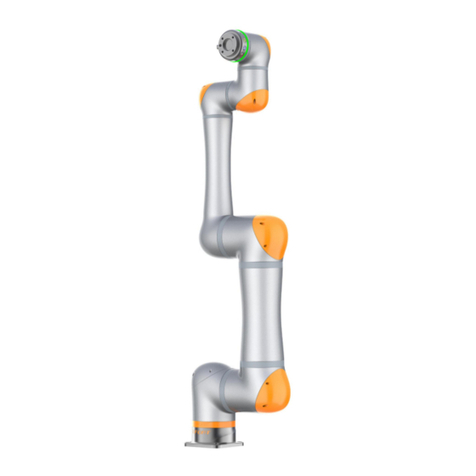

Chapter Two Basic Description....................................................................................................................... 10

2.1 Robot system composition.................................................................................................................10

2.2 Unpacking Check...............................................................................................................................10

2.3 Machine Body Nameplate................................................................................................................. 11

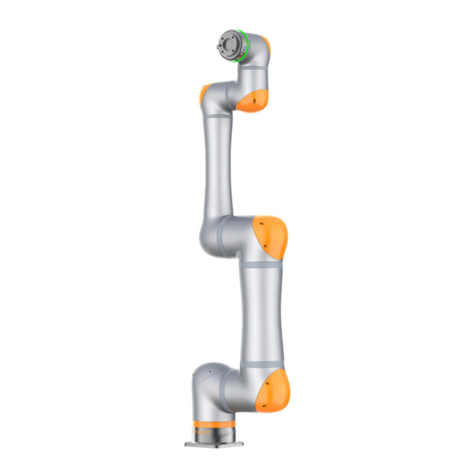

2.4 Body Part Composition and Direction Identification of Each Axis..................................................12

2.5 Robot Axis Range Limit and Home Position.................................................................................... 12

2.6 Robot Performance Parameters......................................................................................................... 13

2.7 Allowable Value of Wrist Payload.....................................................................................................15

2.7.1 Allowable Weight................................................................................................................... 15

2.7.2 Allowable Maximum of Static Payload Torque..................................................................... 15

2.7.3 Allowable Maximum of Moment of Inertia........................................................................... 15

2.7.4 Allowable Payload Curve Diagram........................................................................................15

Chapter Three Handling and Installation.........................................................................................................16

3.1 Robot Handling..................................................................................................................................16

3.1.1 Handling Precautions..............................................................................................................16

3.1.2 Auxiliary Handling Tooling....................................................................................................16

3.1.3 Handling Method....................................................................................................................17

3.2 Robot Installation...............................................................................................................................20

3.2.1 Setting of Safety Fence...........................................................................................................20

3.2.2 Robot Installation Method......................................................................................................20

3.2.3 Ground Mounting................................................................................................................... 21

3.2.4 Supporter Installation............................................................................................................. 22

3.2.5 Suspended Installation............................................................................................................23

3.3 Installation Site and Environment..................................................................................................... 23

3.4 Integrated Application Installation Interface.....................................................................................24

3.4.1 End Flange Installation Interface........................................................................................... 24

3.4.2 external installation Interface................................................................................................. 25

3.4.3 Definition of Wrist I/O Single Cable Connector....................................................................25

3.4.4 Location of Pneumatic and Signal Line Interface..................................................................26

Chapter Four Overhaul and Maintenance........................................................................................................28

4.1 Preventive Maintenance.................................................................................................................... 28

4.1.1 Daily Inspection......................................................................................................................28

4.1.2 Quarterly Inspection............................................................................................................... 28