Enel X JuicePump 150 User manual

JuicePump 150

INSTALLATION AND USER’S MANUAL

WWW.ENELX.COM

PHONE NUMBER:+1-844-584-2329

JuicePump

150 INSTALLATION AND USER’S

MANUAL

Page 2of 68

17-Jun-21

Initial Release

PLEASE NOTE

This document contains useful general information about the product and its installation. Enel X.

reserves the right to make changes to this product without further notice. No part of this

document may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without written permission of Enel X.

Changes or modifications to this product by other than an authorized service facility could void

the product warranty.

If you have questions about the use of this product, contact your customer service representative.

This product should be operated by trained personnel only.

17-Jun-21

Initial Release

JuicePump

150 INSTALLATION AND USER’S

MANUAL

Page 3of 68

TABLE OF CONTENTS

Table of Contents

1. Safety Guidelines ...................................................................................................................5

1.1. Important Safety Instructions.................................................................................................5

1.2. Symbols and Definitions.........................................................................................................6

2. System Overview ...................................................................................................................7

3. Equipment Description ..........................................................................................................8

4. System Specification ...........................................................................................................11

4.1. DCFC Power Unit..................................................................................................................11

4.2. DCFC Dispenser ...................................................................................................................12

5. Pre-Installation......................................................................................................................13

5.1. Location Selection ...............................................................................................................13

5.2. Cable Reach........................................................................................................................14

5.3. ADA Consideration ..............................................................................................................15

5.4. List of Parts, Materials, and Tools Needed for Installation .................................................17

6. Transportation and Handling...............................................................................................18

6.1. Packaging ............................................................................................................................18

6.2. Transport, Handling, and Storage.......................................................................................18

6.3. Receiving and Unpacking ..................................................................................................19

7. Installation ............................................................................................................................20

7.1. Moving and Hoisting Instructions ........................................................................................21

7.2. Mounting Procedures ..........................................................................................................24

7.2.1. Clearance Around the Unit.................................................................................................24

7.2.2. Tower and Dispenser Mounting ..........................................................................................25

7.3. Electrical and Communication Service Connection........................................................28

7.4. Ethernet Port Location.........................................................................................................36

8. Verification and Inspection.................................................................................................38

9. Operation .............................................................................................................................39

9.1. System Power Up..................................................................................................................39

9.2. Output Connectors..............................................................................................................40

9.2.1. CHAdeMO Connector (200 A) ...........................................................................................40

17-Jun-21

Initial Release

JuicePump

150 INSTALLATION AND USER’S

MANUAL

Page 4of 68

TABLE OF CONTENTS

Table of Contents (Continuation)

9.2.2. CCS1 Connector (500 A).....................................................................................................41

9.2.3. CCS1 Connector (200 A).....................................................................................................41

9.3. Operating Instruction...........................................................................................................42

9.4. Troubleshooting....................................................................................................................46

10. Maintenance........................................................................................................................54

11. Product Disposal ..................................................................................................................59

12. Appendix..............................................................................................................................60

12.1. Component Information .....................................................................................................60

a) CCS1 High-Power Liquid Cooled Coupler (500A Rated)..................................................60

b) Cooling Unit System .............................................................................................................61

c) Cool Cable Coolant............................................................................................................62

d) SAE J1772 CCS1 Coupler (200A Rated) .............................................................................64

e) CHAdeMO High Power Coupler (200A Rated) .................................................................64

12.2. Cooling Unit System Overview............................................................................................65

a) Main Parts .............................................................................................................................65

b) Refiling Coolant in Cooling Unit Tank .................................................................................65

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 5of 68

SAFETY GUIDELINES

1. Safety Guidelines

SAVE THESE INSTRUCTIONS

This document contains important instructions for the installation, operation, and maintenance

of the JuicePump 150. These instructions should be retained for future reference.

1.1. Important Safety Instructions

DANGER

READ THIS MANUAL BEFORE YOU BEGIN

This JuicePump 150 manages electricity and may be hazardous. The equipment should be

installed, adjusted, and serviced only by qualified electrical personnel familiar with the

construction and operation of this type of equipment and the hazards involved, and in full

compliance with all local and national codes and standards. Failure to observe this precaution

could result in severe injury or death.

Read this manual completely and become familiar with the equipment prior to performing any

procedures specified in the manual and energizing the equipment. Inspection and

maintenance of this equipment should be performed in accordance with the procedures

detailed in this manual.

In situations where it is not possible to perform an installation following the procedures stated in

this document, contact Enel X. Enel X will not be responsible for any damages that may occur

resulting from custom installations that are not stated in this document.

There are no user serviceable parts inside. For service, please contact customer service or your

local distributor. DO NOT ATTEMPT TO REPAIR THE CHARGE STATION YOURSELF. SERVICE TO THE

UNIT SHALL ONLY BE PERFORMED BY A QUALIFIED PERSONNEL.

If the charging cable is somehow damaged, do not operate the charge station. Contact your

service representative for service immediately. Shut down the power to the tower by switching

the breaker on the supply panel to the off position.

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 6of 68

SAFETY GUIDELINES

1.2. Symbols and Definitions

Please take special attention to all information marked with the following symbols. These symbols

may be found throughout the manual and on labels affixed to the equipment unit.

DANGER

Indicates High Voltage. It calls attention to items or operations

that could be dangerous to person/s operating this

equipment. Read and follow the instructions carefully. Failure

to do so will result in severe injury or possibly death.

WARNING

Indicates a hazard or unsafe practice which, if not avoided,

may result in severe injury or possibly death.

CAUTION

Indicates a hazard or unsafe practice which, if not avoided,

may result in minor to moderate injury.

NOTE

Indicates important information to consider, otherwise,

improper installation and/or damage to components may

occur.

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 7of 68

SYSTEM OVERVIEW

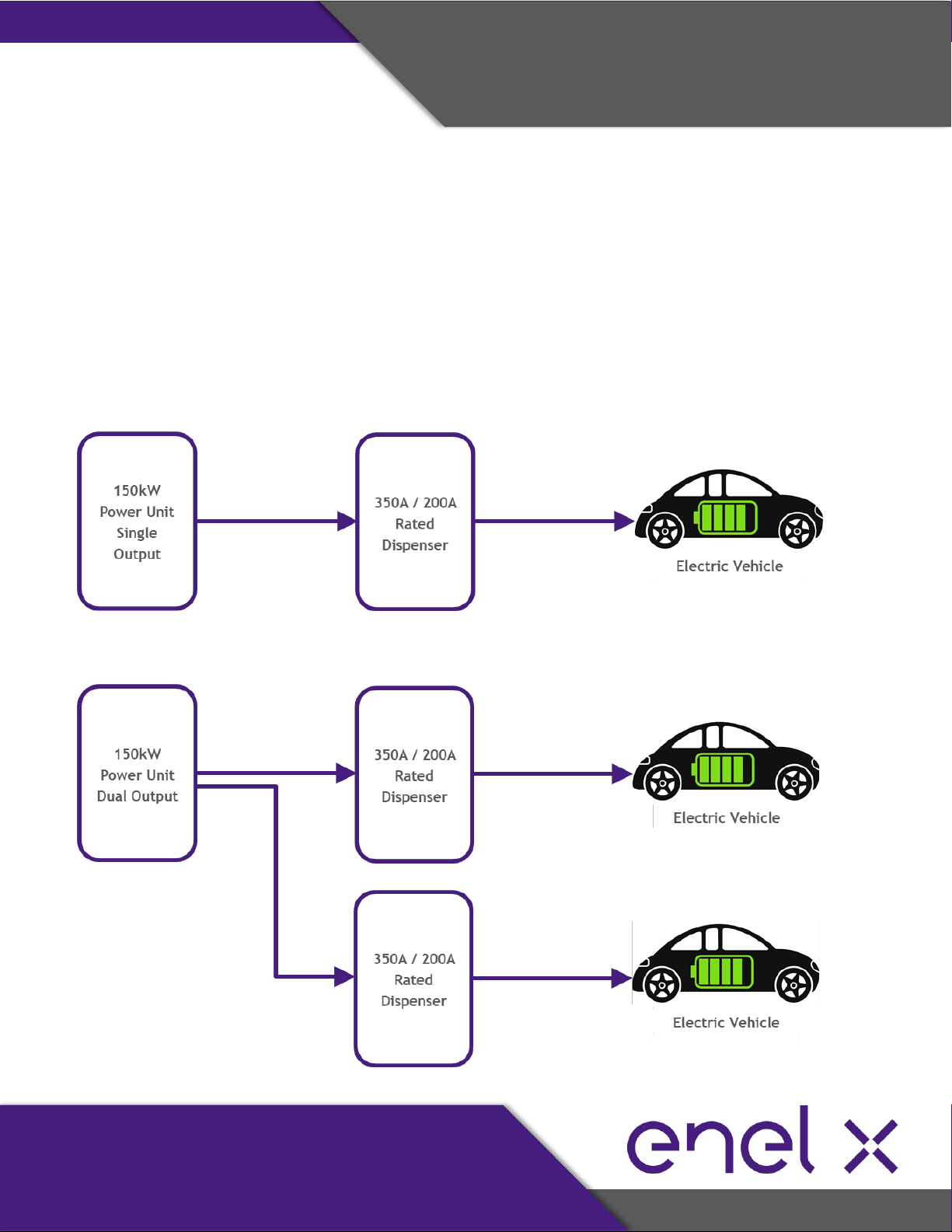

2. System Overview

The JuicePump 150 converts a 480VAC 3-phase voltage into DC voltage to directly charge an

electric vehicle’s lithium-ion battery. It is capable to charge all electric vehicles compliant with

CHAdeMO charging system and Combined Charging System (CCS) standards.

The charger is composed of a 150kW Power Unit (with 3 individual 50kW power modules on it)

and one or two dispenser/s depending on the configuration. The dispensers can either be a Dual

CCS or CCS/CHAdeMO configuration and a 350A or 200A rated.

➢SIMPLIFIED BLOCK DIAGRAM (1-DISPENSER SYSTEM):

➢SIMPLIFIED BLOCK DIAGRAM (2-DISPENSER SYSTEM):

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 8of 68

EQUIPMENT DESCRIPTION

3. Equipment Description

150 kW HIGH POWER UNIT / TOWER

COMPONENT DESCRIPTION

1. 50KW #3 Power Module

2. 50KW #2 Power Module

3. 50KW #1 Power Module

4. Output Contactors (+/-) Power Module #3

5. Output Contactors (+/-) Power Module #2

6. Output Contactors (+/-) Power Module #1

7. Air Vent

8. Master Controller

9. Safety Relays

10. 24VDC Power Supplies

11. 12VDC Power Supply

12. Input Section

13. Output Section

14. Optical Transceivers

15. Empty slot for 50kW upgrade

* Power Module #4 as optional upgrade

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 9of 68

EQUIPMENT DESCRIPTION

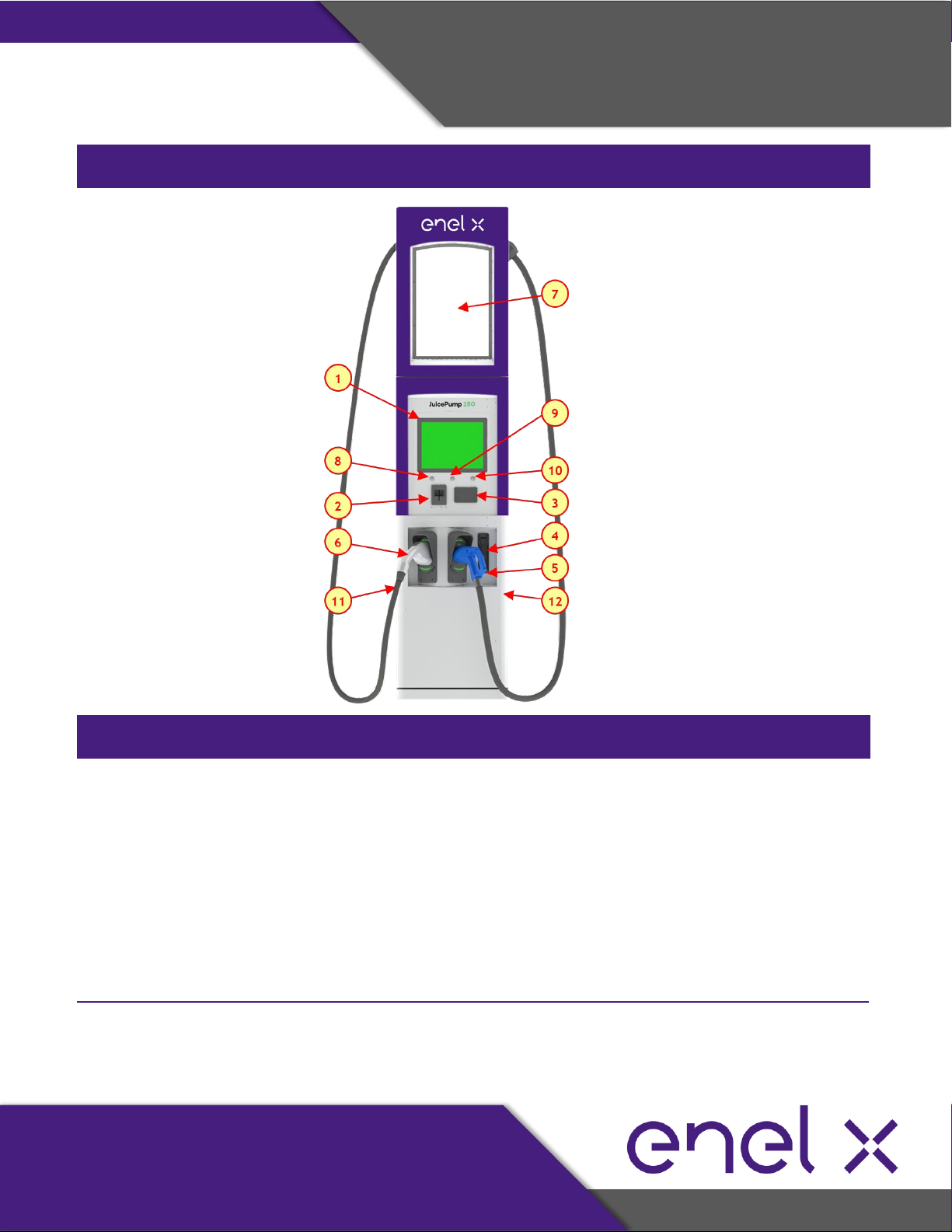

350A / 200A CHARGE DISPENSER

COMPONENT DESCRIPTION

1. 15-inch Outdoor-Rated Display and

Touch Screen

2. Magnetic stripe Credit Card Reader

3. RFID Card Reader

4. High Security Lock

5. Charging Connector 1

6. Charging Connector 2

7. Customer Advertising Panel

8. Start Button / Function Key 1

9. Stop Button / Function Key 2

10. Emergency Stop Button / Function Key 3

11. Air Inlet (left side)

12. Air Exit (right side)

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 10 of 68

EQUIPMENT DESCRIPTION

SYSTEM COMPONENTS

Power Unit / Tower

ITEM

DESCRIPTION

MODEL NUMBER

SKU

1

DCFC Power Unit Dual Output, SCCR 65kA

EVPC-150-2-480-3-65

HPCT-150-480-2

Dispenser

ITEM

DESCRIPTION

MODEL NUMBER

SKU

2

DCFC 350A Dispenser, CCS/CHAdeMO

EVDSP-350-5-120-0-2-C-4-0

HPCD1-350-01-003

3

DCFC 350A Dispenser, Dual CCS

EVDSP-350-4-120-0-2-C-4-0

HPCD1-350-02-003

4

DCFC 200A Dispenser, CCS/CHAdeMO

EVDSP-200-5-120-0-2-C-4-0

HPCD1-200-01-003

5

DCFC 200A Dispenser, Dual CCS

EVDSP-200-4-120-0-2-C-4-0

HPCD1-200-02-003

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 11 of 68

SYSTEM SPECIFICATION

4. System Specification

4.1. DCFC Power Unit

AC to DC Power Converter Specification

Model Number: EVPC-150-2-480-3-65

SKU: HPCT-150-480-2

PARAMETER

150kW POWER UNIT / TOWER

AC Input

Input Voltage Range

480 VAC, 3 Phase, +10% / -15%

Input Frequency Range

47 –63 Hz

Input Current @ 480 VAC

198 A

Power Factor

> 0.99 full load

Total Harmonic Distortion

< 5%

Efficiency

> 92%

SCCR

65 kA

Idle Power Consumption

159.5 W

DC Output

Output Voltage Range

50 –920 VDC

Maximum Output Current

CCS: 350 A, CHAdeMO: 200 A

Maximum Output Power

150 kW

Minimum Output Current

5 A

Output Ripple Current

< 15 Ap–p (Bandwidth 1 kHz)

Protection

Over Temperature

Self–protected and Latched

Output Over Voltage

Output Shutdown and Latched

Output Overload

Output Shutdown and Latched

CAN Communication Loss

1 sec Shutdown Upon Loss of Connection

Safety Standards

Isolation

UL 2231–1/2, UL 840

EMC Standards

Harmonics

IEC 61000-3-12

Immunity

UL 2231-2

Environment Conditions

Operating Temperature Range

-30°C to +50°C

Operating Altitude

6,000 ft.

Humidity

95% Non-Condensing

Mechanical Characteristics

Dimensions

42“ W x 35” D x 82“ H

Weight

1892 lbs

Enclosure IK Rating

IK 08

Enclosure IP Rating

IP 54 (NEMA 3R)

Specifications are subject to change without prior notice.

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 12 of 68

SYSTEM SPECIFICATION

4.2. DCFC Dispenser

High Power Dispenser Specification

Model Numbers: EVDSP-350-5-120-0-2-C-4-0, EVDSP-350-4-120-0-2-C-4-0

EVDSP-200-5-120-0-2-C-4-0, EVDSP-200-4-120-0-2-C-4-0

SKUs: HPCD1-350-01-003, HPCD1-350-02-003, HPCD1-200-01-003, HPCD1-200-02-003

PARAMETER

DISPENSER

350A Rated

200A Rated

AC Input

Auxiliary Input Voltage

120 VAC, Single phase, +/-10%

Auxiliary Input Current

21 A

10 A

Input Frequency Range

47 –63 Hz

Panel Breaker

30 A

Power Quality

IEEE-519 and IEC 6200-3-4

Idle Power Consumption

143.06 W

DC Input

Input Voltage Range

50 –920 VDC

Input Current Range

5 –500 A

DC Output

Dual CCS Configuration

Maximum DC Output Current

CCS, continuous

350 A

500 A

(boost mode; non-continuous)

200 A

CHAdeMO + CCS Configuration

Maximum DC Output Current

CHAdeMO, continuous

200 A

200 A

Maximum DC Output Current

CCS, continuous

350 A

200 A

Environment Conditions

Operating Temperature Range

-30°C to +50°C

Operating Altitude

6,000 ft.

Humidity

95% Non-Condensing

Mechanical Characteristics

Outdoor Enclosure

NEMA 3R, IP 54 equivalent

Dimensions

22“ W x 15” D x 97“ H

Weight

600 lbs

LED Lighting System

580 lumens

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 13 of 68

PRE-INSTALLATION

5. Pre-Installation

Prior performing any installation activities, it is important to go through each of the items

outlined in this section which are essential for the installation process.

5.1. Location Selection

Thing to consider when choosing a location to install the unit:

•Standards for Accessible Design (refer to section 5.3)

•Conformance to all governing standards for location and placement of the charger

•Communications Connectivity

oRefer to Enel X guidelines in “Determining Suitability of Site for Cellular Connectivity”

oEnsure that installation location meets the Cellular Signal Strength Criteria below

Parameter

Min Value

Device

Notes

RSSI

-69 dBm

SureCall

If RSSI < - 69dBm, measure RSRP,

RSRQ, and SNIR

RSRP

-100 dBm

Squid or -Cellular Meter

Please consult Enel X

Application Engineering

RSRQ

-11 dBm

Squid or -Cellular Meter

Please consult Enel X

Application Engineering

SNIR

> 6 dB

Squid or -Cellular Meter

For Reference

•Local Conditions

oArea is not expose to high temperatures, dust, corrosive fumes, combustible materials, or

explosive gases

oArea is dry and well-ventilated

oClearances at both sides for proper ventilation

oClearance at front and sides for accessibility during service (refer to Section 7.2.1)

oWiring and conduit needed to connect the charger to the circuit panel

oLocation of vehicle’s charging inlets while parked

oUse of protective bollards and wheel stops to protect the charger

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 14 of 68

PRE-INSTALLATION

5.2. Cable Reach

The cables of the dispenser come in different lengths depending on the dispenser configuration

and cable/connector type. The table below shows the connector type with its corresponding

cable reach while the figure shows the radius in which the two (2) DC connectors can be used.

Dispenser

Connector

Cable Reach

HPCD1-350-01-003

CCS1 (500A)

11.15 feet

CHAdeMO (200A)

10.5 feet

HPCD1-350-02-003

CCS1 (500A)

11.15 feet

CCS1 (500A)

11.15 feet

HPCD1-200-01-003

CCS1 (200A)

13 feet

CHAdeMO (200A)

10.5 feet

HPCD1-200-02-003

CCS1 (200A)

13 feet

CCS1 (200A)

13 feet

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 15 of 68

PRE-INSTALLATION

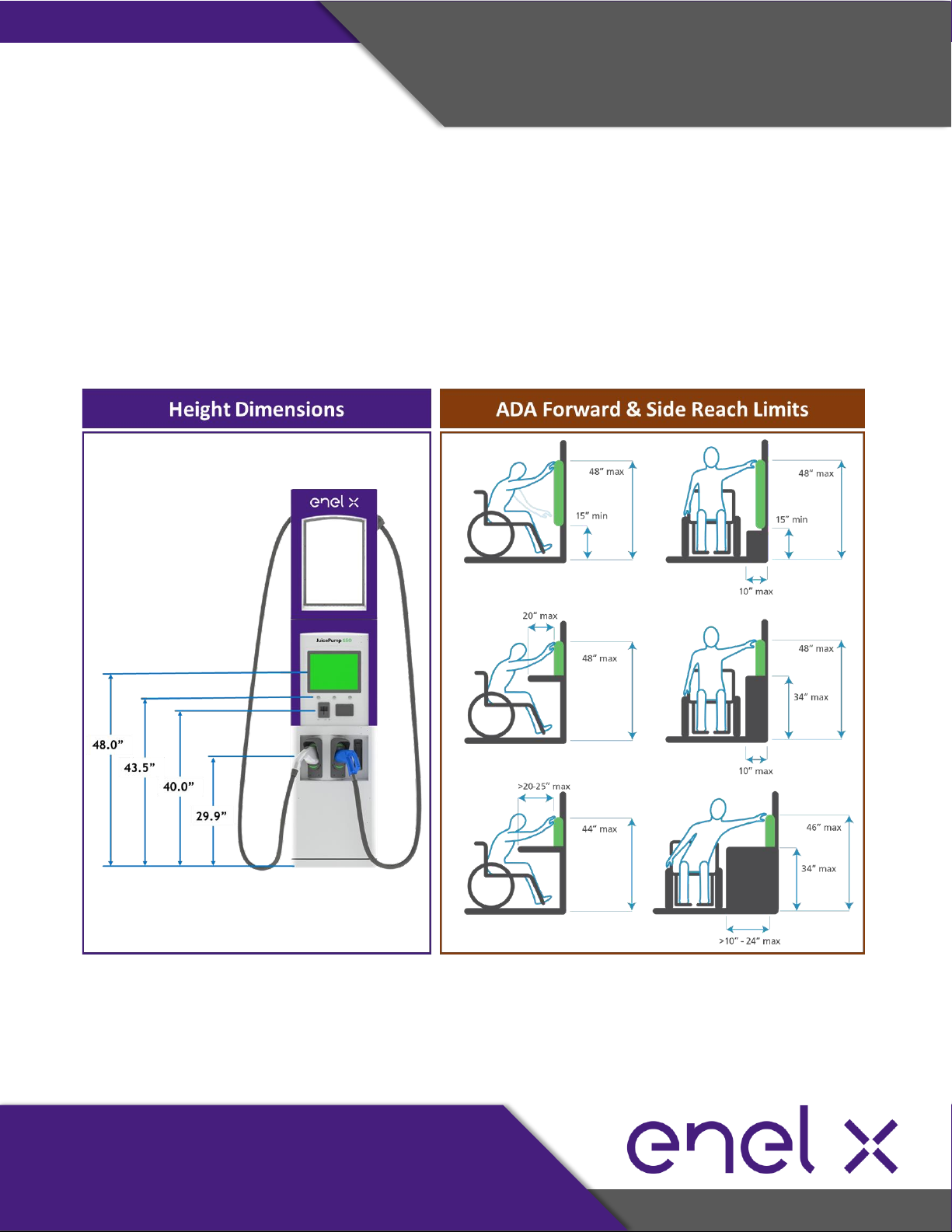

5.3. ADA Consideration

STANDARDS FOR ACCESSIBLE DESIGN for Americans with Disabilities is applicable when choosing

the location and placement of all Electric Vehicle Supply Equipment. The following is a direct

excerpt from the 2010 ADA Standards for Accessible Design:

http://www.ada.gov/2010ADAstandards_index.htm

“The Department of Justice published revised regulations for Titles II and III of the Americans with

Disabilities Act of 1990 “ADA” in the Federal Register on September 15, 2010. These regulations

adopted revised, enforceable accessibility standards called the 2010 ADA Standards for

Accessible Design “2010 Standards” or “Standards”. The 2010 Standards set minimum

requirements –both scoping and technical –for newly designed and constructed or altered State

and local government facilities, public accommodations, and commercial facilities to be readily

accessible to and usable by individuals with disabilities.

Adoption of the 2010 Standards also establishes a revised reference point for Title II entities that

choose to make structural changes to existing facilities to meet their program accessibility

requirements; and it establishes a similar reference for Title III entities undertaking readily

achievable barrier removal.

The Department has assembled this online version of the official 2010 Standards to increase its

ease of use. This version includes:

•2010 Standards for State and Local Government Facilities Title II

•2010 Standards for Public Accommodations and Commercial Facilities Title III

The Department has assembled into a separate publication the revised regulation guidance that

applies to the Standards. The Department included guidance in its revised ADA regulations

published on September 15, 2010. This guidance provides detailed information about the

Department’s adoption of the 2010 Standards including changes to the Standards, the reasoning

behind those changes, and responses to public comments received on these topics. The

document, Guidance on the 2010 ADA Standards for Accessible Design, can be downloaded

from:

http://www.ada.gov

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 16 of 68

PRE-INSTALLATION

For information about the ADA, including the revised 2010 ADA regulations, please visit the

Department’s website www.ADA.gov; or, for answers to specific questions, call the toll-free ADA

Information Line at 800- 514-0301 (Voice) or 800-514-0383 (TTY).”

Compliance to ADA Standards

Access to all the controls and commands including the buttons and the card reader, must

comply with local codes and ADA requirements. That includes being under 48” of distance to

the ground.

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 17 of 68

PRE-INSTALLATION

5.4. List of Parts, Materials, and Tools Needed for Installation

Parts & Materials Needed to Purchase

Item

Part Description

Quantity

Remarks

1

OM3, multimode, 50/125µm,

ST connectors on both ends

2 pairs per

dispenser

Recommended supplier:

https://fibercablesdirect.com/

2

18AWG Twisted Pair, Shielded,

Interlock Cable

1

3

DC Wire

1 pair per

dispenser

4

AC 120VAC Wire

1 pair per

dispenser

5

Ethernet Cable

1 per dispenser

*Note: Extra sets of Fiber Optic Connectors are needed as back-up since these breaks easily.

Tools Needed during Installation

Item

Part Description

Quantity

1

Philips Head Screwdriver

1

2

½” x 4” Concrete Expansion Bolt

4

3

½” Torque Wrench

1

4

Allen Wrench Set

1

5

Keys (shipped with the unit)

1

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 18 of 68

TRANSPORTATION AND HANDLING

6. Transportation and Handling

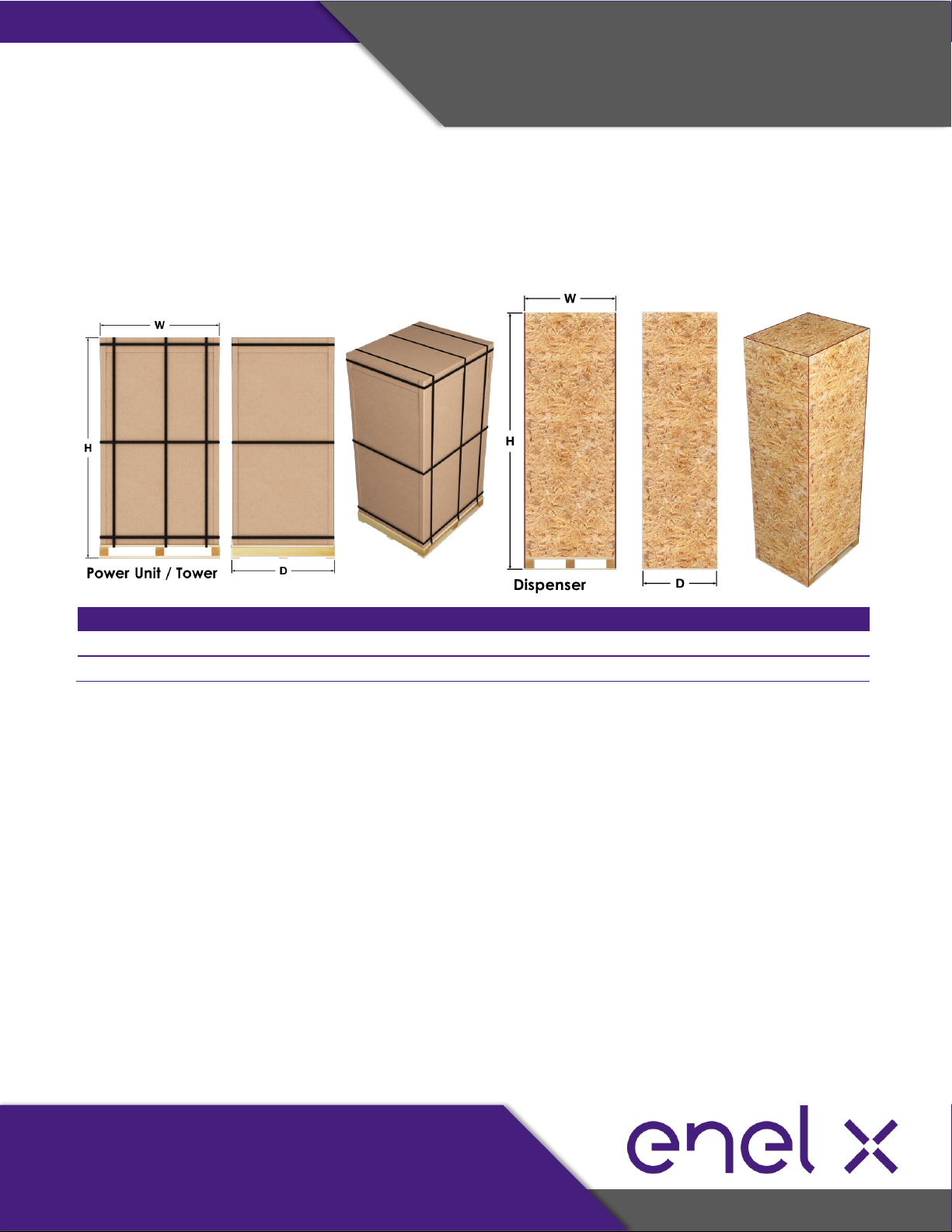

6.1. Packaging

The power unit/tower and dispenser are packaged, shipped, and delivered in wood crates.

Below are the details of its packaging and dimensions for both tower and dispenser.

Item

Width (in)

Depth (in)

Height (in)

Weight (lb)

Power Unit/ Tower

49

42

90

up to 1998

Dispenser

37

30

103

up to 740

6.2. Transport, Handling, and Storage

Transport

The tower and dispenser must be transported upright or in vertical position. Liquid may leak or

other materials may get damaged if tilted or transported on its side.

Moving and Hoisting

Forklift or pallet truck can be used in moving or transporting the tower and dispenser. In addition

to this, the tower and dispenser can be moved or lifted using the lifting eye bolts.

Refer to section 7.1 for more details.

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 19 of 68

TRANSPORTATION AND HANDLING

Storage

The tower and dispenser must be stored in its original wood packaging in a dry environment from

-30°C to +50°C.

6.3. Receiving and Unpacking

Receiving Instructions

Once shipment is received, please follow these receiving instructions. It is the responsibility of the

receiver to perform visual inspection on the shipment and immediately notify Enel X Project

Manager for any damage.

•Unload and carefully inspect the crate or packaging for any damage caused by

mechanical impacts or any incidents during its transportation.

•Inspect the Tip N Tell tilt indicator attached on the crate. Tip N Tell tilt indicator provides

information of the shipment conditions during transit. Blue beads in arrow indicates crate has

been on its side or tipped over in transit.

•Note on the delivery receipt any visible damage to the crate/packaging or shipment has

been tipped based on the Tip N Tell tilt indicator. Provide information of the damage as

detailed as possible.

•For any issues or questions regarding the shipment, please call Enel X Shipment In-charge at

(714) 706 –4970.

17-Jun-21

Initial Release

JuicePump 150

INSTALLATION AND USER’S MANUAL

Page 20 of 68

INSTALLATION

7. Installation

SAFETY INSTRUCTIONS

The JuicePump 150 should be installed in accordance with local codes and all applicable

ordinances.

Read all installations instructions carefully prior to performing the installation.

DANGER

The equipment utilizes high voltages, only qualified electrical personnel familiar with the

operation and construction should install, adjust, modify, and service this equipment. Failure to

observe this precaution could result to severe injury or death.

WARNING

•The equipment may be installed outdoors but only use under environment conditions as stated

in this document.

•Do not perform any live wire operations.

•Do not touch the inside of the equipment while it is running.

•This equipment includes capacitive components such as electrolytic capacitors. Some parts

may still remain charged inside of the unit even after the input power is disconnected.

•This charger should not be modified in any way. This will void the warranty, compromise

protection and could result in a possible shock or fire hazard.

•Personal Protective Equipment should be used at all times when working with the equipment.

CAUTION

During installation of the unit, ensure that the charge station’s supply cable is in such a way that

it will not be tripped over, stepped on, pulled on, or somehow subjected to damage or stress.

This manual suits for next models

5

Table of contents

Other Enel X Batteries Charger manuals

Enel X

Enel X Way JuiceBox User manual

Enel X

Enel X Waypole User manual

Enel X

Enel X Way Next Gen JuiceBox User manual

Enel X

Enel X JuiceBox User manual

Enel X

Enel X JUICEBOX PRO User manual

Enel X

Enel X Waymedia 2 User manual

Enel X

Enel X JuicePump User manual

Enel X

Enel X Waybox Pro User guide

Enel X

Enel X JUICEBOX PRO User manual

Enel X

Enel X JUICEBOX PRO User guide