Enel X JuicePump User manual

50kW DC

RT

www.enelx.com

Phone: +1-844-584-2329

Installation Manual

TRI93-50-01-UL

www.enelx.com

Phone: +1-844-584-2329

Important safety instructions and specications. Save these instructions.........................1

FCC Notice.............................................................................................................................3

Packaging, handling & receipt...............................................................................................4

Site conguration...................................................................................................................5

Underground power preparation...........................................................................................9

Above ground power preparation........................................................................................10

Installation requirements & equipment...............................................................................11

Unpacking & installation preparation...................................................................................13

Installation............................................................................................................................16

Underground conduit and wiring..........................................................................................18

Above ground conduit and wiring........................................................................................20

Wire & commission...............................................................................................................21

Ethernet port access............................................................................................................23

Closing checklist...................................................................................................................24

Installation checklist.............................................................................................................27

Contents

1www.enelx.com

Phone: +1-844-584-2329

Important safety instructions and

specications. Save these instructions

This manual contains important

instructions for the JuicePump electric

vehicle fast charger.

These instructions must be followed

during installation of the unit.

For charger operating instructions, see

JuicePump Operating Manual.

For charger maintenance instructions, see

JuicePump Maintenance Manual.

Identifying symbols

CAUTION

RISK OF ELECTRIC SHOCK

Equipment Grounding

Conductor Symbol

ø Phase Symbol

Alternating Current Supply

Symbol

CAUTION

The JuicePump fast charger must be

installed and serviced only by qualied

electrical personnel. To achieve EMC

compliance, the chassis of the JuicePump

must be bonded to Earth locally at the

charger.

CAUTION

In the event of a circuit breaker trip, the

charger must be inspected by an Enel

X-certied service agent before the char-

ger is re-energized.

Grounding instructions

This unit is to be connected to a

grounded, metal, permanent wiring

system; and an equipment-grounding

conductor is to be run with circuit

conductors and connected to

equipment-grounding terminal or lead on

battery charger. Connections to the bat-

tery charger shall comply with all local

codes and ordinances.

Observe all pertinent national,

regional and local safety laws and

regulations when installing and

commissioning the JuicePump fast char-

ger.

Wiring size

3ø: 4 AWG

Use 90°C Copper Wire

Use 4 AWG insulated

grounding conductor

1ø: 18 AWG

Use 90°C Copper Wire

An insulated grounding conductor that is

identical in size, insulation material and

thickness to the grounded and

ungrounded branch-circuit supply

conductors except that it is green with or

without one or more yellow stripes is to

be installed as part of the branch circuit

that supplies the unit or system. This

grounding conductor is to be grounded to

earth at the service equipment or, when

supplied by a separately derived system,

at the supply transformer.

2www.enelx.com

Phone: +1-844-584-2329

Input:

3ø WYE CONNECTED

277/480V ±10%

60Hz

55kW

1ø, 120V

60Hz

250W

The JuicePump must be connected to a

circuit provided with appropriate branch

circuit over-current protection in

accordance with the National

Electrical Code, ANSI/NFPA 70.

Tightening torque:

Wiring terminals:

Breaker 4.0 Nm/35 lb-in

Service hatch:

2.0 Nm/17.70 lb-in

Operating temperature:

-35° to 50°C / -31° to 122°F

Maximum ambient

temperature:

55°C /131°F

Weather rating:

NEMA Type 3R

Important safety instructions and

specications. Save these instructions

3www.enelx.com

Phone: +1-844-584-2329

FCC Notice

Information to the user

(FCC Part 15.105)

Class A product:

NOTE:

This equipment has been tested and

found to comply with the limits for a Class

A digital device, pursuant to part 15 of

the FCC rules. These limits are designed

to provide reasonable protection against

harmful interference when the equipment

is operated in a commercial environment.

This equipment generates, uses and

can radiate radio frequency energy and,

if not installed and used in accordance

with the instruction manual, may cause

harmful interference to radio communi-

cations. Operation of this equipment in a

residential area is likely to cause harmful

interference in which case the user will be

required to correct the interference at his

own expense.

Modication warning

(FCC Part 15.21)

In addition the user’s manual or

instruction manual shall caution the

user that changes or modications

not expressly approved by the party

responsible for compliance could void

the user’s authority to operate the

equipment (see below for example)

Warning: Any changes or

modications not expressively

approved by (Enel X) could void

the user’s authority to operate this

equipment

4www.enelx.com

Phone: +1-844-584-2329

Read these instructions carefully to

become familiar with JuicePump packag-

ing and handling procedures prior to

unpacking and installation.

In all cases, the JuicePump is to be

transported to the installation site in its

original packaging and only unpacked at

the installation site.

Installation, commissioning and servicing

of the JuicePump should only be carried

out by qualied personnel.

Materials:

The JuicePump is transported in a

reinforced cardboard crate.

Please respect the environment and

recycle/reuse the materials.

Storage:

Store in the original packaging in a

horizontal position.

Storage temperature:

-20 to 45°C / -4 to 113°F.

Handling:

Only lift the JuicePump packaging in its

horizontal orientation using a forklift,

pallet jack or with lifting straps and

engine hoist, forklift or crane. Check the

weight on the delivery documents and

ensure the lifting apparatus used is

compatible.

Receipt:

Check that the crate packaging is in

good condition and that the JuicePump is

not damaged.

If there are any problems noted, make a

formal complaint to the carrier and notify

your supplier.

Packed crate weight:

200kg/440lb

Crate size:

850(W) x 2150(H) x 450(D)mm

33.5(W) x 84.5(H) x 18(D) inches

JuicePump size:

750(W) x 2000(H) x 330(D)mm

29.5(W) x 78.7(H) x 13(D) inches

(without plugs)

JuicePump weight:

165kg/364lbs

Packaging, handling & receipt

5www.enelx.com

Phone: +1-844-584-2329

Site survey:

The JuicePump can be installed onto a

newly prepared concrete pad, or onto an

existing concrete surface, with service

wiring supplied through conduit via the

foundation or above ground.

A qualied engineer must

survey the installation site to determine

the correct ground preparation for the

size and weight of the JuicePump, in

accordance with all local applicable codes

and regulations.

If a foundation to supply power from

underground is to be prepared, follow the

underground power instruction for

installation.

If the charger is to be installed onto an

existing concrete surface, follow the

above ground power instruction for

installation.

The JuicePump is best installed following

the recommended site conguration

requirements.

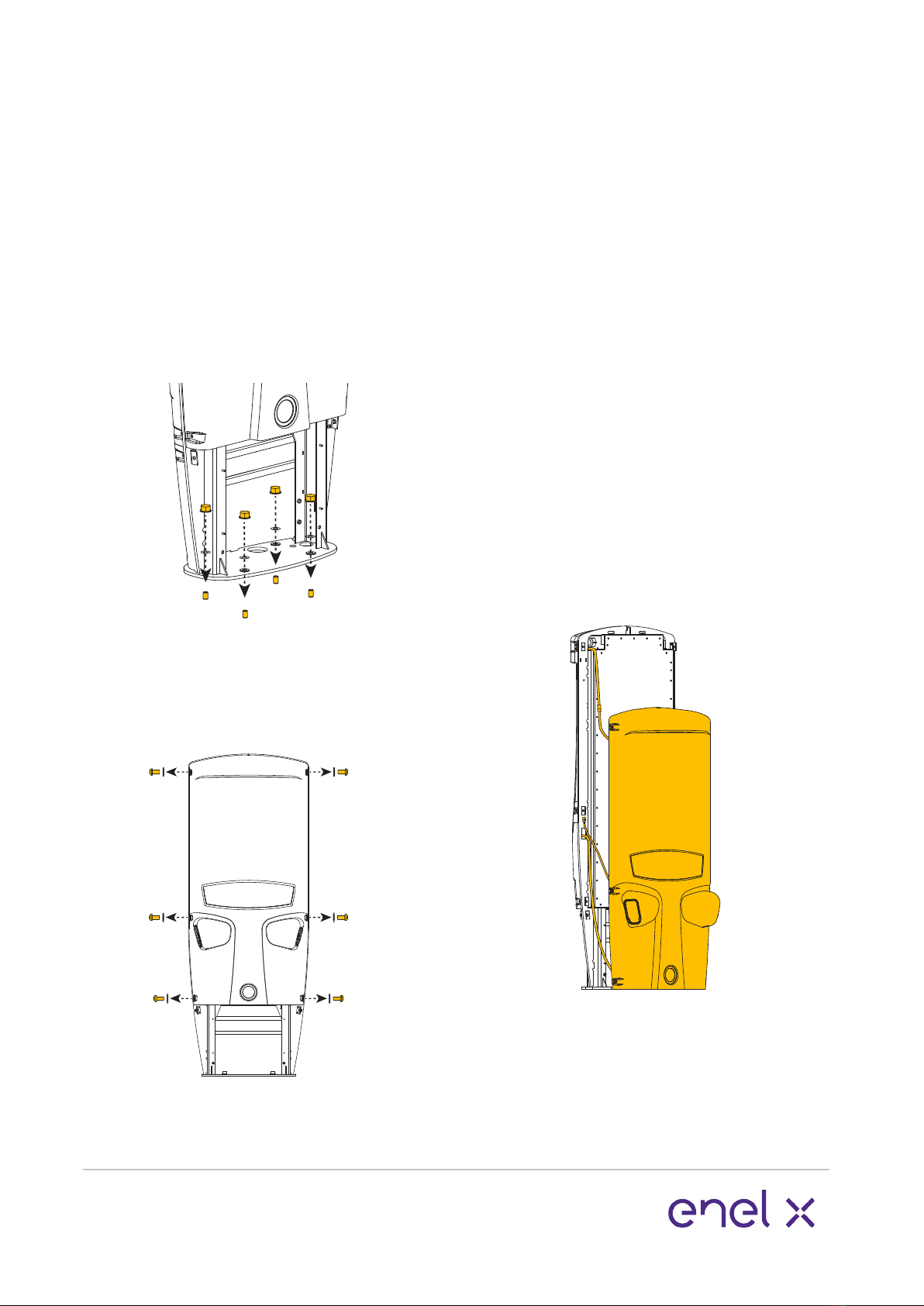

Ground xing:

The JuicePump is to be xed to the

ground through the baseplate xing holes

with 4 x M16 or 5/8-11 inch fasteners

(not supplied). The fasteners should

x the Veel securely to the foundation

through the baseplate and protrude

30-40mm/1.2-1.6 inch maximum from

the foundation surface, in accordance

with the dimensions and xing points

shown in: Figure 5: Fixing guide.

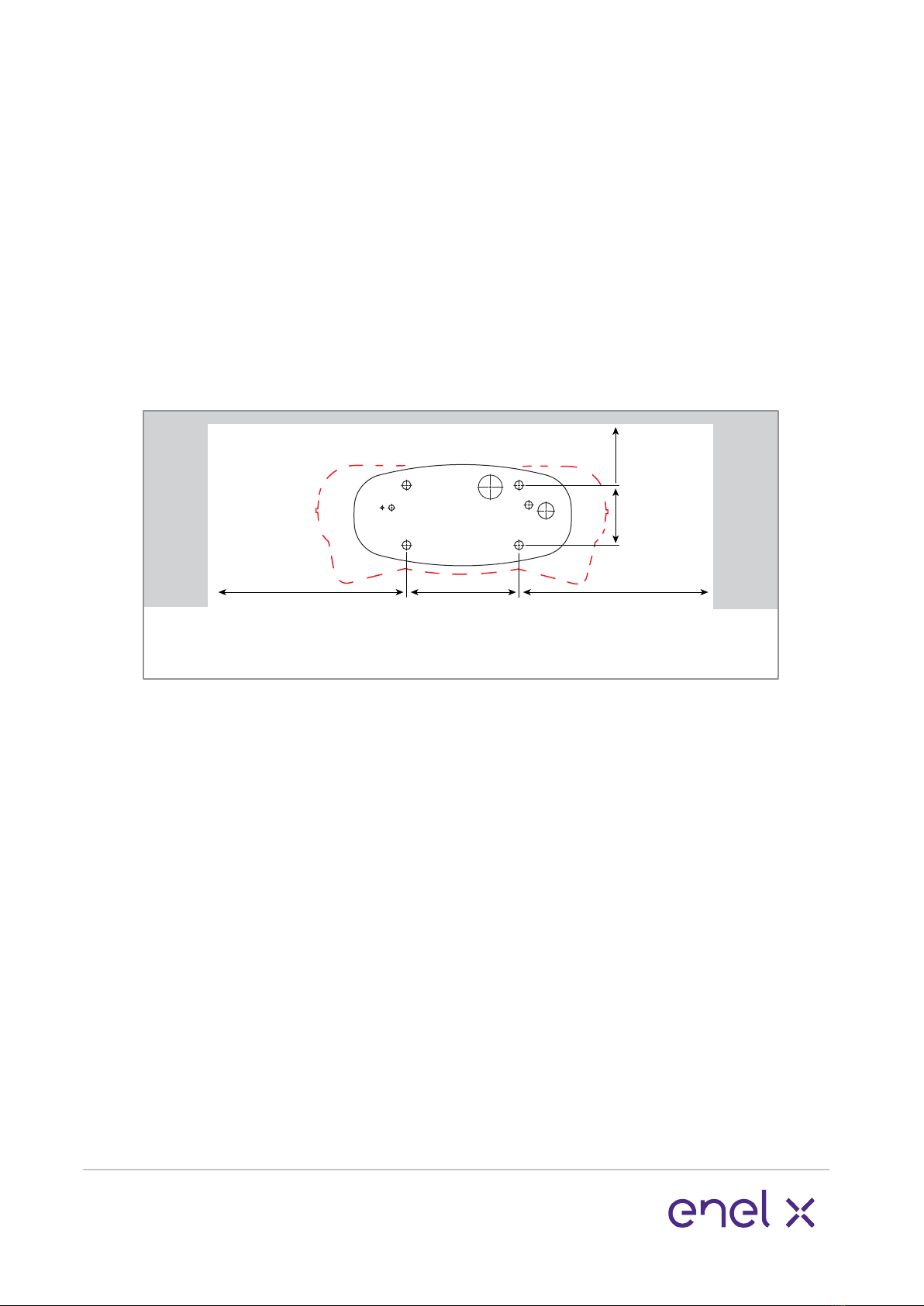

See Figure 1: Dimensions walls or

obstacles, for installation against or near

walls or other obstacles.

Foundation requirements:

The foundation must be at, even, and

the appropriate density for the weight of

the JuicePump.

Check the atness and level of the

foundation and level of the JuicePump

baseplate prior to xing.

Communications:

4G network capability or Ethernet.

The JuicePump is tted with a Harting

external IP65 rated ethernet port. This

port can be accessed temporarily during

installation. If a more permanent, sealed

connection is required, use Harting

external ethernet connector, 9153000401.

See page 23 for ethernet port access.

Site restriction:

Installation shall not be done in a

commercial garage (repair facility) or

closer than 6 meters/20ft of an outdoor

motor fuel dispensing device.

Site conguration

6www.enelx.com

Phone: +1-844-584-2329

Site conguration

Minimum measurement

requirements:

Contact your Enel X representative for

installation advice if your mimimum

measurements are smaller than shown in

Figure 1.

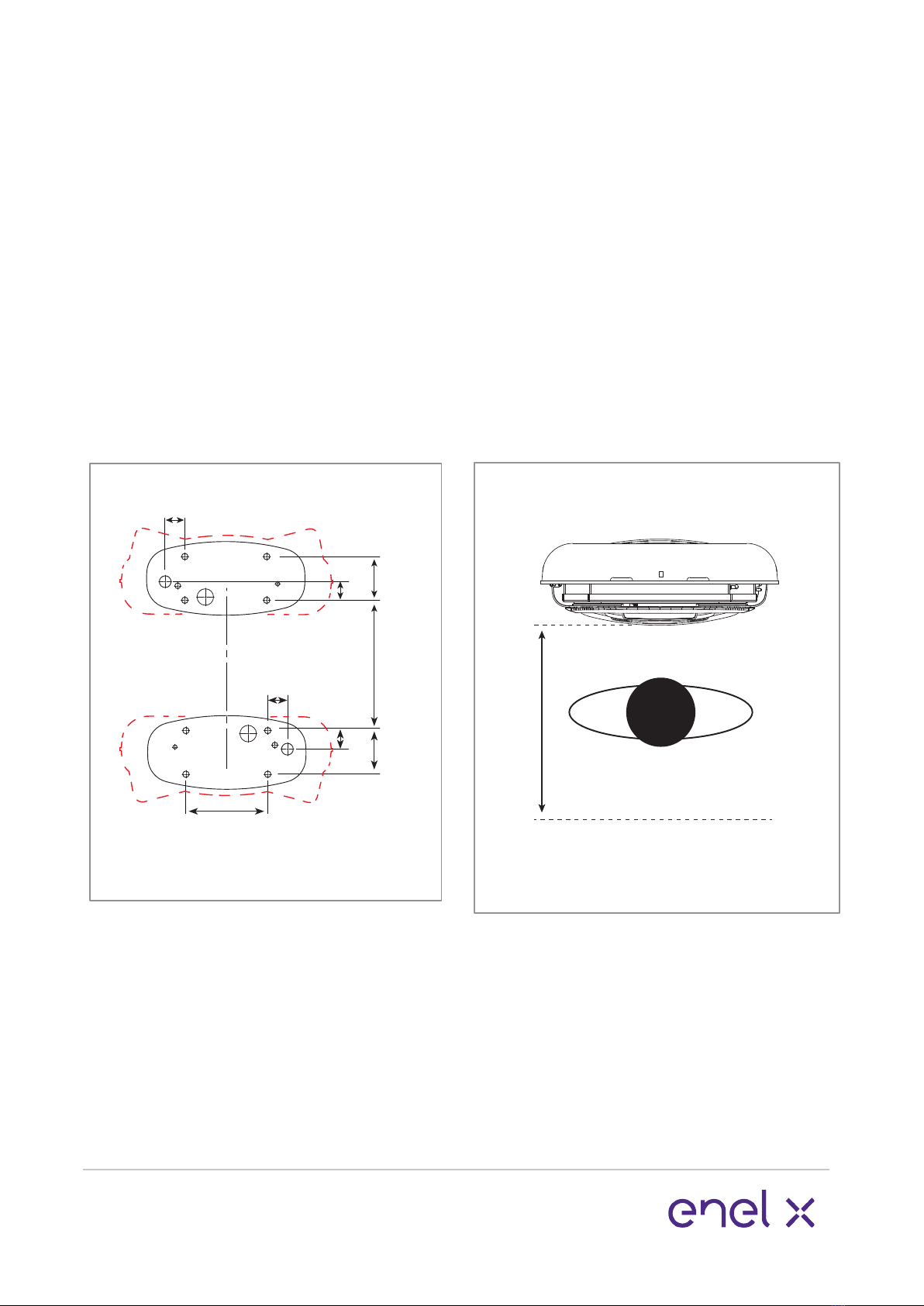

28.5” (725)

minimum

6.3”

160

9.8”

(250)

11.8”

(300)

Do not scale

Wall Wall

Figure 1.

Dimensions walls or obstacles

28.5” (725)

minimum

7www.enelx.com

Phone: +1-844-584-2329

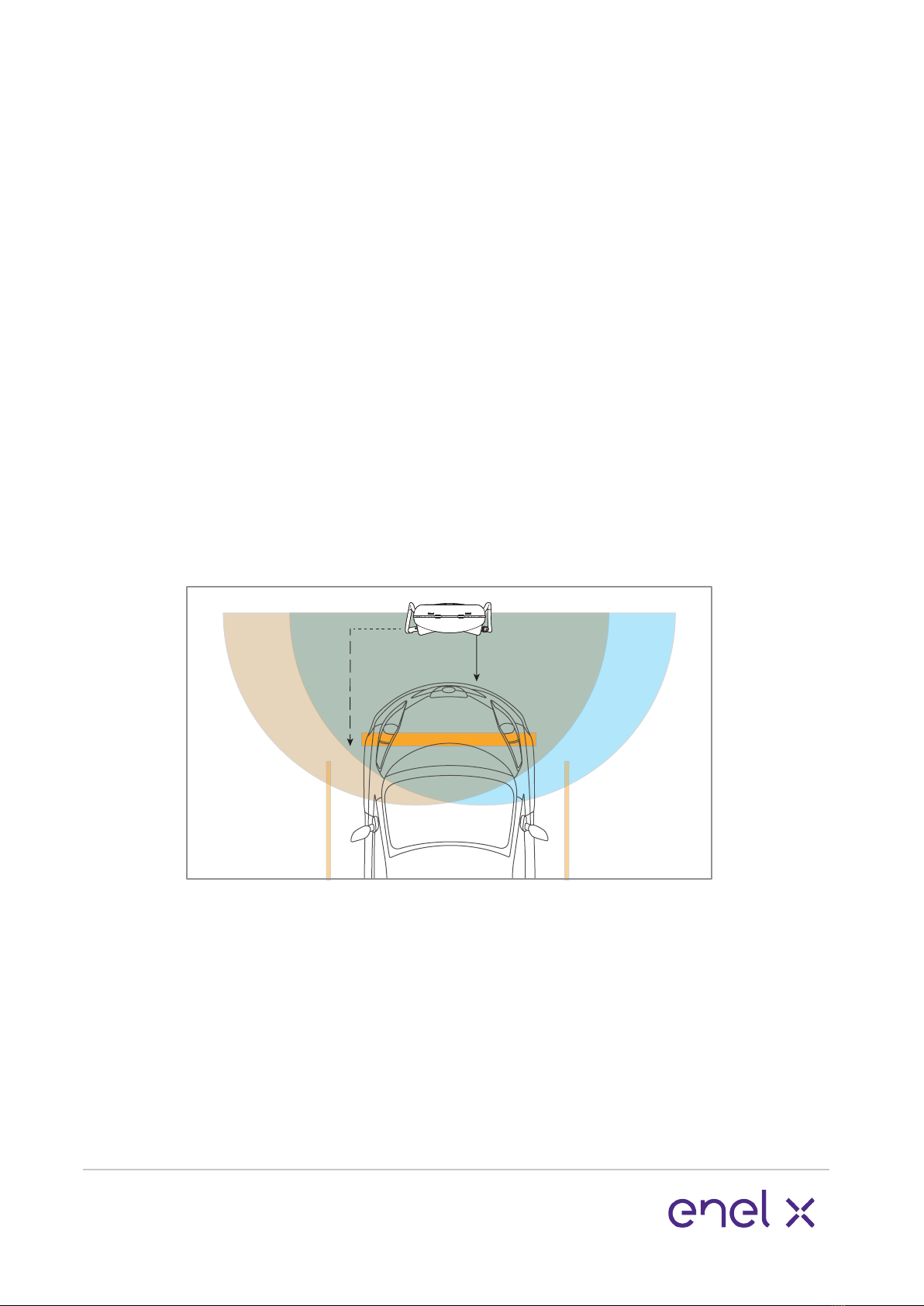

JuicePump charging cable range:

The standard JuicePump cable reach is

approximately 2.0 metres/6.5 feet as

shown in these site layouts.

Customised lengths are also available.

Contact your supplier should your

requirements dier.

If longer length cables are used please

ensure the cable is kept tidy and close

to the JuicePump sides at all times.

Single carparking bay:

To service one car bay, 500mm/20 inches

of space is recommended between the

car and the JuicePump front and back for

ease of use.

Wheel stops installed at 1200mm/4 feet

from the centre front of the JuicePump

can achieve this.

If the JuicePump is to be installed with it’s

back or sides against or near a wall or

other obstacle, use the minimum

distances shown in Figure 1.

Top view

Do not scale

20”

(500)

SAE Combo

Plug Range

CHAdeMO

Plug Range

47”

(1200)

WHEEL

STOPS

Figure 2.

Site conguration

8www.enelx.com

Phone: +1-844-584-2329

Site conguration back to back

units:

When being installed back to back, a

minimum distance of 300mm/12 inches

between the JuicePump chargers is

recommended.

To ensure this minimum distance is

observed use the dimensions for

foundation positioning in Figure 3.

30.3”

(72)

2.7”

(68)

6.3”

(160)

16”

(410)

11.8”

300

Figure 3. Back to back units

Do not scale

6.3”

(160)

30.3”

(72)

2.7”

(68)

Site conguration servicing:

A additional space of 700mm/27.5 inches

from the center front of the baseplate is

required to open the front panel for

servicing, as shown in Figure 4.

Do not scale

27.5”

(700)

Figure 4. Servicing distance

requirement

Site conguration

9www.enelx.com

Phone: +1-844-584-2329

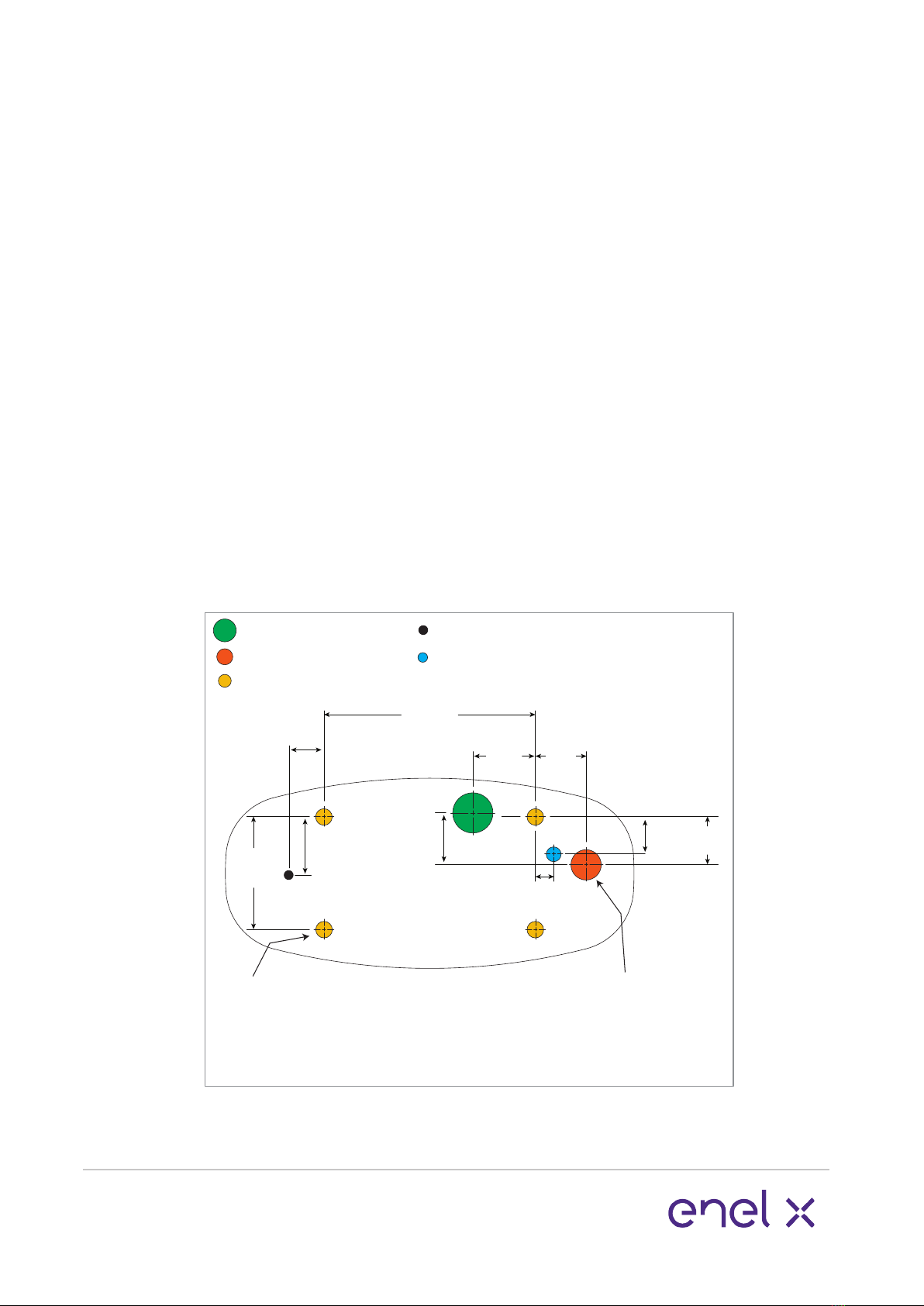

If a concrete foundation is being pre-

pared to bring power into the JuicePump

through the baseplate, use the following

as a guide for preparation.

Use the JuicePump template (supplied in

the crate kit) or measure as per Figure 5,

to ensure the xing points are correct.

Locate mounting studs and conduit within

0.05” (1.25mm) tolerance.

Foundation power hole:

When preparing the concrete foundation

a 1-1/4” NPT female coupling (not

supplied) is to be inserted ush with the

top surface of the concrete pad and

precisely located in the 50mm power hole

location in relation to the mounting studs.

This ensures the sealing of the supplied

exa conduit system into the foundation.

Fixing points:

Use 4x 5/8-11 studs, protruding 1.2-1.6

inches above the surface. If the studs

protrude more than this it will be

impossible to remove and replace the

radiator if required.

Ethernet cable hole:

If hardwiring in the ethernet, use this

hole for the cabling.

Underground power preparation

50mm power hole

Fixing point holes

Ethernet cable hole

Figure 5. Mounting reference.

6.3”

(160)

JUICEPUMP FRONT

11.8”

(300)

2.8”

(72)

2.7”

(68)

1.0”

(26)

2.1”

(53)

1-1/4” NPT

Female coupling

top to be flush

w/surface

Do not scale

4x 5/8-11 studs

Protruding 1.4”

±0.2” above

the surface

3.4”

(86)

2.5”

(63)

70mm power hole

2.3”

(60)

1.6”

(40)

Grounding rod hole

10 www.enelx.com

Phone: +1-844-584-2329

Figure 7. Top view

1 metre/3 feet

Not to scale

Back

left

fixing

point

Fixing points.

Use 4x 5/8-11 studs, protruding 1.2-1.6

inches above the surface. If the studs

protrude more than this it will be

impossible to remove and replace the

radiator if required.

Ethernet cable hole:

If hardwiring in the ethernet, use the hole

referenced in Figure 5.

If power via conduit is being supplied to

the JuicePump above ground, the conduit

will enter the JuicePump via the back

radiator panel on the left hand side as

shown in Figure 6.

Use the JuicePump template (supplied in

the crate kit) or or measure as per Figure

5, to ensure the xing points are correct.

Locate mounting studs and conduit within

0.05” (1.25mm) tolerance.

To ensure the correct seal is

maintained into the JuicePump, only use

Flexa 1-1/4 inch ROHRex conduit,

order code 0237.202.036 (not sup-

plied) to bring power cabling into the

JuicePump.

Figure 6.

Leave at least 1 metre/3 feet of power

cabling from the back left xing point, for

installation as shown in Figure 7.

Prior to installation the conduit and wiring

will require trimming.

Above ground power preparation

11 www.enelx.com

Phone: +1-844-584-2329

Installation requirements & equipment

These instructions provide a systematic

guide for installing and commissioning

the JuicePump.

The JuicePump must be installed and

serviced by qualied electrical personnel.

Observe all pertinent national, regional,

and local safety regulations when you

install and commission the JuicePump.

The JuicePump has a NEMA Type 3R

electronics enclosure rating, however, as

it must be opened for installation, this is

best done in dry weather or under

cover to avoid moisture or debris ingress.

Installation shall not be done in a

commercial garage (repair facility) or

closer than 6 meters/20ft of an outdoor

motor fuel dispensing device.

The JuicePump must be properly in-

stalled, assembled and commissioned

according to these instructions before it is

used.

Prior to installation contact your supplier

to organise commissioning information.

Supplied with JuicePump:

5mm pin hex tool to remove the M8

security screws xing the plastic panels.

2.5mm hex ‘L’ wrench

Lifting straps

Blanking plugs are tted for transport and

storage.

Flexa conduit system

Black ferrite ring ID13x40mm

Black ferrite ring ID25x43mm

Grey ferrite ring

Baseplate template

The JuicePump is shipped with a tem-

porary single phase power cable which

allows the unit to be powered prior to

installation.

This allows for software updates,

charger conguration and/or 4G

connectivity testing. The cable has a male

IEC socket and an IEC female lead is

required to supply power.

If pre installation power up is required

contact your supplier prior to the

installation date to synchronize with

Enel X.

12 www.enelx.com

Phone: +1-844-584-2329

Required equipment:

Lifting apparatus. See pg 4 for weights.

Ensure lifting apparatus is suciently

rated.

For height restricted areas alternative

lifting methods are available. Contact

your supplier for more information.

4x M16 or 5/8 glavanised or SS washers

4x M16 or 5/8-11 galvanised nuts to

match fasteners.

Flexa PN 0237.202.036 conduit (above

ground power installations only).

Tools:

Socket set & ratchet or adjustable

spanner.

Allen keys or socket set hex bits.

Power driver

Sockets required:

8mm for radiator removal and service

hatch removal.

10mm socket for earthing strap removal.

16mm for removal of shipping baseplate

bolts.

Approved external sealant.

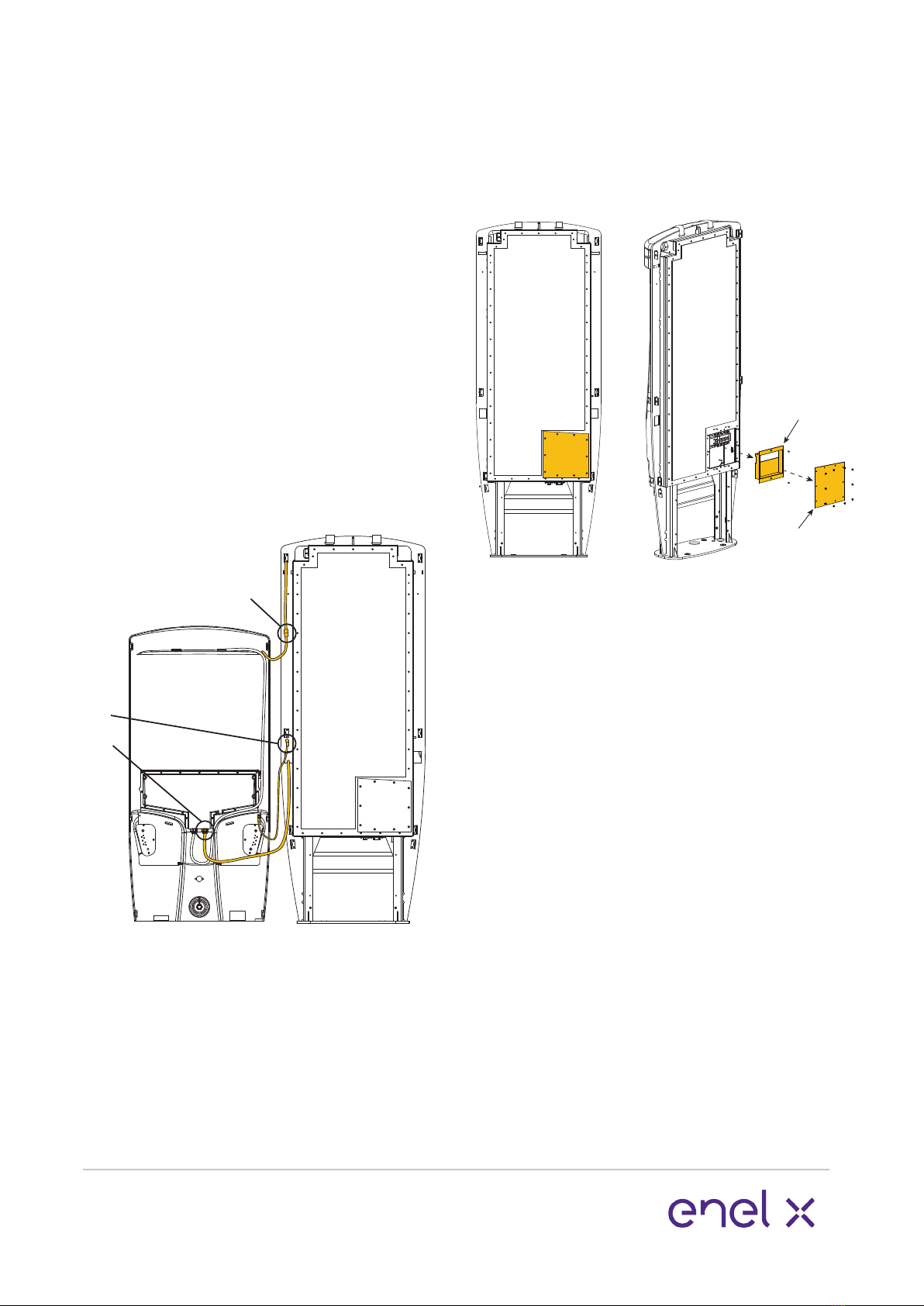

DOCUMENT KEY:

Items shown in orange are parts that

require action for that step.

Installation requirements & equipment

13 www.enelx.com

Phone: +1-844-584-2329

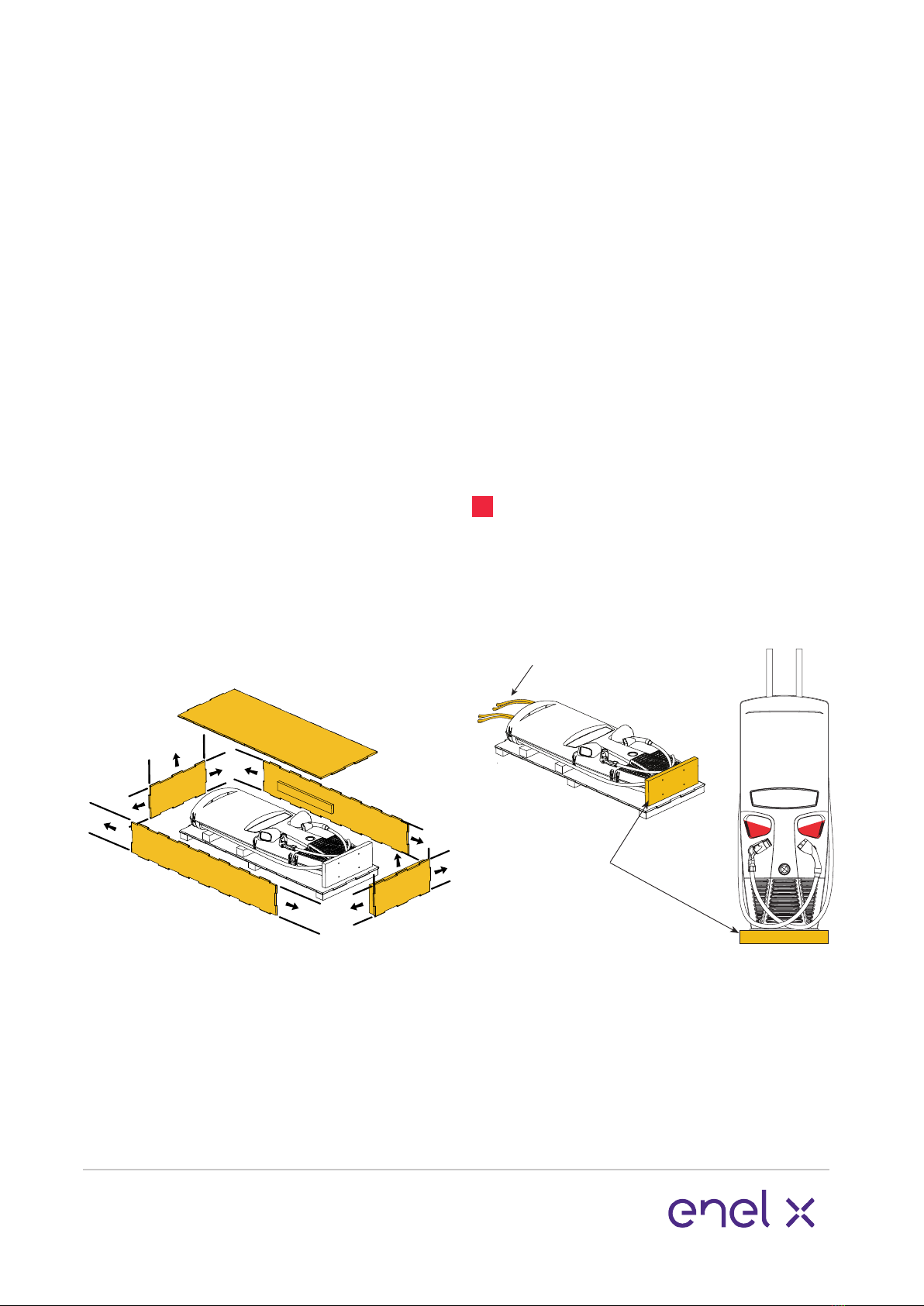

1. Open crate

Move the crate as close to the

prepared installation site as possible.

Ensure there is enough room to

manoeuvre the lifting apparatus.

Remove/slide out all crate tubes to

disassemble the cardboard crate.

2. Lift Veel-RT to vertical

Securely attach the lifting straps at the

top of the JuicePump to the lifting appa-

ratus and gently raise to a standing posi-

tion on the shipping baseplate.

The JuicePump must remain attached to

the lifting equipment until the mounting

bolts have been installed.

NOTE: The JuicePump is 2050mm/6.72ft

tall on the shipping baseplate.

Do not use the plug holders to assist

lifting the charger at any stage.

Once upright remove all wrapping.

Lifting Straps

Shipping

Baseplate

Unpacking & installation preparation

14 www.enelx.com

Phone: +1-844-584-2329

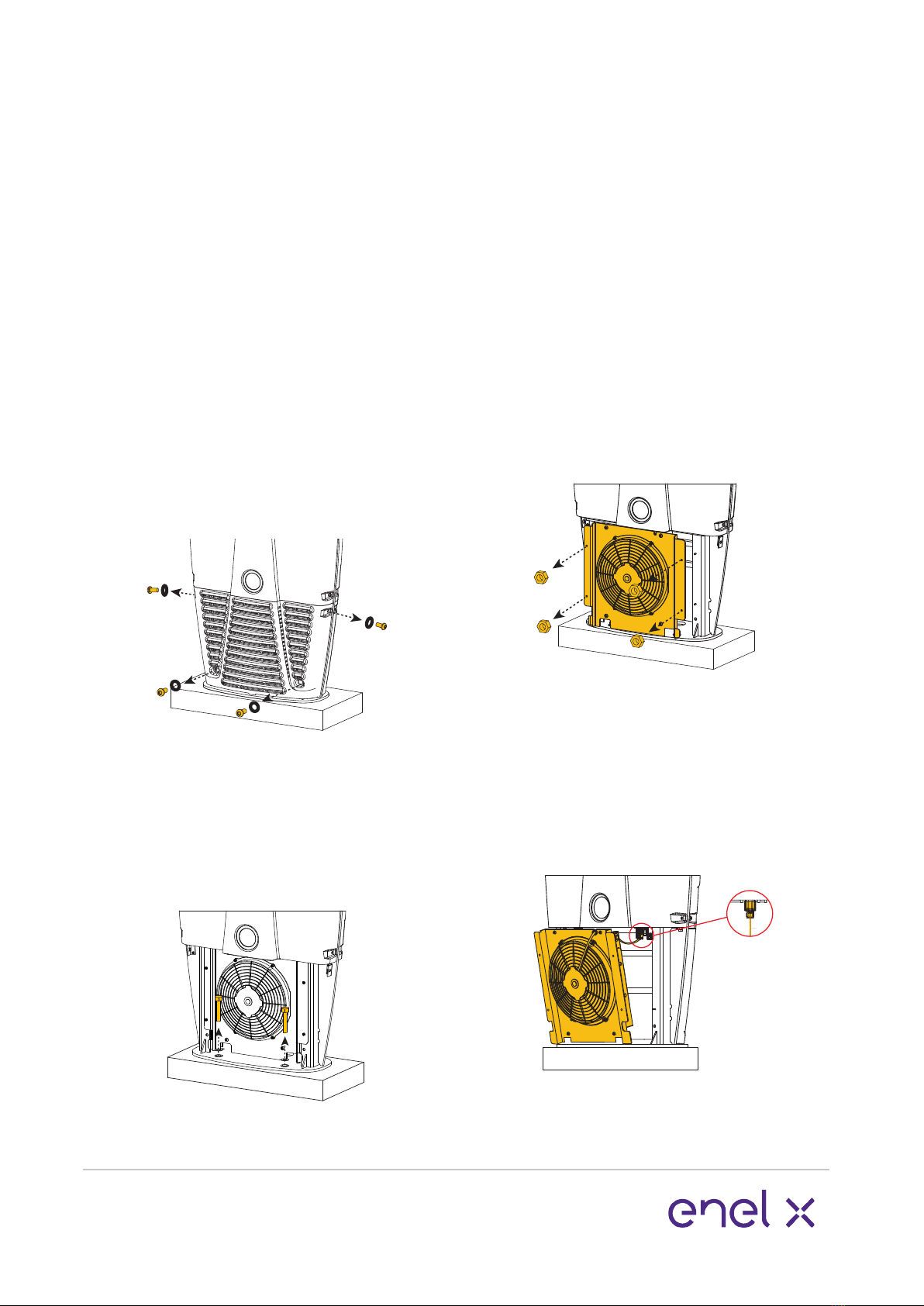

Removing the radiator from the base of

the JuicePump gives more space for

bringing power into the unit, however,

removing the radiator is not always

required. Assess the situation on site.

5. Remove radiator (optional)

Unscrew the 4x nuts using an 8mm nut

driver to remove the radiator. Pull the

radiator o the fasteners, and sit the

radiator on the base plate.

Reach behind and unclip the four way

connector.

The four way connector is the left hand

plug attached to the underside of the

unit. Squeeze front clip and pull down to

release.

3. Remove front and rear radiator

panels

If access to the rear radiator panel is

dicult, the internal radiator may be

removed to access the rear base xing

points. If so, remove the front radiator

panel only, and go to item 5.

Unscrew the 8x security screws and

remove them and the washers from both

radiator panels using the 5mm pin hex

tool. Pull the radiator panels away from

the metalwork frame to remove.

4. Remove shipping bolts

Unscrew the 4x bolts from the shipping

base to disengage. 16mm socket

required.

Note: Keep the plastic inserts from the

bolts for later use.

Unpacking & installation preparation

15 www.enelx.com

Phone: +1-844-584-2329

The radiator cooling system must be

disengaged from the unit. Unclip the two

quick release parts. One is on the base

behind the radiator, the other is on the

left side with the expansion bag.

NOTE: Do not twist or pull on the

tubing engaged with the metal quick

release parts. Pull on the metal parts to

release, and press the metal parts

together to join.

PULL

DO NOT TWIST

PULL TO RELEASE

PRESS TOGETHER TO JOIN

Store the radiator in a safe place ensuring

no damage to cooling hoses for later

re-assembly.

For the purpose of this manual, the

following installation pictures are shown

without the radiator.

Unpacking & installation preparation

16 www.enelx.com

Phone: +1-844-584-2329

Installation

3. Place front panel on ground

The front panel is attached to the

enclosure with wiring and an earthing

strap on the front left hand side.

Lift the front panel up to release from the

top hook and gently lower to the ground

in front of the JuicePump.

In calm conditions it may be possible to

keep the front panel connected during

commissioning. If this is possible, go to

page 17, item 5.

If in doubt, disconnect the front panel

(see pg 17, item 4) and store in a safe

place until the unit is ready to close for

use.

1. Secure to foundation

Lift the JuicePump by the supplied lifting

straps, place onto the prepared

foundation and secure with the specied

fasteners.

Note: Use the plastic inserts you kept

earlier in the baseplate holes.

2. Remove fasteners from front panel

Remove the 6x security screws and

washers from the front panel using the

provided 5mm pin hex tool.

17 www.enelx.com

Phone: +1-844-584-2329

EXPLODED VIEW

Service

Cover

Service

Hatch

FRONT VIEW

The Service Hatch has an attached

gasket. Ensure this is carefully stored to

avoid damage or accumulation of debris.

6. Pre-installation power up

The JuicePump is shipped with a tem-

porary single phase power cable which

allows the unit to be powered prior to

installation. This is attached to the M40

blanking plug. This allows for software

updates, charger conguration and/or 4G

connectivity testing.

The cable has a male IEC socket and an

IEC female lead is required to supply

power.

If pre installation power up is required

contact your supplier to synchronize with

Enel X.

7. Remove IEC cable wiring

Remove the M40 blanking plug and IEC

cable wiring from the switch gear.

4. Disconnect front panel

There are three points to disconnect:

1. Wiring to the top rear panel.

Squeeze the connector to disconnect.

2. Earthing strap.

Unscrew the nut on the metalwork with

a 10mm socket. Remove the nut and

earthing strap lug from the stud.

3. Connector ‘B’ on the HMI panel.

Connector ‘B’ detaches by squeezing the

connector front and rear with your ngers

and pulling down.

1

2

3

5. Remove service covers

Remove the service hatch and cover to

access the internal enclosure to prepare

the JuicePump for wiring. Use an 8mm

socket and 2.5mm hex bits.

Installation

Other manuals for JuicePump

4

Table of contents

Other Enel X Batteries Charger manuals

Enel X

Enel X Waypole User manual

Enel X

Enel X Waypole User manual

Enel X

Enel X JUICEBOX PRO User manual

Enel X

Enel X Way Next Gen JuiceBox User manual

Enel X

Enel X JuicePump 150 User manual

Enel X

Enel X JuiceBox User manual

Enel X

Enel X Way JuiceBox OpenPay User manual

Enel X

Enel X JUICEBOX PRO User manual

Enel X

Enel X Waybox Pro User guide

Enel X

Enel X Way JuiceBox User manual