Erbe VIO 300 D User manual

2022-0480116-288_V23381

USA

SERVICE MANUAL

VIO®300 D

V 2.1.x

V 2.2.x

V 2.3.x

V 2.7.x

ELECTROSURGERY

SERVICE MANUAL

VIO®300 D

Erbe Elektromedizin GmbH owns these trademarks in the United States: APC, APC 300, AUTO CUT, BICLAMP, ENDO CUT,

ERBE, ERBECRYO, erbe power your performance., ERBEJET, ERBELIFT, ERBOKRYO, FIAPC, FORCED COAG, HYBRIDAPC,

HYBRIDKNIFE, ICC 200, KYRON, NESSY, NESSY Ω, PRECISE APC, PULSED APC, REMODE, SOFT COAG, SWIFT COAG, THERMO

SEAL, TWIN COAG, VIO.

Trademarks®

Erbe USA, Inc. owns these trademarks: CLEVERCAP, ECO2, ERBEFLO, ERBEFLO AeroRinse, THE TRUE BLUE PROBE FOR APC,

THE TRUE BLUE PROBE FOR ARGON PLASMA COAGULATION and the color blue for APC probes.

TrademarksTM

Erbe USA, Inc. uses these trademarks: APC 360° Circumferential Probe, AUTO START, AUTO STOP, BIPOLAR COAG, BIPOLAR

CUT, DRY CUT, dryCUT, EIP, ESM, FORCED APC, forcedAPC, highCUT, POWER PEAK SYSTEM PPS, preciseSECT, PULSED COAG,

PULSED CUT, SPRAY COAG, sprayCOAG.

For an up-to-date list of all Erbe trademarks, please visit www.erbe-med.com/IP.

All rights to this manual, in particular rights of duplication, dissemination and translation, are reserved. No part of this man-

ual may be reproduced in any form (by photocopying, microfilming or other methods) or processed, duplicated or dissem-

inated by the use of electronic systems without the written consent of Erbe Elektromedizin GmbH.

The information contained in this manual may be amended or supplemented without prior notice and represents no obli-

gation on the part of Erbe Elektromedizin GmbH.

The display illustrations in these instructions may deviate from one another depending on the software version. The display

illustrations used in these instructions are generally taken from the latest software version. Display illustrations from older

software versions will only be used if necessary due to service activities; these will be specifically labeled.

Printed by Erbe Elektromedizin

Printed in Germany

Copyright © Erbe Elektromedizin GmbH, Tübingen 2022

5 / 110

Table of Contents

80116-288_V23381

2022-04

Table of Contents

1Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Classification of the safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Meaning of the note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Knowledge of the User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Protection from the risk of electric shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrostatically sensitive components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Liability and warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

From VIO version 2.2.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

From VIO version 2.3.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

From VIO version 2.7.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Controls at the front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Controls at the rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5Circuit Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Block diagram VIO 300 D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Description of the various assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Line input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Low voltage power supply unit (l.v. supply) . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power supply (high-voltage power supply unit) . . . . . . . . . . . . . . . . . . . . . . 20

HF generator II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CPU + Sensors II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

User Interface (control panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ECB (Erbe Communication Bus) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

IIF (Instrument Interface). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

NESSY2 II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overview of settings for Setup level 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overview of settings for Setup level 2 (Service settings). . . . . . . . . . . . . . . . . . 28

Call up Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Change settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table of Contents

6 / 110

80116-288_V23381

2022-04

7Remedying malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

ERROR list for VIO system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

A-Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

B-Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

C-Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

F-Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2,3,5,6-Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

4 (NE)-Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

9-Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

8Maintenance and servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Who is allowed to perform servicing and maintenance work? . . . . . . . . . . . . . 67

What is a technical safety check?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

How often does a technical safety check have to be performed? . . . . . . . . . . . 67

Technical safety check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

For front frame: 30140-218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

For front frame: 30140-233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

For front frame: 30140-243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Circuit Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Socket modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Bipolar sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Monopolar sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Multifunction sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Sockets for return electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

10 Circuit and Component diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

HF generator II: 30140-828 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

HF generator II: 40140-828 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

CPU and Sensors II: 30140-830 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

CPU and Sensors II: 40140-830 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Power Supply: 30140-810 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Power Supply: 40140-810 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Motherboard: 30140-811. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Motherboard: 40140-811. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

CAN-HF II: 30140-833 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

CAN-HF II: 40140-833 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

NESSY2 II: 30140-832. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

NESSY2 II: 40140-841. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Instrument Interface: 30140-814 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Instrument Interface: 40134-800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7 / 110

1 •Safety information

80116-288_V23381

2022-04

CHAPTER 1

Safety information

Classification of the safety information

DANGER

indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE

indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

Meaning of the note

"Note:"

Refers a) to manufacturer's information that relates directly or indirectly

to the safety of people or protection of property. The information does not

relate directly to a risk or dangerous situation.

Refers b) to manufacturer's information that is important or useful for op-

erating or servicing the unit.

Knowledge of the User Manual

The User Manual for this unit constitutes an integral part of this Service

Manual. For performing servicing activities it is assumed that the reader

has knowledge of the User Manual, especially procedures for installation,

putting into operation, and handling.

1 •Safety information

8/ 110

80116-288_V23381

2022-04

Protection from the risk of electric shock

WARNING

Line voltage applied to the unit housing in a single-fault

condition.

Risk of electric shock and resulting consequential injuries.

The unit/objects in the vicinity of the unit can be damaged.

Use a ground fault interrupt system, e.g. personal pro-

tection outlet with a circuit breaker/r.c.c.b. independent

of line voltage, or an isolating transformer. If an isolating

transformer is used, the tests for ground conductor re-

sistance and ground leakage current must be performed

without the isolating transformer. For these tests the

unit is supplied with current via the safety tester.

Connect the unit to a properly installed grounded power

outlet.

Only connect the unit using an Erbe power cord (see the

user manual for REF numbers). Alternatively: power ca-

bles with a length of no more than 5 m can be used in

accordance with country/region requirements, e.g. hos-

pital grade power cables.

Multiple outlets and extension cords should not be used.

If their use is unavoidable for servicing work, only use

multiple outlets and extension cords with proper ground

terminals.

WARNING

Unit accidentally carrying voltage.

Risk of electric shock and resulting consequential injuries.

The unit/objects in the vicinity of the unit can be damaged.

Before opening, repairing and cleaning, switch off the

unit and unplug at the power outlet.

9 / 110

1 •Safety information

80116-288_V23381

2022-04

WARNING

Open unit intentionally carrying voltage for servicing

work.

Risk of electric shock and resulting consequential injuries.

The unit/objects in the vicinity of the unit can be damaged.

Under no circumstances should you touch live compo-

nents, e.g. unprotected wires, conductive surfaces inside

of the unit.

Use insulated, non-conductive tools (conforming to IEC

60900).

Use a ground fault interrupt system, e.g. personal pro-

tection outlet with a circuit breaker/r.c.c.b. independent

of line voltage, or an isolating transformer.

WARNING

Moist or defective power cord.

Risk of electric shock and resulting consequential injuries.

The unit/objects in the vicinity of the unit can be damaged.

Check the power cord for damage. Do not use a damaged

power cord.

Connect the unit with a dry power cord only.

WARNING

Incorrect line fuse.

The unit/objects in the vicinity of the unit can be damaged.

Have blown line fuses replaced by a competent techni-

cian only.

Only use line fuses with the rating indicated on the rating

plate of the unit.

Before resuming operation on the unit have a perfor-

mance test conducted by a competent technician (see

Repair Instructions, chapter "Maintenance and servic-

ing", section "Performance tests").

1 •Safety information

10 / 110

80116-288_V23381

2022-04

NOTICE

Incorrect line voltage.

The unit will be damaged or destroyed beyond repair.

Make sure the line voltage agrees with the voltage indi-

cated on the rating plate of the unit.

Make sure the line voltage agrees with the voltage indi-

cated on the line input module of the unit.

Electrostatically sensitive components

NOTICE

Electrostatically charged persons or environment during

servicing work.

The unit or unit components will be damaged. The damage

causes a unit failure either instantly or with a delay.

Put on a grounding armband.

Provide the workbench with a grounded antistatic mat.

Use antistatic containers when transporting electrostat-

ically sensitive components, e.g. printed circuit boards.

Liability and warranty

CAUTION

Servicing work not performed properly.

Risk of total or partial unit failure that can result in hazards

to the patient and medical staff.

System adjustments, modifications, and repair work may

only be performed by Erbe or persons trained and autho-

rized by Erbe. If any unauthorized work as stated above

is performed, Erbe accepts no liability and warranty

rights become void.

CAUTION

Use of non-original Erbe replacement parts.

Risk of total or partial unit failure that can result in hazards

to the patient and medical staff.

Only use original Erbe spare parts. Erbe accepts no liabil-

ity and warranty rights shall be void if non-original Erbe

spare parts are used.

11 / 110

2 •Modifications

80116-288_V23381

2022-04

CHAPTER 2

Modifications

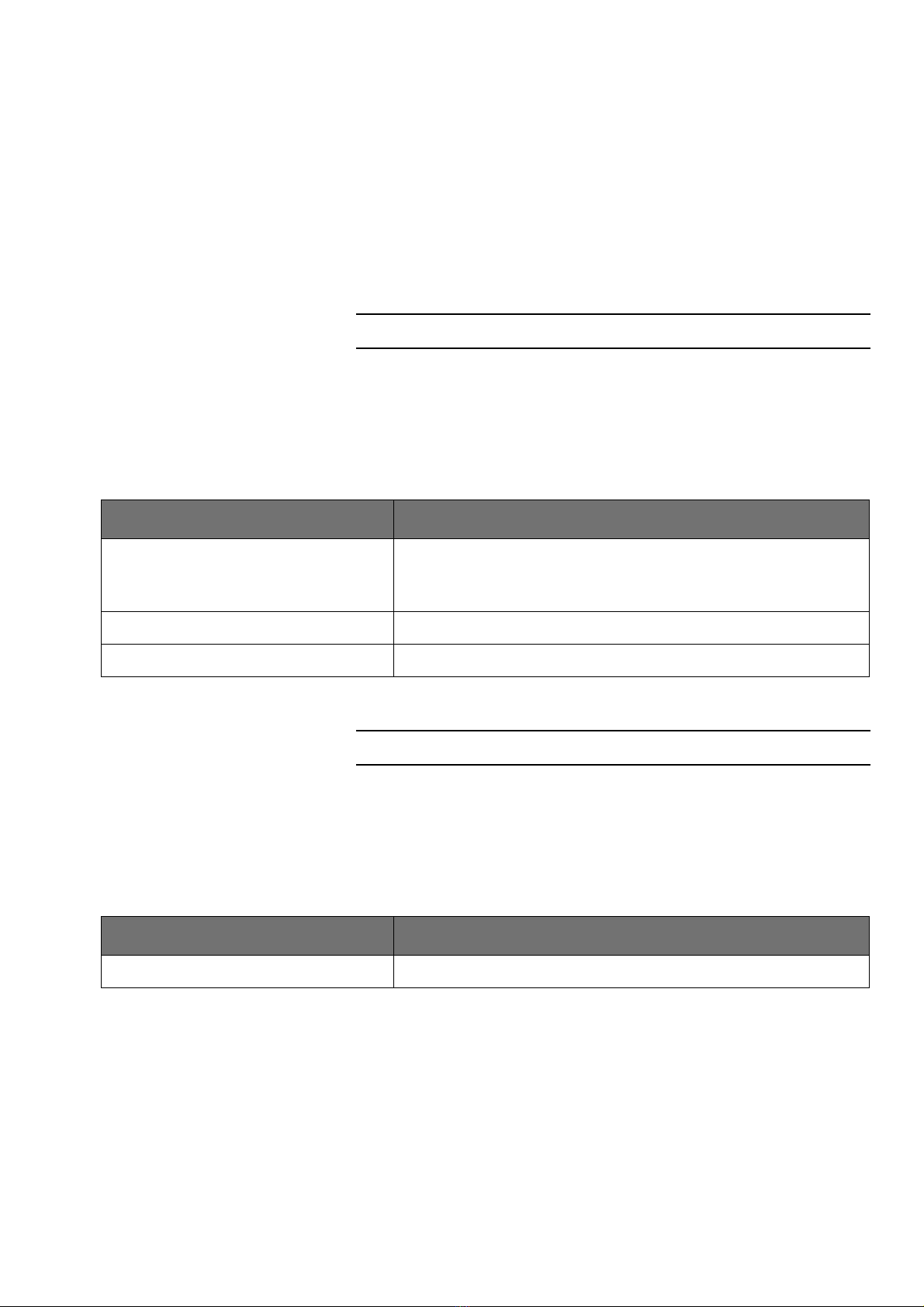

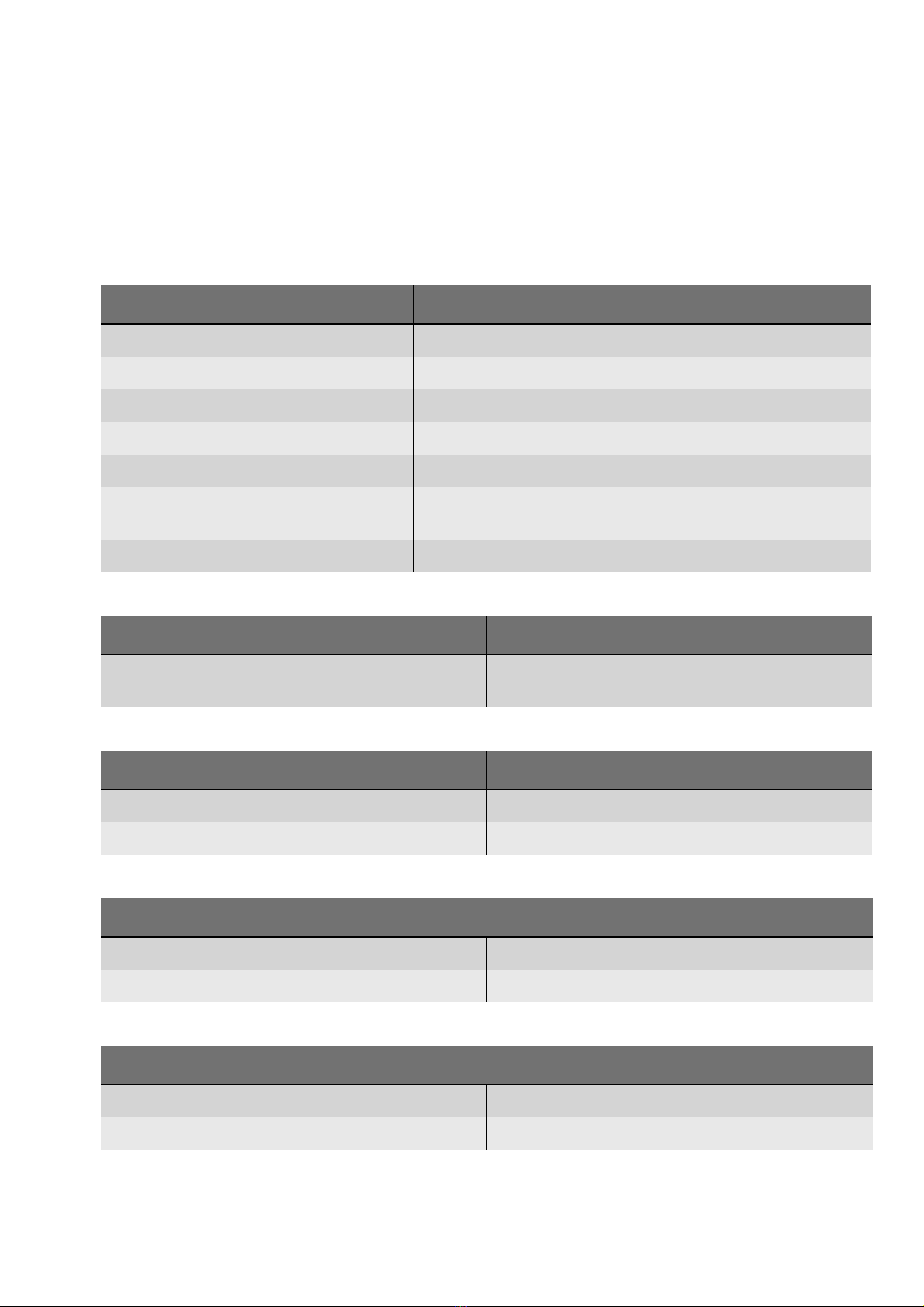

From VIO version 2.2.x

Hardware

No changes

Software

From VIO version 2.3.x

Hardware

No changes

Software

Component affected Description of the modification

Bipolar resection adapter The bipolar resection adapter can be connected to the multifuc-

tion socket on the VIO. Supplement to the safety check to test the

bipolar resection adapter.

Setup 2 settings New setup setting ° modes

Generator adjustment Generator adjustment is possible without APC 2.

Component affected Description of the modification

Setup 2 settings New setup setting AUTO START Limit

2 •Modifications

12 / 110

80116-288_V23381

2022-04

From VIO version 2.7.x

Hardware

No changes

Software

Component affected Description of the modification

Setup 2 settings New setup setting BiCision SC Info.

13 / 110

3 •Controls

80116-288_V23381

2022-04

CHAPTER 3

Controls

Note: This chapter contains an overview of the controls of the unit(s). The

relevant User Manual for the unit(s), knowledge of which is assumed for

servicing work, provides detailed information about how to use the unit(s).

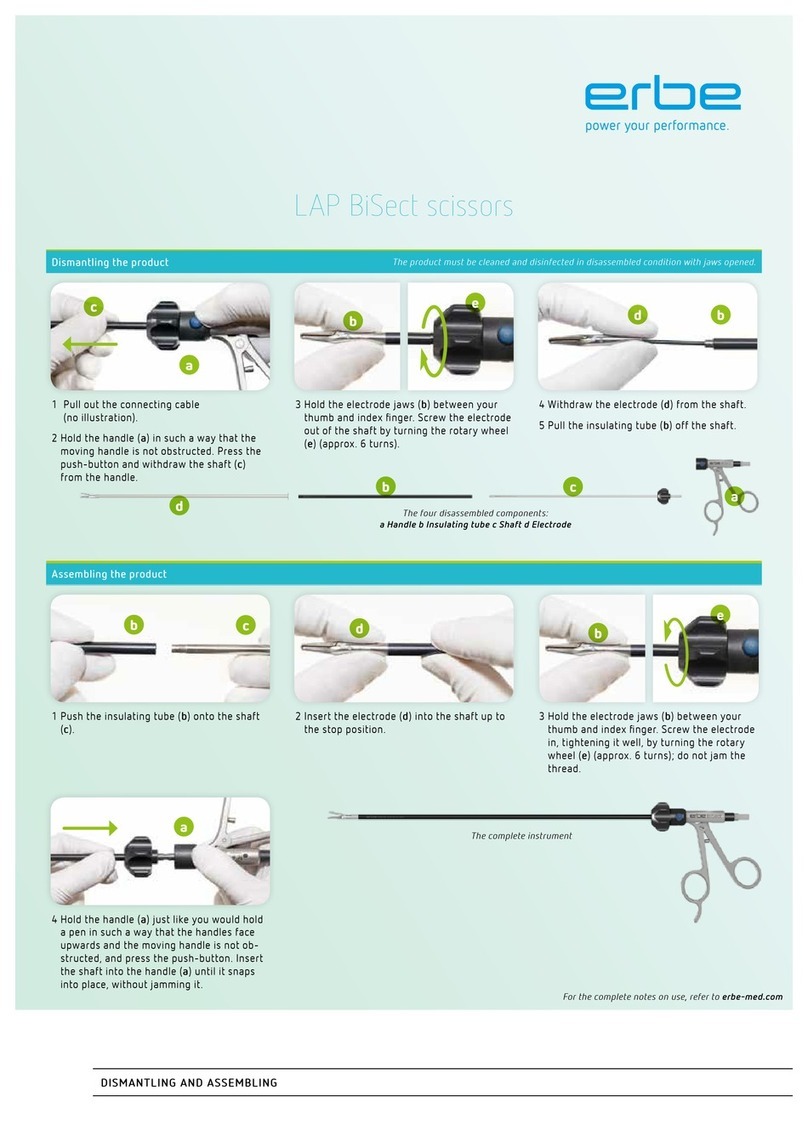

Controls at the front

Fig. 3-1

1Power Switch

2 – 9 Selection buttons

10 Up/Down buttons

11 Enter button

12 – 15 Focus buttons

16 Indicator lights for footswitches

17 Indicator light for AUTO START

18 Indicator lights for neutral electrode

VIO 300 D

F

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

3 •Controls

14 / 110

80116-288_V23381

2022-04

Controls at the rear

Fig. 3-2

ECB

234

1

1 Footswitch sockets

2ECB socket (Erbe Communication Bus)

3Grounding terminal pin

4Power supply module with fuses

15 / 110

4 •Technical Data

80116-288_V23381

2022-04

CHAPTER 4

Technical Data

Power connection

Rated supply voltage 100 V – 120 V (± 10%) 220 V – 240 V (± 10%)

Rated supply frequency 50 / 60 Hz 50 / 60 Hz

Line current 8 A 4 A

Power input in standby mode 40 watts 40 watts

Power input with max. HF output 500 watts / 920 VA 500 watts / 920 VA

Terminal for grounding (potential equal-

ization)

yes yes

Power fuses T 8 A H / 250 V T 4 A H / 250 V

Operating mode

Intermittent operation ON time 25% (e.g. activated for 10 sec. / deacti-

vated for 30 sec.)

Dimensions and weight

Width x height x depth 410 x 165 x 380 mm / 16.1" x 6.5" x 15.0"

Weight 9.5 kg / 20 lbs. 17 oz.

Ambient conditions for transport and storage of unit

Temperature -40 °C to +70 °C / -40 °F to +158 °F

Relative humidity 10% – 95%

Ambient conditions for operation of unit

Temperature +10 °C to +40 °C / +50 °F to +104 °F

Relative humidity 15% – 80%, noncondensing

4 •Technical Data

16 / 110

80116-288_V23381

2022-04

Acclimatizing

If the unit has been stored or transported at temperatures below +10 °C (+50 °F) or above +40 °C (+104 °F),

the unit will require approx. 3 hours to acclimatize at room temperature.

Standards

Protective class according to UL 2601-1 I

Classification according to EC Directive 93/42/EEC II b

Protection class as per EN 60 601-1 I

Type as per EN 60 601-1 CF

17 / 110

5 •Circuit Descriptions

80116-288_V23381

2022-04

CHAPTER 5

Circuit Descriptions

5 •Circuit Descriptions

18 / 110

80116-288_V23381

2022-04

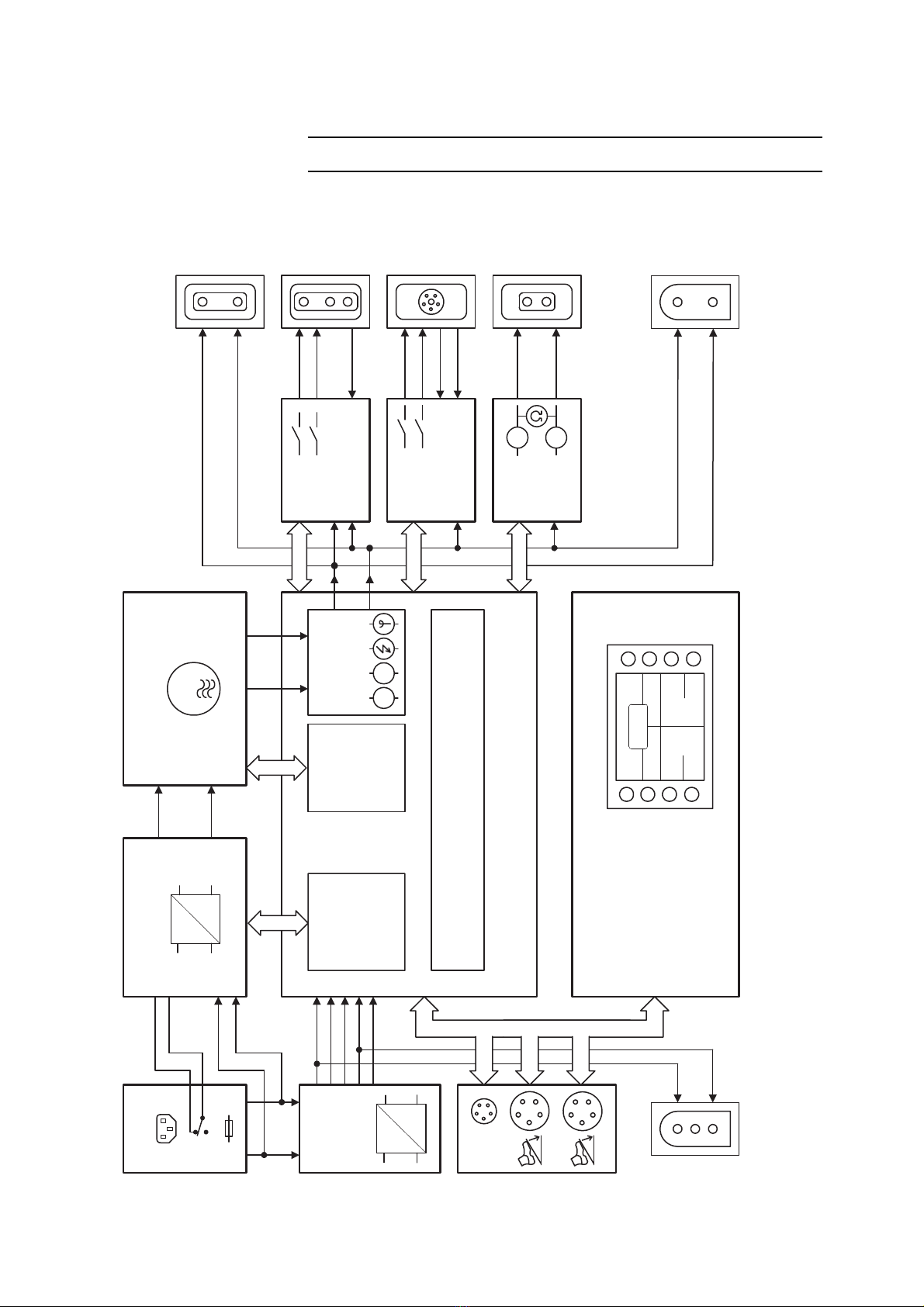

Block diagram VIO 300 D

Fig. 5-1

SCI

SCI

SPI

115 V

230 V

AC

DC

AC

DC

ECB

1

2

AE NE

AE

NE

AE

NE

AE

NE

A

A

IK

LN

CUT COAG

NE1

NE2

ECB ERBE Communication Bus

Power Supply HF generator II

CPU + Sensors II

Line Input

I.v. supply

Power Supply

Control

Generator

Control

CPLD

Sensors

Controller Unit

IIF

NESSY2 II

User Interface

AE

NE

Display

Keyboard

Power PC

Operating

Voltages

AK

AE

NE

AK

Instrument

Interface

VA

IIF

Instrument

Interface

G

0...450V

0...3,5A

230V 50Hz

115V 60Hz

BIPOLAR

MONOPOLAR/

MF/

NEUTRAL

Connector

to APC 2

AK: Aktivierungserkennung

activation recognition

IK: Instrumentenerkennung

instrument recognition

+5V

+15V

+24V

0V

-15V

Connector

to APC 2

BIPOLAR

MONOPOLAR

19 / 110

5 •Circuit Descriptions

80116-288_V23381

2022-04

Description of the various assemblies

Line input

The VIO system can be operated with a line voltage of either 220 – 240 V

or 100 – 120 V. For this the corresponding value (230 V for a line voltage

of 220 – 240 V or 115 V for 100 – 120 V) must be visible in the inspection

window on the power connection, and fuses corresponding to the value

given on the rating plate must be used.

Low voltage power supply unit (l.v. supply)

The low voltage power supply unit produces the operating voltages +5 V,

+15 V, –15 V and +24 V. A special socket on the underside of the unit is

used to supply the +24 V voltage to other system components (e.g. APC 2).

The input voltage range for this power supply unit is 90...264 V with 50 or

60 Hz. Switching over the line voltage at the power connection has no ef-

fect on this power supply unit.

Pin assignment

Fig. 5-2

5 •Circuit Descriptions

20 / 110

80116-288_V23381

2022-04

Power supply (high-voltage power supply unit)

The high-voltage power supply unit provides the HF generator with a DC

voltage which may reach 450 V. It depends on the surgical effect selected

and the alternating voltage necessary for this.

The line input voltage is directly rectified using a bridge-connected recti-

fier. The AC line voltage of 230 V changes to a DC voltage of approx. 320

V; this can be checked between MP3 (ground) and the holding clips of the

fuse holder.

If the power connection is set to 115 V, the bridge circuit becomes a volt-

age doubler connection, also producing approx. 320 V.

The input circuit contains two NTC resistors to limit the high charging cur-

rent which flows when the unit is switched on. Once the capacitors of the

high-voltage power supply unit are charged, limitation is no longer neces-

sary. The NTC resistors are therefore jumpered during activation via the

closed contacts of relay Rel10.

The resulting DC voltage is changed by a chopper regulator and supplied

to a transformer. The transformer is equipped with two identical output

windings which produce a DC voltage through the rectification. With relay

Rel13 these two output windings can be connected either in series or in

parallel, resulting in two operating ranges for the power supply unit: in the

range up to 250 V the maximum output current is 3.5 A, and in the range

up to 450 V 1.75 A max. is possible.

The high voltage power supply unit is controlled by two analog inputs:

The nominal voltage is predefined at J21 pin 11. Thus 4.5 V control voltage

results in a power supply unit output voltage of 450 V. The current limita-

tion is predefined at pin 9. Here 5 V corresponds to the maximum current

of 3.5 A.

Measuring equipment for voltage and current is available. The measured

values are also reported back analogously to pin 8 (voltage actual value)

and pin 6 (current actual value) with the same gain factor.

In addition, there are also two control inputs available: an enable signal

(pin 7 5 V –> off), with which the high voltage power unit can be switched

on and off, and the activation for the discharge circuit (pin 1 5 V –> on),

with which the output capacitors can be discharged.

Other manuals for VIO 300 D

5

Table of contents

Other Erbe Medical Equipment manuals

Erbe

Erbe ICC 200 User manual

Erbe

Erbe BiClamp 110/340 User manual

Erbe

Erbe 20183-067 User manual

Erbe

Erbe APC 2 User manual

Erbe

Erbe LAP BiSect User manual

Erbe

Erbe 20191-331 Operating instructions

Erbe

Erbe 20191-395 User manual

Erbe

Erbe 20191-179 Operating instructions

Erbe

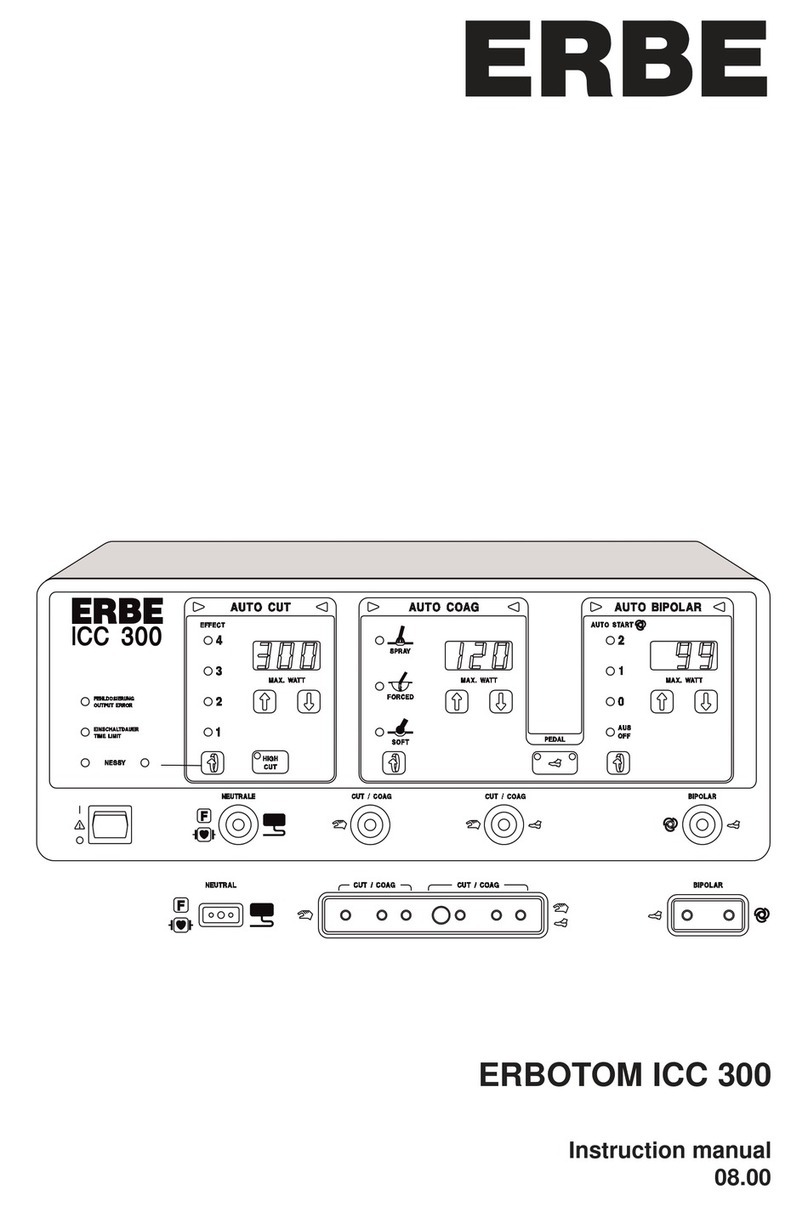

Erbe ERBOTOM ICC 300 User manual

Erbe

Erbe 20150-020 Operating instructions