9

ENGLISH

N.B.: 1) For installation of electrical cables use suitable rigid

or flexible piping.

2) Alwayskeepthelowvoltageaccessoryconnection

cables separate from the 230 V power cables. Use

separate sheaths to avoid any interference.

3. INSTALLATION

3.1 PRELIMINARY CHECKS

Toensurecorrectoperationoftheautomaticunitthestructure

of the existing door must meet the following requirements:

-

length and weight as specified in Table 3 (section 1.1);

- max. doorpost depth as specified in Table 4;

- robust and rigid structure of the leaf;

- good condition of the existing hinges;

- smooth, uniform movement of the leaf with no abnormal

friction at any point of its travel;

-

“neutral” position of the door during its entire travel. If the

door tends to close or open, check the alignment of the

hinges.

- Presence of mechanical end stops.

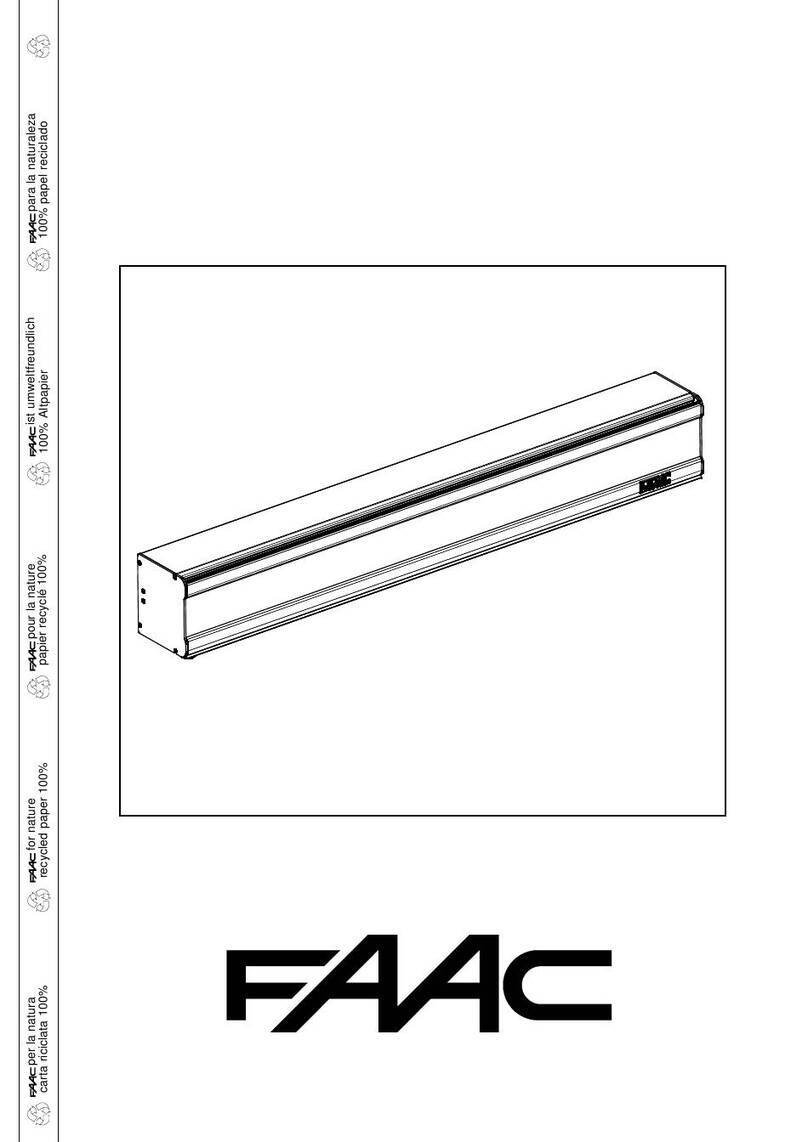

3.2 MOUNTING THE OPERATOR

1) Remove the protective casing (fig. 3) and the end covers

(fig. 4) from the operator.

Warning: Before removing the end cover with the function

switch, remove the connector joining the switch to the 959MP

electronic control unit.

2)

As regards the mounting position of the operator (on the

lintel or on the door) and the type of arm to use (pushing,

pullingorsliding), refertotherelevantmountingtableand

drill the holes required to mount the operator and the

pulling arm.

N.B.: The two intermediate operator fixing holes are not in a

central position (see mounting tables). The holes are offset in

order to ensure that the operator is mounted with the correct

direction of rotation of the mechanism.

The mounting tables are the following:

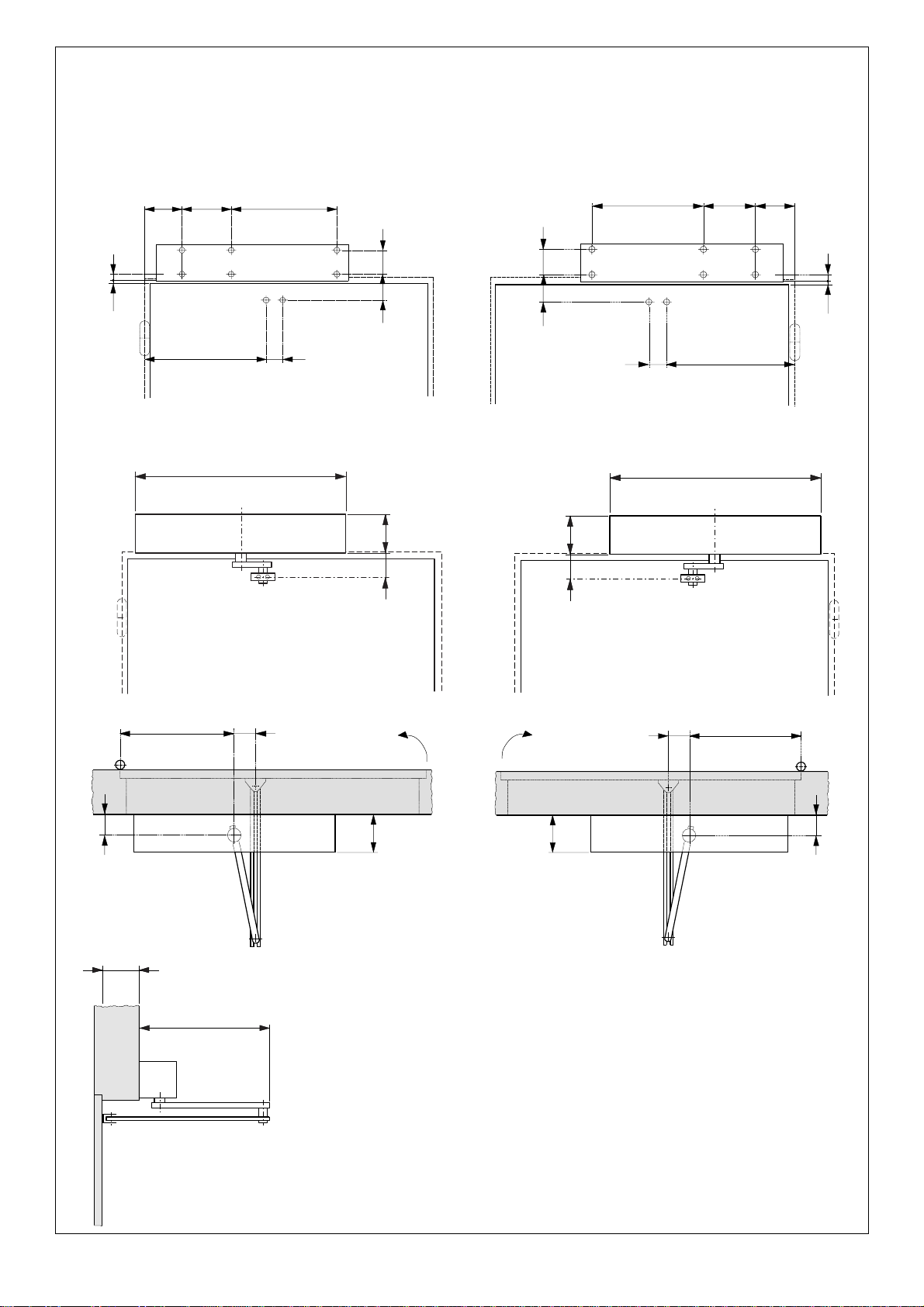

Table A: LINTEL MOUNTING (PUSHING ARTICULATED ARM)

Outward opening

Table B: DOOR MOUNTING (PUSHING ARTICULATED ARM)

Inward opening

Table C: LINTEL MOUNTING (SLIDING ARM) Inward opening

3) Mount the operator using the six M6 screws and washers

provided.

Warning:

- The structure of the lintel (or the door) at the operator

mounting position must not exhibit any significant

deformation.

- The operator must be mounted parallel to the floor.

N.B.: If the sliding arm is to be used, the driving arm must be

mounted before the operator is fixed on the lintel (see section

3.3.3.).

3.3 MOUNTING THE DRIVING ARMS

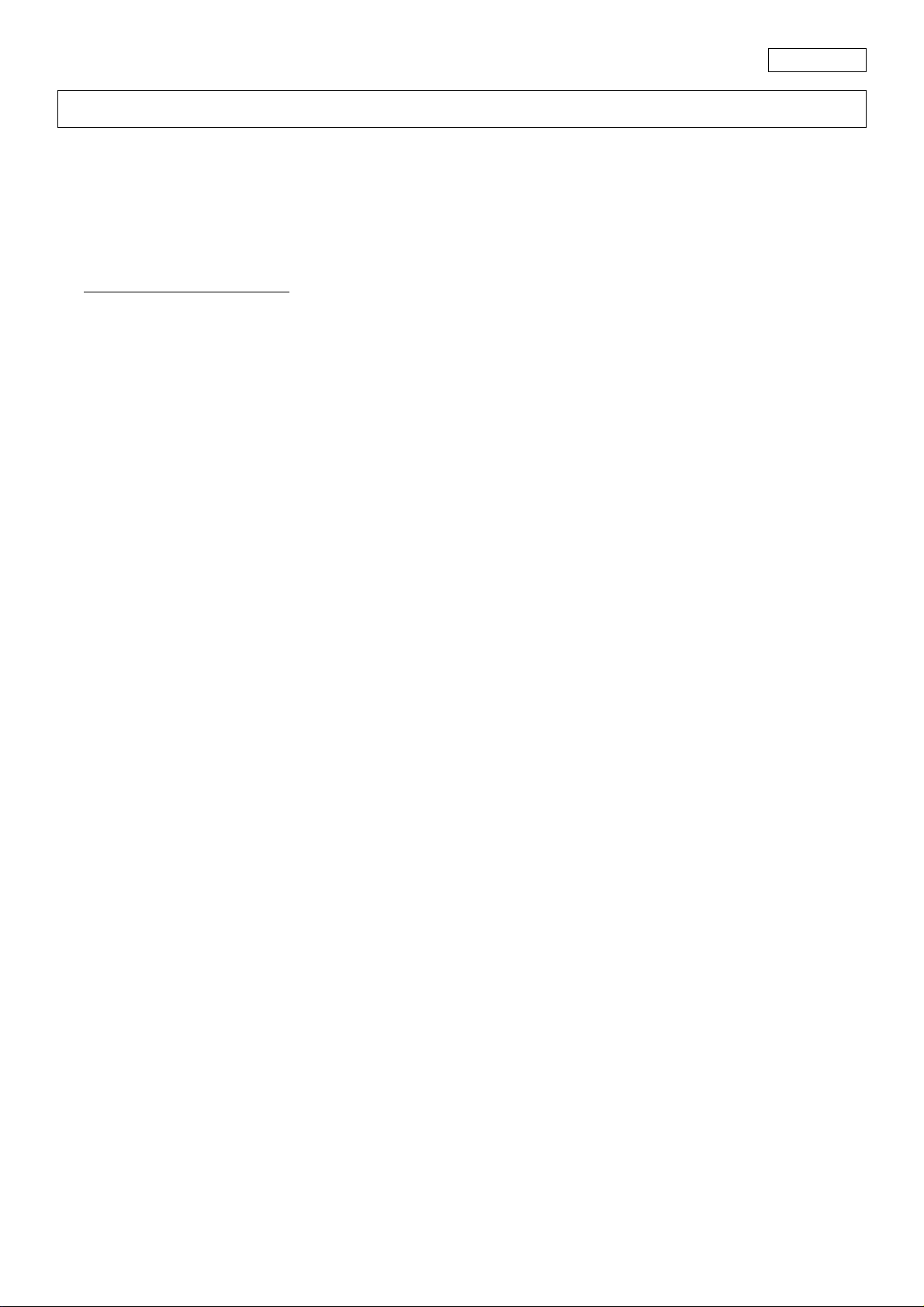

3.3.1 MOUNTING THE PUSHING ARTICULATED ARM (fig. 5)

1) Close the door.

2) Free arms (1) and (2) by pulling apart the coupling (3)

manually as shown in fig. 5.

3) Fit arm (1) on the operator transmission shaft by means of

the extension and the screw (4) provided (fig. 5). The arm

must be mounted perpendicular to the closed door.

N.B.:

If a greater distance between the operator and the arm

is required, use the higher extensions available as accessories

(see Table A/B).

4) Mountplate(5)ofarm(2)onthedoororthelintelusingthe

two M6 screws and the washers provided (fig. 5). The

installation distances are given in Table A/B.

5) Slackenthefixingscrew (6) andassemblethetwoarms by

means of coupling (3) (fig. 5).

6) Turn arm (1) until arm (2) is perpendicular to the closed

door or the lintel as shown in fig. 5 (a-b), sliding the spacer

(7) along arm (2).

7) Tighten the fixing screw (6) between the two arms.

The length of arm (2) is given in the relevant mounting

tables.Ifnecessary,cutoffthesectionofthearmextending

beyondthearticulationandthencovertheendsusingthe

caps provided (fig. 5).

8) Check manually that the door is free to open and close

fully and that it comes to rest against the mechanical end

stops.Ifthedoordoesnotclosecorrectly,adjustthereturn

spring as described in section 10.

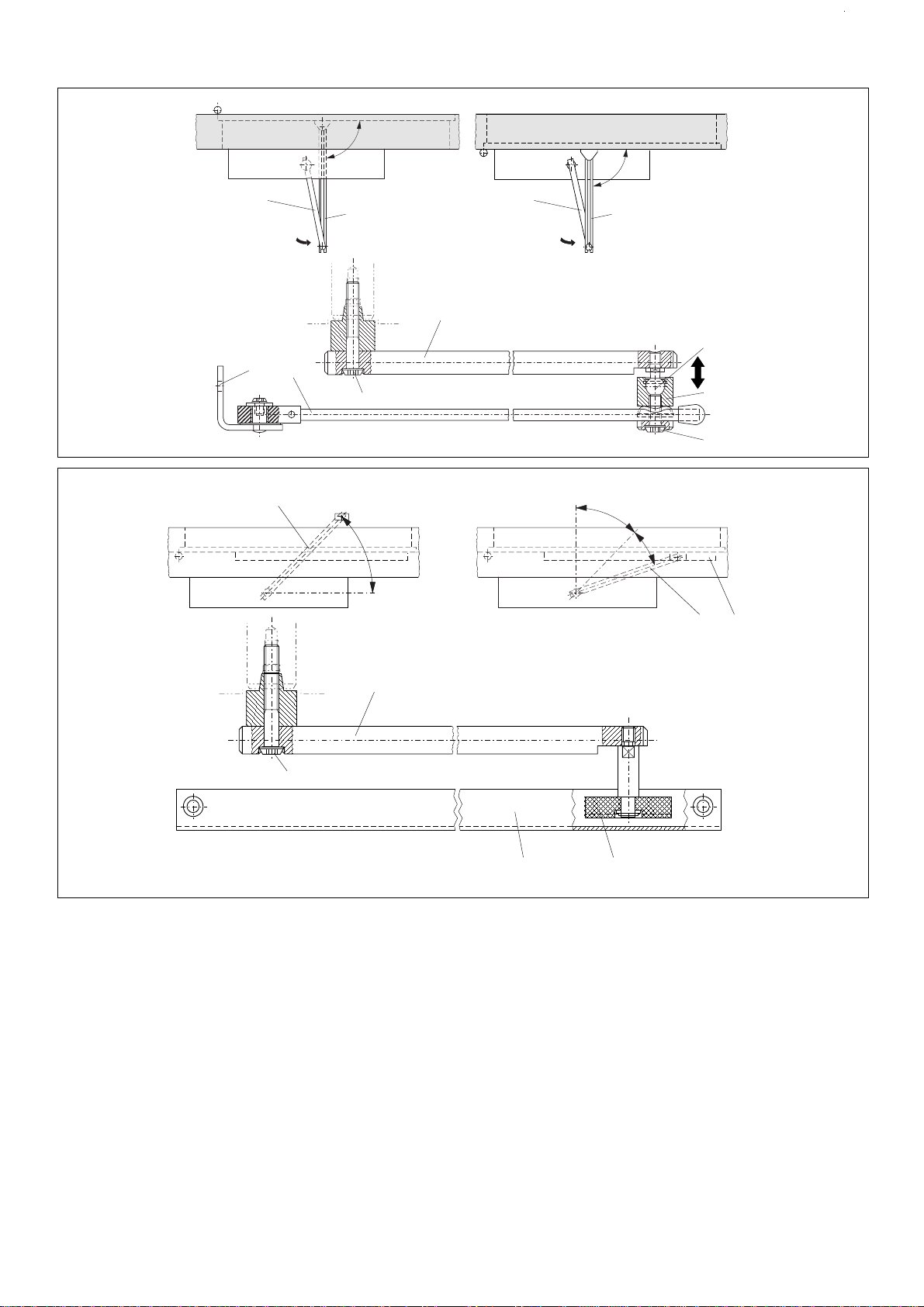

3.3.2 MOUNTING THE SLIDING ARM (fig. 6)

1) Mountarm(1)ontheoperatortransmissionshaftbymeans

of the extension and the screw (2) provided (fig. 6). The

arm must be fitted pointing 45° outwards as shown in fig.

6(a).

N.B.: Ifa larger distance is required between theoperatorand

thearmusethehigherextensionsavailableasaccessories(see

Table C).

Warning: Mount arm (1) on the transmission shaft before fitting

the operator on the lintel (fig. 6).

2) Insert the roller (3) inside the sliding guide (4) (fig. 6).

3) Pull arm (1) inwards manually as shown in fig. 6(b) and

secure the sliding guide (4) by means of two M6 screws on

the closed door as shown in Table C.

4) Check manually that the door is free to open and close

fully and comes to rest against the mechanical end stops.

Ifthedoordoesnotclosecorrectly,adjustthereturnspring

as described in section 10.

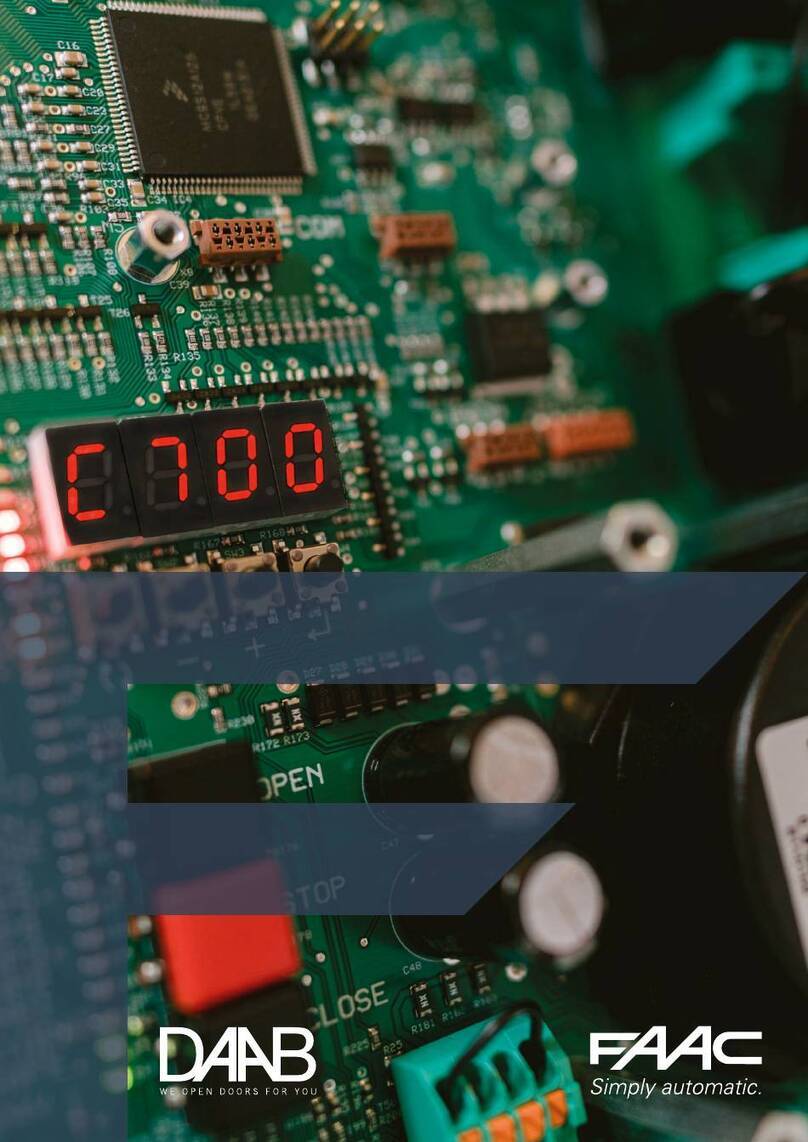

4. START-UP

1) Make the electrical connections to the 959 MP electronic

control unit as described in section 6.

Togainaccessto thecontrolunit,passthe cables through

the special conduit (fig. 1 - ref. 1) as shown in fig. 8.

2) Fitthetwoendcoversandconnectupthefunctionswitch.

Theendcoverwiththeswitch may be fitted on the right or

the left. For cable routing refer to fig. 8.

3) Turn the operating function switch (fig. 1 - ref. 12) to

position I (AUTOMATIC logic).

4) Check that the programming unit microswitches (fig. 10)

are all in the OFF position.

Important:Whenmountingthe“pullingarticulated”or“sliding”

arms or for opening angles greater than 90°, turn microswitch

no. 2 to ON before connecting power to the system.

5) Close the door.

6) Poweruptheoperator.Poweringissignalledbyanacoustic

signal from a buzzer.

7) Check that the 5V LED on the programming unit (fig. 9)

lights up.

8) Attheendof the initialisation procedure, check the status

ofthesignallingLEDs on the programming unit as shown in

Table 5.