24

ENGLISHENGLISH

1.2 DOOR MAX OPENING ANGLE

According to the type of mounting and respecting the installation

dimensions shown in Tables A,B,C, or D, different door max.

opening angles can be obtained according to the lintel thickness.

Table 5 and 6 shows the maximum values of the opening angles

that can be obtained in the different configurations.

Tab.5: Door max opening angle with pushing articulated arm.

Type of installation Jamb depth (mm) Max opening angle

operator on lintel 0 100°

operator on lintel 125 110°

operator on lintel 250 125°

operator on door 0 100°

Tab.6: Door max opening angle with sliding arm.

Type of installation Jamb depth (mm) Max opening angle

operator on lintel 0 90°

arm L=430 mm

operator on lintel 160 105°

arm L=430 mm

operator on lintel 0 90°

arm L=330 mm

operator on lintel 160 90°

arm L=330 mm

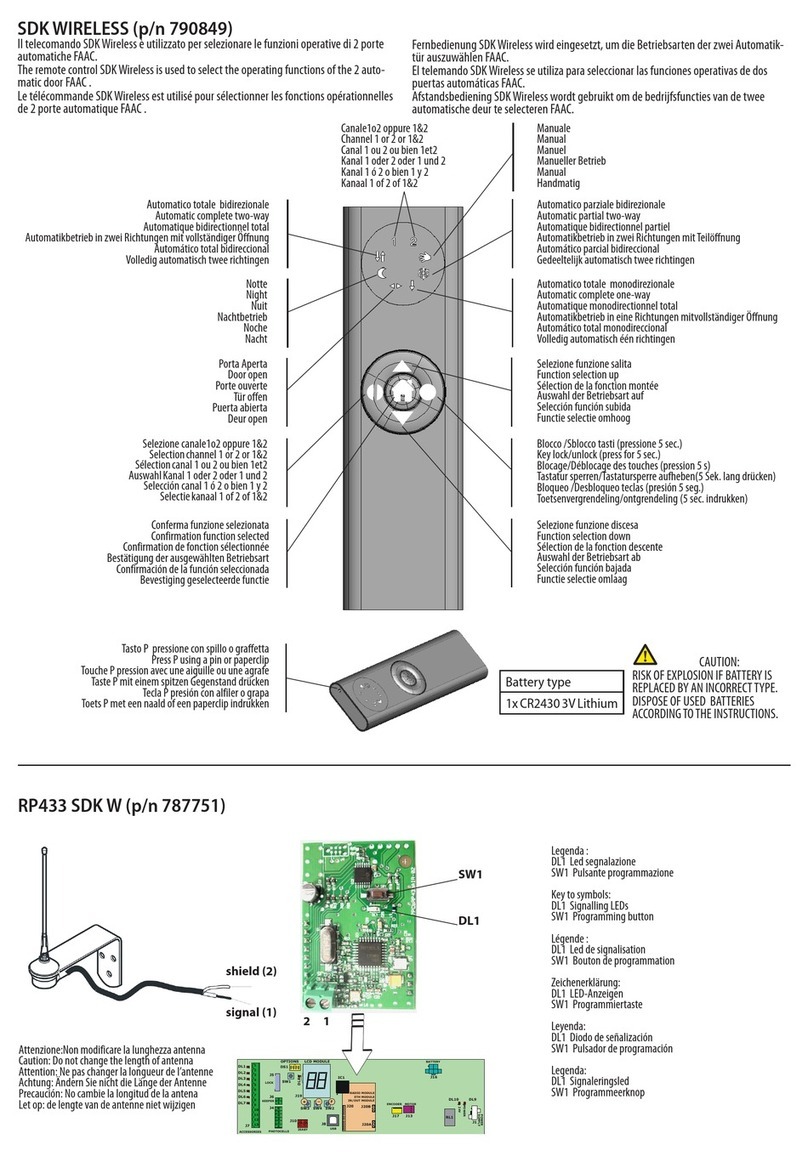

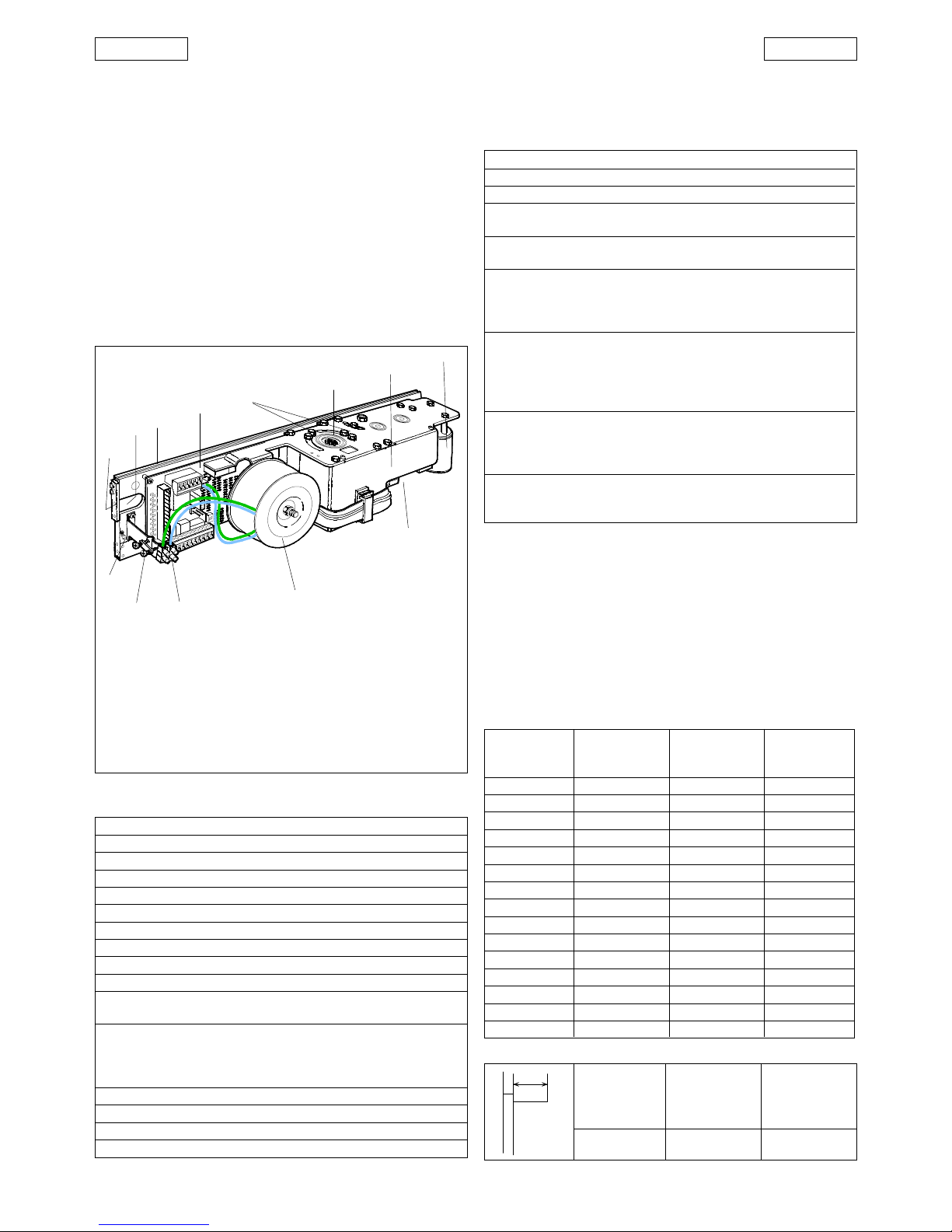

2. ELECTRICAL SETUP (fig. 2a Standard system)

950 BM operator

Microwave radar / Passive infrared sensor

T20E outdoor key-operated selector switch

(KEY command)

Emergency Closing/Opening pushbutton

KP-CONTROLLER programming unit (optional)

KP-CONTROLLER inhibition switch (optional)

24 Vdc electric lock

Junction box

If the operator is installed on the door, make the electrical

connections using a junction box and suitable commercially

available pipes/unions (fig. 2b).

Notes: 1) To lay electric cables, use suitable rigid and/or flexible

piping.

2) Always keep the low voltage accessory connection

cables separate from the 230 V power cables. To avoid

interference, use separate sheaths.

3. INSTALLATION

3.1. PRELIMINARY CHECKS

To ensure correct operation of the automated system the structure

of the existing door must meet the following requirements:

- length and weight as specified in Table 3 (paragraph 1.1.);

- max. jamb depth as specified in Table 4;

- robust and rigid structure of the leaf;

- good condition of the existing hinges;

- smooth, uniform movement of the leaf with no abnormal friction

during its entire travel;

- “neutral” position of the door during its entire travel. If the door

tends to close or open, check the alignment of the hinges.

- Presence of mechanical travel stops.

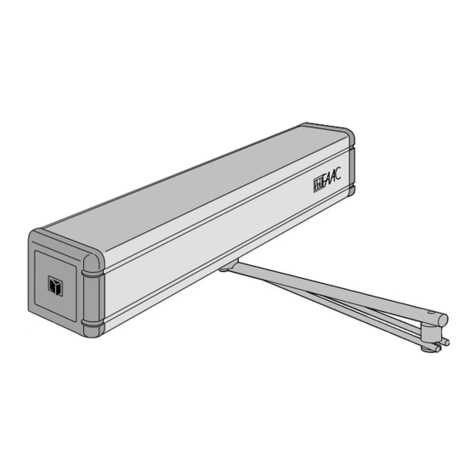

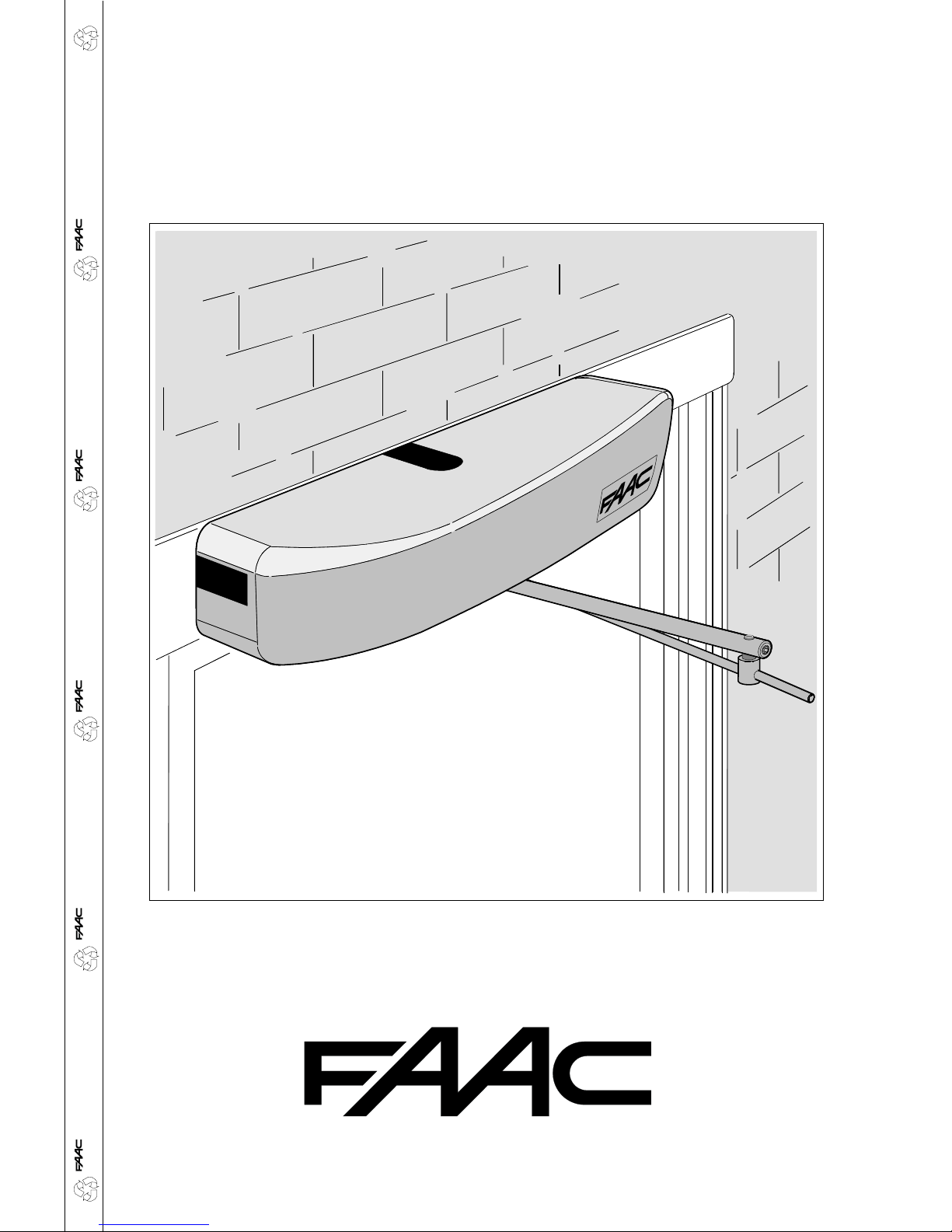

3.2. MOUNTING THE OPERATOR

1) As regards the mounting position of the operator (on the lintel

or on the door) and the type of arm to use (pushing or sliding),

refer to the relevant mounting table and drill the holes

required to mount the operator and the pulling arm.

N.B.: The two intermediate operator fixing holes are not in a central

position (see Mounting tables). The holes are offset in order to

ensure that the operator is mounted with the correct direction of

rotation of the mechanism.

The mounting tables are the following:

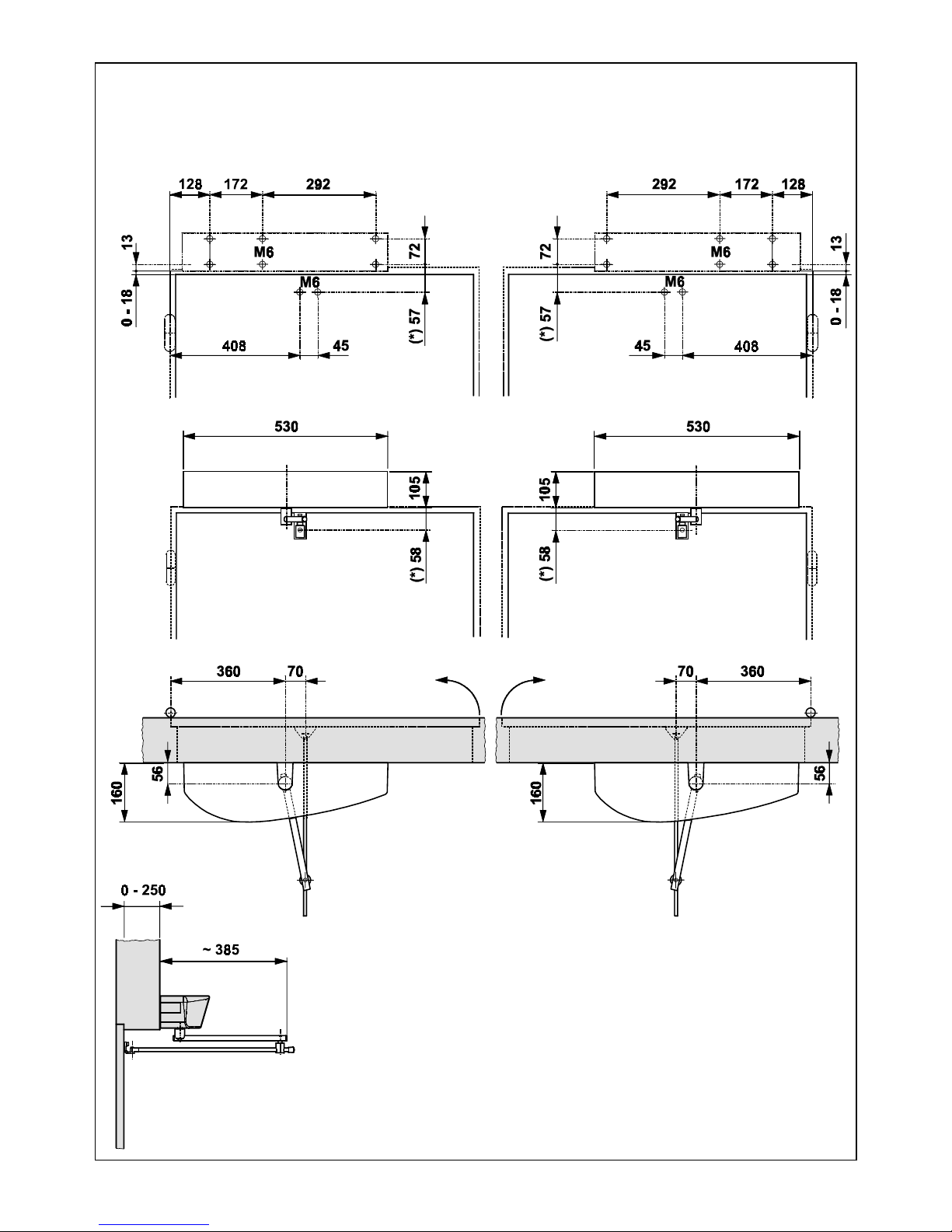

Table A: LINTEL MOUNTING (PUSHING ARTICULATED ARM): Outward

opening.

Table B: DOOR MOUNTING (PUSHING ARTICULATED ARM): Inward

opening.

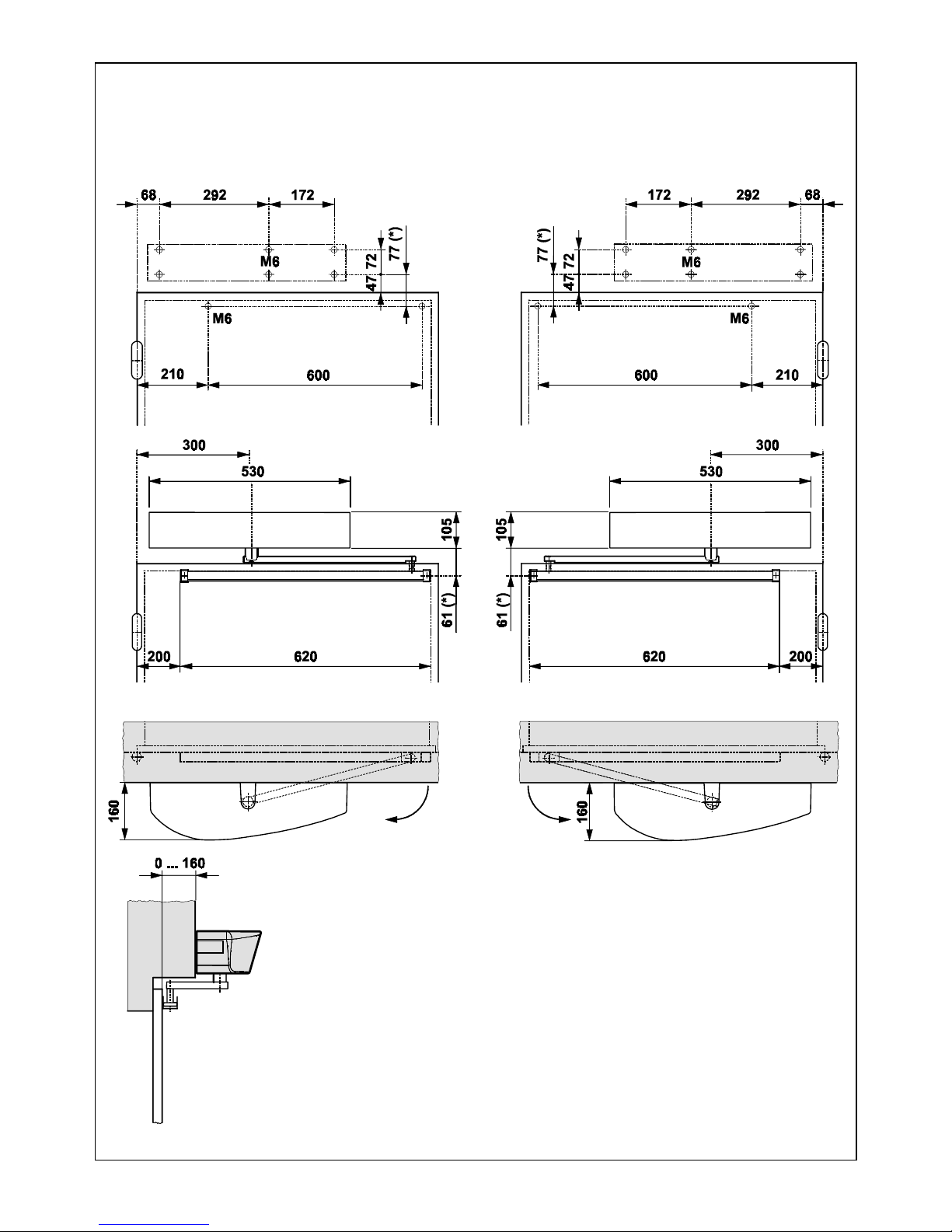

Table C:LINTEL MOUNTING (SLIDING ARM LENGTH 330mm): Inward

opening.

Table D: LINTEL MOUNTING (SLIDING ARM LENGTH 430mm):Inward

opening.

2) Mount the casing fixing brackets as shown in fig.3 according

to the type of mounting to be made. Tighten the screws (fig.3-

ref.1) and fit the screws (fig.3-ref2) without tightening them

completely.

3) Mount the operator using the six M6 screws and washers

provided.

Warning:

- The structure of the lintel (or the door) at the operator mounting

position must not exhibit any significant deformation.

- The operator must be mounted parallel to the floor.

N.B.: If the sliding arm is to be used, the driving arm must be

mounted before the operator is fixed on the lintel (see paragraph

3.3.2.).

3.3. MOUNTING THE DRIVING ARMS

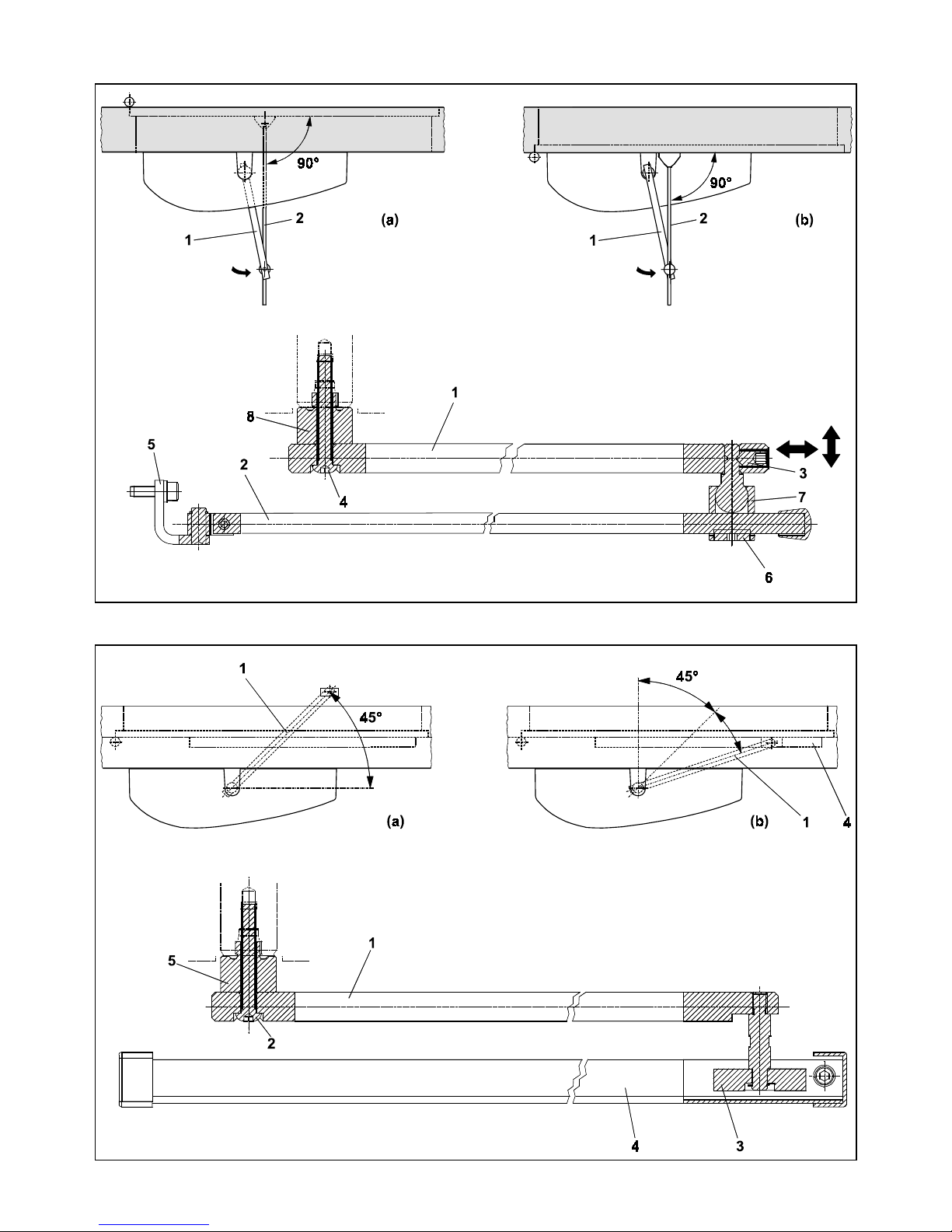

3.3.1. MOUNTING THE PUSHING ARTICULATED ARM (fig.5)

1) Close the door.

2) Free arms (1) and (2) by loosening the fixing dowel (3) as shown

in fig.5.

3) Fit arm (1) on the coupling of the operator transmission shaft

by means of the standard shaft (8) and the screw (4)

provided (fig.5). The arm must be mounted perpendicular to

the closed door.

Note: If a greater distance between the operator and the arm is

required, use the shaft modular extensions, available as

accessories, until the required distance is reached. (see Table A/

B).

4) Mount plate (5) of arm (2) on the door or the lintel using the

twoM6 screws andthe washersprovided (fig. 5).The installation

dimensions are given in Table A/B.

5) Slacken the fixing screw (6) and assemble the two arms by

tightening the dowel (3) (fig.5).

6) Turn arm (1) until arm (2) is perpendicular to the closed door

or the lintel as shown in fig. 5 (a-b), sliding the spacer (7) along

arm (2).

7) Tighten the fixing screw (6) between the two arms.

The length of arm (2) is given in the relevant mounting tables.

If necessary, cut off the section of the arm extending beyond

the articulation and then cover its end using the cap provided

(fig. 5).

8) Check manually that the door is free to open and close fully

and that it comes to rest against the mechanical stops. If the

door does not close correctly, adjust the return spring as

described in paragraph 9.

Important: The two driving arms must never touch.

Note: it is advisable to always adjust the operator internal

mechanical stops (fig.1 -ref 4), open/closed, so that they can be

activated when the leaf mechanical stops are reached.