6

ENGLISHENGLISH

T21IF). The motor lock unit acts directly on the motor by locking it

mechanically.

Motor lock control

This controls if the motor lock operating efficiently and checks if the

door has actually closed. If necessary, the system is designed for

remote activation of an indicator-light or buzzer.

Emergencybatteries(fig. 1ref.)

In the event of a mains power cut, on-battery operation provides a

range of 30 minutes at 100% use frequency.

The battery charge status test is automatic and indicated by a LED.

The charge control board is designed for remote activation of a

'batteryoperating' signal.

Pair of side fixing brackets (fig. 9)

3.2 Supplementaryaccessories

These are the peripheral accessories for completing the automated

system.

-Miniswitch photocells

-T20E : outdoor key-operated selector switch

-T20I : flush-fitting key-operated selector switch

-T21EF : Outdoor key-operated selector switch designed for motor

release

-T21IF : Flush-fitting key-operated selector switch designed for

motorrelease

-Detection sensors.

-SD Keeper

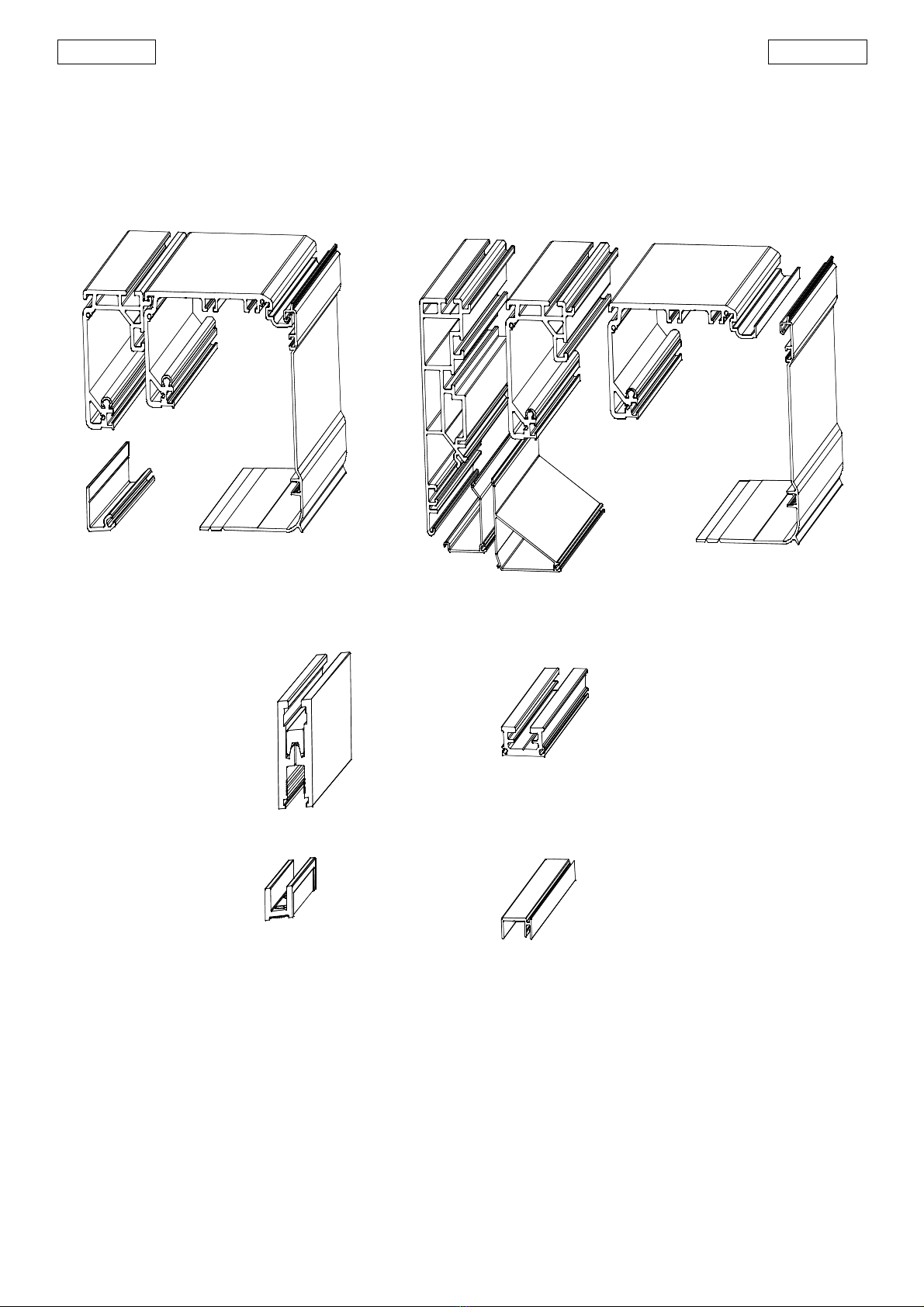

3.3 Doorframeaccessories

To facilitate adapting the door frame profile to the carriages and to

enablecorrectfinishingof theinstallation,FAACoffers thefollowing

seriesofarticles:

Closing profile (fig. 2 ref. )

Available in natural and anodised aluminium versions, the profile is

used for closing the space between the mobile leaf and the wall on

which the head profile is secured.

Closing profile for free-standing facility (fig.3 ref. )

Available in anodised aluminium versions, the profile is used for

closing the space between the mobile leaf and the wall on which

the head profile is secured.

Brush for closing profiles (fig. 2 ref. and fig. 3 ref. )

Prevents dust reaching inside the head profile.

Pair of sliding blocks (fig.14 ref.)

Supplied as a pair, they can be secured to the wall (or on the

stationary leaf) or directly on the floor.

Bottom track profile (fig. 14 ref. )

Allows the bottom leaf profile to adapt to the sliding block

mentionedabove.

Brushforbottom track profile (fig. 14 ref. )

This completes the on-ground track system.

Leafattachmentprofile(fig. 17ref.)

Allows the top leaf profile to adapt to the carriage attachments.

Pair of bottom sliding blocks for glass leaf

They enable the glass leaves to slide.

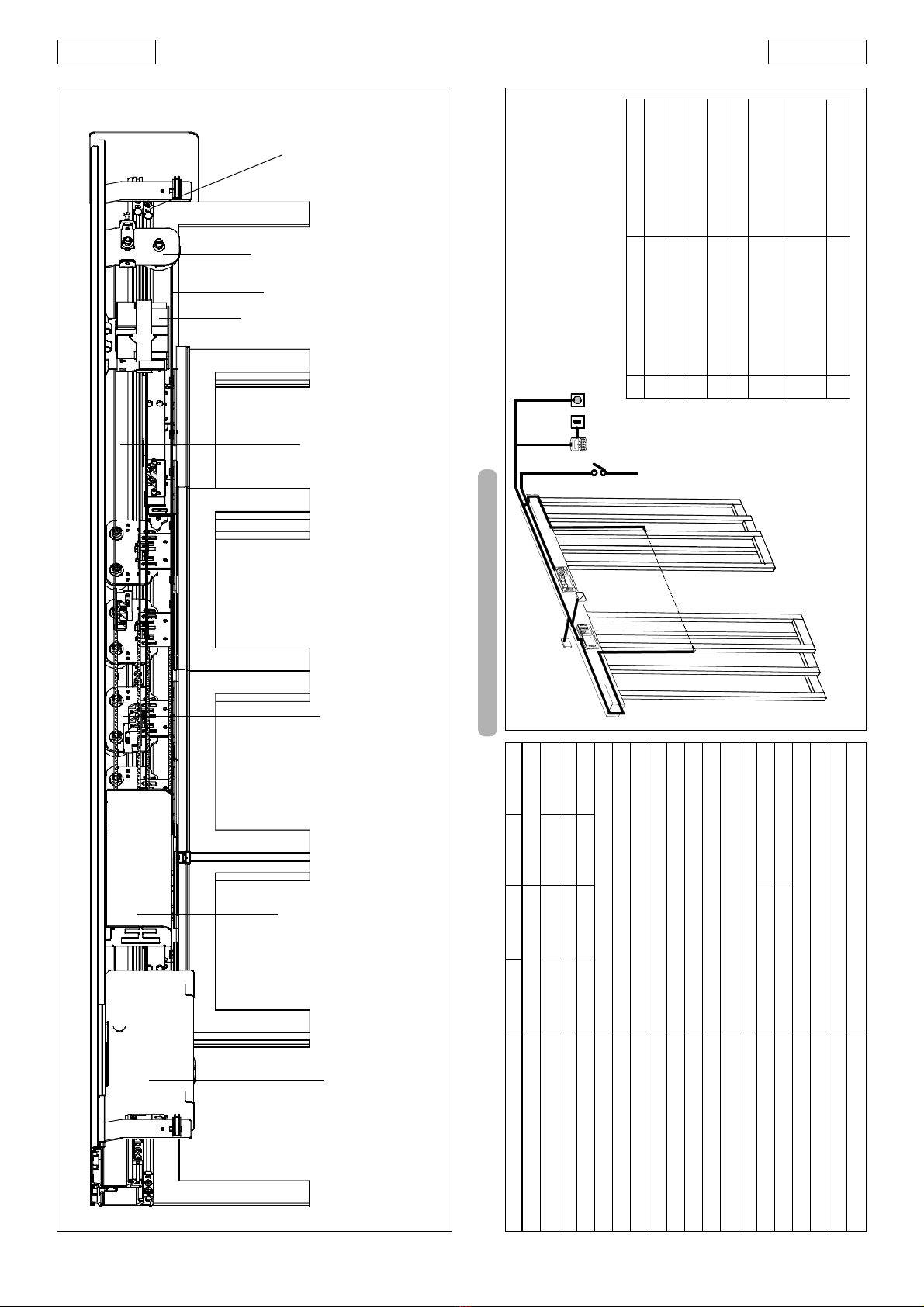

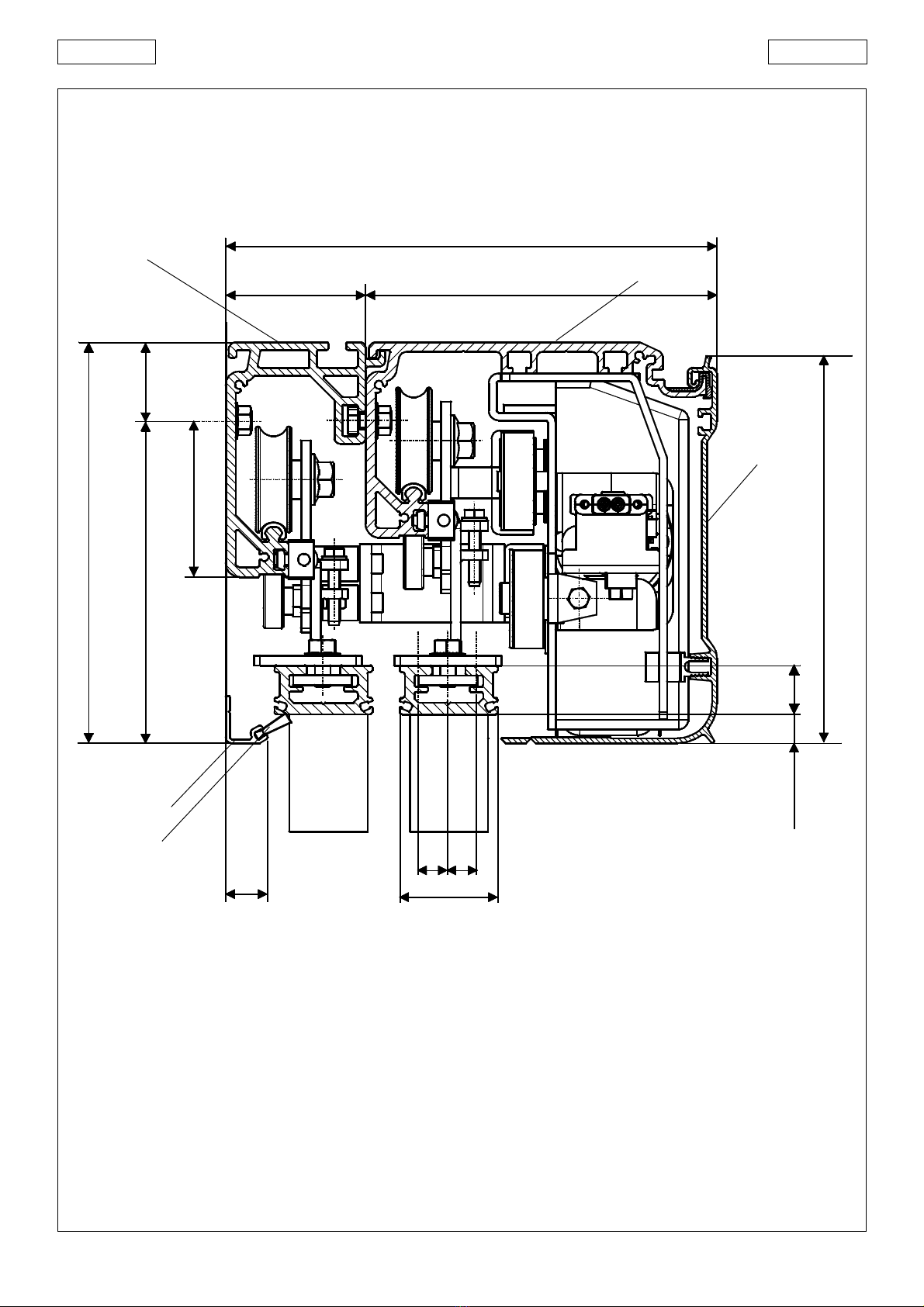

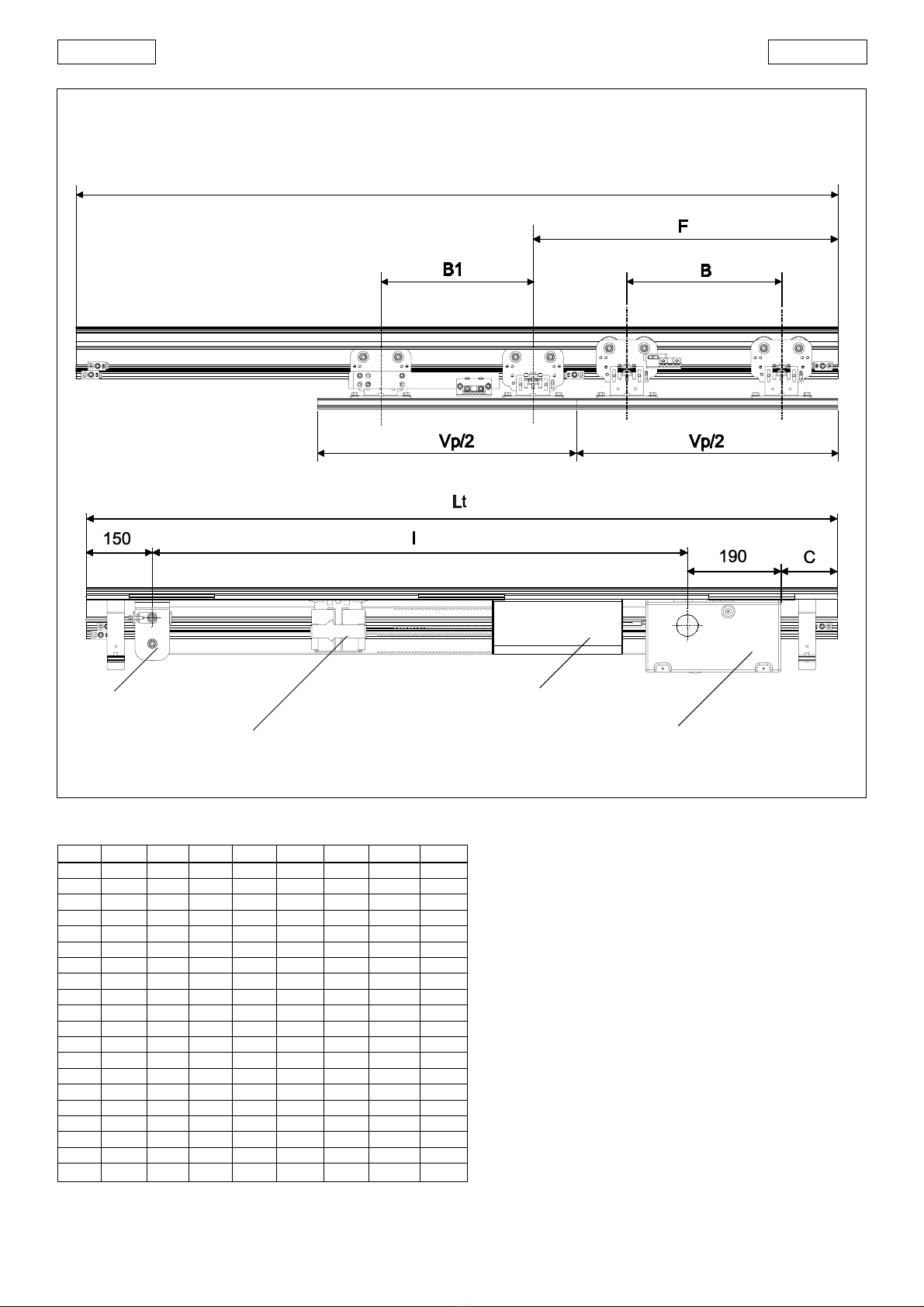

4. HEAD PROFILE CONFIGURATION

To correctly position the head profile parts, refer to the dimensions of

thefollowingfigures:

Fig. 4 right opening, Fig. 5 left opening and Fig. 6 double-leaf.

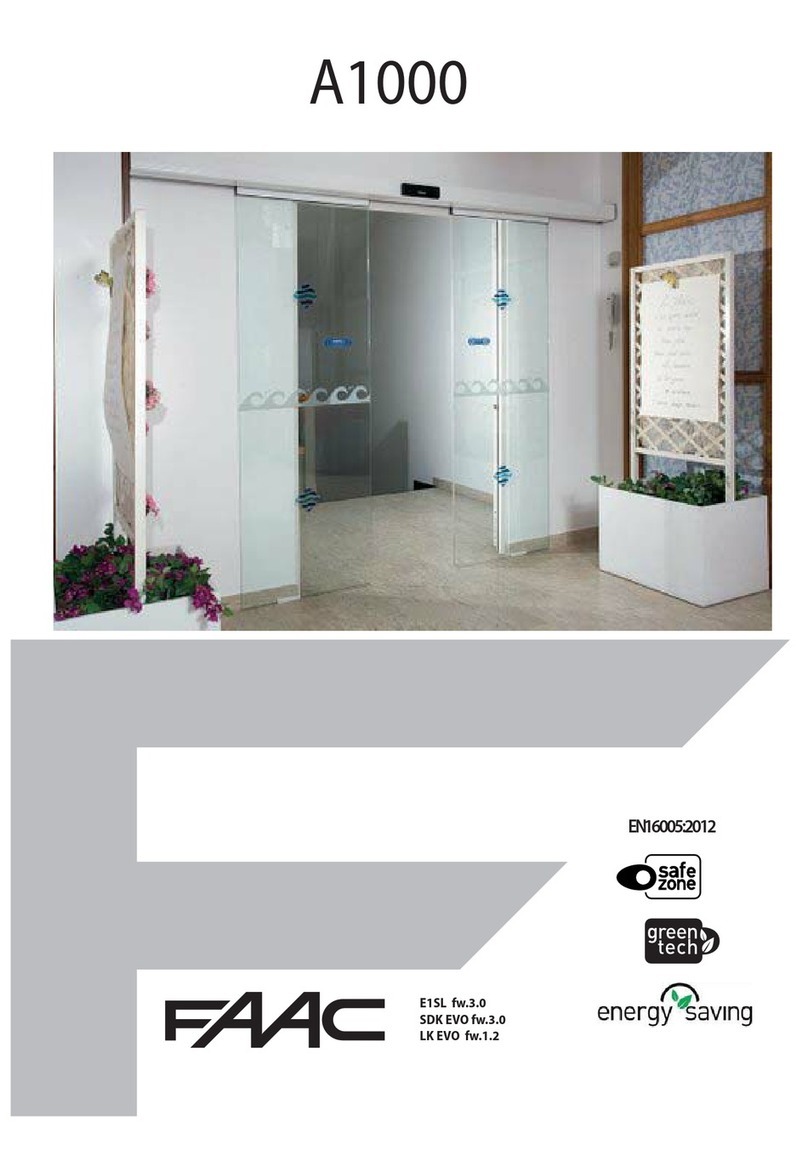

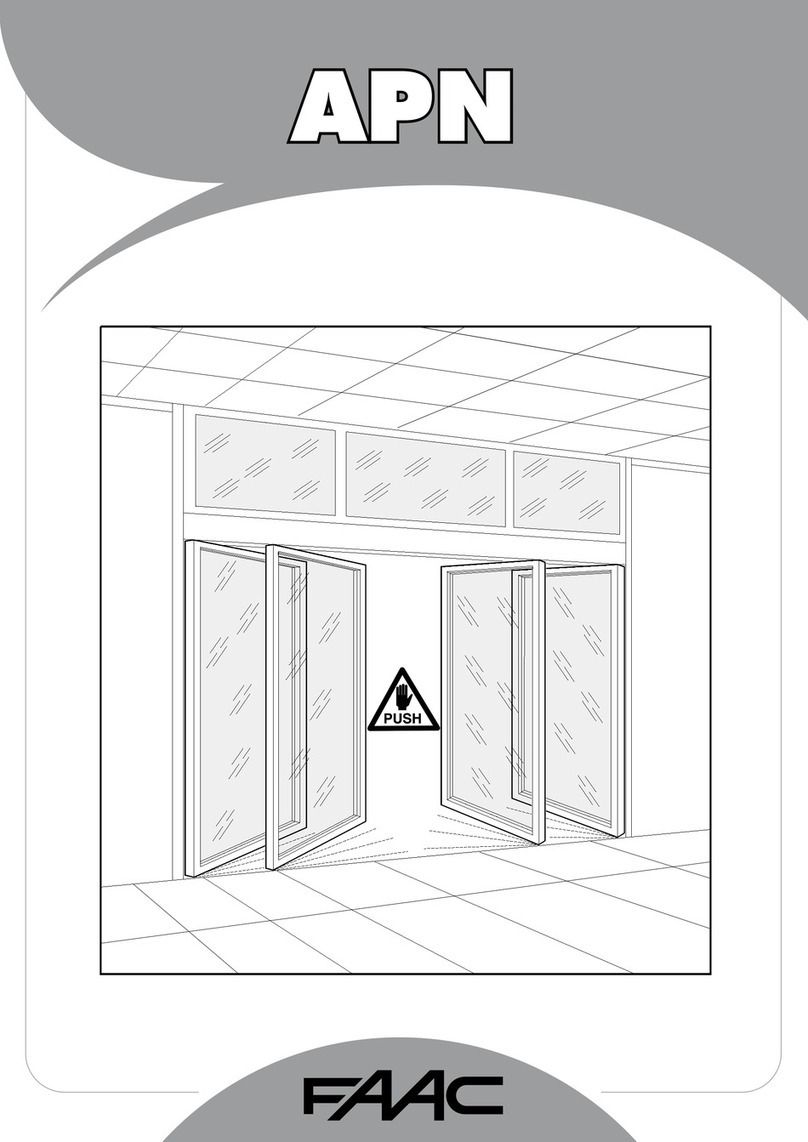

With the FAAC series 940 SMT systems, two- or four-leaf sliding doors

can be automatically activated, managed and controlled.

The FAAC series 940 SMT automated systems are supplied fully

assembled, wired and tested in the configuration requested by the

customer on the order form, or supplied as a kit.

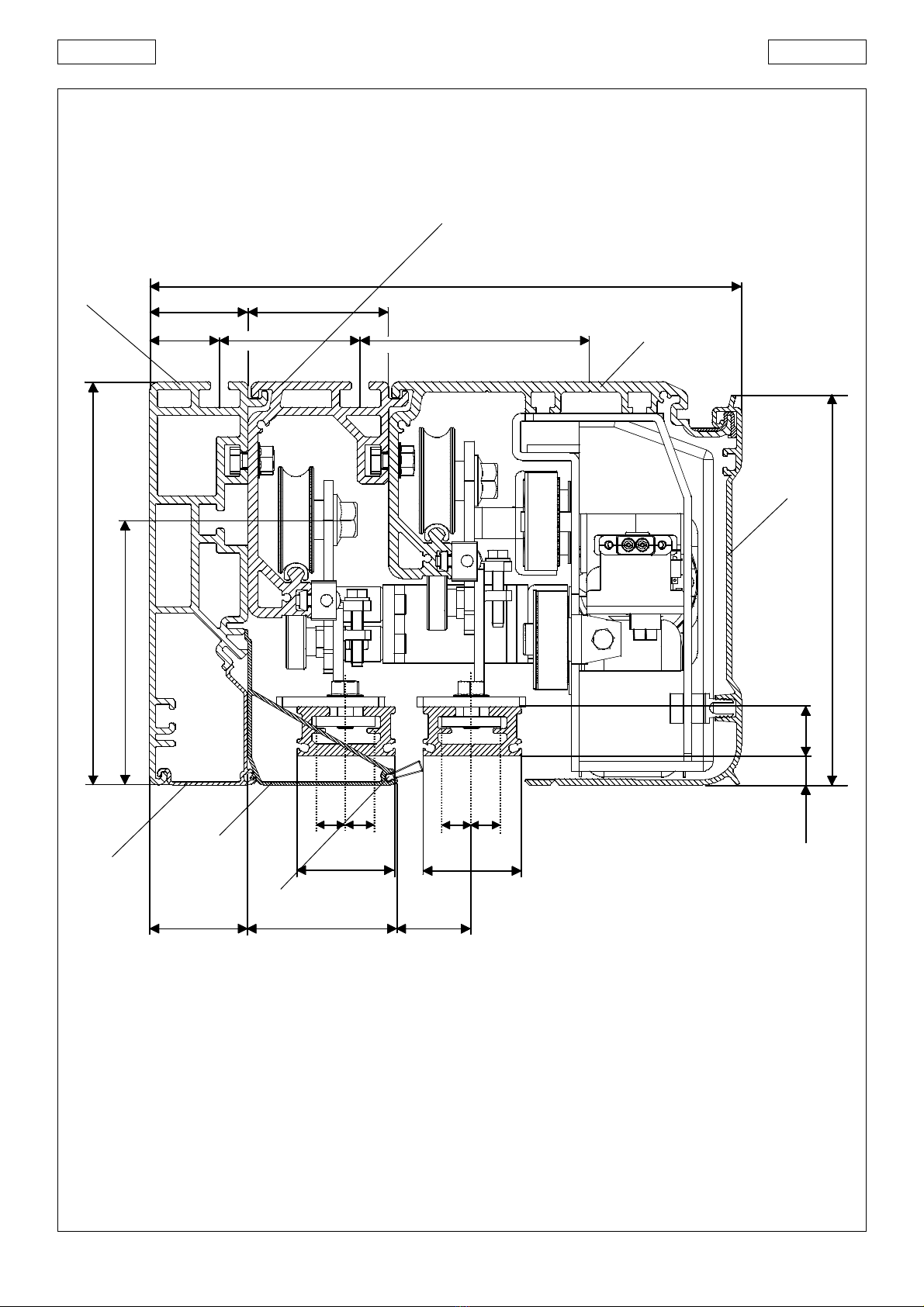

An automation head profile (fig.1 ) consists of the following parts:

Headprofile (fig.1ref. )

The profiles in extruded aluminium, used for the different head profile

models(tab.1) comein twoversions:

Profile SM (fig.2 and 3 ref. )

This is the support profile which is used when the head profile can be

entirely fitted on a bearing structure. The profile's sliding track is

coated with a special plastic material which, in addition to

protectingthe aluminium profileagainst wear, ensuressilent

operationwith avery low frictioncoefficient.

Telescopic profile (fig.2 and 3 ref. )

This is the support profile for the telescopic leaves.

Profile SMA (fig.3 ref. )

This consists of a support profile (SM) and another profile (A)

providingthefree-standingcharacteristic.

The head profile can be secured at the two ends, using the "Side

fixingbracketskit".

The free-standing profile secured at the ends is guaranteed up to a

maximum length of 3,000 mm - for greater lengths, the head profile

must be secured at its intermediate points too, using the

appropriateslots.

Leafsupportcarriages (fig.1ref.)

The carriages are provided with two wheels on ball bearings, a

counter wheel on the lower part, and a screw system for adjusting

leafheight.

Motor/transformer unit (fig. 1 ref.)

The DC motor is supplied with an encoder and a leaf locking system

(accessory).

Control unit (fig. 1 ref. )

When the microprocessor control unit is powered up, it executes an

initialisationprocessof thedoor's functionalparameters.

Opening mechanical stop (fig. 1 ref. )

Transmission pulley unit (fig. 1 ref. )

Drive chain (fig. 1 ref. )

3. ACCESSORIES

FAAC has three groups of articles complementing the installation of

the automatic door.

3.1 Supplied accessories for the head profile

These are the articles which, following a request on the order form,

are assembled on the head profile directly by FAAC. These

accessories, which can be, if necessary, installed later on, are as

follows:

Front housing (fig.2 ref. and fig. 3 ref. )

The front housing is available in natural or anodised aluminium.The

side panels fully enclose the system.

Motor lock unit

The motor lock unit guarantees mechanical locking of the door in

any position. A single type of motor lock is used for either single- or

double-leafapplications.

The motor lock is supplied with an internal release device enabling

emergencyopening if necessary; itis also designed forinstallation of

the external release (paragraph 3.2 key push-buttons T20EF and

940SMT2/SMT4 SERIES AUTOMATIC DOORS

2. DESCRIPTION AND TECHNICAL SPECIFICATIONS