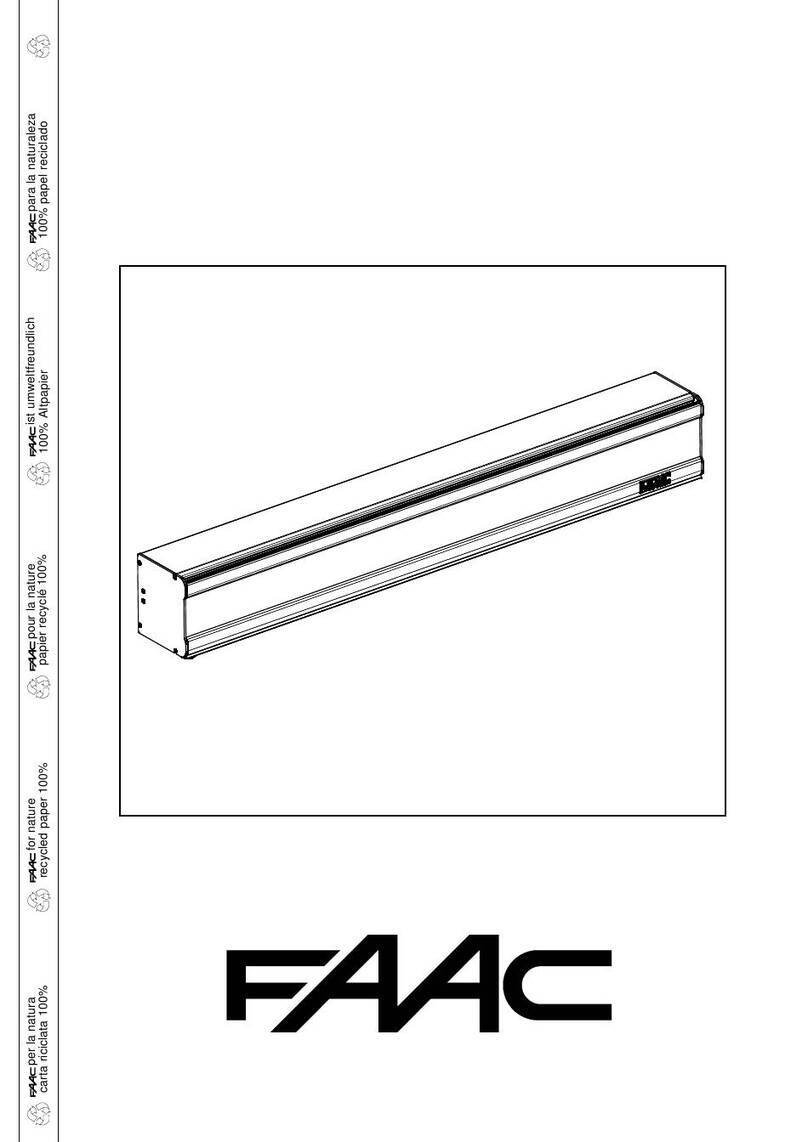

A1400 AIR RDT 6 53211904 - Rev. C

Translation of the original instructions ENGLISH

CONTENTS

EC Declaration of conformity of a machine ................... 4

EC Declaration of conformity................................... 4

Declaration of incorporation of partly completed machinery5

Declaration of incorporation of partly completed machinery5

1. INTRODUCTION TO THE INSTRUCTIONS MANUAL ......... 9

1.1 Safety recommendations ........................................ 9

Safety of the installer/maintenance technician .............. 9

Workplace safety ................................................ 9

Operator safety .................................................. 9

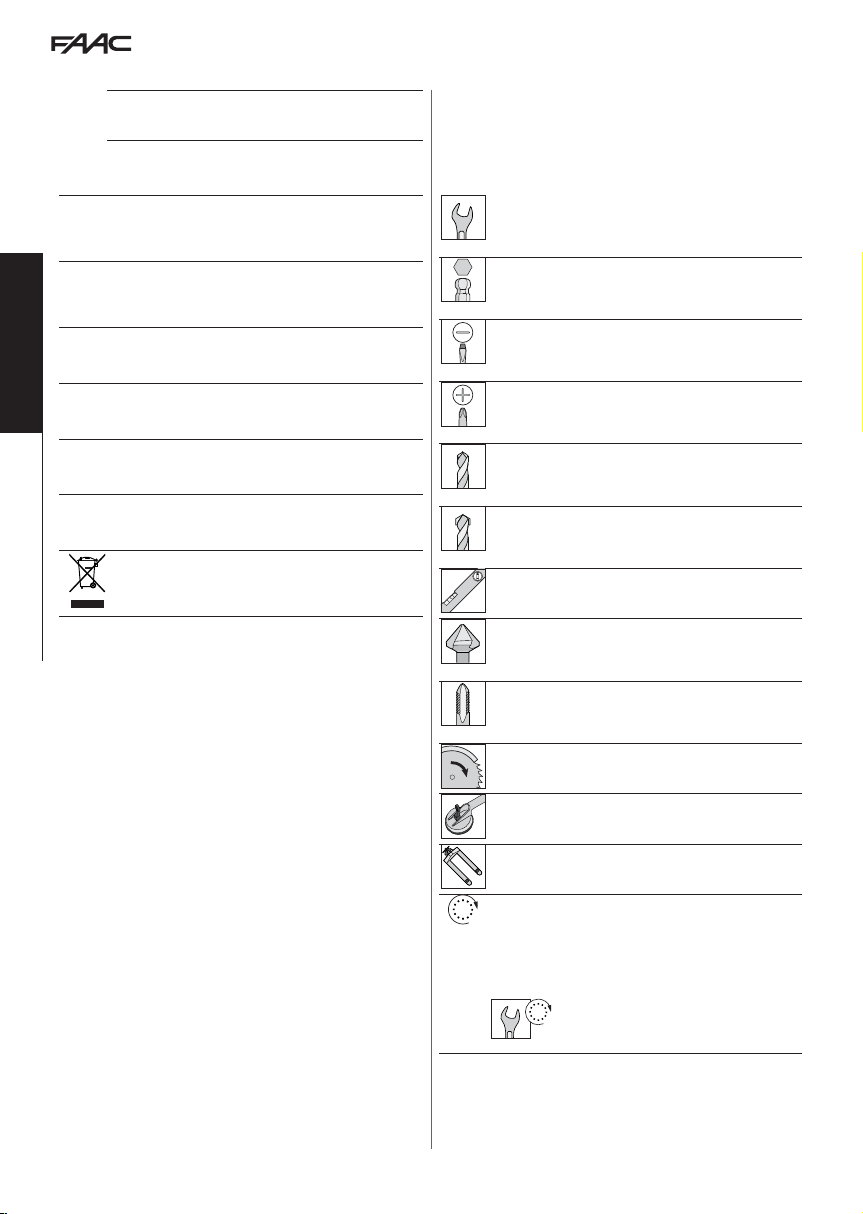

1.2 Meaning of the symbols used ..................................10

2. AUTOMATION A1400 AIR RDT ................................ 12

2.1 Intended use .....................................................12

Limitations for use..............................................12

2.2 Unauthorised use................................................12

2.3 Identification plate ..............................................13

2.4 Technical specifications .........................................14

2.5 Composition of the supply .....................................15

Installation stages according to type of supply ............. 15

Components of the automation ..............................16

3. REQUIRED INSPECTIONS AND ARRANGEMENTS ......... 18

3.1 Preliminary inspections .........................................18

3.2 Arrangement of electrical cables ..............................18

4. TRANSPORT AND RECEPTION OF THE CONSIGNMENT.. 19

Handle packages................................................19

Unpack and Handle.............................................19

5. CUT THE PROFILES .............................................. 20

6. ASSEMBLE THE HEAD SECTION .............................. 21

6.1 Preliminary for self-supporting head section (if any)........21

6.2 Assemble the components .....................................22

Mechanical stops ...............................................22

Electronics module and telescopic profile Rod..............23

Safety cables and spacers......................................23

Motor_1..........................................................23

Auxiliary_motor.................................................23

Motor release monitor XB LOCK...............................24

Internal release..................................................24

Motor block operation test XB LOCK .......................24

Cover drilling ....................................................25

Closed door monitor sensor ...................................25

Emergency battery kit .........................................25

7. ASSEMBLE THE FRAME A1400 AIR RDT CS ................. 26

7.1 Entry door with Profiles TK50...................................26

Preliminary operations.........................................26

Assembling the frame..........................................26

Fastening the fixed leaves .....................................27

Mounting mobile leaves .......................................27

Glazing installation .............................................27

Assembly of the head section to the upper profile .........27

7.2 Entry door with profiles TK20 ..................................27

Preliminary operations.........................................27

Assembling the frame..........................................28

Mounting MOBILE LEAVES ....................................28

Assembly of the head section to the upper profile .........28

8. INSTALL THE HEAD SECTION.................................. 29

8.1 Preliminary operations..........................................29

8.2 Wall fastening ....................................................29

8.3 Self-supporting automation fastening........................30

8.4 Mount the transom..............................................31

9. INSTALL LEAVES ................................................. 32

9.1 Mount the lower shoes .........................................32

Shoe with bracket TK50........................................32

Swivel shoe TK50 ...............................................32

Shoe with bracket TK20........................................32

9.2 Mount profiles on the leaves ...................................33

9.3 Mount the lower brush strip....................................33

Glass leaves......................................................33

9.4 Install leaves......................................................33

9.5 PREPARING THE EXTERNAL CARRIAGES .......................34

9.6 Telescopic profile assembly.....................................35

9.7 plate on telescopic profile ......................................36

9.8 PREPARING EXTERNAL CARRIAGES ............................36

9.9 Steel cable fixing ................................................38

9.10 Adjust leaves and carriages ...................................39

Height of the leaves ............................................39

Depth of the leaves.............................................39

Counter wheel ..................................................39

10. INSTALL GLASS LEAVES ...................................... 40

10.1 Mount the sweepers ...........................................42

11. ASSEMBLE THE BELT, CASING AND ACCESSORIES ...... 43

11.1 Mount the belt .................................................43

Adjust the belt...................................................44

11.2 Belt tensioning .................................................45

11.3 Adjust the mechanical stops..................................46

Stops on opening...............................................46

Double leaf closing stops ......................................46

Single leaf closing stops........................................46

11.4 Mount the side profiles........................................47

11.5 Install the casing brackets.....................................47

11.6 Fit the closing cover............................................48

11.7 Mount motor block XB LOCK..................................49

11.8 Adjust Motor block XB LOCK..................................49

11.9 Align Motor block ..............................................50

11.10 Mount motor block XM LOCK ...............................50

11.11 Mount the cable gland guides ..............................50

12. ELECTRONIC INSTALLATION................................. 51

12.1 Electronics module.............................................51

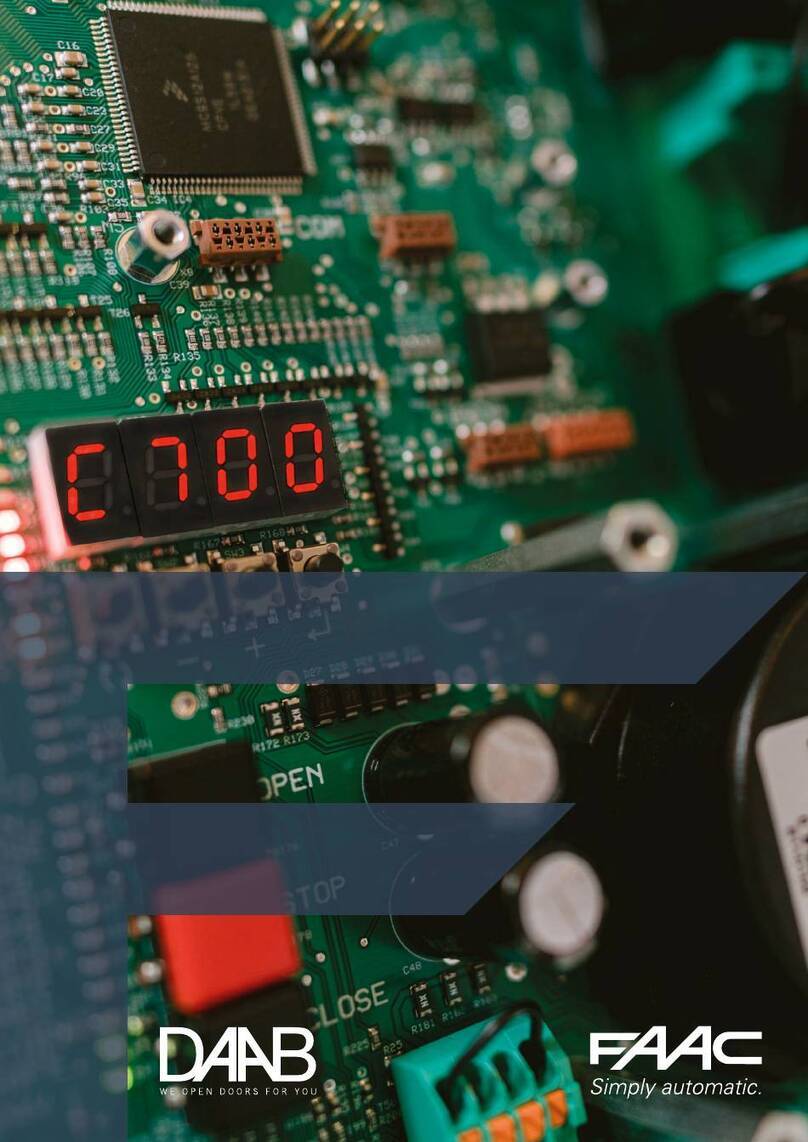

Electronic board E1400 RD.....................................51

12.2 Terminal boards and connectors .............................53

J1 J2 J3 J4 - Safety detectors...................................53

J5 - Internal motion detector ..................................53

J6 - External motion detector .................................53

J7 - Emergency: remote opening .............................53

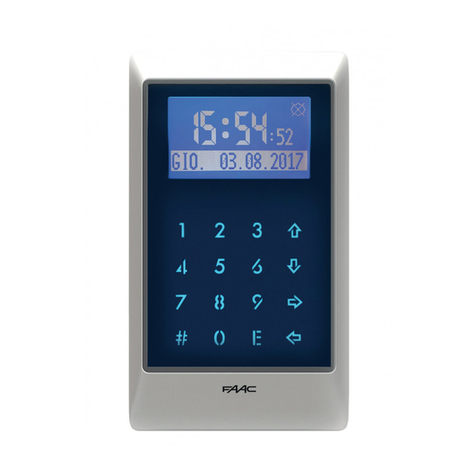

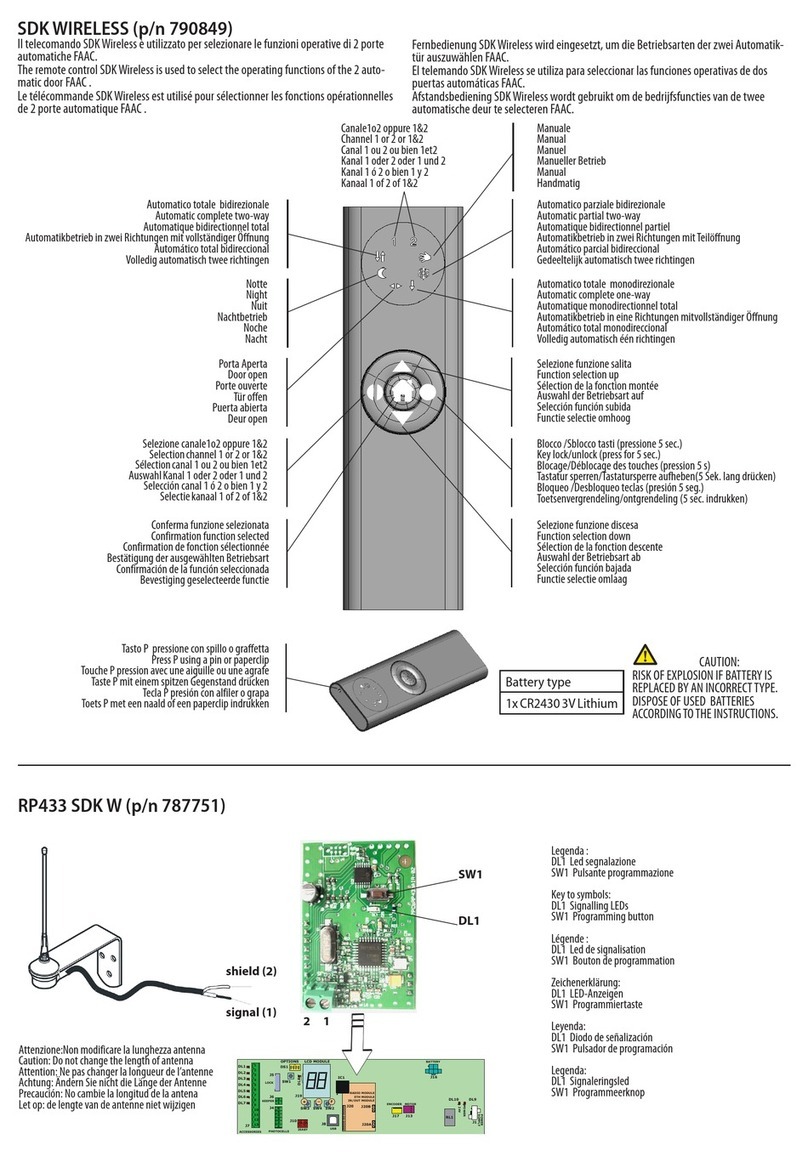

J8 - SDK EVO.....................................................53

J9 - Button photocells XFA.....................................53

J10 - Main power supply 36V - 4A.............................53

J11 - Motor_1 ....................................................53

J12 - Motor_1 Encoder..........................................53

J13 - Motor block and monitoring (OPTIONALS) ............54

J14 - Emergency battery .......................................54