INSTRUCTION MANUAL MT, MA2, MK2, M10 DRIVE UNIT

2

Innehåll

EU Declaration of incorporation...............................3

Safety ........................................................................4

General ....................................................................4

Packing, transport and unpacking...........................4

General ....................................................................4

Introduction ..............................................................5

Intended use ............................................................5

Machine marking .....................................................5

Manufacturer ...........................................................5

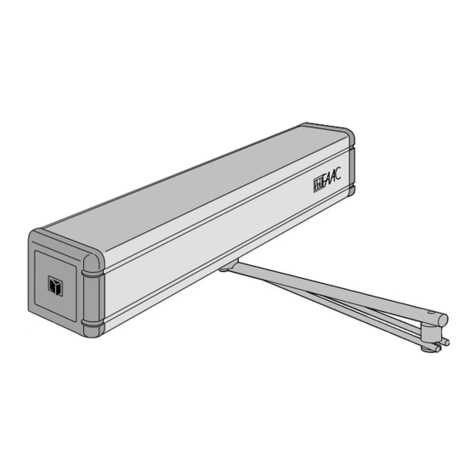

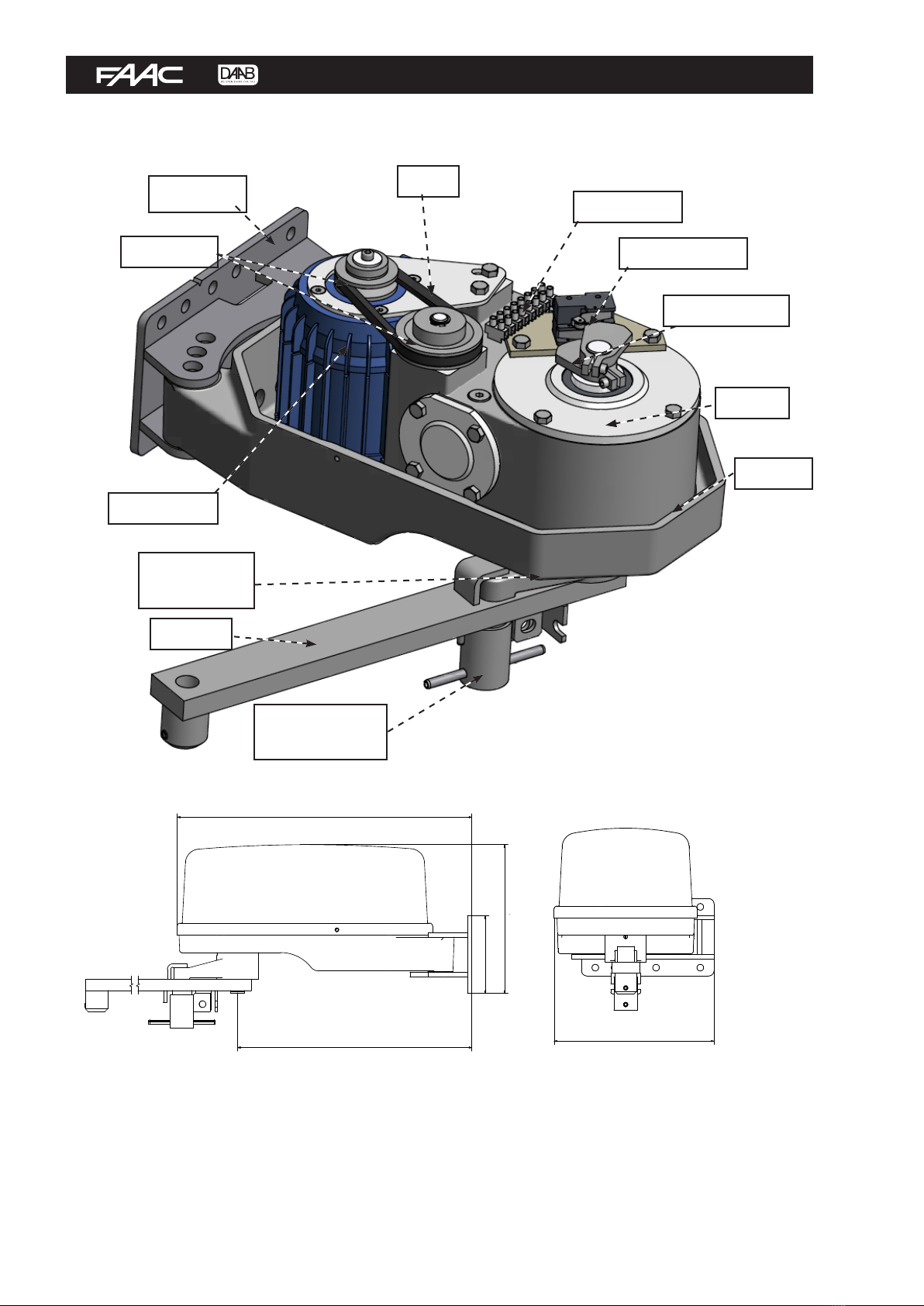

Drive unit MA2/MK2...................................................6

Function description ................................................6

Design and function .............................................6

Dimensions...........................................................6

Technical specification.............................................7

Electric motors......................................................7

Gears ....................................................................7

Installation and commissioning...............................7

General installation ..............................................7

Side installation.......................................................8

Mounting plate .....................................................8

Drive arm..............................................................8

Gate mounting and link arm.................................9

Top mounting ...........................................................9

Bracket & mounting plate.....................................9

Drive arm............................................................10

Gate mounting....................................................10

Link arm .............................................................10

Top mounting with limited lateral space................11

Bracket & mounting plate...................................11

Drive arm............................................................11

Gate mounting....................................................11

Mounting plate for the swing arm bracket..........12

Link arm .............................................................13

Wing mounting.......................................................14

Bracket & mounting plate...................................14

Drive arm............................................................14

Installing the drive unit .........................................15

Drive unit MT ...........................................................16

Function description ..............................................16

Design and function ...........................................16

Dimensions.........................................................16

Technical specification...........................................17

Electric motors....................................................17

Gears ..................................................................17

Installation and commissioning.............................17

General installation ............................................17

Side installation.....................................................18

Mounting plate ...................................................18

Drive arm............................................................18

Gate mounting and link arm...............................19

Top mounting .........................................................20

Bracket & mounting plate...................................20

Drive arm............................................................20

Gate mounting....................................................20

Link arm .............................................................21

Top mounting with limited lateral space................22

Bracket & mounting plate...................................22

Drive arm............................................................22

Gate mounting....................................................22

Mounting plate for the swing arm bracket..........22

Link arm .............................................................23

Adjusting the drive unit .........................................25

Disengagement......................................................25

Quick release ......................................................25

Release handle ...................................................25

Electrical connection..............................................26

General ..................................................................26

Engaging the electric motor...................................26

Limit positions .......................................................27

Maintenance and service........................................27

General ..................................................................27

Lubrication.............................................................27

Oil filled gearbox.................................................27

Open gearbox......................................................28

Spare parts..............................................................28

Fault search............................................................28

In the event of a blockage......................................28

In the event of a collision.......................................28

The motor is running but the gate is not moving ...28