This document is composed by 1 page

Questo documento è composto da 1 pagina

Nemko Spa

Via del Carroccio 4

I - 20046 Biassono (MI)

T+39 03922012.01 r.a.

F+39 0392201221

www.nemko.com

www.nemko.it

Doc.:C105 Rev.: 7 Date: 2006-12-20 Pag.: 1/1

STATEMENT OF CONFORMITY TO STANDARDS

No. 89668SOCSTD

ATTESTATO DI CONFORMITA’ ALLE NORME

N°89668SOCSTD

Equipment

Apparato

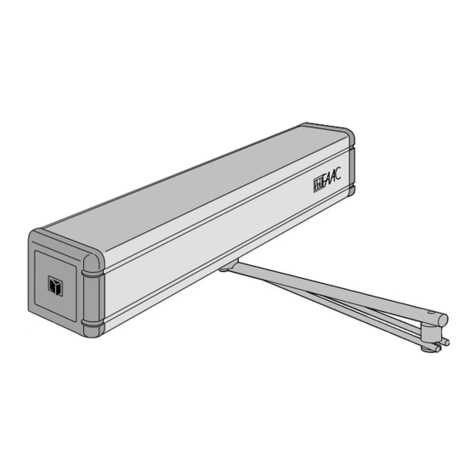

Anti-panic break-out system for powered pedestrian door leaf and

side screen model 930SNF – 930SNFA – 940SM – 940SMA –

A100-Compact

Sistema antipanico a sfondamento per ante mobili e semifisse per porte pedonali

automatiche modello 930SNF – 930SNFA – 940SM – 940SMA – A100-Compac t

Applicant

Richiedente

FAAC SpA

Via Benini, 1 – 40069 ZOLA PREDOSA

ITALY

Manufacturer

Costruttore

FAAC SpA

Via Benini, 1 – 40069 ZOLA PREDOSA

ITALY

Model/type

Modello / Tipo

APN

Ratings

Dati tecnici

--

Additional information

Informazioni aggiuntive

--

Variants

Varianti

APN1 – 1 leaf

APN2 – 2 leaves

APN1+1 – 1 leaf and 1 side screen

APN2+2 – 2 leaves and 2 side screens

The tested equipment was found

complying the requirements of the

standard(s)

L’apparato provato è risultato conforme alla(e)

norma(e)

DIN 18650-1:2005

Sub-clause 5.8.3.3 Powered doors with break-out

(Additional requirements for doors in escape routes and emergency

exits)

DM 10-3-1998 n°64

Allegato III – Misure relative alle vie di uscita in caso di incendio –

Punto 3.11 – Porte scorrevoli e porte girevoli

Results of performed tests are shown

in the test report(s)

I risultati delle prove eseguite sono riportati

nel(i) rapporto(i) di prova

Nemko Spa 89668TRFSAF issued 2007-07-20

This Statement of Conformity to Standards refers to the tested sample(s), does not involve production

surveillance and does not allow the use of the Nemko mark on the product.

Questo Attestato di Conformità alle Norme si riferisce al campione(i) provato(i), non include la sorveglianza della produzione e non

permette l’apposizione del marchio Nemko sul prodotto.

Date of issue: 2007-07-20

Data di emissione

Nemko S.p.A.

Certification Dpt.

…………………….

Alberto Reati