950N 6 732708 - Rev. F

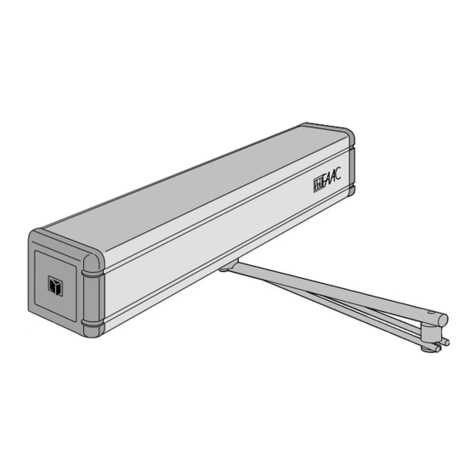

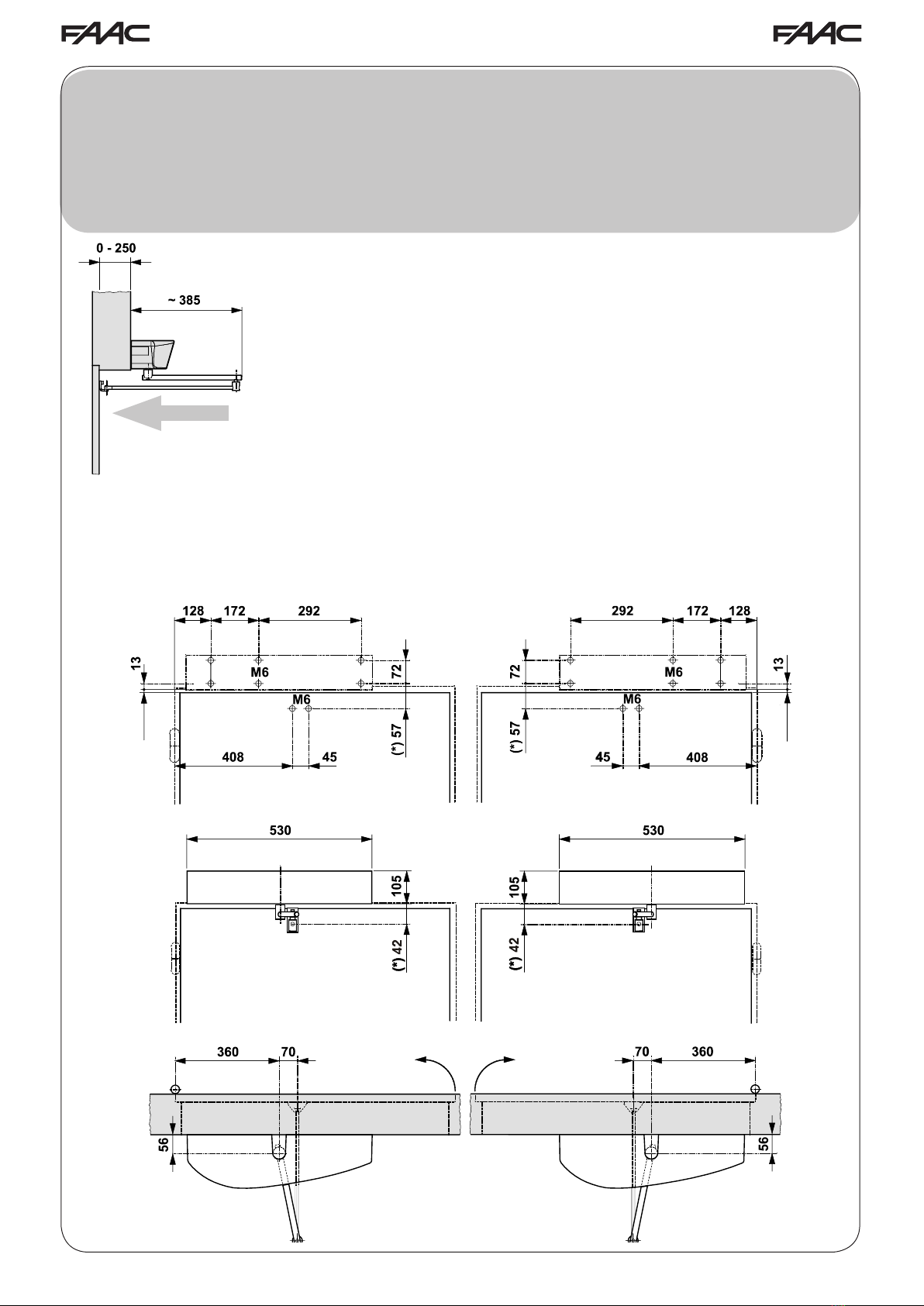

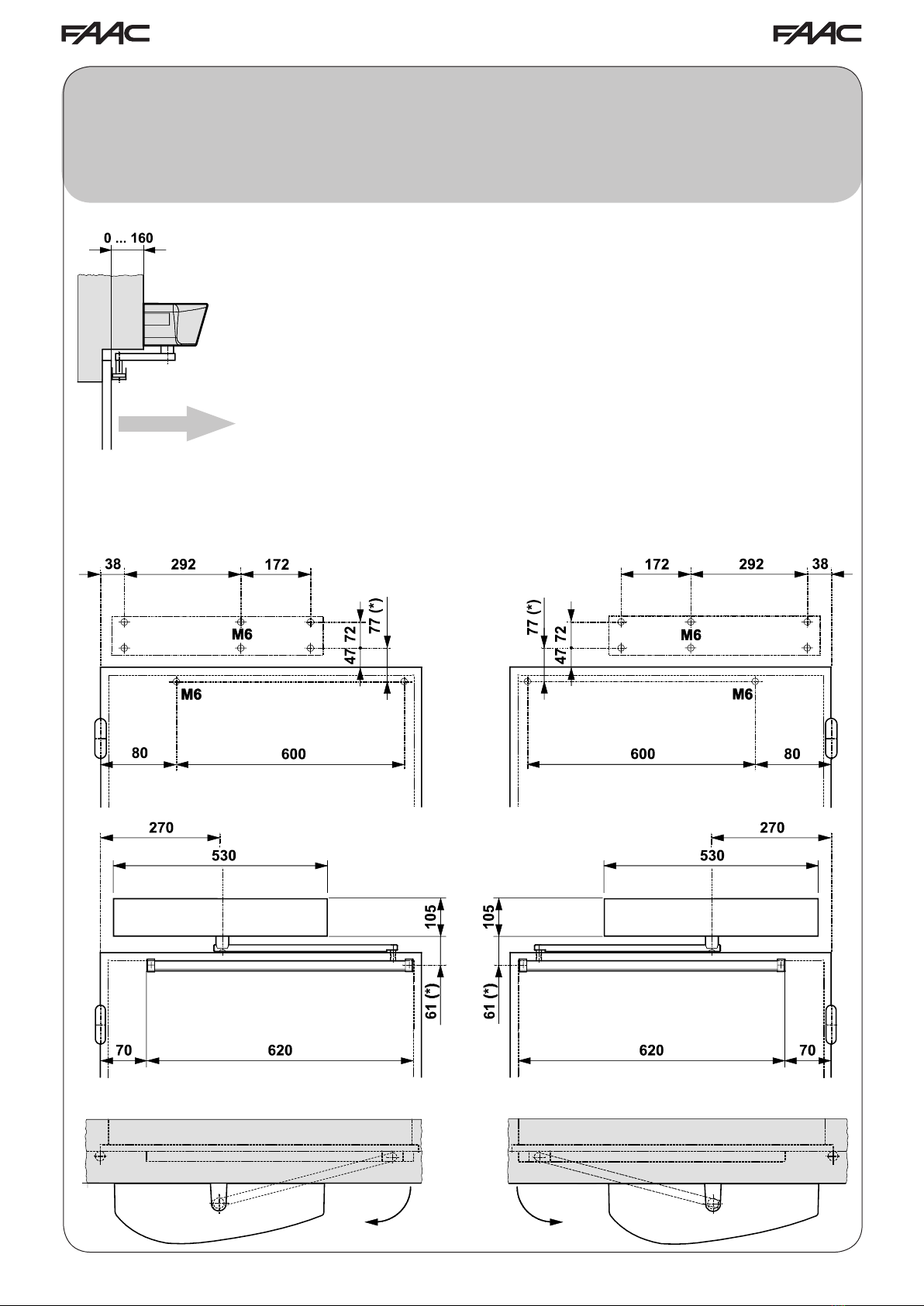

TAVOLA D: BRACCIO A PATTINO L=330 mm CON MONTAGGIO OPERATORE SULL’ARCHITRAVE

TABLE D: SLIDING ARM L=330 mm WITH OPERATOR INSTALLATION ON THE ARCHITRAVE

TABLE D: BRAS À PATIN L=330 mm AVEC MONTAGE DE L’OPÉRATEUR SUR LE LINTEAU

LÁMINA D: BRAZO DE PATÍN L=330 mm CON MONTAJE DEL OPERADOR EN EL DINTEL

ÜBERSICHT D: GLEITKUFENARM L = 330 mm MIT MONTAGE DES ANTRIEBS AM STURZ

TEKENING D: ARM MET GLIJSCHOEN L=330 mm MET MONTAGE AANDRIJVING OP DE BOVENDORPEL

BILD D: GLIDARM L = 330 mm MED DÖRRÖPPNAREN MONTERAD PÅ KARMÖVERSTYCKET

OPEN

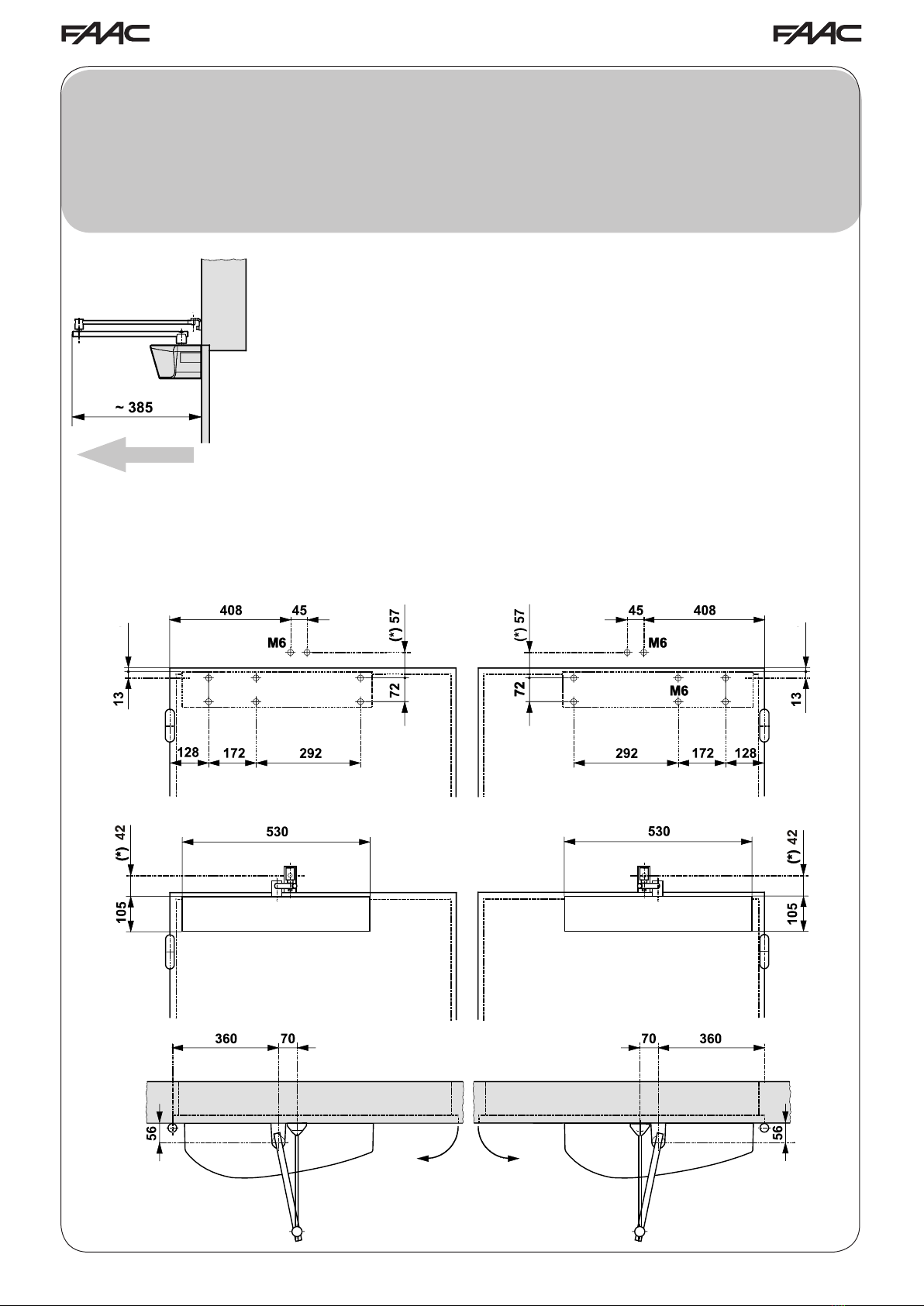

* Quota con albero standard 20 mm. Nel caso fosse necessario aumentare la distanza tra l’operatore ed il braccio,

utilizzare le prolunghe opzionali ( Quota con albero 50 mm = 107mm. - Quota con albero 80 mm = 137 mm)

* Standard shaft dimension 20 mm. Should it become necessary to increase the distance between the operator

and the arm, use the optional extensions (dimension with 50 mm shaft = 107 mm - with 80 mm shaft = 137 mm)

* Cote avec arbre standard de 20 mm. S’il est nécessaire d’augmenter la distance entre l’opérateur et le bras,

utiliser les rallonges en option (Cote avec arbre de 50 mm = 107mm. - Cote avec arbre de 80 mm = 137 mm)

* Cota con árbol estándar 20 mm. Si fuera necesario aumentar la distancia entre el operador y el brazo, utilizar

los alargues opcionales (Cota con árbol 50 mm = 107mm. - Cota con árbol 80 mm = 137 mm)

* Maß mit Standardwelle 20 mm. Wenn der Abstand zwischen dem Antrieb und dem Arm erhöht werden muss,

die optionalen Verlängerungen verwenden (Maß mit 50-mm-Welle = 107 mm; Maß mit 80-mm-Welle = 137 mm)

* Afstand met standaardas 20 mm. Indien de afstand tussen de aandrijving en de arm groter moet zijn, gebruik

dan de optionele verlengstukken (Afstand met as 50 mm = 107mm. - Afstand met as 80 mm = 137 mm)

* Mått med standardaxel 20 mm. Om det är nödvändigt att öka avståndet mellan dörröppnaren och armen,

använd de extra förlängningarna. (Mått med axel på 50 mm = 107mm - mått med axel 80 mm = 137 mm.)

gh

BRACCIO ARTICOLATO (B=250-160 mm)- ARTICULATED PUSH ARM (B=250-160 mm) -

BRAS ARTICULÉ À POUSSÉE (B=250-160 mm) - BRAZO ARTICULADO DE EMPUJE (B=250-160 mm)-

DRUCKGELENKARM (B=250-160 mm) - KNIKARM MET DUWSYSTEEM (B=250-160 mm) - LEDAD ARM (B = 250-160 mm)

- LUNGHEZZA ANTA - LEAF LENGTH

- LONGUEUR VANTAIL -

FLÜGELLÄNGE

- LONGITUD HOJA - LENGTE VLEUGEL

DÖRRBLADETS LÄNGD ( mm )

PESO PORTA - LEAF WEIGHT - POIDS VANTAIL -

FLÜGELGEWICHT - PESO DE LA HOJA - GEWICHT VLEUGEL -

DÖRRBLADETS VIKT (Kg)

20 40 80 100 120 140 160 180 200 220 240 260

700 853222111111

800 7 4 2 2 1 1 1 1 1

900 6 3 2 1 1 1 1

1000 5 3 1 1 1

1100 4 2 1 1

1200 4 2 1

1300 3 2

1400 3 1

-Velocità apertura e chiusura da impostare tramite KP CONTROLLER

- Opening and closing speed to be set via KP CONTROLLER

- Vitesse d’ouverture et de fermeture à régler par KP CONTROLLER

- Über den KP CONTROLLER einzugebende Öffnungs- und Schließungsgeschwindigkeit

- Velocidad de apertura y cierre para congurar mediante KP CONTROLLER

- Snelheid openen en sluiten in te stellen via KP CONTROLLER

-Öppnings- och stängningshastighet ställs in med programmeringsenheten KP CONTROLLER

BRACCIO ARTICOLATO ( B=0 mm-) ARTICULATED PUSH ARM (B=0 mm) -

BRAS ARTICULÉ À POUSSÉE (B= 0 mm) - BRAZO ARTICULADO DE EMPUJE (B= 0 mm) -

DRUCKGELENKARM (B= 0 mm) - KNIKARM MET DUWSYSTEEM (B= 0 mm) - LEDAD ARM (B = 0 mm)

- LUNGHEZZA ANTA - LEAF LENGTH

- LONGUEUR VANTAIL -

FLÜGELLÄNGE

- LONGITUD HOJA - LENGTE VLEUGEL

DÖRRBLADETS LÄNGD ( mm )

PESO PORTA - LEAF WEIGHT - POIDS VANTAIL -

FLÜGELGEWICHT - PESO DE LA HOJA - GEWICHT VLEUGEL -

DÖRRBLADETS VIKT (Kg)

20 40 80 100 120 140 160 180 200 220 240 260

700 8 5 3 2 2 2 1 1 1 1 1 1

800 7 4 2 2 1 1 1 1 1

900 6 3 2 1 1 1 1

1000 5 3 1 1 1

1100 4 2 1 1

1200 4 2 1

1300 3 2

1400 3 1

-Velocità apertura e chiusura da impostare tramite KP CONTROLLER

- Opening and closing speed to be set via KP CONTROLLER

- Vitesse d’ouverture et de fermeture à régler par KP CONTROLLER

- Über den KP CONTROLLER einzugebende Öffnungs- und Schließungsgeschwindigkeit

- Velocidad de apertura y cierre para congurar mediante KP CONTROLLER

- Snelheid openen en sluiten in te stellen via KP CONTROLLER

-Öppnings- och stängningshastighet ställs in med programmeringsenheten KP CONTROLLER