2

ENGLISH

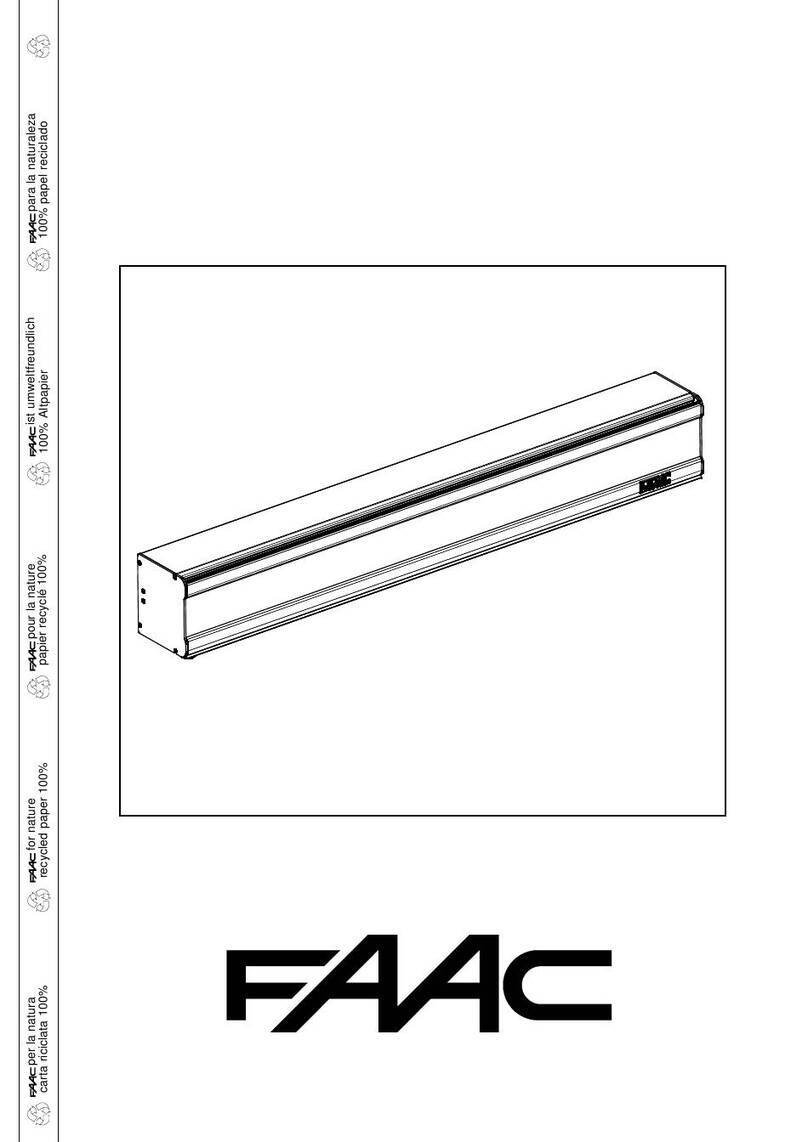

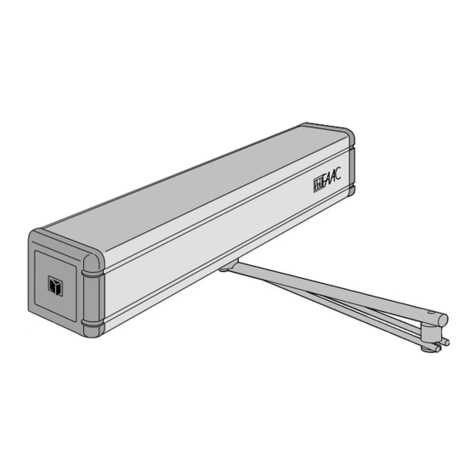

AUTOMATIC DOOR A140 AIR-T

fig. 1

1 DESCRIPTION

The FAAC series A140 AIR-T systems automatically activate,

manage and control the operation of single-leaf or two-leaf

telescopic sliding doors.

The FAAC series A140 AIR automated systems are supplied

completely assembled, wired and tested in the configuration

requested by the customer, using the appropriate order form, or

in kits to be assembled by the installation technician.

An automation cross beam (fig.1) consists of the following parts:

Support profile (fig.1 ref.)

This is the profile used when the cross beam can be completely

secured to a load bearing structure.

Telescopic profile (fig.1 ref. )

This profile is used to assemble the internal carriages

Motor unit (fig. 1 ref.)

The 24V= motor has an encoder and a leaf locking system

(accessory).

The Electronics Module includes:

Control unit (fig. 1 ref. )

When powered, the control unit with microprocessor, initialises

the door’s operational parameters.

Power feed unit (fig. 1 ref. )

The power feed unit, directly connected to the control unit,

supplies the voltage values required to correctly power the

automated system.

Internal and external carriages supporting the leaf (fig.1 ref.

)

The carriages have two wheels with ball bearings, one counter

thrust wheel in the top part, and a screw based system for

adjusting the height of the leaves.

Drive belt (fig. 1 ref. )

Transmission pulley unit (fig. 1 ref. )

1.1 ACCESSORIES SUPPLIED WITH THE CROSS BEAM

These parts are assembled on the cross beam.

Closing housings (fig. 1 ref. )

This is the aluminium profile enabling closure of the automated

system. The side panels (fig.1 ref.) completely close the system.

Motor lock unit (fig. 1 ref. )

The motor lock unit guarantees mechanical locking of the door

while the leaves are closed. The motor lock unit can be used for

single and double leaves.

The motor lock unit is supplied with the internal release device

(Fig.1 ref.) used for emergency opening if needed. It is also

designed for installation of the external release (optional) if

required. The motor lock unit acts directly on the motor, locking

it mechanically.

Supervision of motor lock

It controls if the motor lock unit is operating correctly and verifies

if the door is actually closed. If necessary, the system is designed

for remotely activating an indicator light or buzzer/siren.

Emergency battery (fig. 1 ref. )

In the event of a mains power cut, the battery kit enables the

automated system to operate until its charge is exhausted. The

battery condition test is performed continuously by the control

unit.