6 / 36 Festo 7ADN-KP_ADN-ELa_en

1 Important information

1.1 About these repair instructions

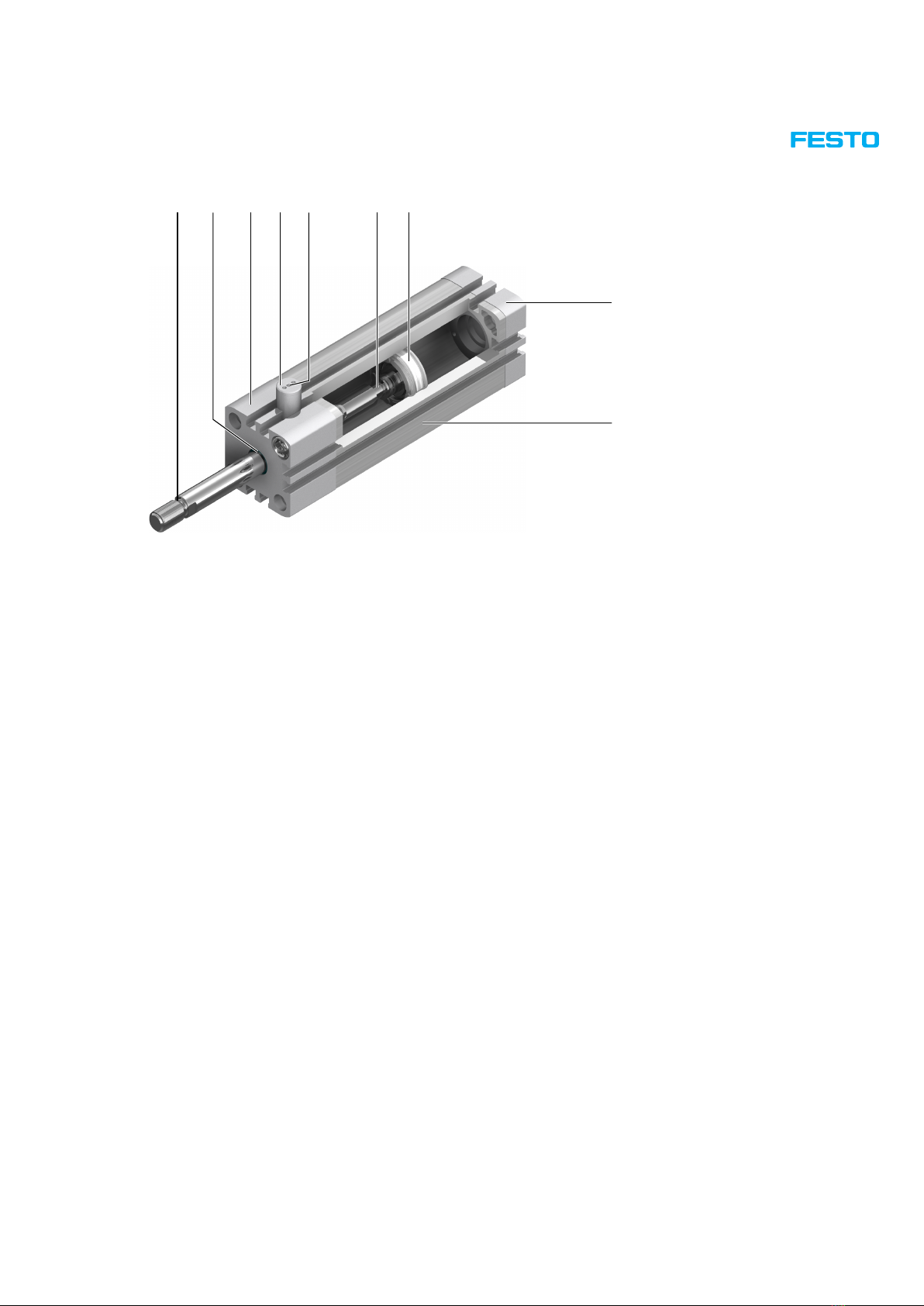

This document contains important

information about the professional

repair of the cylinder with piston rod

of the type ADN-…-KP and ADN-…-EL.

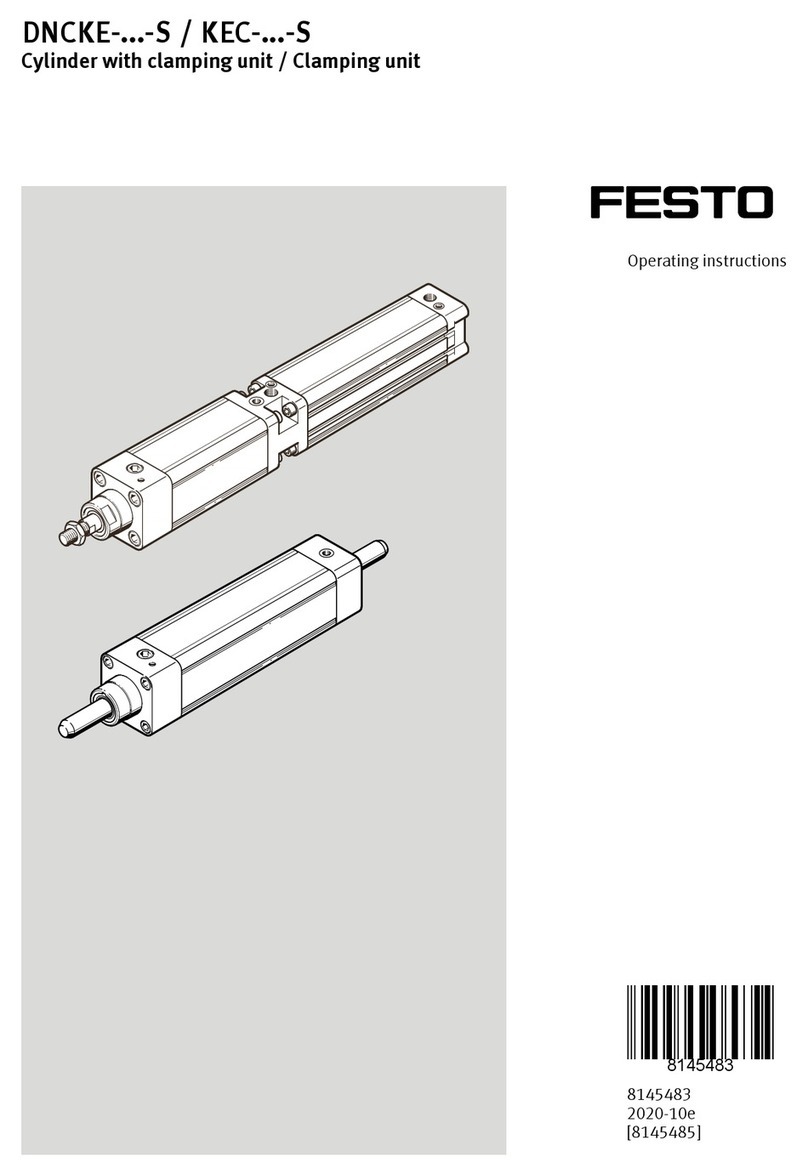

The cylinder with piston rod ADN-…-KP

and ADN-…-EL is fully repairable in the

event of damage due to normal wear.

The entire cylinder must be replaced

in the event of damage to the cylinder

barrel.

Before carrying out a repair, the

relevant chapter in these instructions

must be read in full and followed

consistently.

For reasons of clarity, these repair

instructions do not contain complete

detailed information. The following

documents should therefore also be

available when repairing the cylinder

with piston rod:

• Operating instructions for the

respective cylinder with piston

rod

Contains information about

the operating elements and

connections of the cylinder with

piston rod as well as the function,

structure, application, installation,

commissioning, maintenance and

care, etc. can be found on the

Festo website (www.Festo.com).

• Spare parts documentation

Contains an overview of the spare

and wearing parts as well as

information on their installation.

Can be found in the online spare

parts catalogue on the Festo

website (spareparts.festo.com).

• Assembly aids

Contains an overview of available

assembly aids such as lubricating

greases, locking agents,

maintenance tools, etc. (aids

for assembly and maintenance).

Can be found in the online spare

parts catalogue on the Festo

website (www.Festo.com).

1.2 Pictograms used in these repair instructions

Warning

This sign indicates a dangerous situation for persons and/or the product. Failure to observe this warning can result

in injury to persons and/or damage to the device.

Note

This sign provides important tips and information that can make your work easier.

Environment

This sign provides information on the steps required for environmentally-friendly use of materials and equipment,

as well as the guidelines and regulations that may need to be observed.

Accessories

This sign contains information on accessories and attachments relevant to the context.

Documents

This sign contains references to other chapters or documents containing additional information.