ABOUT THIS MANUAL

INFORMATION

This document contains general descriptions which are verified to

be accurate at the time of printing. However, because continuous

improvement is a goal at GARO, we reserve the right to make

product and software modifications at any time. This range is

subject to continual product development. Errors, typos and

omissions excepted. Latest manuals can always be found at

https://www.garo.se

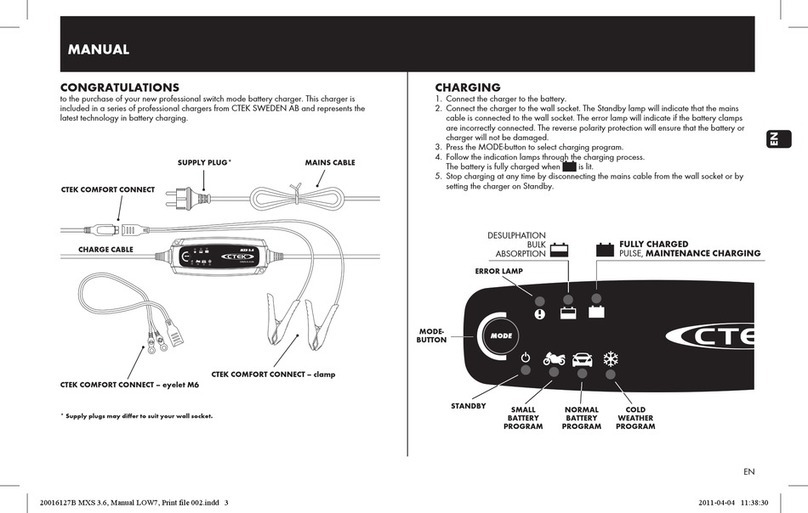

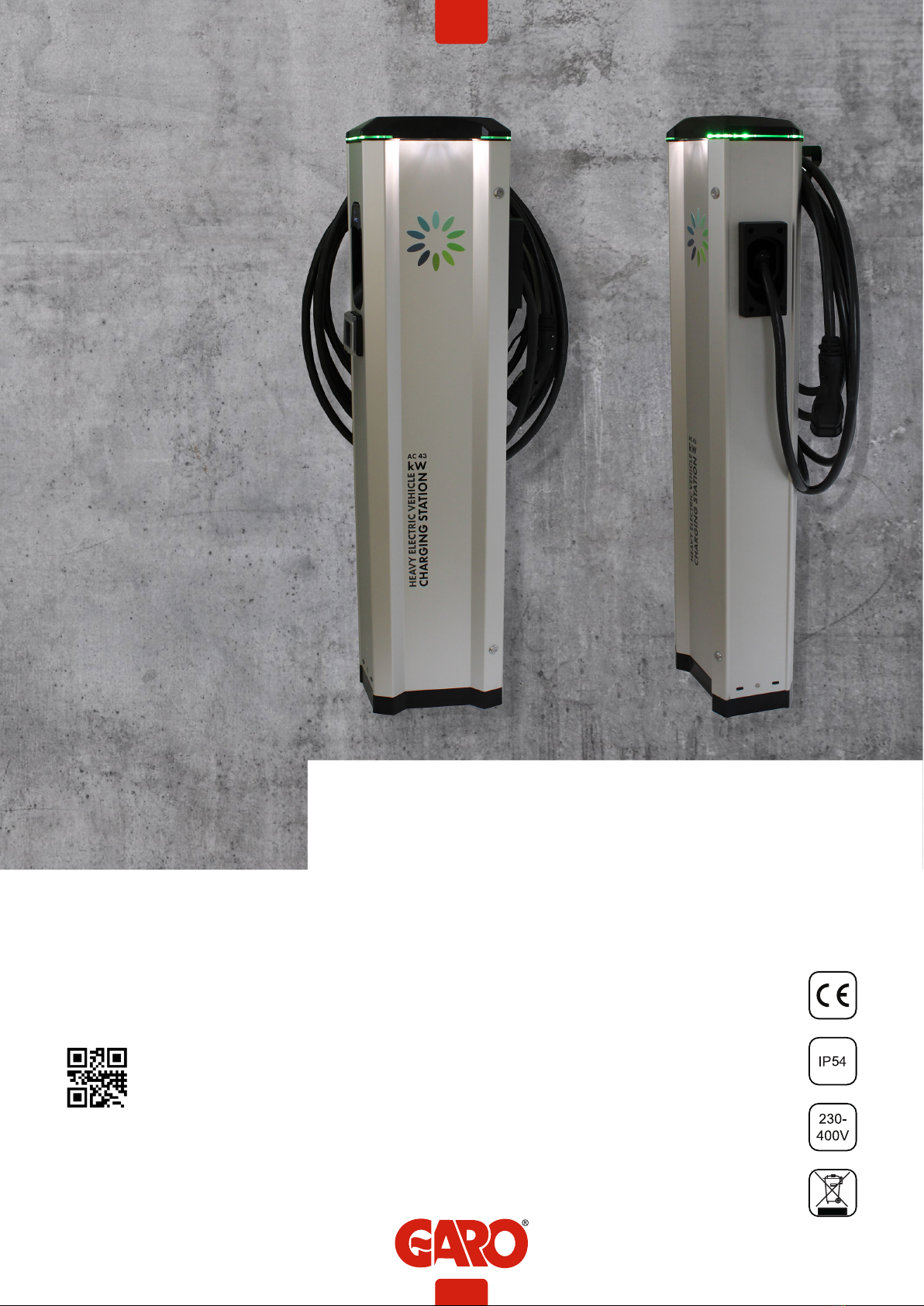

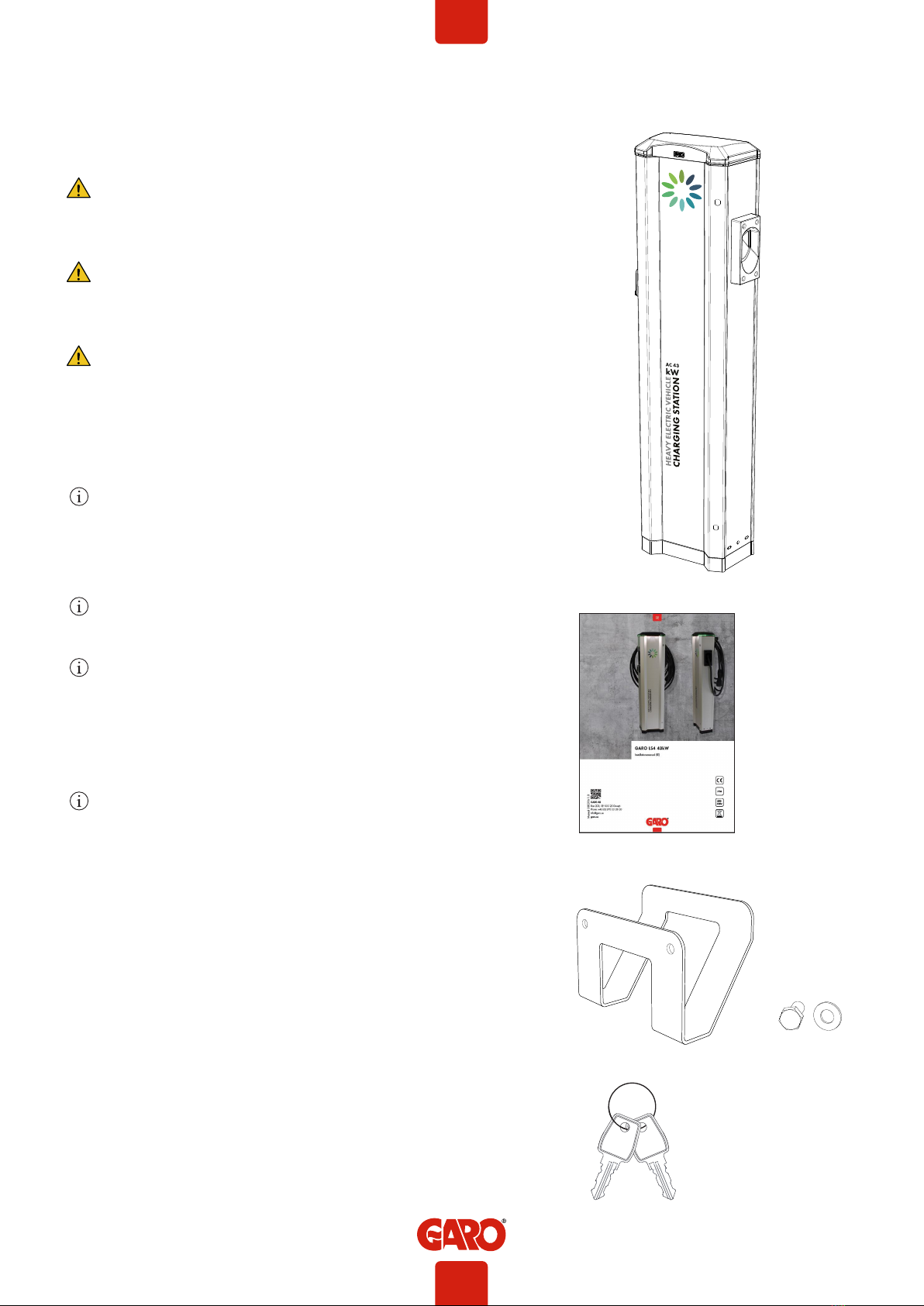

GARO LS4 is an EVSE station for Mode-3 AC charging up to

43kW.

Below are some example of standard features:

• Fixed cable for Mode-3 EV charging.

• Suitable for installation on ground.

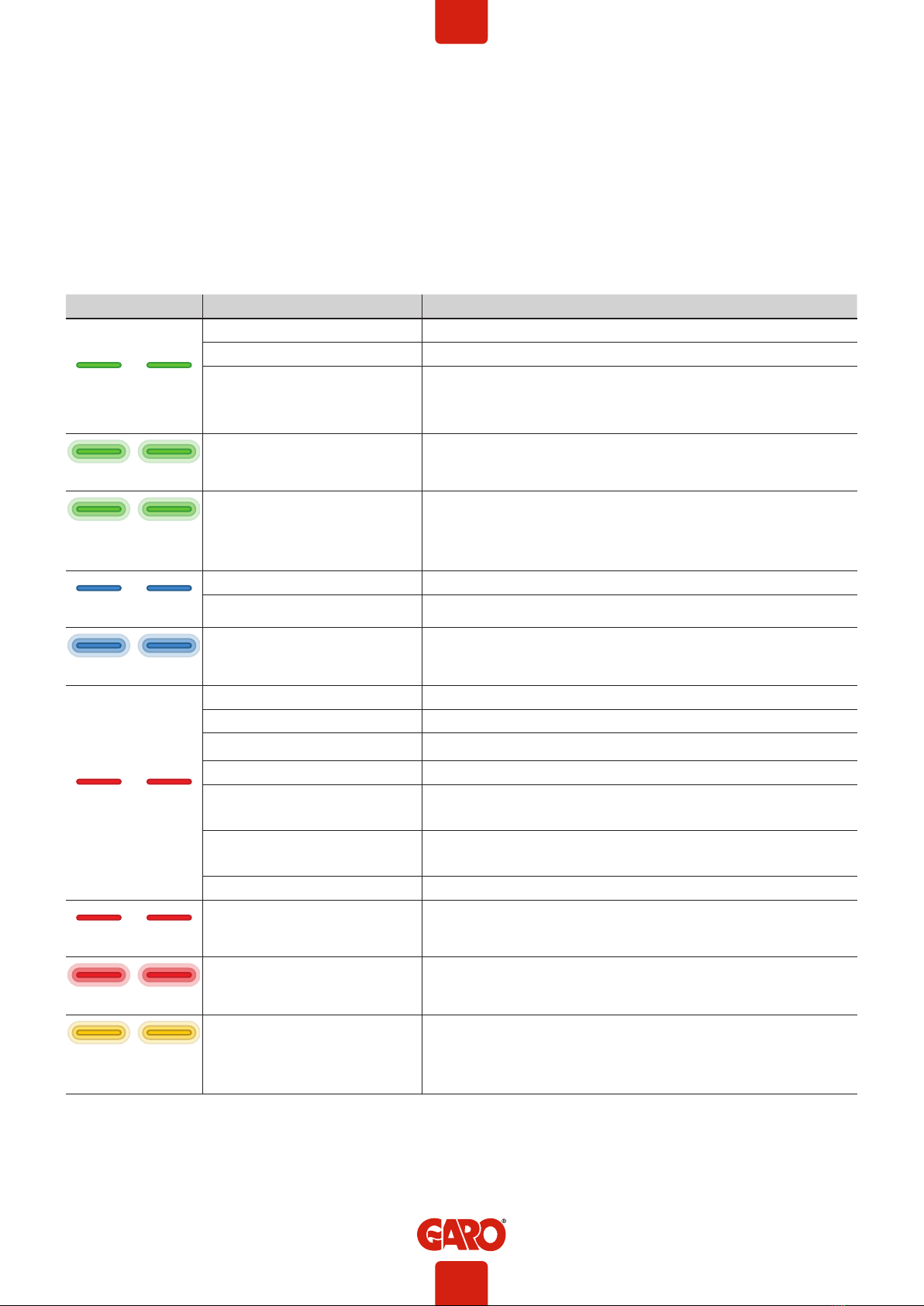

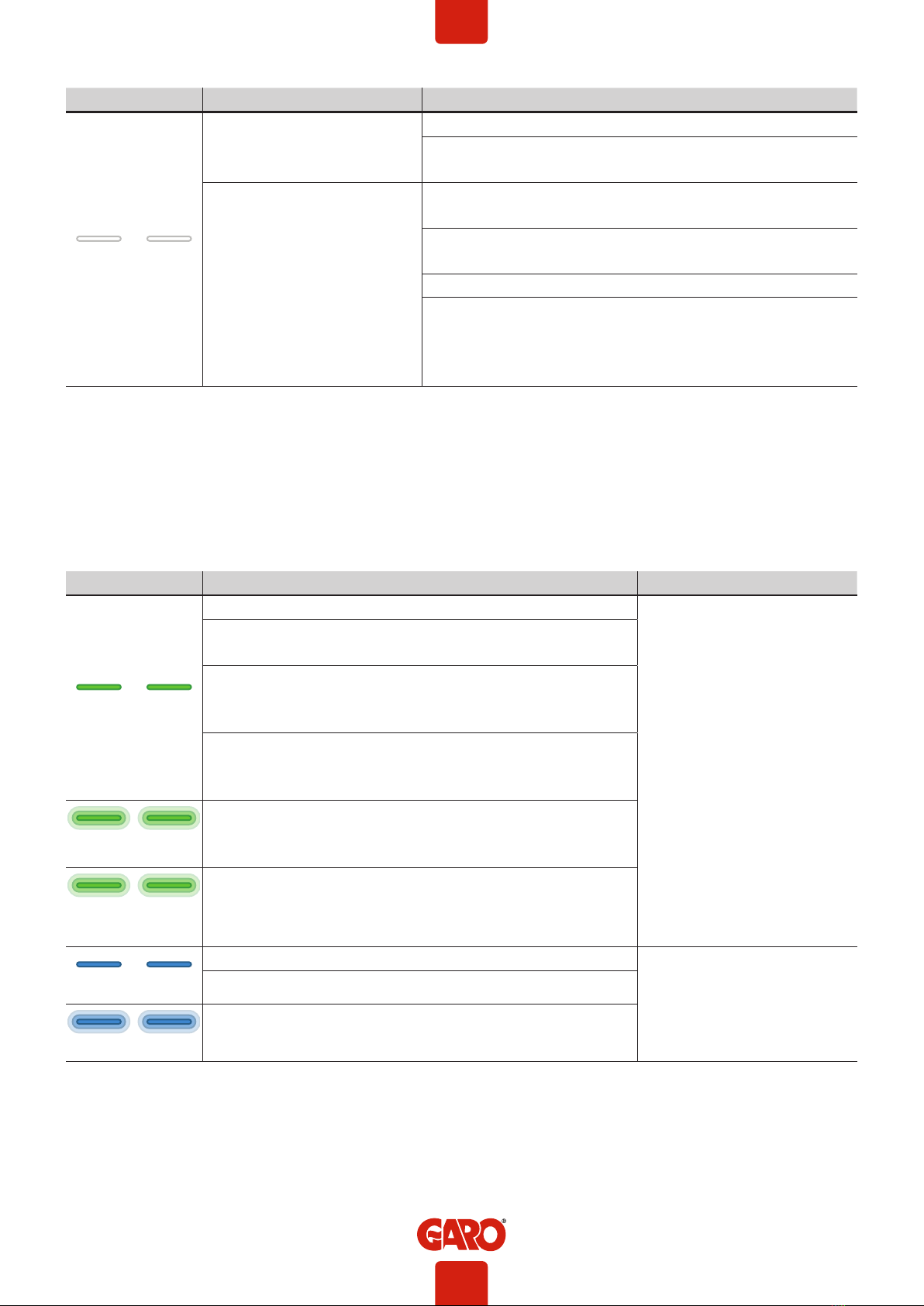

• LED status indication.

• Upgradeable firmware*

• Visible energymeter

• OCPP via 4G or LAN*

• RFID reader for secure authorization (not activated as default)*

LS4 supports following features:

• External DLM energy meter*

• Cluster installation of multiple LS4 via Ethernet*

• Cluster installation of multiple LS4 MINI, LS4 and GLB+ via

Ethernet*

* Require certified technician

SAFETY INFORMATION

The LS4 stations are designed exclusively for charging

electric vehicles.

All installation must be carried out by an authorized

installer and comply with local country installation

regulations. If any questions, please contact your local

electrical authority.

Refer to local standards and regulations not to exceed

charging current limitations.

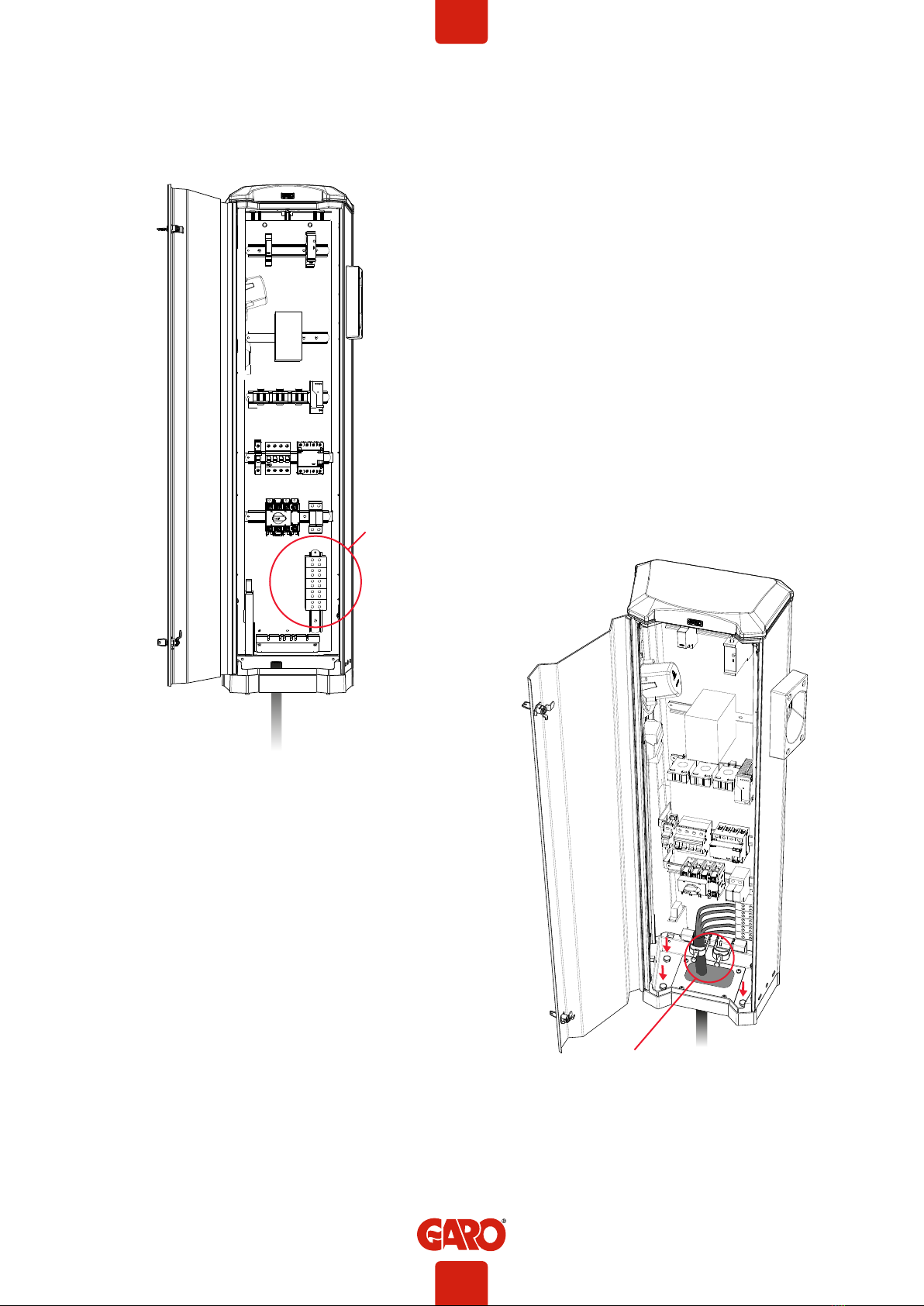

To even out the load, it is important to rotate the phases

when connecting several of LS4 stations to the same

system. Note that 1-phase charging is common in electric

vehicles and L1 (left side) and L2 (right side) in the LS4 is

used for this purpose.

Ventilation signal from EV is not supported. This means that

test of “State D” is not possible.

Adapters for charging connectors are not allowed to be

used.

Cord extension sets for charging cable is not allowed to

be used.

Do not use private power generators as a power source

for charging.

Incorrect installation and testing of the LS4 stations could

potentially damage either the vehicles battery and/or the

LS4 itself.

Do not operate the LS4 stations in temperatures outside its

operating range – see technical specifications.

INFORMATION

3

EN