MANUAL

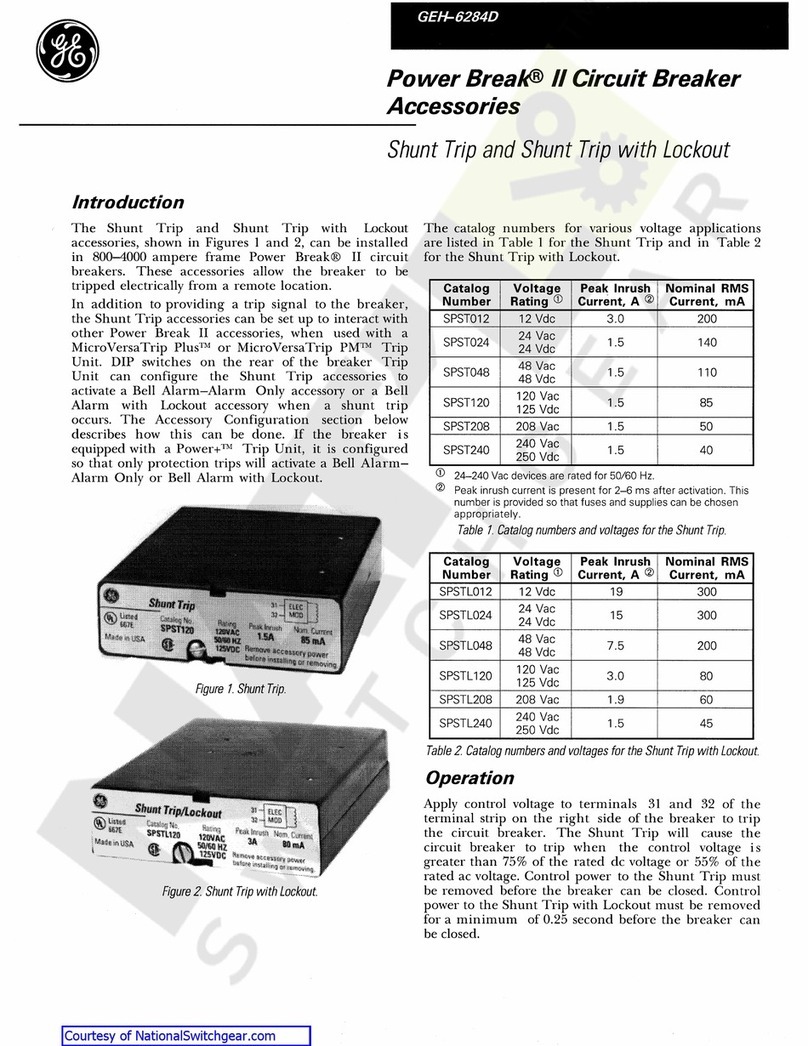

CLOSING

AK-16/26 manually operated

breakers

are

closed by turning the handle

90

degrees

counterclockwise and then clockwise

90

degrees back to the original position. The

initial counterclockWise movement resets

the closing mechanism. The clockwise

movement closes the breaker.

'!'he closing mechanism

of

the

AK~2/3

60/76/100 manual

breakers

is

a

spring

charged mechanism

~imilar

to the

one

used

on AK-2/3-50/76/.100 electrically op-

erated

breakers,

AK-2/3-50/75/100 manual

breakers

are

closed

by

rotating the closing

handle counterclockwise through approxi-

mately 120 degrees, and then clockwise

back through

120

degrees to·

the

normal

handle position. Four suchcomplete move-

ments

of

the handle

are

required to close

the

breaker.

During the four

counterclock~

wise movements and the

first

three clock-

wise movements

of

the handle, the springs

are

charged. After approximately 70

de

..

grees

travel

of

the fourth clockwise handle

movement, the spring ·charged mechanism

is

driven over

...

center

ttµd

the

breaker

closes. A charge

..

indioator, numbered 1 to

4, viewed through the breaker front

esA

cutcheon, moves with each complete handle

movement and indicates the number of

complete handle movements that have been

performed.

AK-4/5R50 manual brealters

are

also

closed

by

means

of

energy releasedthrough

the discharge of a closing spring. The

charging

of

the spring

is

done by a single

stroke

of

the brealcer handle. This involves

raising the handle counter.clqckwise from

the vertical position until

a·

stop

is

en

..

countered after about 140 degrees

of

rota-

tion. The spring

is

then extended to

its

fully charged position

as

the handle is

re-

turned to

its

normal vertical position,

Release of the spring, and resultantclosina

of

the

breaker,

occurs when the

11

closel'l

button in the escutcheon

is

pushed.

(The

breaker

will close onlr ifthe racking

mech~

anism

is

in the

"CONN'

or

11

TEST

11

position.)

ELECTRICAL

CLOSING

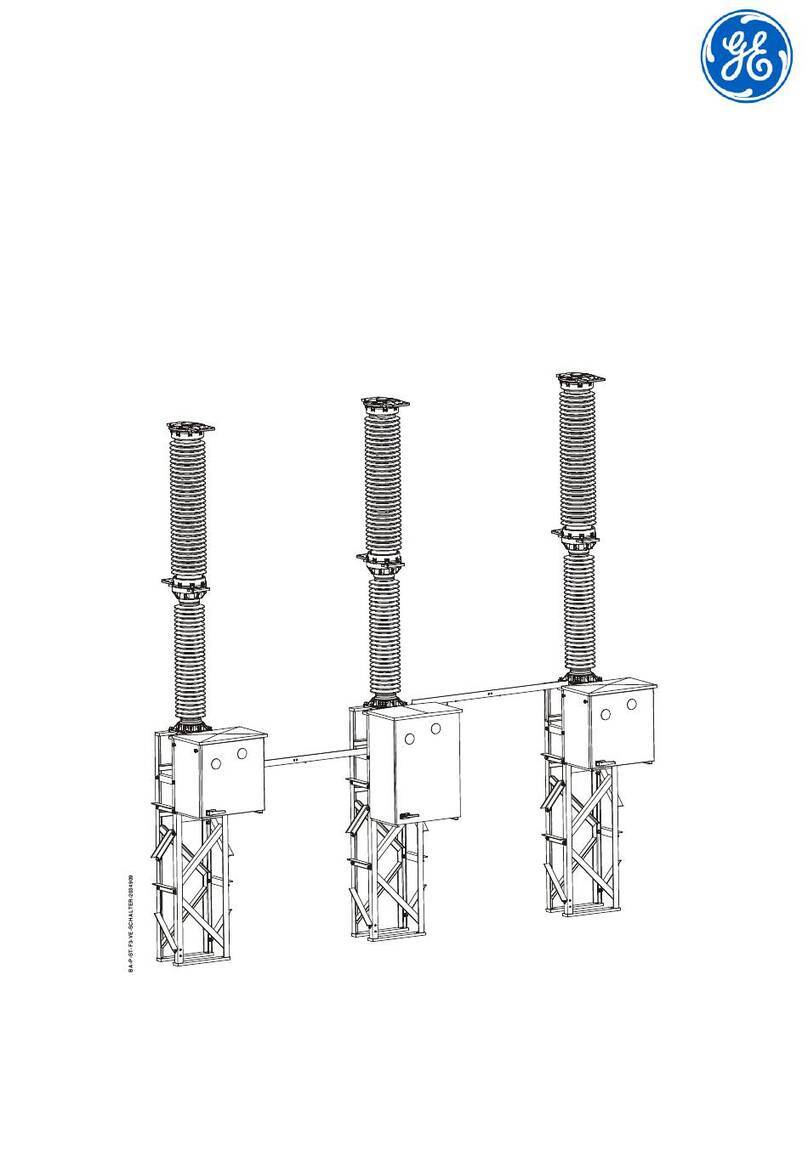

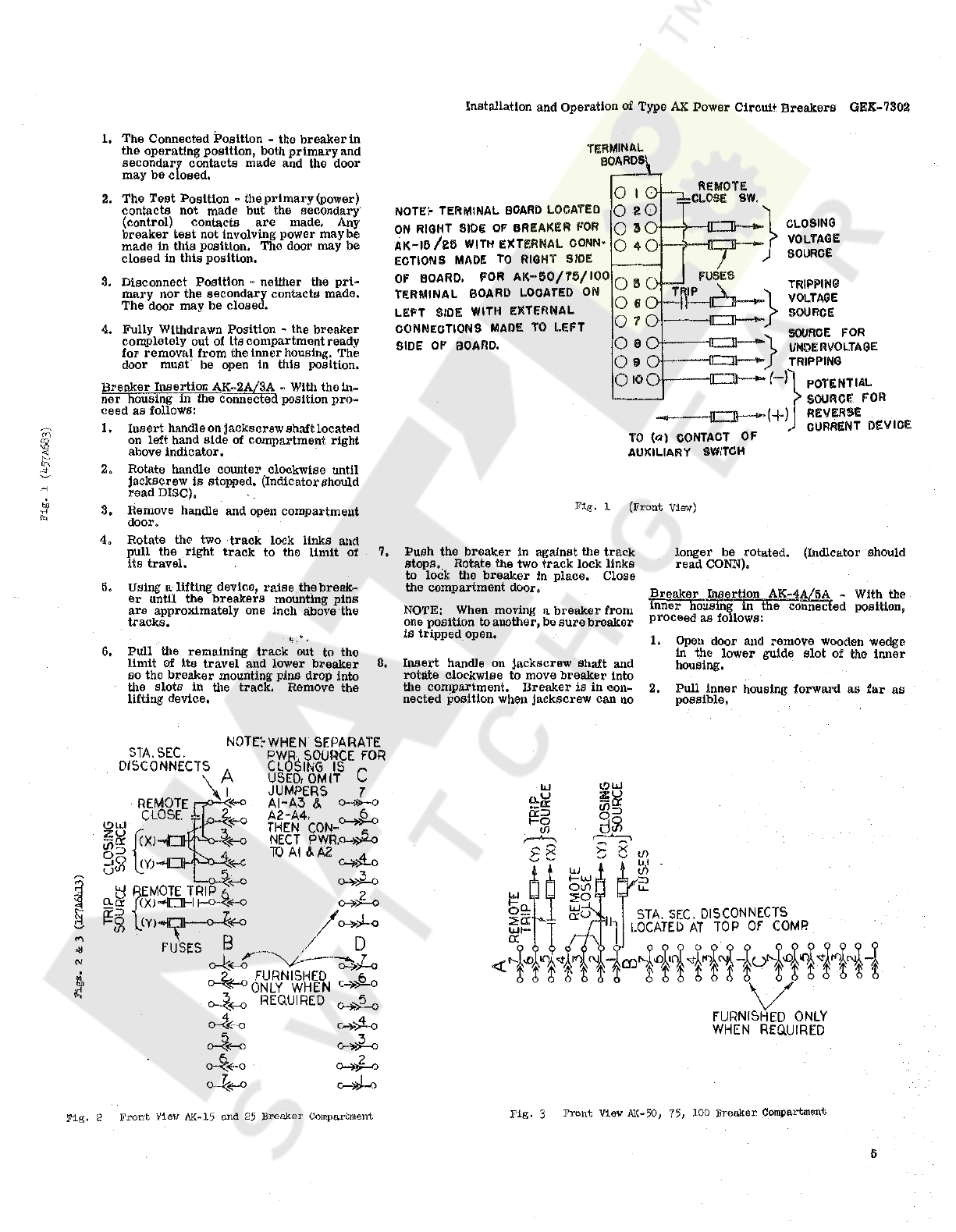

(Figures 6 and

7)

STANDARD

BREAKERS

AK~15

and AK-25 electrically onerated

REMOTlt-hJ

Cl..OOIMO

OL.OSE

-1

=

SWITCH

y

t:

~~

~

O>

L

___

6h

vj:~,~

'I

x -

COIL

L.EGENO

J1.

• X

RELAY

COIL

1J

•

){

REL.A'(

CONTAOT

::t~

• Y

REI.AV

COIL

.If

u Y

RELAY

O.ONTAOT

t"il·bb •

MEOHANIOALLY

OPERATED

&WITOH!8

:f

•NORMALLY

OPEN

SWITCH

OON'fAOT8

*.

NORMALLY

OLOMD

swtrOtt

OONTAOTG

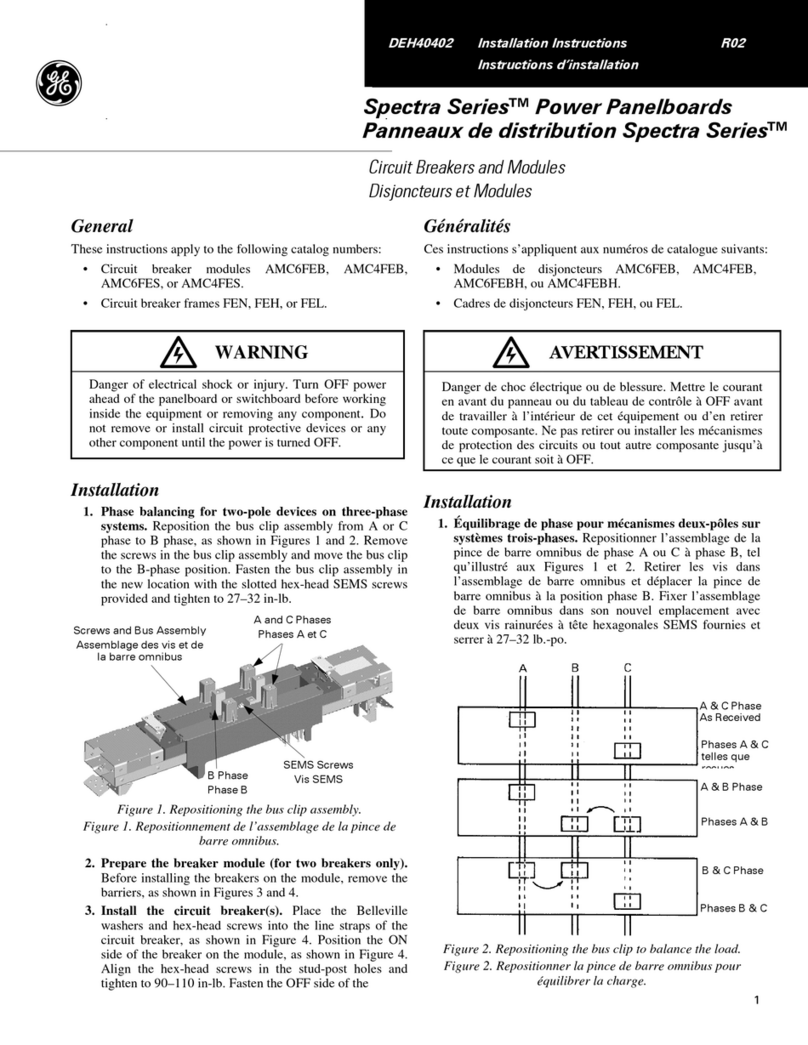

Fig,

6

Simplified

Elementary

Diagram

In-te~'nal

Wiring

AK-15

and 25

Installation and Operation

of

Type

AK

Power Circuit

Breakers

GEK-'7302

OPERATION

breakers

are

closed

by

a solenotdcoll. The

armature

of

the solenoid

is

llnk.ed

to

the

breaker mechanism and tta movement,

operating through

t_he

mechanism, closes

the breaker. The closing Solenoid circuit

may be operated

by

a push button closing

switch

on

the breaker

or

by

a remote

switch

or

relay, depending

on

the individual

arrangements desired.

When

a closing

signal

ts

given, the X relay coil

ts

ener-

gized.and tt

in

turn closes

its

contacts.

One

of

these

seals

in

the X coil circuit; the

other three, which

are

arranged in

series,

energize the solenoid closing coil.

As

the

breaker closes, a mechanically operated

switch opens one

pair

of

its

contacts

(bb)

and. closes another (aa). The contacts

which

Opeh

cut out the X relay

coU.

The

contacts which close

~.nergize

the Y rela,y

coll, whose contacts

now

seal

in the Y coil

and hold open.the X relay collcircuit. This

prevents another closing ope1·ation

if

one

of

the protective ·devices·

ope"rateS

to trtp

the breaker before contact

at

the closing

switch

ls

released,

Large

AK

breakers

(AK-50/75/100)

are

closed

by

the discharge

of

a closing

spring, This rotates a crankshaft which,

by

means

of

an attached

roller,

operates

a closing cam, forcing the movablebreaker

contacts against the .stationary contacts.

1'he

closing spring

is

charged through the

operation

of

a motor and gear reduction

unit.

The electrical control system

ts

com-

prised

of

an X relay,

two

double contact

mechanically operated switches (F and

G),

a push button closing switch and

any

means

for remote closing which the

user

may

incorporate into the system.

When

voltage

is

first

applied to the

breaker,

(before

any

closing signal

is

given) the motor

is

ener~

gized through

two

of

the X relay contacts

and the

two

G switch contacts. The motor

tl1en

compresses the closing springs

to

the

"pre~charged"

position

at

which point the

mechanically operated F and G switches

are

operated. Thia opens the G contacts,

stopping the motor, and closes the F con

..

tacts, which readies the system for the

actual closing

of

the breaker,

When

the

push button

or

remote switch signals for

a closing operation, the X relay coli is

"'T

,,

fl1

i~~~~tf

:

' --lt--J

""

~~

'

REMOTE

_____t-:

01.0SF.

oo

,,

o>

-L

J__

~

x

LEGEND

@ •

OLOSING

MOTOR

ll

e

RELAY

COIL

,,, •

RELAY

OONTAOT

F&G •

MEOHANIOALLY

OPERATED

SWITGtlES

+•

NORMALLY

OPEN

SWITOff

OONTAOTS

JI'>

•

NORMAL.LY

CLOSEO

SWITCH

OOHTA01S

L •

AUXILIARY

SWITCH

CONTACT

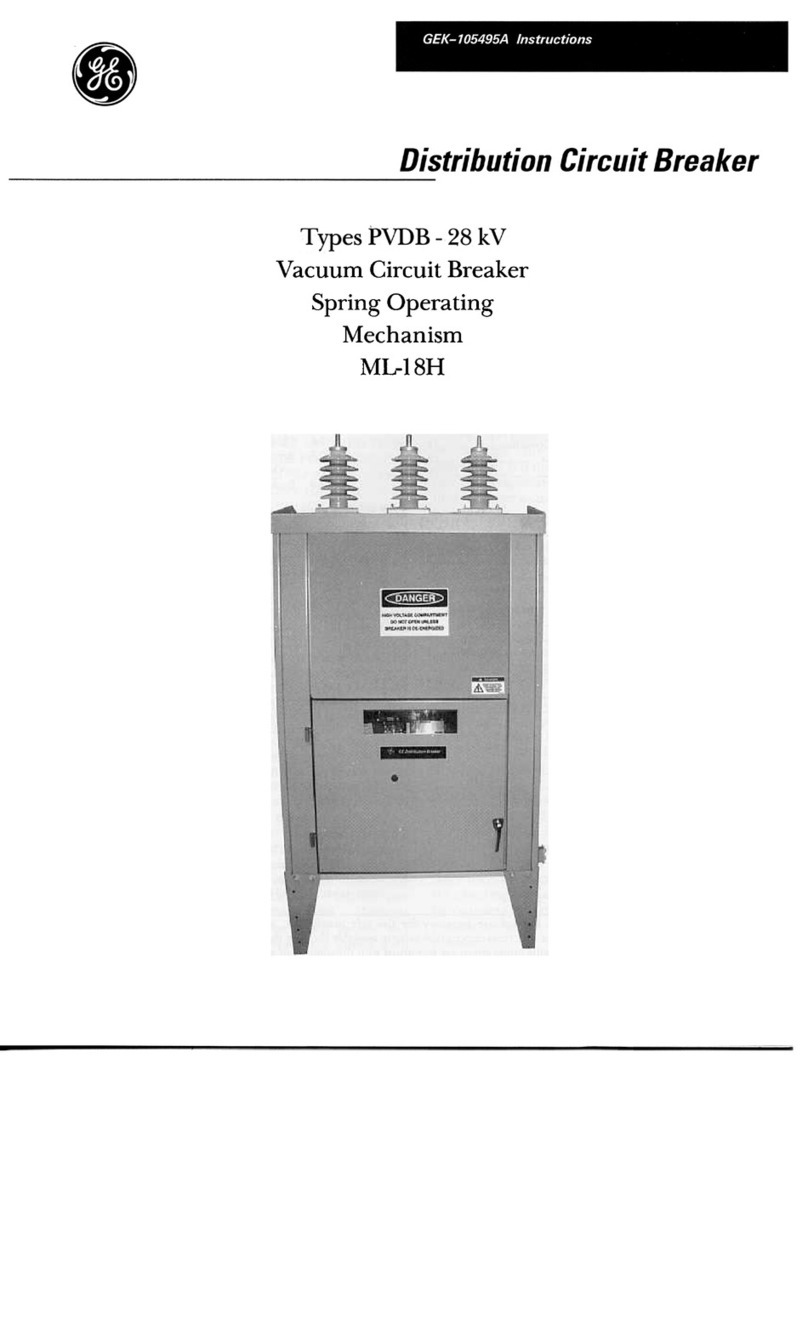

I•'ig. 7

Simplifiea

]gltimentary

D1.agrum

In·ternal

Wiring

AK~50

1

75

and

100

l~ig.

8

energized, operating the

:X

contacts. This

seals

in the X

relay

and energizes tho

motor once again and the closing operation

takes place.

QUICK

CLOSE BREAKERS

(Figure

8)

Functionally, tho quick close

me

ch

..

anism differs from the standard electrical

mechanism in that

thepre

..

chargeoperation

ia extended

to

completely

cha1•ge

theclosing

springs.

At

the end

of

the charging opera

..

tion, which takes apP,roximately 5 seconda,

(2

seconds

for

AK-4/6·50

breakers)

a latch

plate engages the prop

roller

to preventthe

closing springs from discharging.

With the closing springs fully charged

the breaker

is

ready for a closingoperation

upon release

of

the prop,

roller.

Thia

may

be accomplished

either

manually1 by de··

pressing the closing

lever

on the oreaker,

or

electrically

by

closingthe remote closing

switch,

Upon

the

release

of

the prop

roller

the closing springs discharge and

close the breaker

h1

the same manner

as

on thestandard electrical

breaker.

AK

..

4/5

..

50

breakers

are

closed through a remote

switch

or

the close button in the escutch-

eon,

(if

the breaker

is

equipped

With

a push

button closing switch),

With control voltage applied, themotor

is

energized through the G switchcontacts,

and charges the closing springs.

When

the

springs reach the fully charged position,

the mechanicallyoperatedswitchesoperate,

reversing their contacts.

Upon

operation

of

these switches the motor

ts

stopped by

the opening

of

the G switch, The closing

of

the F switch

prepares

the breaker for

~

closing operation.

7

Courtesy of NationalSwitchgear.com