NX-320E Power Supply 3

TABLE OF CONTENTS

I. GENERAL DESCRIPTION ............................................................................................................4

II. ORDERING INFORMATION ........................................................................................................4

III. UNDERWRITERS LABORATORIES INFORMATION .................................................................4

IV. ENCLOSURE DIAGRAM..............................................................................................................5

V. BATTERY CALCULATION TABLE...............................................................................................5

VI. TERMINAL DESCRIPTIONS........................................................................................................6

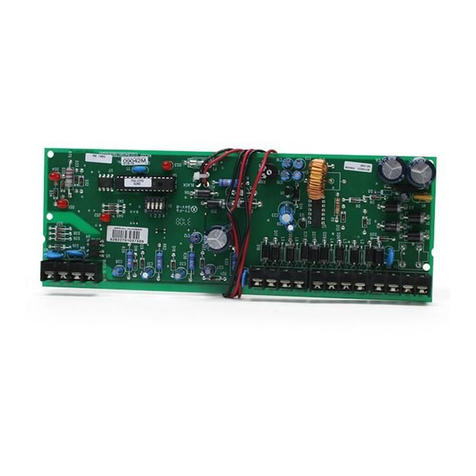

VII. WIRING REQUIREMENTS...........................................................................................................6

VIII. LAYOUT .......................................................................................................................................7

IX. ADDRESSING ..............................................................................................................................8

X. ENROLLING .................................................................................................................................8

XI. UNDERSTANDING THE LEDS....................................................................................................8

XII. PROGRAMMING .........................................................................................................................9

I.A. USING THE LED KEYPAD.................................................................................................. 9

I.B. USING THE LCD KEYPAD................................................................................................ 10

I.C. PROGRAMMING DATA ................................................................................................... 10

LOCATION 0 PROGRAMMING EVENT & TIME FOR OUTPUT A........................ 11

LOCATION 1 PROGRAMMING SPECIAL FEATURES FOR OUTPUT A .............. 12

LOCATION 2 PROGRAMMING THE EVENT & TIME FOR OUTPUT B................ 12

LOCATION 3 PROGRAMMING SPECIAL FEATURES FOR OUTPUT B............... 12

LOCATION 4 PROGRAMMING THE EVENT & TIME FOR OUTPUT C................ 13

LOCATIONS 6 & 7 RESERVED........................................................................................ 13

LOCATION 8 CODES 1-10 OUTPUT ENABLE....................................................... 14

LOCATION 9 CODES 11-20 OUTPUT ENABLE..................................................... 14

LOCATION 10 CODES 21-30 OUTPUT ENABLE..................................................... 14

LOCATION 11 CODES 31-40 OUTPUT ENABLE..................................................... 14

LOCATION 12 CODES 41-50 OUTPUT ENABLE..................................................... 14

LOCATION 13 CODES 51-60 OUTPUT ENABLE..................................................... 14

LOCATION 14 CODES 61-70 OUTPUT ENABLE..................................................... 15

LOCATION 15 CODES 71-80 OUTPUT ENABLE..................................................... 15

LOCATION 16 CODES 81-90 OUTPUT ENABLE.................................................... 15

LOCATION 17 CODES 91-99 OUTPUT ENABLE.................................................... 15

LOCATION 18 A/C DELAY AND DYNAMIC BATTERY TEST ................................. 15

LOCATION 19 DEVICE OPTIONS ........................................................................... 15

XIII. PROGRAMMING WORKSHEETS .............................................................................................16

XIV. SPECIFICATIONS.......................................................................................................................20