GE POWER-BREAK TAK-TS1 User manual

Other GE Test Equipment manuals

GE

GE EVT-Pro User manual

GE

GE DMS Go+ User manual

GE

GE ADTS 405F Mk2 Setup guide

GE

GE Druck DPI 610 User manual

GE

GE Druck DPI 620-IS User manual

GE

GE PK-2 User manual

GE

GE Druck PC6-IDOS User manual

GE

GE Druck DPI 821 User manual

GE

GE Druck ADTS 2 Series Use and care manual

GE

GE MicroVersaTrip TVTS1 User manual

GE

GE Druck MCX-II User manual

GE

GE PACE5000 Use and care manual

GE

GE Druck ADTS 542F Setup guide

GE

GE Druck DPI 880 User manual

GE

GE Multilin EPM 7000 User manual

GE

GE Druck DPI 610 User manual

GE

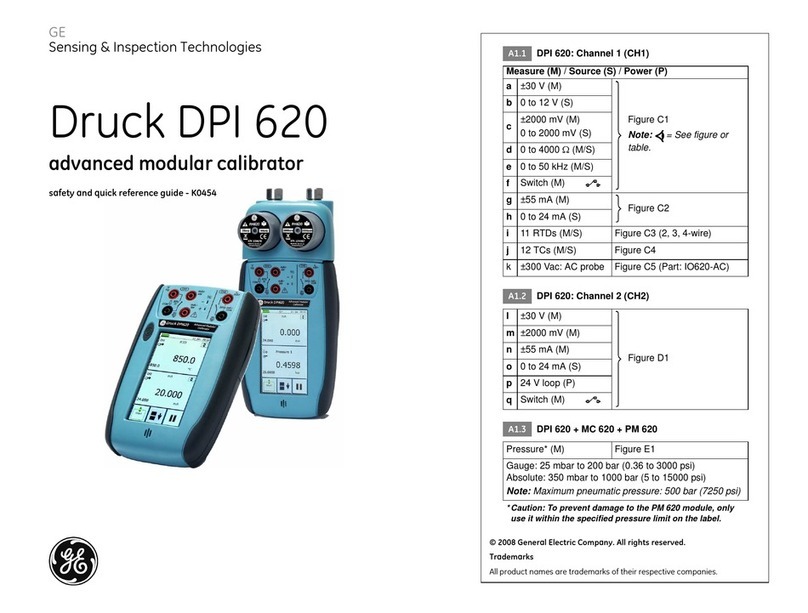

GE Druck DPI 620 User manual

GE

GE EntelliGuard User manual

GE

GE Druck DPI 832 User manual

GE

GE Druck DPI 610 User manual