hager New VegaD User manual

Other hager Circuit Breaker manuals

hager

hager CEA263U User manual

hager

hager h Series User manual

hager

hager TR 304A Installation instructions

hager

hager ZY9NK User manual

hager

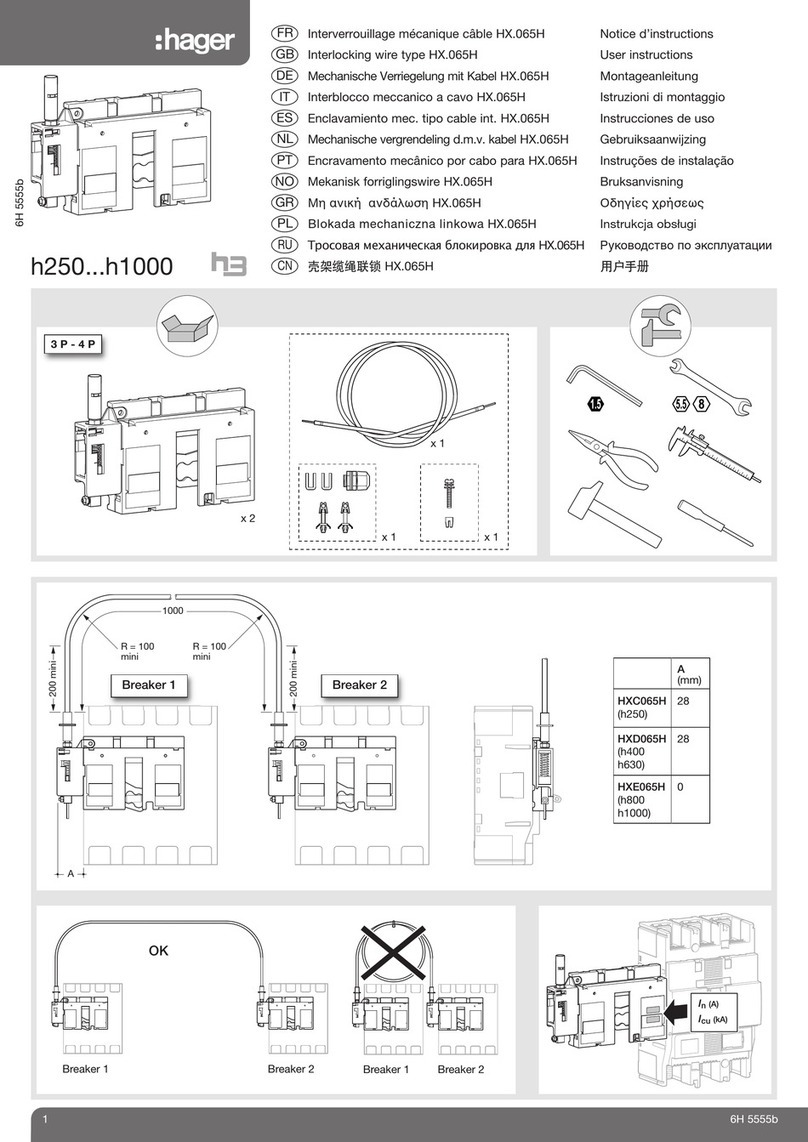

hager h250 User manual

hager

hager HNE Series User manual

hager

hager TR521 User manual

hager

hager EP 071 User manual

hager

hager HY 801, HY 802 User manual

hager

hager h3 HNC125G User manual

hager

hager hw+ User manual

hager

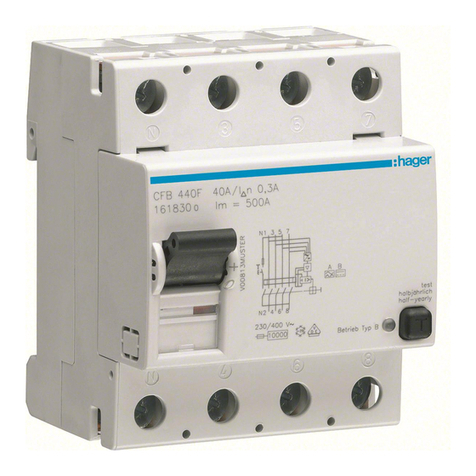

hager CFB740F User manual

hager

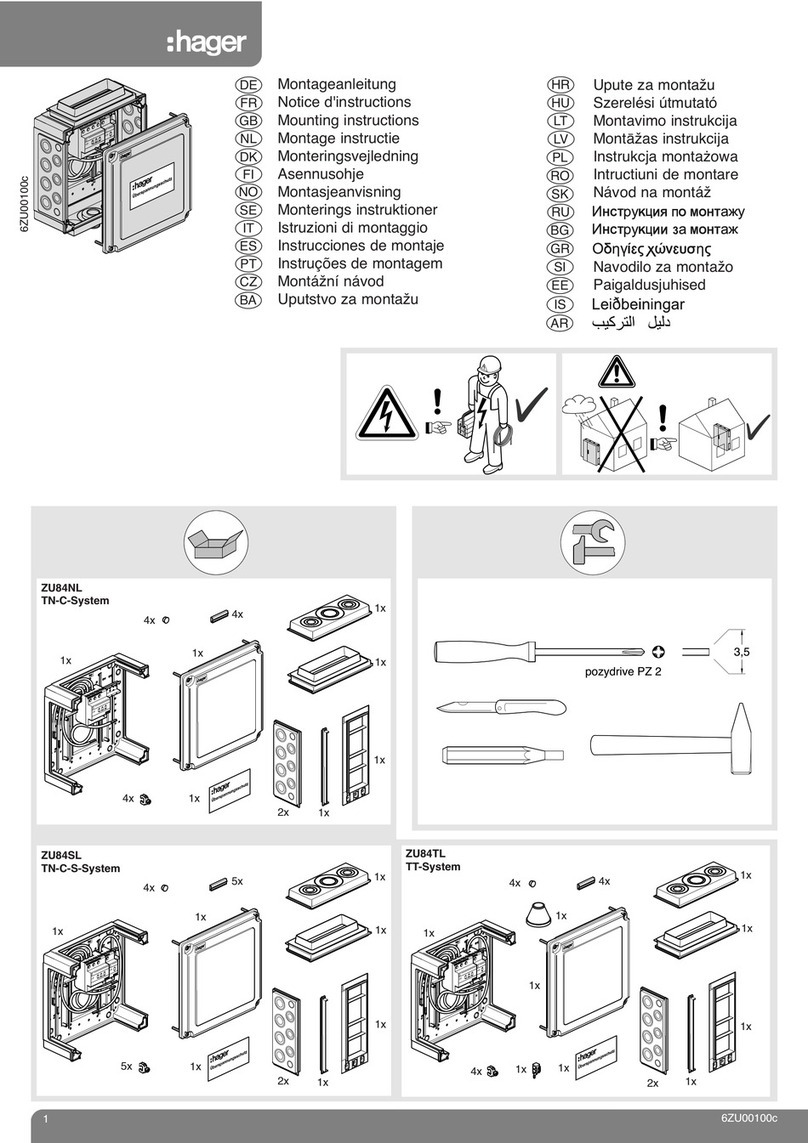

hager ZU84NL User manual

hager

hager h3+ Use and care manual

hager

hager HBB161H User manual

hager

hager h3+ HTP610H User manual

hager

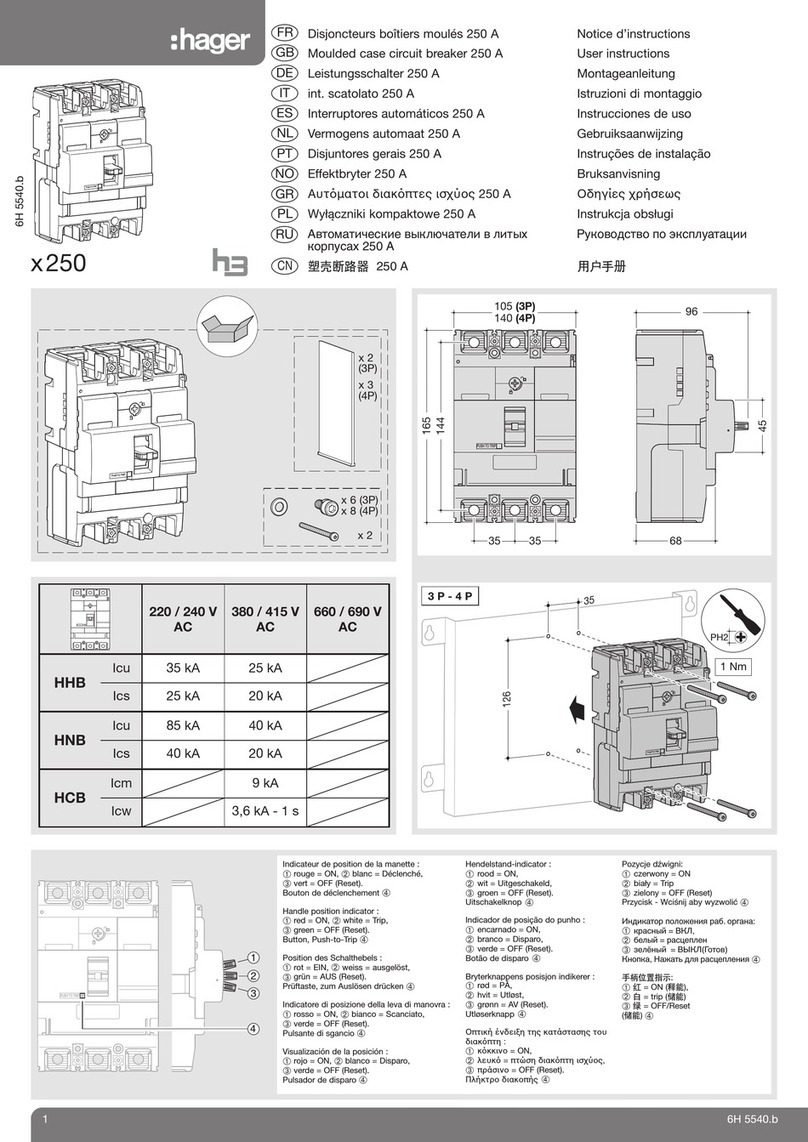

hager H3 h250 User manual

hager

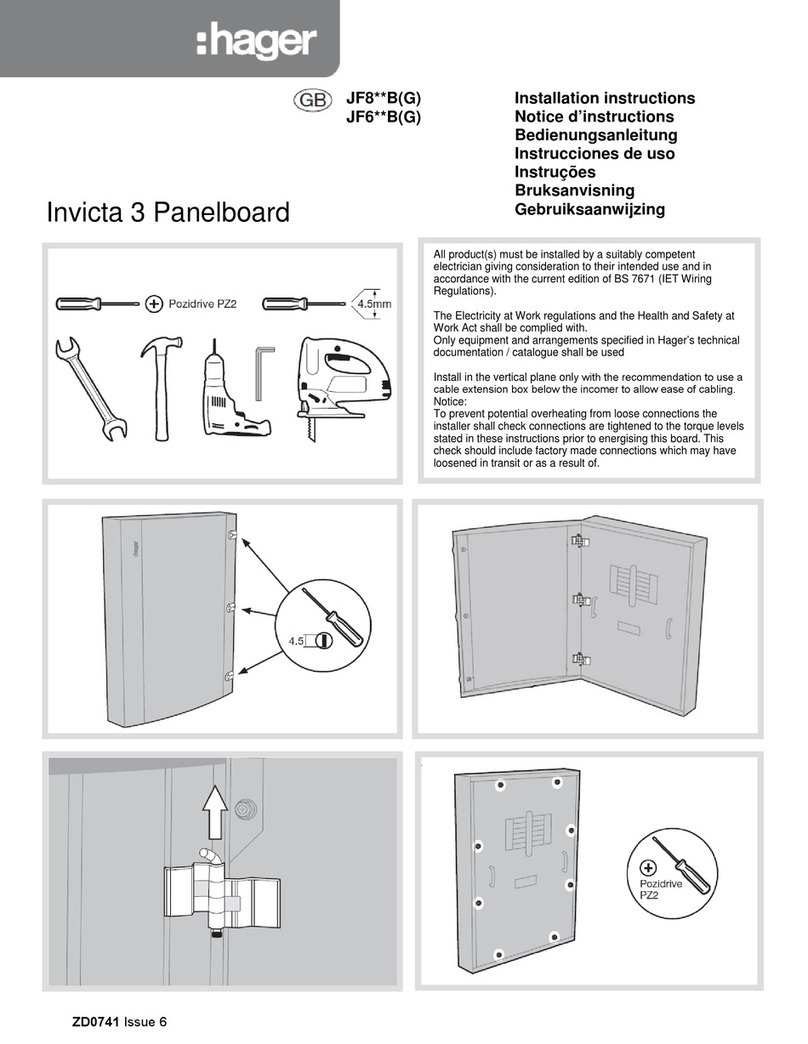

hager Invicta 3 JF8 B Series User manual

hager

hager CDB D Series User manual

hager

hager H125 User manual

Popular Circuit Breaker manuals by other brands

WEG

WEG FHU ACW125 installation instructions

TERASAKI

TERASAKI NHP TemBreak PRO P160 Series installation instructions

Siemens

Siemens Sentron 3VA9157-0PK1 Series operating instructions

ETI

ETI EFI-4B Instructions for mounting

Gladiator

Gladiator GCB150 Installation instruction

nader

nader NDM3EU-225 operating instructions