Warranty

Warranty malfunctions occurring under conditions of nor-

mal use in conformity with the Instruction Manual and

Product Precautionary Markings will be repaired free of

charge.Thiswarrantyis validfora periodof three(3)years

from the date of purchase. Please contact the distributor

from which you purchased the product for further informa-

tion on warranty provisions.

Introduction

Thank you for purchasing the HIOKI 9699 SMD TEST FIX-

TURE. To obtain maximum performance from the product,

please read this manual first, and keep it handy for future

reference.

This HIOKI 9699 SMD TEST FIXTURE can be directly

connected to the measurement terminals (UNKNOWN) of

the HIOKI LCR HiTESTERs for testing a SMD compo-

nent.

Please check a HIOKI catalog for instruments to which this

product can be connected.

Initial Inspection

When you receive the product, inspect it carefully to en-

sure that no damage occurred during shipping. If damage

is evident, or if it fails to operate according to the specifi-

cations, contact your dealer or HIOKI representative.

Preliminary Checks

• Before using the product the first time, verify that it oper-

ates normally to ensure that the no damage occurred

during storage or shipping. If you find any damage, con-

tact your dealer or Hioki representative.

Maintenance and Service

• To clean the product, wipe it gently with a soft cloth

moistened with water or mild detergent. Never use sol-

vents such as benzene, alcohol, acetone, ether,

ketones, thinners or gasoline, as they can deform and

discolor the case.

• If the product seems to be malfunctioning, contact your

dealer or Hioki representative. Pack the product care-

fully so that it will not be damaged during shipment, and

include a detailed written description of the problem.

Hioki cannot be responsible for damage that occurs dur-

ing shipment.

Follow these precautions to ensure safe operation and to

obtain the full benefits of the various functions.

Safety Symbol

The following symbols in this manual indicate the relative

importance of cautions and warnings.

Plug the fixture into the measurement terminals (UN-

KNOWN) of the tester, with the product name up. Fasten

it in place with the left and right fixing levers.

• Samples you can clamp must be 1 to 4 mm in width and

1.5 mm in height.

• Be careful to keep dirt away from the clamping portion.

To enhance the accuracy of measurement, perform the

open and short circuit compensation.

Procedures for connecting and using this product vary ac-

cording to the instrument with which it is used. Refer to the

instruction manual for the specific instrument.

Open circuit compensation

Remove the sample from the sample clamping portion to

open the high and low terminal circuits.

Short circuit compensation

Overview

Specifications

Measurement frequency

range DC to 120 MHz

Maximum apply voltage ±40 VDC

Dimensions of sample to

be tested Width:1 mm to 4 mm (0.04” to 0.16”)

Height: 1.5 mm (0.06”) or less

Residual resistance

Short-circuited 100 mΩ max. (at 100 Hz)

Floating capacitance

between terminals 2 pF max. (at 1 MHz)

Dimensions and Mass Approx.100.5W x 28.6H x 40D mm

(3.96”W x 1.13”H x 1.57”D)

(excluding protrusions),

Approx.125 g (4.4 oz.)

9699

SMD TEST FIXTURE

Instruction Manual

Aug. 2018 Revised edition 3 Printed in Japan

9699A980-03 18-08H

EN

Operating temperature

and humidity range 0 to 40°C (32 to 104

°F)

, 80% RH or

less (with no condensation)

Storage temperature and

humidity range -10°C to 55°C (14 to 131

°F)

, 80% RH

or less (with no condensation)

Operating environment Indoors, altitude up to 2000 m

(6562-ft.)

Accessories Instruction Manual, short bar

Product warranty period 3 years

Inspection and Maintenance

Safety

Mishandling during use could result in injury or

death, as well as damage to the product. Be certain

that you understand the instructions and precau-

tions in the manual before use. We disclaim any

responsibility for accidents or injuries not resulting

directly from product defects.

In the manual, the symbol indicates particu-

larly important information that the user should

read before using the product.

Indicates that incorrect operation presents a

significant hazard that could result in serious

injury or death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to

the product.

Advisory items related to performance or cor-

rect operation of the product.

Usage Notes

• Do not store or use the product where it could be ex-

posed to direct sunlight, high temperature or humidity,

or condensation. Under such conditions, the product

may be damaged and insulation may deteriorate so

that it no longer meets specifications.

• Donotuse the product where it maybe exposed to cor-

rosive or combustible gases. The product may be dam-

aged.

• This product is not designed to be entirely water- or

dust-proof. To avoid damage, do not use it in a wet or

dusty environment.

• To avoid damage to the product, protect it from vibra-

tion or shock during transport and handling, and be es-

pecially careful to avoid dropping.

• If the fixture has gotten seriously wet, oily, or dusty,

stop using it and send it for service at an approved

HIOKI service facility.

• Please refer to the instruction manual for the instru-

ment to which this product is connected for how to use

the instrument and apply direct current voltage.

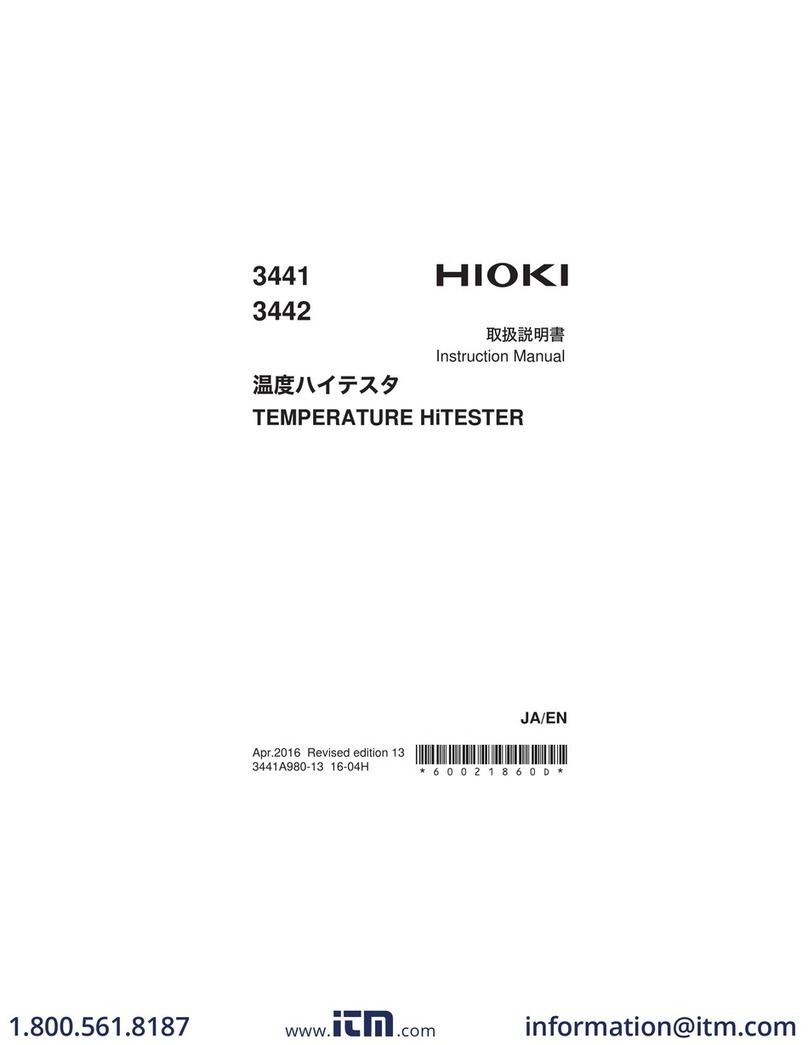

Parts Names

Connecting the Test Fixture

Knob

Positioning slider

Stopper

Connecting

terminals

Sample clamping

portion

Sample fixing

cover

Fixing

lever

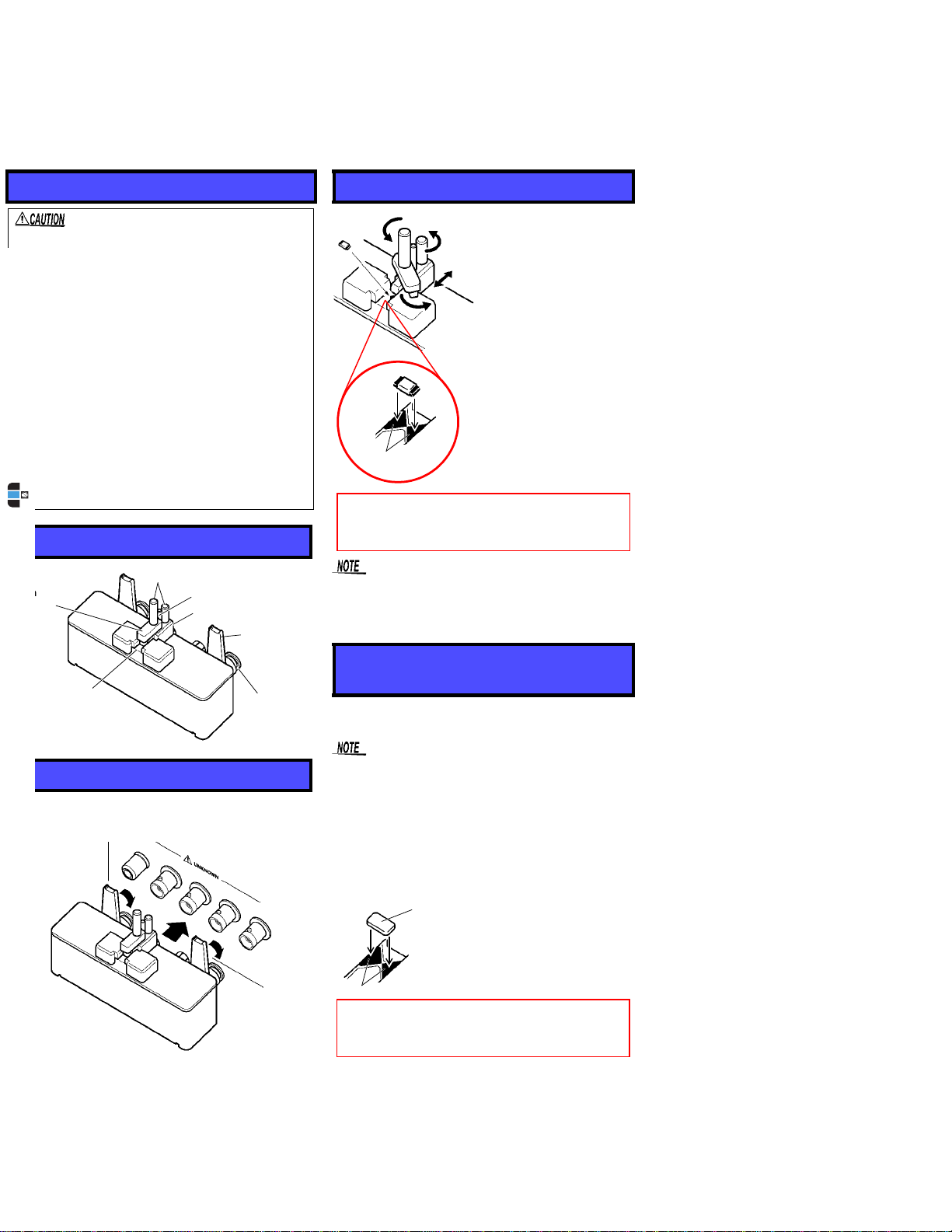

Fixing the Samples

Open and Short Circuit

Compensation

Sample 1. Rotate knob A to loosen it,

and then open the sample

fixing cover.

2. Adjust the depth of the

sample clamping portion, if

necessary.

(Adjusting Procedure)

Loosen knob B and move

the slider forward or back-

ward into position. Tighten

knob B to fix the slider.

3. Place a sample in the cen-

ter of the sample clamping

portion.

4. Replace the sample fixing

cover. Rotate knob A to fix

the sample.

Knob

Make sure that the terminals on both sides of the

sample are placed on both measurement terminals of

the clamping portion. Do not place the sample in con-

tact with any other metal portions of the test fixture.

3

AB2

1

Sample

clamping

portion

Measurement

terminals

Clamp the short bar (supplied with

the 9699 model) in place of a sample

to close the high and low terminal cir-

cuits.

Sample clamping

portion

Measurement terminals

Make sure that the short bar is placed on both mea-

surement terminals of the clamping portion. Do not

place the short bar in contact with any other metal

portions of the test fixture.

Short bar

www.calcert.com sales@calcert.com1.888.610.7664 0

5

10

15

20

25

30