1

1

2

3

4

5

6

7

8

9

10

11

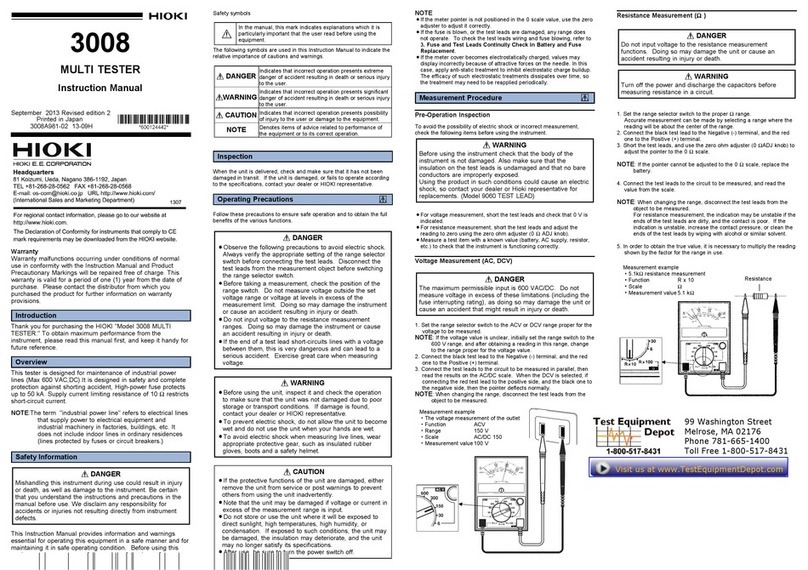

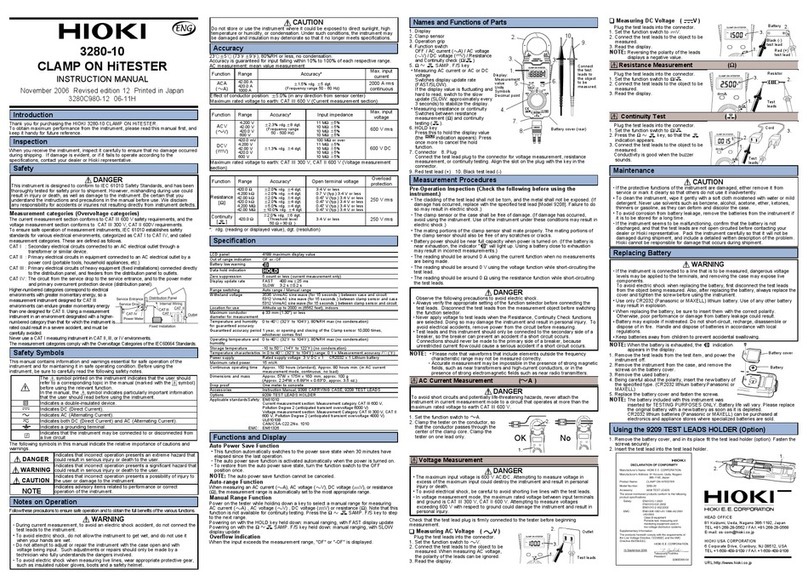

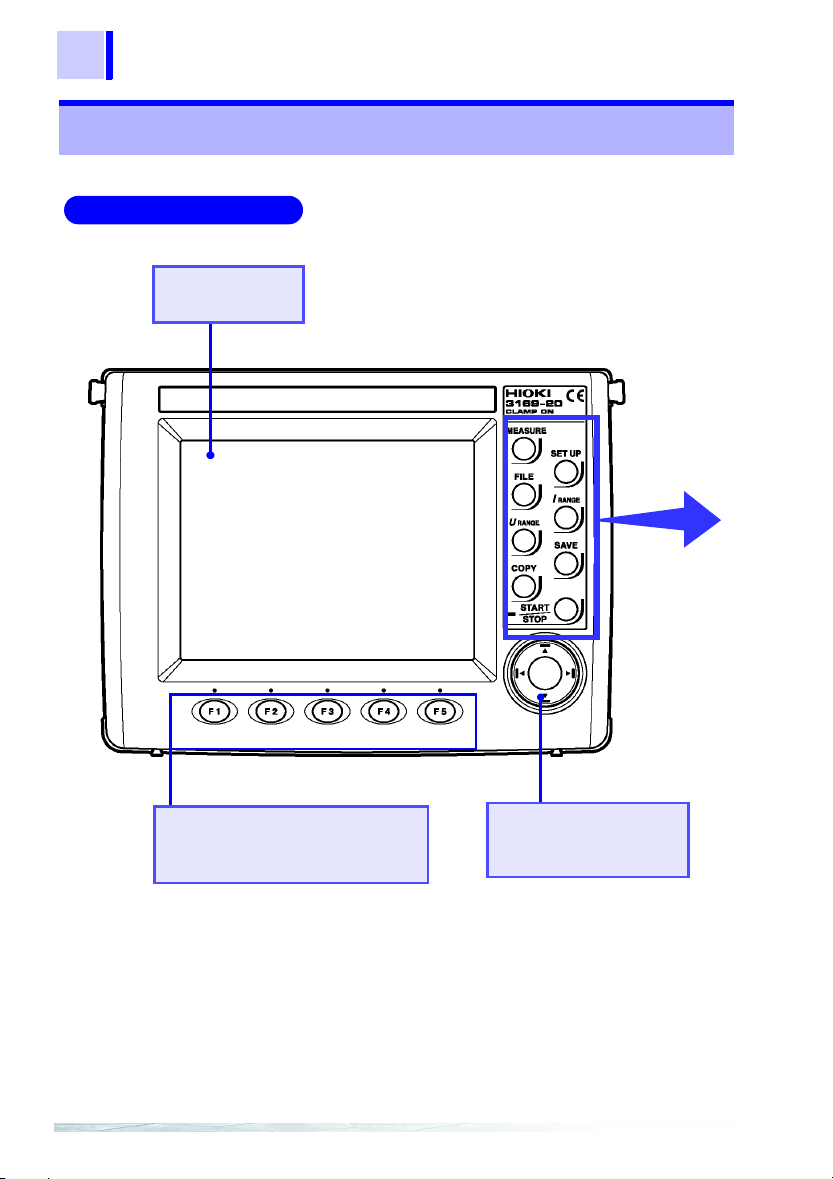

Introduction

• The 3169-20/21 CLAMP ON POWER HiTESTER is supplied

with a instruction manual in addition to this manual. Please be

sure to read both manuals.

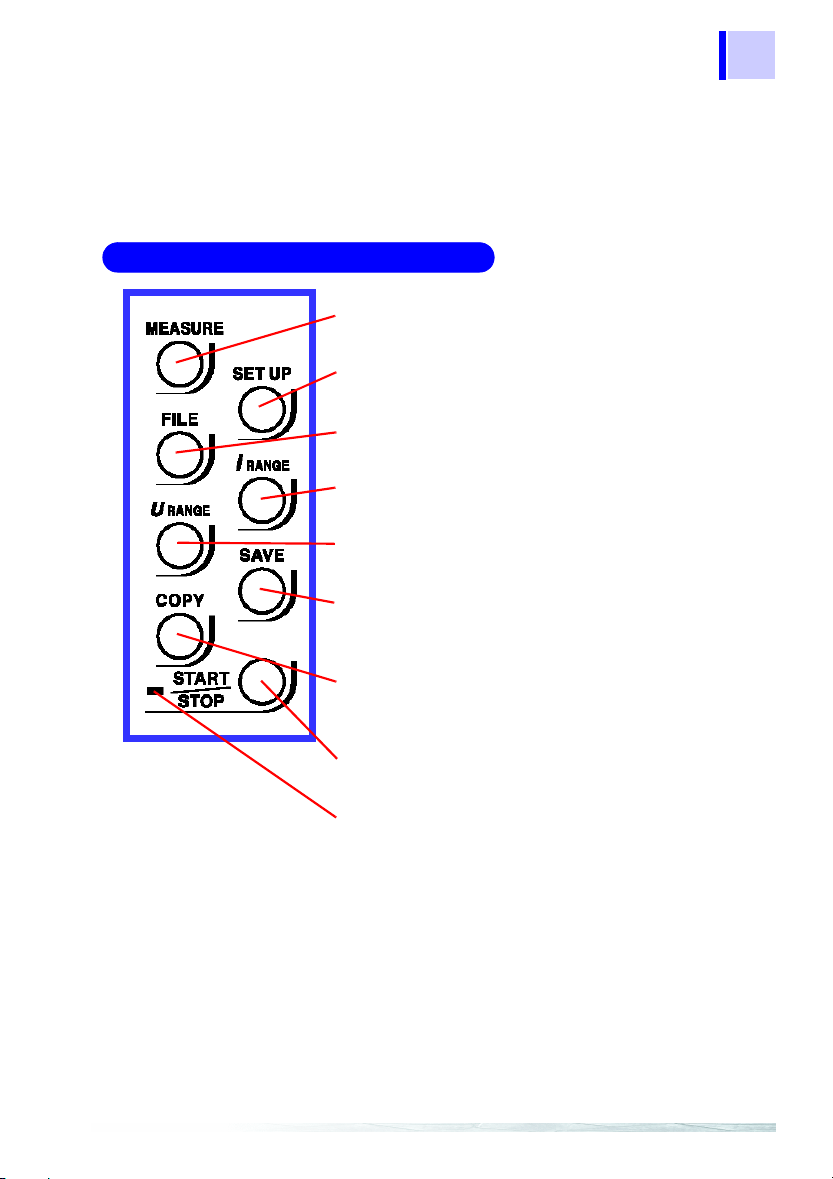

• This manual is a quick reference source with examples and infor-

mation regarding the setting-up of and key operation for the

3169-20/21 CLAMP ON POWER HiTESTER for measurement

purposes.

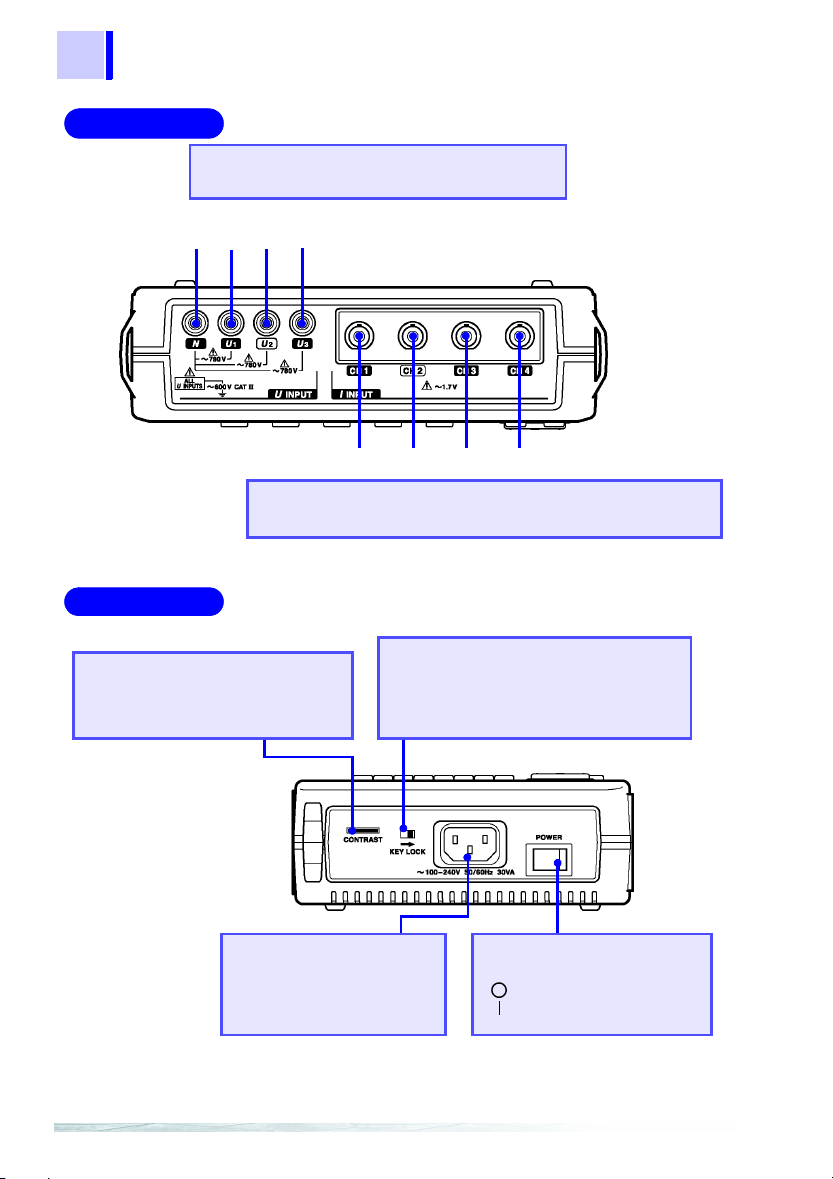

• For current input with this device, a clamp-on sensor (optional) is

required. For details, refer to the instruction manual for the

clamp-on sensor you are using.

Safety Notes

The following symbols in this manual indicate the relative impor-

tance of cautions and warnings.

Other Symbols

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a signifi-

cant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a possi-

bility of injury to the user or damage to the product.

Advisory items related to performance or correct

operation of the product.

Indicates the prohibited action.

❖Indicates the reference.

Indicates quick references for operation and reme-

dies for troubleshooting.

*Indicates terminology explained at the bottom of

the page.