IHP.us.com

126913-01A 9

INSTALLATION

Continued

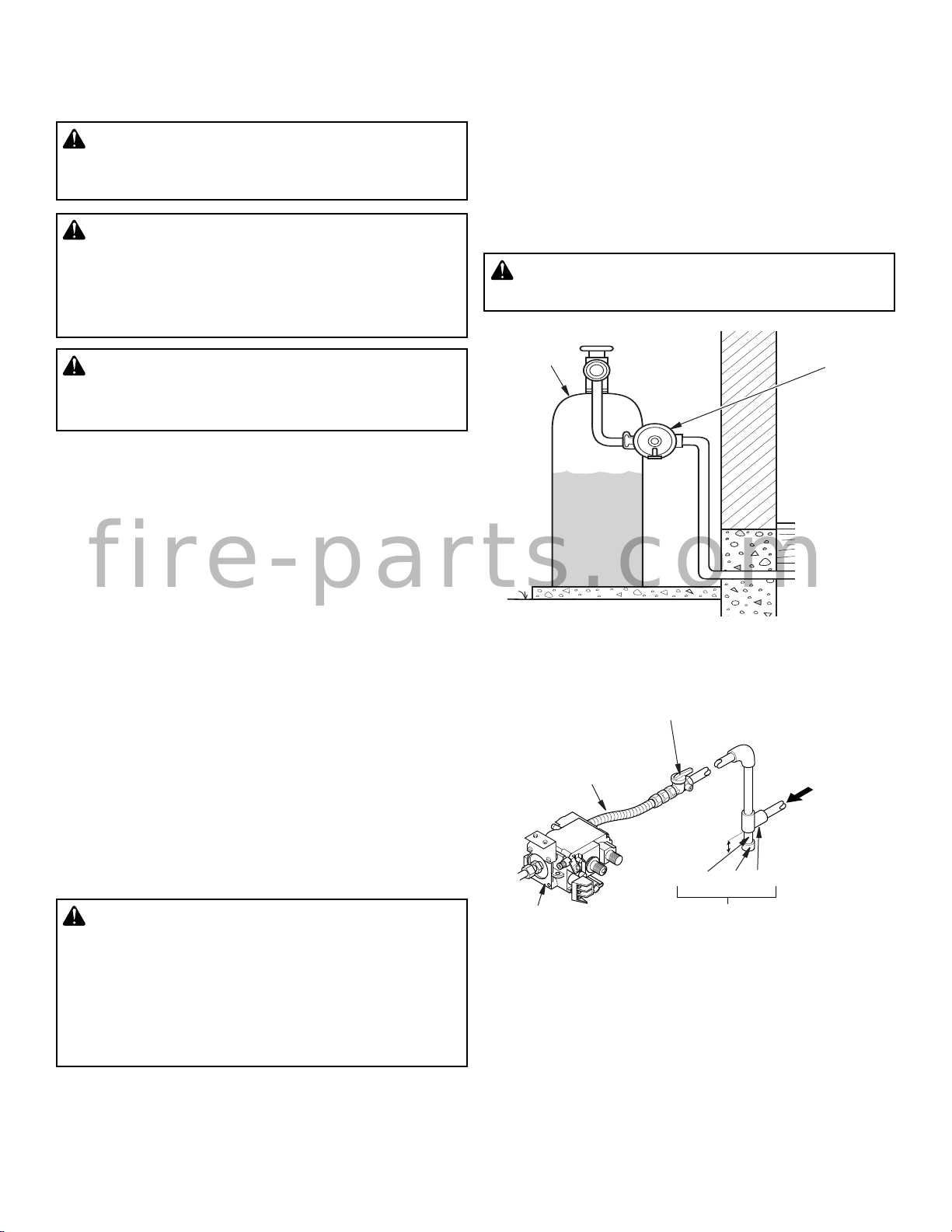

PRESSURE TESTING APPLIANCE GAS

CONNECTIONS

1.

Open equipment shutoff valve (see Figure 12, page 8).

2. Open main gas valve located on or near gas meter for

natural gas or open propane/LP supply tank valve.

3. Makesure controlknobofapplianceis inthe OFFposition.

4. Check all joints from gas meter to equipment shutoff valve

for natural gas or propane/LP supply to equipment shutoff

valve for propane/LP (see Figure 13, or Figure 14, page 8).

Applynoncorrosive leakdetection fluid toall joints. Bubbles

forming show a leak.

5. Correct all leaks at once.

6. Light appliance (follow the Operation instructions accom-

panyingyour burnersystem). Checkall otherinternal joints

for leaks.

7.

Turnoffappliance(seeTo Turn OffGas toAppliance,

follow

the instructions accompanying your burner system

).

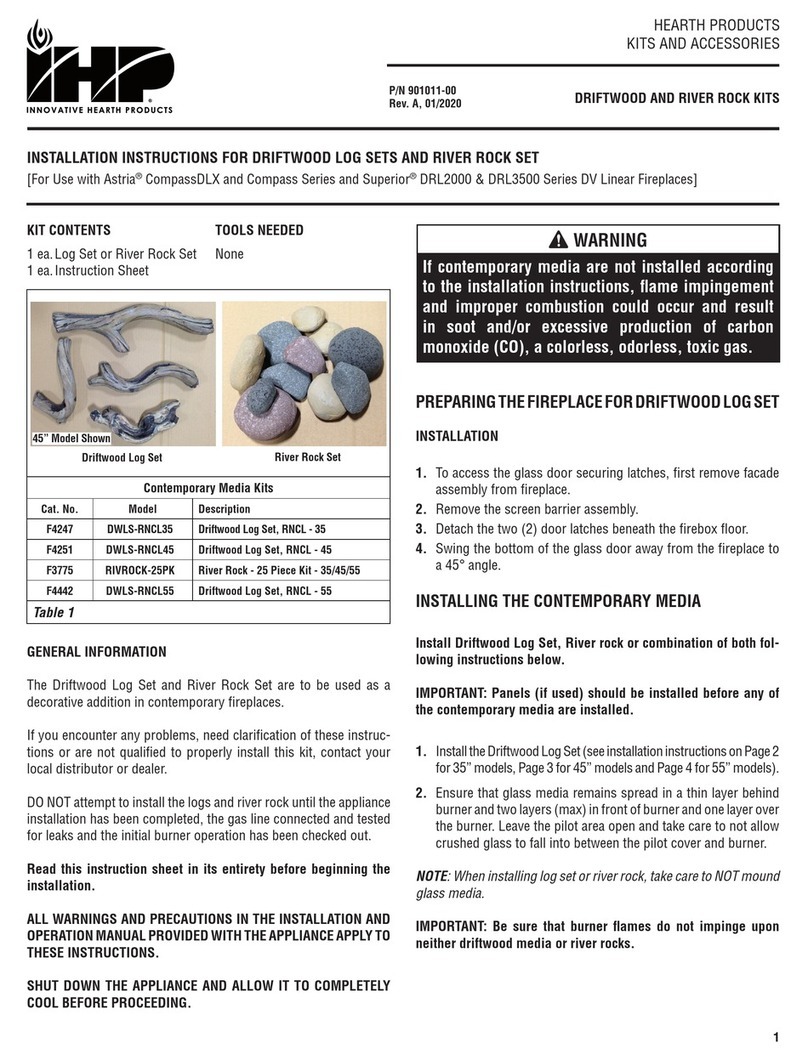

ADDING PAN MATERIAL

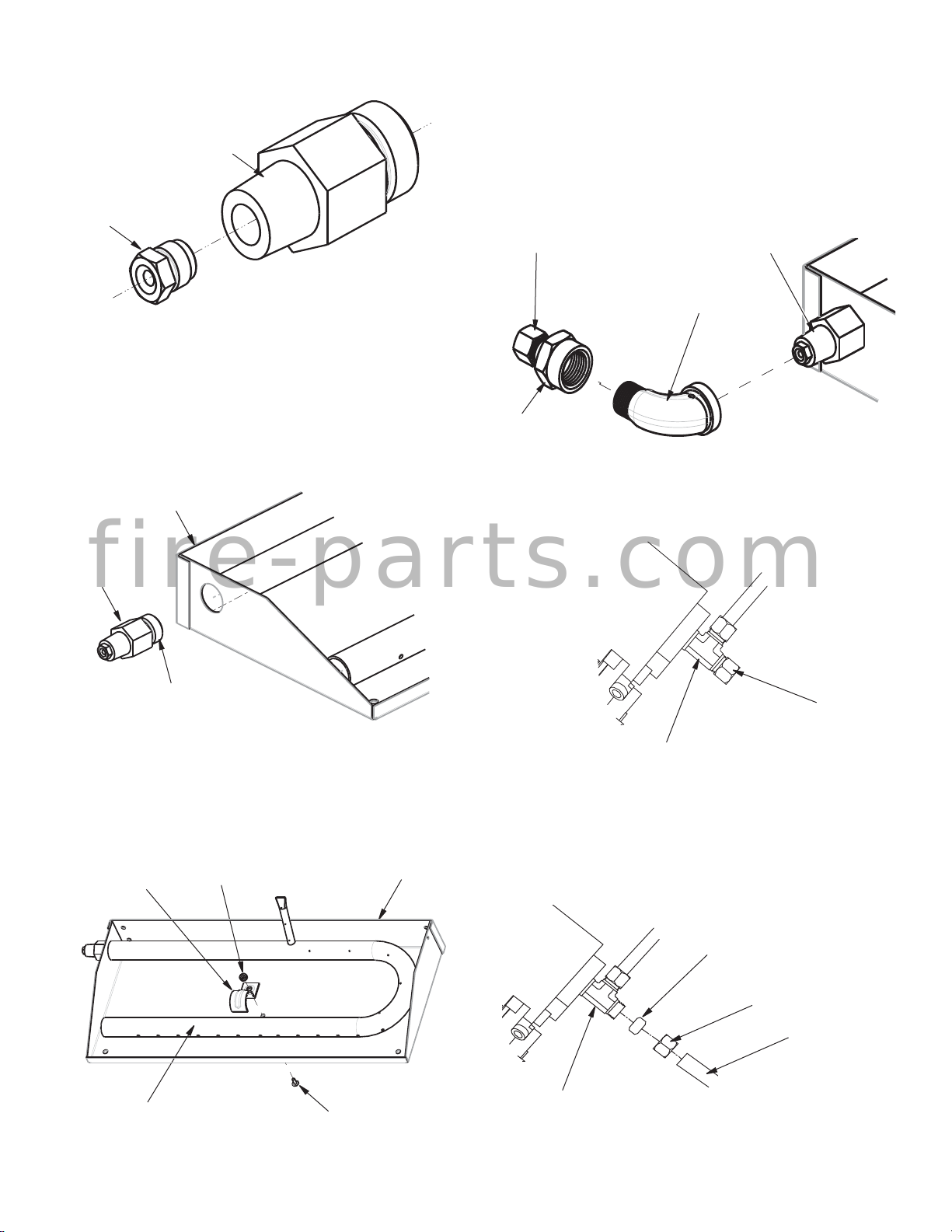

Two pan materials are included with the MFEB. Lava rock,

small grey/black rock is for use on the burner pan for outdoor

applications. Vermiculite, light tan - lightweight material, is

for use on the burner pan for indoor applications.

Apply the material for your application on the burner pan by

spreading it evenly across the burner pan so that it is level

with the edges of the burner pan and covers the round, tu-

bular burner.

ADDING EMBER MATERIAL (INDOORS ONLY)

Two ember materials are included with the MFEB. Apply

rock wool glowing embers by spreading a 1/2 inch layer of

rock wool on top of the pan material. Pull any clumps apart

so that the flames will pass through the pieces. Apply Plati-

num Bright Embers by placing the pieces randomly over the

rock wool.

WARNING: Failure to position the parts in

accordance with these diagrams or failure to

use only parts specifically approved with this

appliance may result in property damage or

personal injury.

OPERATION

CAUTION: Follow the OPERATION instruc-

tions accompanying your burner system for

criticalsafetyinformationandforinstructions

on how to operate your burner system.

SPECIFICATIONS

MAGNIFLAMEOD24PE, MAGNIFLAMEOD24PM,

MAGNIFLAMEOD30PE, MAGNIFLAMEOD30PM,

MFBOD24MP, MNF24OPE, MNF24OPM,

MNF30OPE, MNF30OPM

Burner systems with MFEB optional ember burner installed.

• Rating (Variable): 50,000/70,000 Btu/Hr

• Type Gas: Propane/LP

• Manifold Pressure: 10.0" W.C.

• Inlet Gas Pressure (in. of water):

Max - 14" W.C., Min* - 11" W.C.

*For purpose of input adjustment

MAGNIFLAMEOD24NE, MAGNIFLAMEOD24NM,

MAGNIFLAMEOD30NE, MAGNIFLAMEOD30NM,

MFBOD24MN, MNF24ONE, MNF24ONM,

MNF30ONE, MNF30ONM,

Burner systems with MFEB optional ember burner installed.

• Rating (Variable): 40,000/65,000 Btu/Hr

• Type Gas: Natural

• Manifold Pressure: 3.4" W.C.

• Inlet Gas Pressure (in. of water):

Max - 10.5" W.C., Min* - 5" W.C.

*For purpose of input adjustment

REPLACEMENT PARTS

Normally, all parts should be ordered through your IHP distributor

or dealer. Parts will be shipped at prevailing prices at time of order.

NEVER USE SUBSTITUTE MATERIALS. USE OF NON-APPROVED PARTS

CAN RESULT IN POOR PERFORMANCE AND SAFETY HAZARDS.

When ordering repair parts, always give the following information:

1. The model number of the appliance.

2. The serial number of the appliance.

3. The part number.

4. The description of the part.

5. The quantity required.

6. The installation date of the appliance.

If you encounter any problems or have any questions concerning the

installation or application of this appliance, please contact your dealer.

TECHNICAL SERVICE

You may have further questions about installation, operation, or

troubleshooting. Please contact your IHP dealer for any ques-

tions or concerns. When contacting your dealer please have

your model and serial numbers of your appliance ready. You

can also visit our web site at IHP.us.com.

fire-parts.com