IMER COMBI 250 V Guide

COMBI

250

V

SAWINGMACHINE

cgp. 1188trg9

$lN 403189

207'-a

:,(eNae

A'.,enue

Sc San Fran:rsco,

CA f.i080

Tel 650

- 872

- 22aC

Fax 553 - 87Jr

- 5-i32

OPERATI

NG,

MAI

NTENANCE,

SPARE

PARTS

MANUAL

IMER u.s.A.

tnc.

207,Lawrence

Avenue

SouthSan

Francisco.

California94080IMEREAST

ZZ WestnamptonPlace

Capitol

Heights,

MD

20743

Tel 301

-336

- 3700

Fax301

- 336

- 6681

612002-R1

-Cod.3210213

-

(6s0)

872-2200

@TMESH;;#

rnc.

Dear

Customer,

Congratulations

on your choice of purchase:

IMER saws are

the resultof years of experience

and are equipped

with all the

latest

technical

innovations.

[- woaKNG tN sAFEry.

Towork

in complete

safety,

read

the

following

instructions

carefully

before

usingthe

machine.

Towork

in complete

safety,

read

the

following

instructions

carefully

before

usingthe

machine.

This

OPERATION

AND

MATNTENANCE

manuatmust

be

kepton

site

bythe

person

in

charge,

e.g.

the

SITEFOREMAN,

and

must

aiways

be avaiiabie

for

consuiiaiion.

The

manual

is

tobe

considered

integralpart

ofthe

machine

and

must

bekept

for

future

reference

untilthe

machine

is

disposed

of.lfthe

manual

is

damaged

or

lost,

areplacement

maybe requested

from

themanufacturer.

The

manual

contains

important

information

regarding

site

preparation,

machine

use,

maintenance

procedures,

and

requests

forspare

parts.

Nevertheless,

the

installer

and

the

operator

must

bothhave

adequate

experience

and

knowledge

ofthe

machine

prior

to

USE.

To guarantee

complete

safety

oftheoperator,

safeoperation

and

long

life

ofequipment,

follow

theinstructions

inthis

manual

carefully,

and

observe

all

safety

standards

currenily

in

force

for the prevention

of accidents

at work(use

of safety

footwear

and

suitable

clothing,

helmets,

gloves,

goggles

etc.).

A Make sure that

alt signs are legible.

/!\ - It is strictly forbidden to carry out any form of

modification to the steel structure o7 workin! parts of

tltemachine.

IMER

INTERNATIONAL

declines

altresponsibility

for

failure

to

coinply

with

laws

and

standardsgoverning

the

useof this

equipment,

in particular,

improper

use,

cjefective

power

supply,

lack

ofmaintenance,

unautho:-ised

modifications,

and

partiat

ortotal

failure

to

observe

the

instructions

contained

in

this

manual.

IMER

INTERNATIONAL

reserves

the

right

to

modifyfeatures

of

the

saw

and

contents

ofthis

manual,

without

the

obligation

to

update

previous

machines

andlor

manuals.

1. TECHNICAL

DATA

ffid intable

1

and

electrical

specifications

intable

2.

Feature 115/60

Hz

Power (kW

)11

Rated voltage(V) 115

Frequency

(Hz) 60

Absorbed current 14.4

Number

of

poles 2

rpm 3400

Service type s6 40%

Insulation

category F

Protection

category tP55

Capacitor

(pF) 110(o

50xl

20)

2. DESIGN

STANDARDS

Thesaws

have

beendesigned

andmanufactured

according

tothe

foflowing

europeanstandards:EN292-1-2;

EN60204-

1:EN

12418.

3. NOISE

EMISSIONLEVEL

Table

3specifiesthesound

emissionlevelsmeasured

onthe

saw(Lwa) inaccordancewith

ENISO 3744andthe

sound

pressure

level

measuredat the

earof theoperator

under

no

lload

conditions

(\o) .

TABI.E3

SAATTI3MICHI€ T\PEOFI\4OTCR \o \^

OM25OV AETRC 70 85

4. GENERAL

SAW DESCRIPTION

4.

I General description:

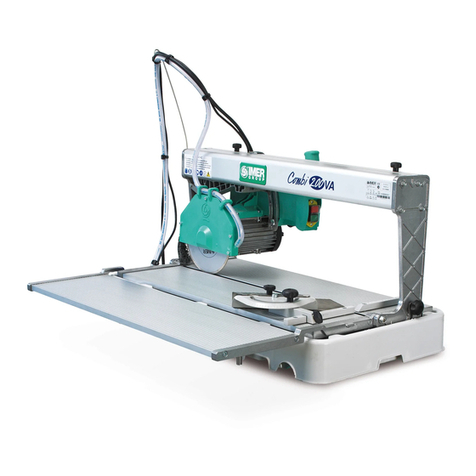

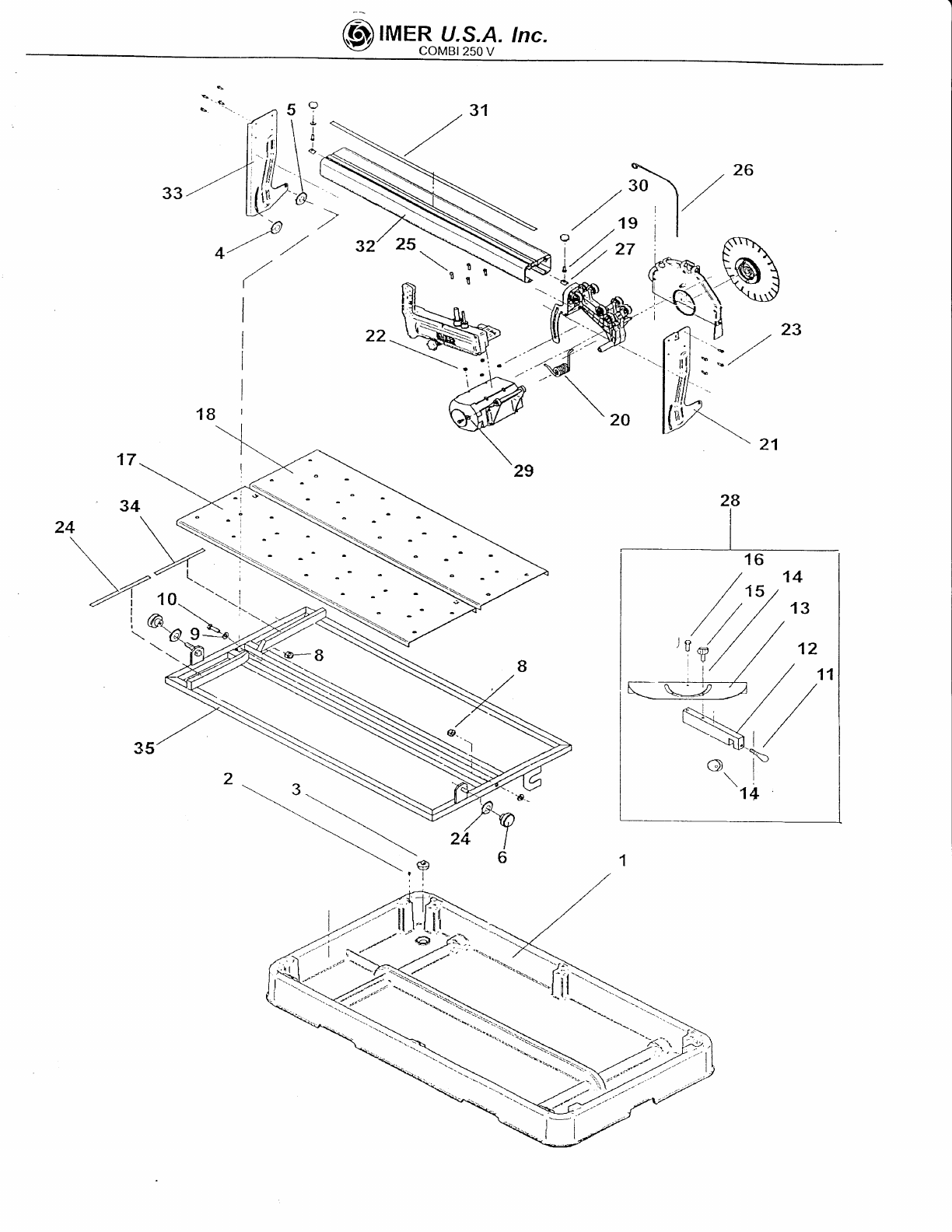

The Combi 250 V is a saw comprisingthe following

main sub-

groups :

- cutting

head (ref.

A fig.1).

- sliding

guide (ref.

B fi9.1).

- water collectiontank (ref.

C fi9.1).

- frame (ref.

D fiq.2).

- cutting surface (ref. F fig.2).

- stand (ref.G fig.s).

The cutting

head is mountedon a reinforced

aluminium

profile

and is equipped

with horizontal

and verticalmovement

facilities.The

aluminium

profile

is hinged

onto sheetsteelarms

(ref.H

fig.5) and the entireunitcan rotatethrough

a5" ( fig.6)

by means of the relative

handwheels

(ref.Lfig, 7).

The cutting

surfaces

are positioned

on the tubularframe of the

saw which is placed on the tank constructedin impact-

resistant

plastic.

The waterimmersion

pump is mountedbelow the cutting

surfaceson a specialbracket and supplies a water distributor

inside

the blade

guardfor cooling

the cutting

bladeduring

operation.

The high resistance

plastic

handle(ref.M

fig. 6), is equipped

with the main ON-OFF switch on the ooerator

side to facilitate

saw activationand shutdown.Theraised oositionof the red

OFF buttonon the handle is designed

to facilitate

shutdown of

the machinein the eventof an emergency.

The motor

capacitoris locatedin a protected

position

insidetlre handle.

The saw is fittedwith a guard to guarantee

optimalsafety

during

operationand to protect

the user during cutting

cycles.

A valveis mounted above the blade

guard to adjust the flow

rateof water deliveredto the cuttino

blade.

4.2 Processable

materials:

This saw has been designed for cutting the following

materials:

ceramictiles,

masonry and stone in general

with

TECHNICAL DATA

- Tabte

1

Model coMBt

250v

Max. diamond blade diameter 10inches

Diamond blade hole diameter 1 inches

Singlephase

motor

(11SV

60Hz)

output 1.1

Kw

Max.

blade rotation

speed (115V

60Hz) 3.400rpm

Worktop dimensions 500x840

mm

90' cut length

(th=16mm) 660mm

Lengtlr of cuts from above 785mm

Maximum

cut depth

with single

s

tro

ke 66mm

Maximum cut depth with two strokes 95mm

Water pump flow rate 10

L/nriir

Water tank capacity 42L

Machine dimehsions 1

040x560x640mm

Packed machine dimensions 1050x570x660mm

Ww

@IMERU.;#

rnc.

maximum

dimensions

compatible

with

thelength,

cutting

depth

anddimensions

of thesurfaces

specified

inTable

1.

Maximum

weight

ofprocessable

materials:

25

kg.

4.3 Unsuitable

materiat:

Materials

unsuitable

forthis

machine

areall

those

not

specified

inparagraph

4.2.

ln any event,

before

usingthesawwith

materiats

otherthan

as specified

by themanufacturer

forthissawmodel,

contact

IMERINTERNATIONAL

S.o.A.

4\i - IJse

of this machine with workpiece.s

oufside the

specified dimensions is strictty prohibited and constitutes

a hazard for the operator.

5. APERATIONSAFETY

Ai Before,using the saw, ensure

that att protection

devices are fitted.

/!\l - Neveruse fhe sawin environments

subject to the

risk of explosions, fire or underground.

Thesaw is notfitted

withspecific

lighting

andtherefore

the

workplace

mustbe sufficiently

litfor this

purpose.

The

power

lines

must

belaid

to

prevent

any

possible

damage.

Never

standthe

sawon the

power

supplycable.

Ensure

that

theelectrical

connection

is protected

against

the

riskof waterpenetration

in connectors.

Useexclusively

connectors

and couplings

equipped

withwater

spray

protection.

- Never

useinadequate

or makeshift

electricallines

or cables

without

earthing;

if in doubt

consult

a specialisedtechnician.

- Repairs

to theelectrical

circuit

must

beperformed

exclusively

by specialised

personnel.

Disconnect

the

machine

fromthe power

supply

before

performing

maintenance

or

repairs.

6.GENERAL

SAFEry WARNINGS

Note

that

this

machine

has

been

designed

toensure

optimai

performance

andmaximum

safety:however

theoperator

must

also

guarantee

this

level

of safetyby paying

specialattention

tothe

machine

throughout

allwork

phases.

It, Ensure that an efficient earthing sysfem rs

installed.

2. Work only with all protection devices fitted

correctly and in efficient working order.

J. Keep the machine clean: general cleaning

(and the work surfaces in particutar) represents an

important safety factor.

4. Always stop the machine and disconnect from

the power supply before cleaning or removing any

protection device (for maintenance or drsassembly

purposes).

lf water jets are used for cleaning, never point jets

directly at the power supply unit or electric motor.

5. Remove rings, watches, bracelefs or ties before

using the machine,' fhese elements constitute a serjous

ttazard to the operator.

A/so ensure that s/eeyes are tight around the wrists,

hair is tied back and robust footwear is used.

6. Never cut workpieces that have dimensions or

weiglrt that are not suited to machine i capacity as

specified by the manufacturer (see point 4.2)

7. Always use personal protection devices such

as safety goggles, suitably sized g/oves, ear muffs or

plugs and hair caps when necessary.

B. Use original diamond blades as recommended

by the manufacturer to ensure optimal pertormance of

the machine-

9. Always keep hands well away from the working

zone while the machine is running; before removing

workpieces from the blade area, always press fhe stop

pushbutton to shut down rotation.

10. The instrucfions in this manual are aimed at

machine users (operators, maintenance engineerfl-

11. Never use diamond blades that are chipped.

or

deformed.

12. Never use blades over the rotation speed

specified by the manufacturer.

13. Use exclusively water-cooled continuous rim

blades suited to the material to be cut.

14. Never dry cut material or cut when cooling

water levels are low.

15. Ensure that the machine, with or without stand,

is placed on a stable surface with a maximum

inclination of 5".

7. SAFEW DEVICES

Tffi been

constructed

taking

intoaccount

current

harmonisedEuropeansafetystandards.

Accordingto machine

directive9B/37lEECallsafetydevices

have

been

installedwiththeaimofsafeguardingthe

operator.

7.1Guards and safety devices

Themachine

is equipped

withfixed

guards,

securedby

meansof screwsand protections

thatprevent

access

to

movingor dangerous

parts.

All fixed

guards,

covers,shields

fixedby meansof screws

havebeen

envisaged

to protect

theoperator

(maintenance

engineers,

techniciansand others)frorn

possible

accidents

causeby electricaldischargeor movingmechanical

parts.

Therefoi'e

useof the machinewith

guards

removedor

modifiedin anyway is sti'ictly

prohibited.

A g"tore performing maintenance

or repairs to the

machine,

turn it off via ihe main switch and disconnect

from the power supply to prevent inadvertent start-up

and isolateall machine electricalcircuits.

8. MACHINE INSTALLATION

8.1 Lifting and handling

TheCombi250V sawweights

39Kg andcanbemovedby

meansofthe

sidehandlesonthetank

(ref.N

fig.s).

A aW"ys empty the tank beforemoving the machine.

8.2 POSITIONING.

Themachine

mustbeplaced

ona smoothsurfacethatis at

least

aslarge

asthetank,withthe

sawontherelativestand.

A - Ensurethat the standis positioned

on the relative

inserfs on the tank base and thus secured.

Thecorrectsidefortheoperatoris as shown

in Fig.3

position

Inthe

eventof moving

thesaw,

take

caretosecurethehead

bymeans

of thefixing

knobs

(ref.O,

L fig.7)andcarrythe

machine

bymeansofthe

handles

onthetank

(ref.N

fi9.5)

afterdisconnectingthepower

supply.

1l\ atways remove the ptug from the mains

power before

moving the machine.

8.3SIAT{DASSEMALY

@-assembled. Before

usecomplete

assemblyby inserting

thefoot

(ref.T

fi9.5)

in the

stand

frame

andtighteningthe

screwandnut

(ref.U

ng.5).

9. ELECTRICAL CONt:tECTtON

A .Ensure that vottage

da

ta

p

I

a

te s

p

ec

ifi

c

ations.-

Connect the machine to an efficient earthing system.

The size of the power cable wires must be based on

operating current and length of the power line to prevent

excessive voltage drops (ref.Table

4).

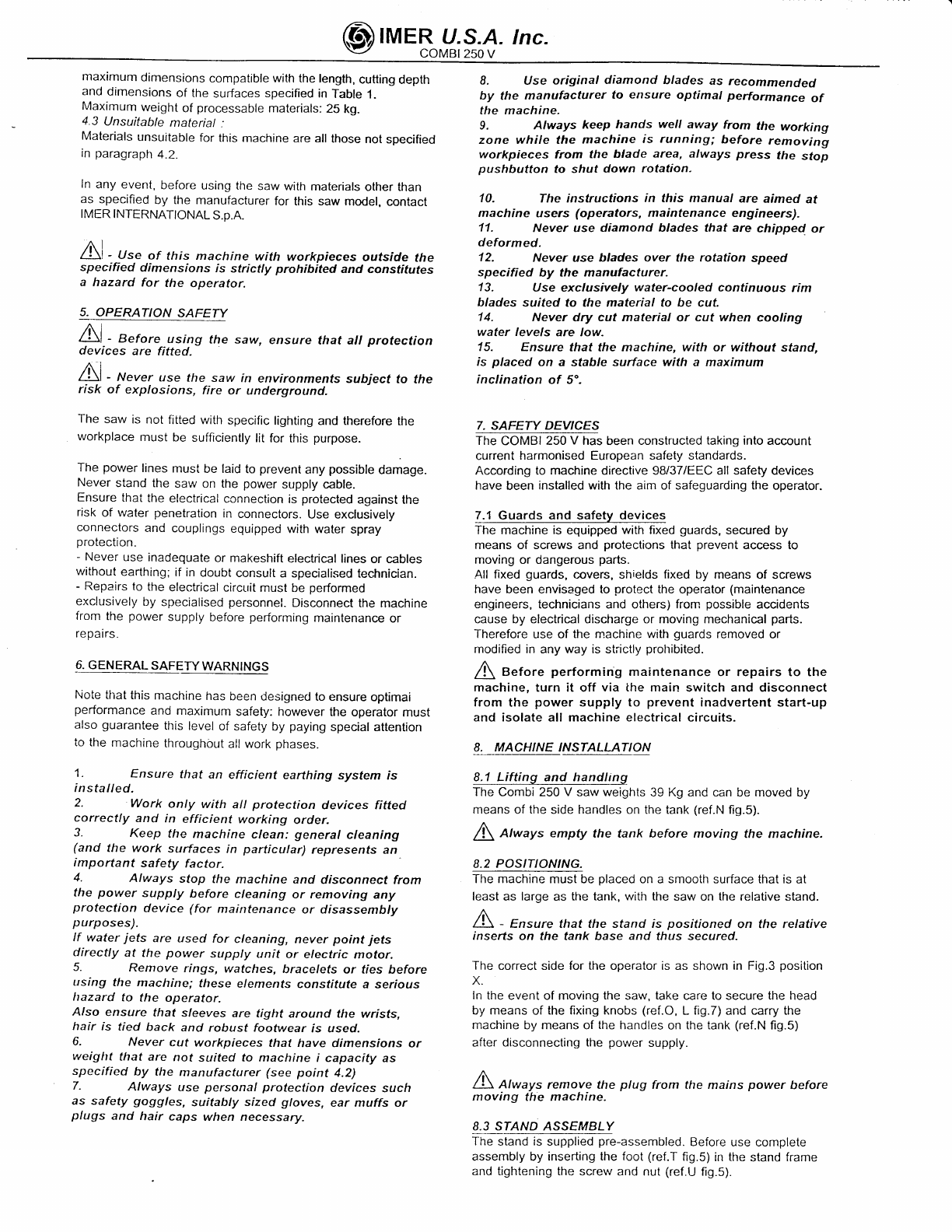

Combi250V-Tab.4

Cable length (m) v115

l= 14.4

Ao+12 13+20 21 32

Cable (mm,) 1.5 2.5 4

/r\

1

: \ Ensure that the electric line hasa suitabte

differential overtoad switch(RCD)(GFCI-USA).

Connect

the

sawplug

tothe

mains

.

- The saw is now ready

foroperation.

11.SAW START-IJP

connect

the

mains

power

cable

tothe

plug

on

the

electrical

panel.

Then

start

the

saw by means

of the

switch

on thehandle

(ref

.

P fig.6), comprising

two buttons:

green

forstart,red for

stop.

The switch

is fitted

with.low

voltage

protection:

in theevent

of accidentalpowerfailure,

press

thegreen

button

again

to

resume

operation.

In

the

event

of an emergency,press

thered

pushbutton

to

shut

down

the

machine

and

disconnect

the

plug

fromthe

power

mains.

TH

ERMAL

CUTOUT

PROTECTION:

A The electric motor

is protected against overload

by a thermal cutout; in the-

event of olerheating this

device shufs down the motor.

Cool the motor and restartby means the main switch

cn the handle (ref.P tig. 6).

12 . MACH'NE USE

Operation

The

correct

sidefortheoperator

isshowninfig.

3 ref

X.

Fill

thewater

tank

tothe

maximum

level

(approx.

42litres).

Connect

the

machine

tothe

power

mains

and

startas

described

in

paragraph

11.

Open

the valve

(ref.V

fig.7)

andensuresufficient

flow

of

cooling

water

tothe

diamond

blade.

qqtlils

Place the material to be cut on the cuttingsurface against the

fence at the required angle using a protractor.

Adjust the height of the cutting head by means of the

handwheel

(ref.

R fig. 6).

Ensure that the handwheels for angled cuts (ref. L fig. 7)

and tightened

fullydown.

Start

the saw as described

in paragraph

1

1.

Proceed with cutting moving the saw head by means of the

handle.

In the event of blade rotation

shutdown due to excessive

force, free the disk by moving it forwards and wait for the

saw to reach normal operating speed before resuming

operation.

AlsEq_sle

Loosen the handwheels (ref.Lfig. 7), set the cutting head at

the required angle, retighten

the handwheels, and proceed

as described

in the point

above.

Ensure

that

thd tank is kept

full

duringallwork phases

and in

the event of prolonged work intervals replace water

regularly and remove all processing residue.

Press the workpiece by hand onto the cutting surface.

Apply sufficient pressure on the handle to move the cutting

head without blocking the blade.

13 . Maintenance

13.1Premise

Routine maintenance operations can also be performed by

non-specialisedpersonnel provided that all safety standards

specified in the relative sections of this manual are observed

at

alltimes.

13.2

Machine

clean

The

machine

shouldbe cleanedexclusively

when

it is

siationary.

/\

l\ - All p.ower swifches must be sef fo "0" and plugs

must be disconnected from the mains.

r Never use compressed air; this could cause infiltration of

dust or residue in enclosed parts.

r Ensure that the cooling water nozzles are not obstructeo.

rAbove all the cooling water in the tank must be changed

every day.

r Recommended product for cleaning and lubricating

the

mechanical parts of the saw: WD40

13.3 Waste disposal

As regards disposal of processing waste observe all current

legislation

in the country of use.

13.4

Repairs

Repairs to the electrical installation must be performed

exclusively by specialised personnel. Use exclusively

original IMER spare parts; modifications to parts are strictly

prohibited.

The special design of the COMBI 250 V ensures

ihat no other maintenance cther than as specified

above is

required.

Ensure that the contacts of the power plug and plug-switch

assembly are efficient.lf oxidation is detected, clean

immediately

13,5 Cleaning the tank

Clean the tank in the event of build-up

of sedimenton the

base, or at least once a day. Failureto clean the tank could

impair

operationof the immersion pump used for circulation

of the diamond blade coolinq water. :

13.6

Blade

replacement

The

diamondbladeismade of material

thatmay be damaged

vrhensubject to high temperatures, and therefore must be

cooled during the work phases.

To replace the blade, proceed as follows:

l.Block axial movement of the cutting head by means of the

handwheels(ref.

O fig. 7).

2. Disassemble the front guard (ref.D fig-a).

3. Loosen the locknut by rotating clockwise (leftthread),

using

a 19 mm wrench.

4. Move the cutting head forward slightly

and inclineto

remove the blade from its seat.

5 - Ensure that there are no foreign objects between the

fixingflange

and diamondblade.During

disassembly,

avoid

use of tools that could dent or deform the flange.

6 . Insert the new blade proceeding in reverse order of the

operationdescribed at point 4. Take specialcare to ensure

correct direction of rotation of the diamond blade.

7. Tighten

the bladelocknut

fullydown by rotating

anticlockwise(left thread), to a torque of 40 Nm.

13.7

Cleaningthe cooling

water supplvcircuit

At regular intervals (or when the flow rate of the blade

cooling water is reduced) clean the cooling water supply

circuit.To do this, disassemble the deliverynozzle (ref. S lq.

4) locatedinsidethe blade guard

and cleanin water.

Periodically

clean the cooling water delivery line between the

pump and valve, (ref.V

fig. 7) and bladeguardusingwater.

corresponds to machine

@IMERU,;# tnc.

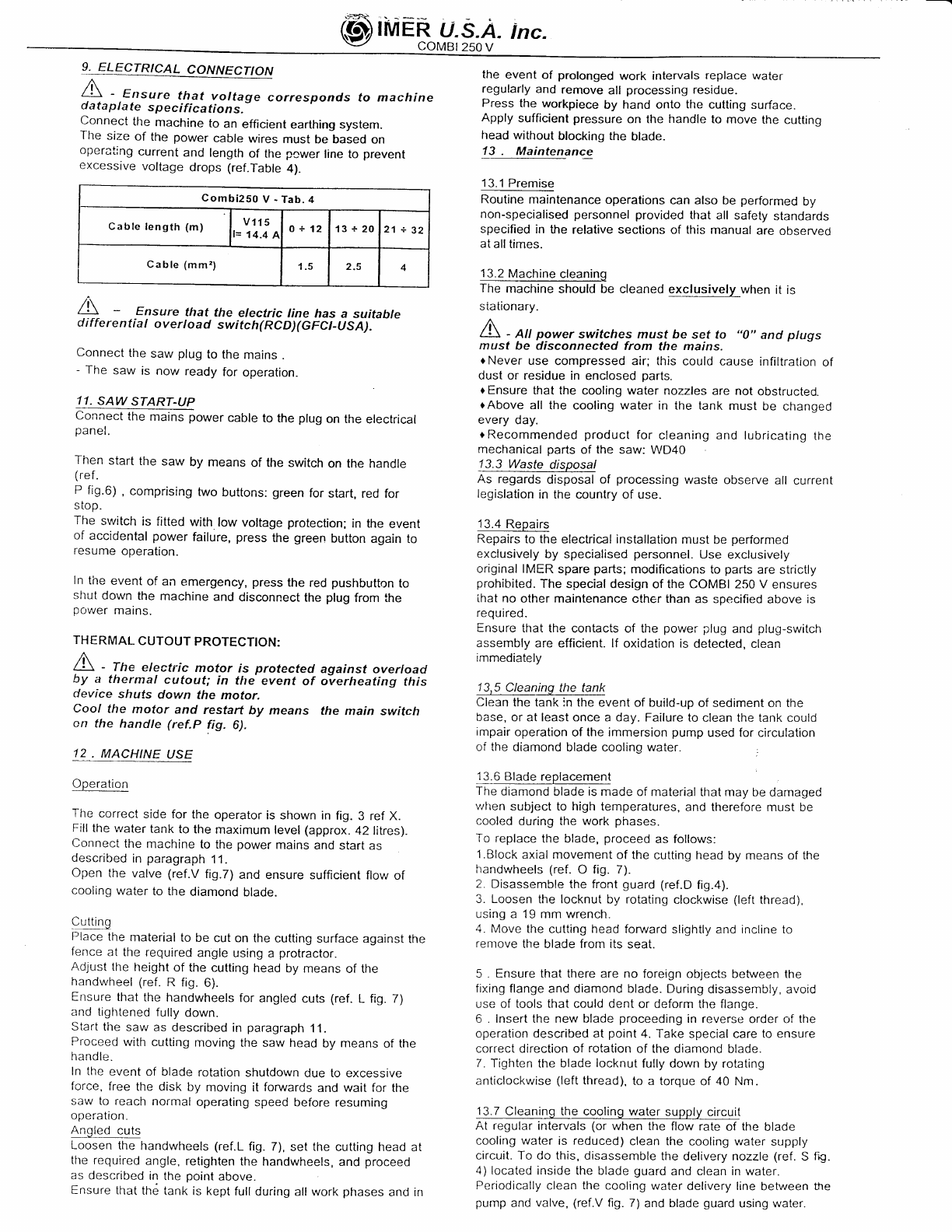

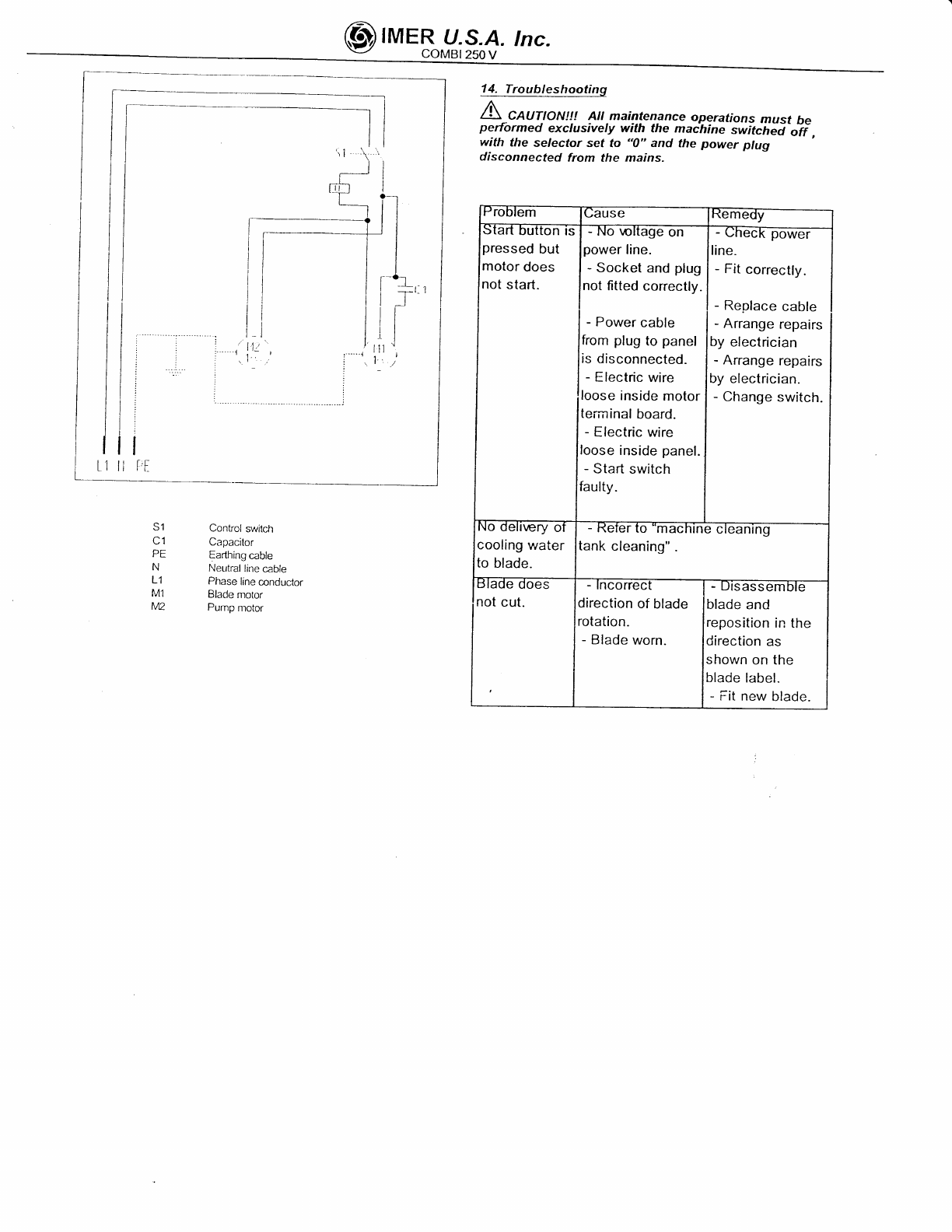

14. Troubleshooting

A-CaUf!ONt!! 4!!.maig.lenance oggrationsmust be

performed exctusivety with the maihine switc-ied-ii,

with the se/ector sef fo "0" and the power plug

disconnected from the mains-

power

pressed

but

motor

does

not

start.

- Power

cable

from

plug

topanel

is

disconnected.

- Electric

wire

loose

inside

motor

tei-minal

board.

- Electric

wire

loose

inside

panel.

- Start

switch

faulty.

not

cut.

-Socket

and

plug

not

fitted

corectlv. - Fitcorrecfly.

- Replace

cable

- Arrange

repairs

by electrician

- Arrange

repairs

by

electrician.

- Change

switch.

S1

C1

PE

N

L1

M1

lv12

Control switch

Capacitor

Earthing

cable

Neutrallinecable

Phase lineconductor

Blade motor

Pump motor

\oltage on

cooling

water

toblade.

erer

to "machtne c

tank

cleaning"

direction

ofblade

rotation-

- Blade

worn.

- ursassemble

blade

and

reposition

in the

direction as

shown on the

bladelabel.

- Fit new blade.

@IMERr/.*# tnc.

t8' SPARF P4RIS :All

orders

forspare

parts

mustindicate

thefollowing:

1- Typeof machine

.2- partnumbercnO po.iti* nr.r*Uu,.

each part.3 - Serial number and year of manufacture reported on the machine's identification

plate.

SYMBOL: Interchangeability

(example):Pos..1

P.n.

2222oo2was installed

on machincs

up toN; SZaOand pos.1.1 p.n. 2222O1Bin

onmachineN'5241 onwards.Pos.

1.1

isinterchangeable( )withPos. 1.Pos.

landPos. 1.1

arenotinterchangeableifthe( )s

appears in the table.

SPARE

PARTS TVOIES

Ref. Code

I2222002 SCREW 5240

2222018 SCREW 5241 _9

TAV.1 MACHINE STRUCTURE

Description

32

10055

22224

49 SCREW

2235

430

2224140 WAS

HE

R6593 8xl8

3207

076 WASHER NYLON 10.5x21xl

M8

5739 8x30

22S4866

2222005 SCREW

2223920

2?24

140 WASHER 6593 10x21

2222098 |

SCREW 5739 10x40

3210625

3210064 GONIOMETER

SUPPORT

32084

23 GONIOMETER

3209332

HANDWI]EEL

JZUOUbJ

32084

1

6GONIOMETER

PIN

3210060 L.n. JUKr^uf

3210061 R.H.

SURrnCe

SCREW 57396x16

3210087 SPRING

3210097 FRONT

ARM

2223280 5588

M6

3210099 SCREW

3210056 RIGHT

FENCE

ADHESIVE

LAEEL

a1)4qtt SCREW 59316x25

3210070

3210071 SUPPORT

3210063 GONIOMETER

ASSEMBLY

2224

530 WASHE

R6592 6x12.5

320

4eA5

3210069 FENCE

ADHESUVE

LABEL

3210068 SLIDEWAY

3210073 REARARM

3210057 LEFTFENCE

ADHESIVE

LABEL

3210018 FRAME

@IMERU,*#tnc.

,/'u

otP.'

) ,23

,a

\21

17

34

t'r F

@tMERu.*# rnc.

13

Q0t

6?

gr-

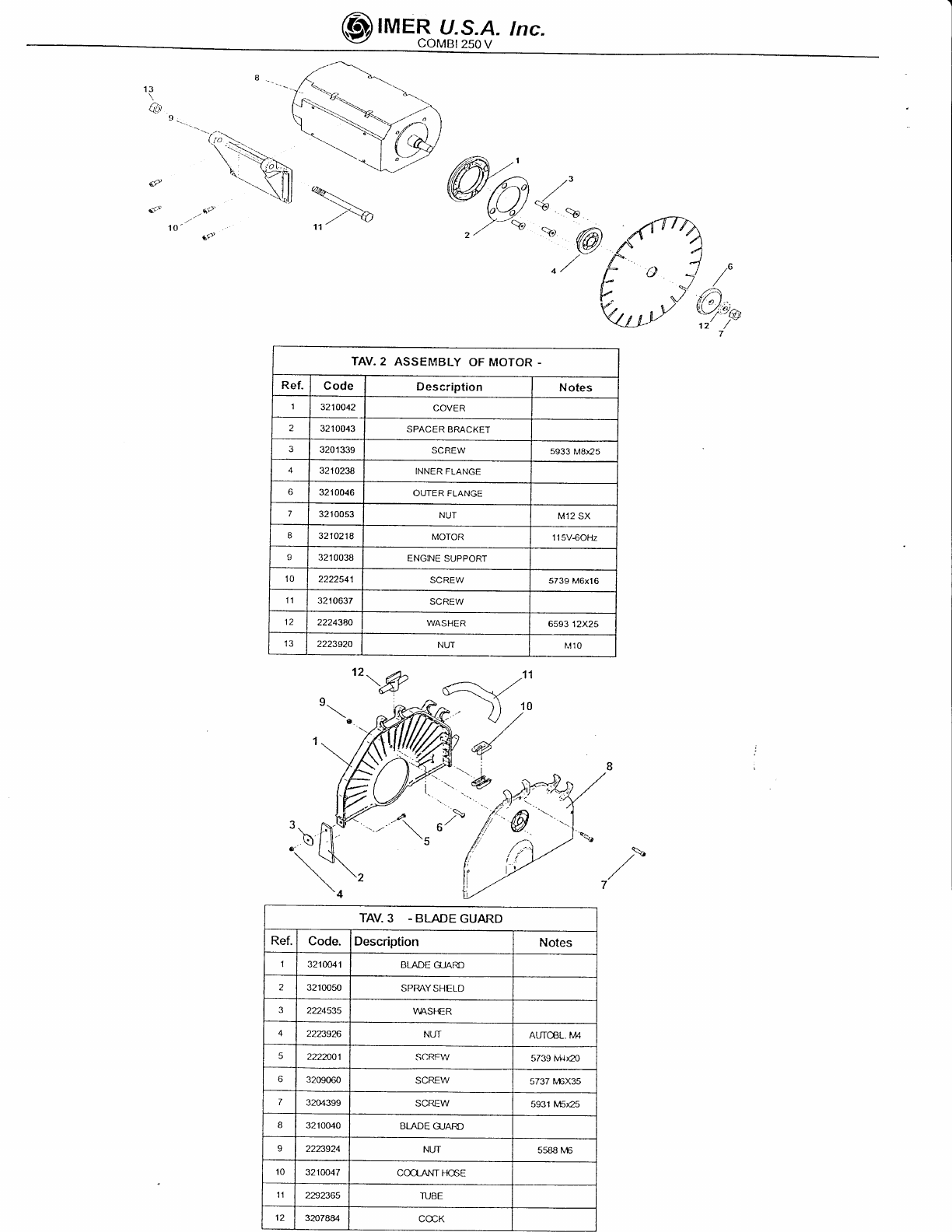

TAV.2 ASSEII,IBLY

OF MOTOR

Ref. Code Desc:'iption Notes

3210042 COVER

z321

0043 SPACER BRACKET

J320

133s SCREW s933

MBx25

32't0238 INNERFLANGE

3210046 OUTER FLANGE

732't00s3 NUT M12

SX

R3210218 MOTOR 11SV$OHz

32

10038 ENGINE

SUPPORT

10 2222541 SCREW 5739 M6x16

11 3210637 SCREW

12 2224380 WASHER 6s93

12X25

13 2223s20 NUT r,,t10

12\& ,t11

10

TAV.3 . BLADE

GUARD

Ref. Code. Description Notes

I32'tOO41 BLADEGJARD

3210050 SPRAYSHELD

2224535 V1IASFER

42223926 NUT AUTGL. t'44

2222!,01 SCRFW 5739ivilfl

o3209060 SCREW 5737l/6X35

73204399 SCREW 5931ft4525

a3210040 BLADE GJARD

2223924 NUT 55BBl\,6

10 3210047 cooiNTl-r6E

't1 22s2365 ruBE

tz 32078A4 CCCK

@IMERU.l;f

rnc.

@b,

)\

'4r' 14

I

6

--\ lg/ 9'/t I

2 -tt -'-, .13

$

4 r -.,_

-tt'

\ ---'

'c\/

\€}.

7./

\

\

B

\^.r-/

(>

ll:<t

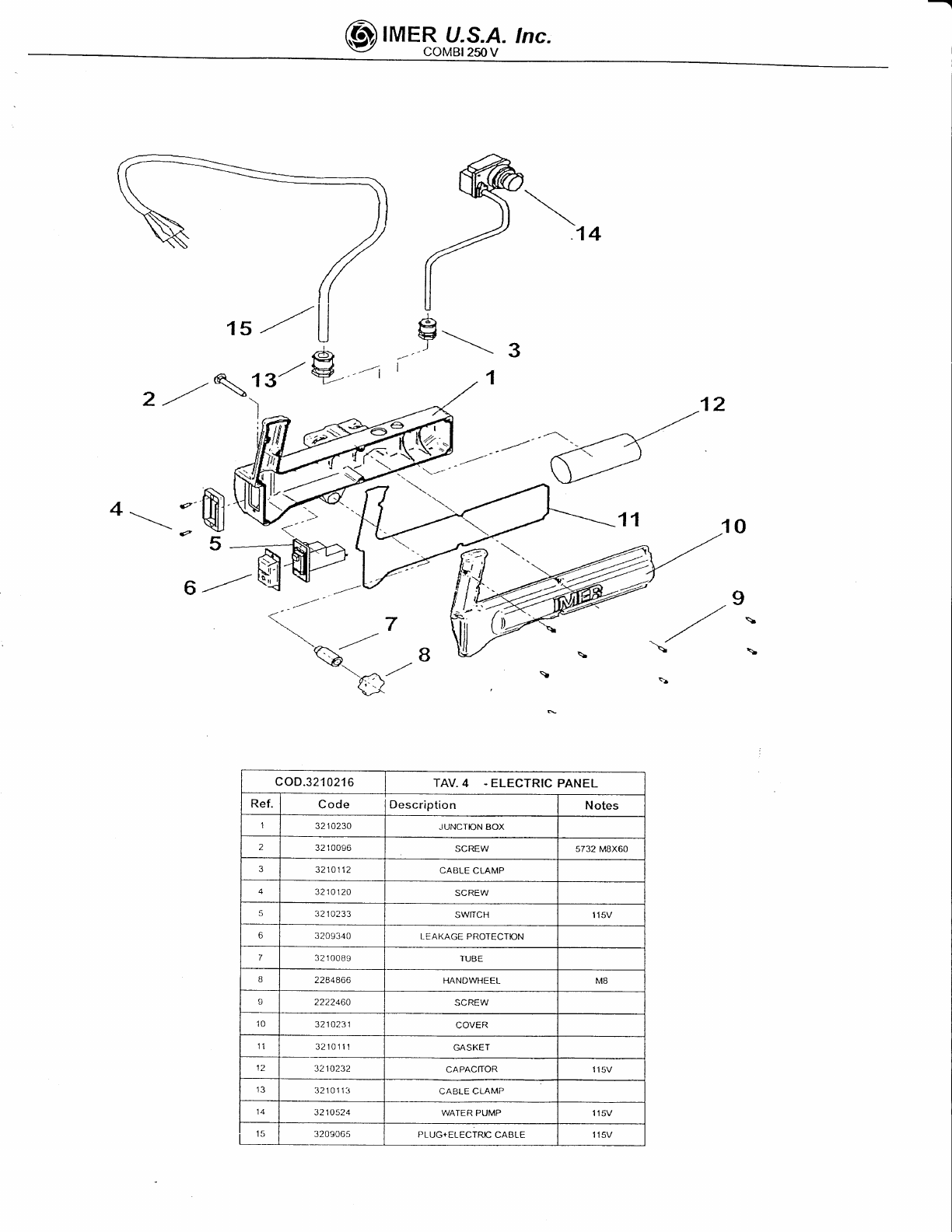

coD.3210216 TAV.4 .ELECTRICPANEL

Ref Code Description Notes

13210230 JUNCTION BOX

23210096 SCREW s732

MBX60

3210112 CABLE CLAMP

3210120 SCREW

53210233 SWIICH 115V

63209340 LEAKAGE PROTECTION

73210089 TUBE

B2284866 HANDWHEEL M8

I2222460 aa Dtrl^t

10 3210231 an\/Eo

'l1321011'! GASKET

12 3210232 CAPACrIOR 115V

3210113 CABLE CLAMP

13210s24 WATER PUMP 115V

15 3209065 PLUG+ELECTRC

CABLE 115V

@tMERui;#.tnc,

,r9

N{s

/

b'

12

., ,2

,,. ,0.

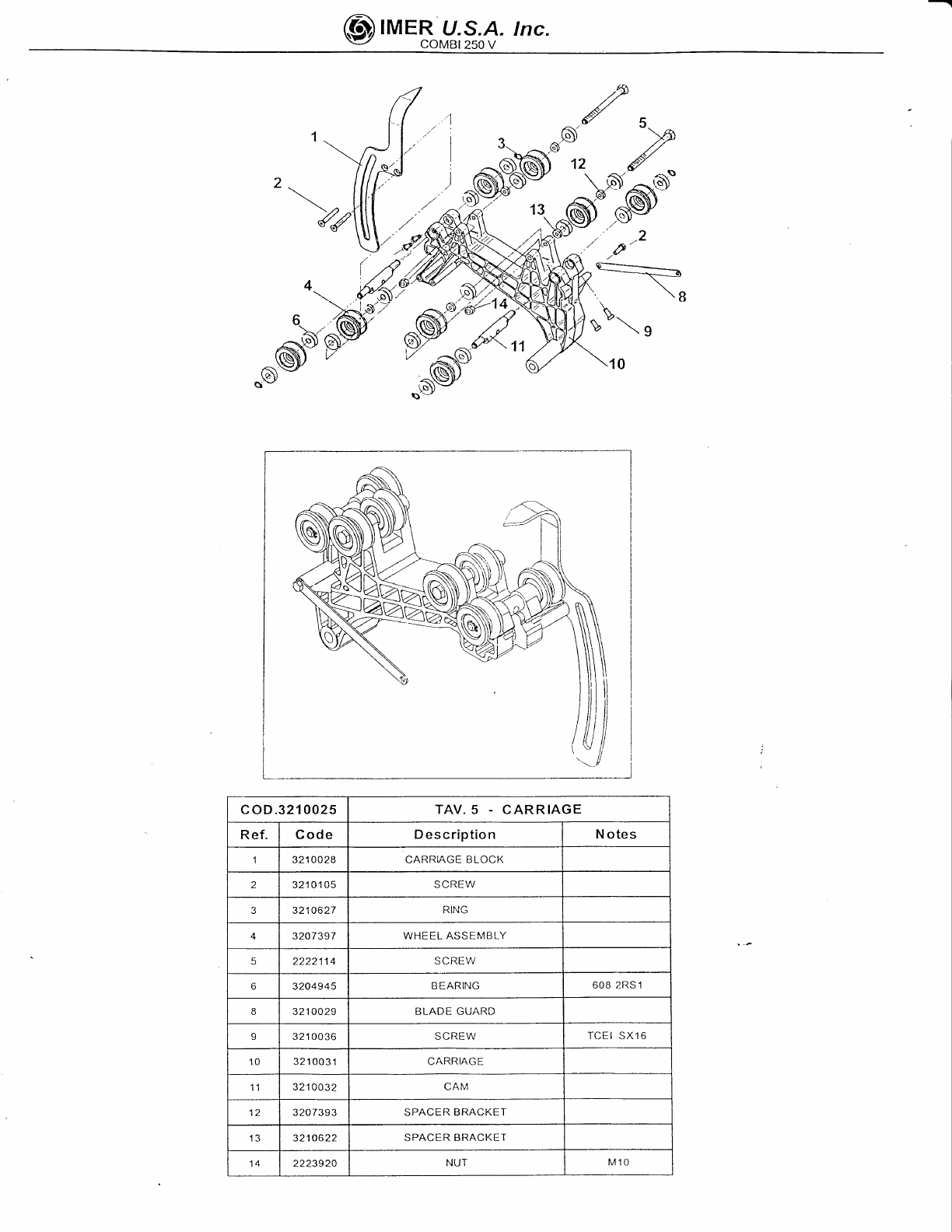

coD.3210025 TAV.5 . CARRIAGE

Ref. Code Description N

otes

3210028 CARRIAGE BLOCK

232't0

105 qaatr\A/

33210627 RING

A3207397 WHEELASSEMBLY

52222114 SCREW

o3204945 BEARING 608 2RS1

a3210029 BLADEGUARD

I3210036 SCREW TCEI SX16

10 3210031 CARRIAGE

tl 3210032 CAM

12 3207393 SPACER BRACKET

13 3210622 SPACER BRACKET

14 2223920 NUT M10

@rME["g;;#

tnc.

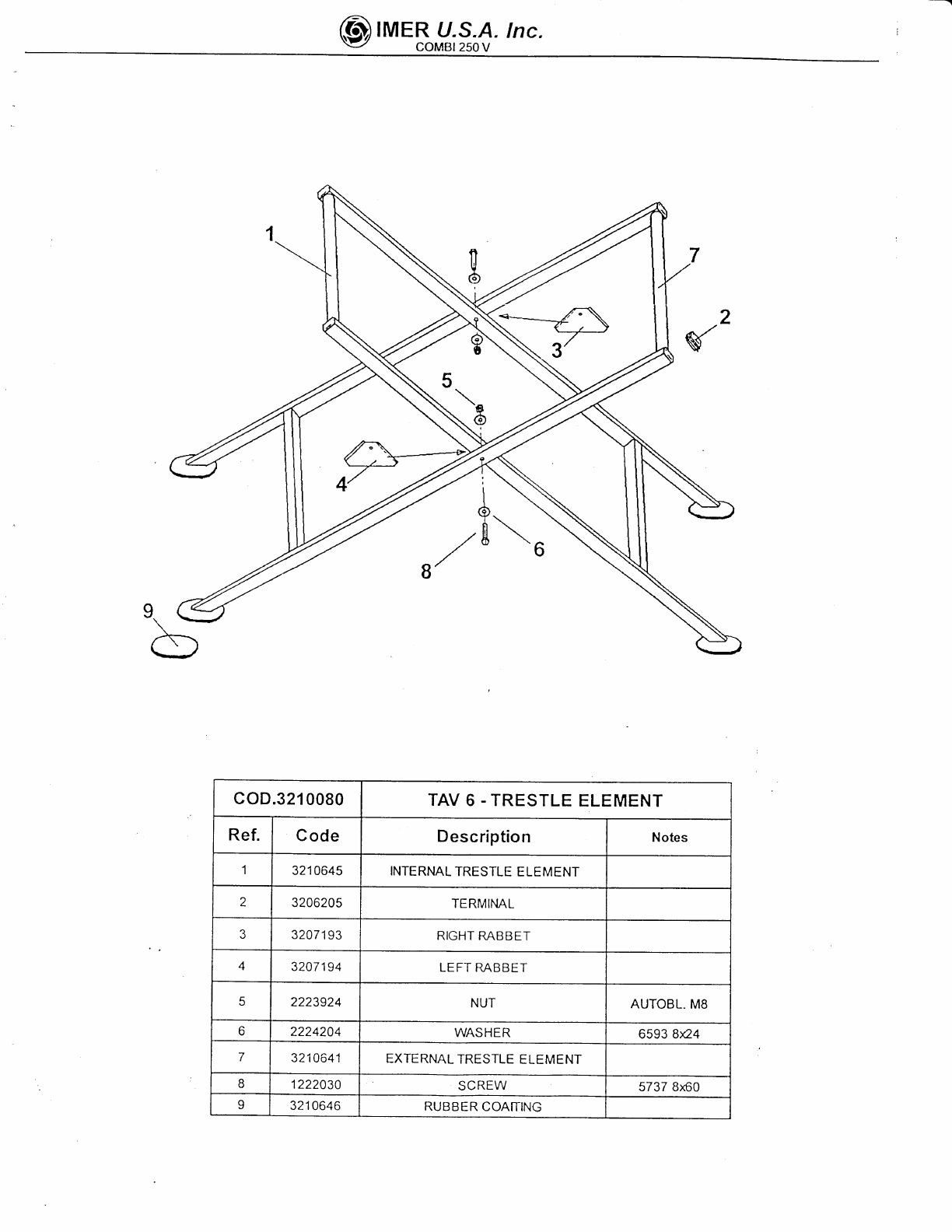

coD.3210080 TAV

6.TRESTLE

ELEMENT

Ref. C

ode D

escription Notes

13210645 INTERNAL

TRESTLE

ELEMENT

23206205 TERMINAL

32071

93 RIGHTRABBET

.+ 3207194 LEFT

RABBET

52223924 NUT AUTOBL.MB

b2224204 WASHER 65938x24

73210641 EXTERNAL

TRESTLEELEMENT

I1222030 SCREW 5737Bx60

9321

0646 RUBBER

COATTING

@tlleRu.;# rnc.

ONE

YEAR

WARRANTY

We

warrant

to

the

originalpurchaser

thattheIMERequipment

described

herein

(the

"equipment")

shall

be

freefrom

defectsinmaterial

and

workmanship

under

normal

use

and

service

forwhich

itwas

intended

fora

period

of

one

(1)yearfrom

the

dateof

purchase

by

the

original

purchaser.

Our

obbligation

under

this

warranty

is

expressely

limited

toreplacing

orrepairing,

free

of charge,

F.O.B.

our

designated

servicefacility,

such

part

or parts

oftlre

equipment

as

our

inspection

shall

discloseto

bedefective.

Parts

such

asengines,

motors,

pumps,

valves,

electric

motors,

etc.furnished

byusbut

notmanifactured

by

us

will

carry

only

thewarranty

of

themanifacturer.

Transportation

chargesorduties

shall

be

borne

bythe

purchaser.

This

shall

be

thelimit

ofourliability

withrespect

to

the

quality

of

the

equipment

This

warranty

shall

not

apply

to

any

equipment,

or

parts

thereof,which

hasbeen

damaged

byreason

ofaccident,

negligence,

unreasonable

use,

faulty

repairs,

or

which

has notbeenmantained

andoperated

in accordance

withourprinted

instructions

for

our

equipment.

Further,

thiswarranty

isvoid

if

theequipment,

or

any

ofits

components,

is

altered

ormociified

inany

way.

THIS

WARRAI.JTY

ISEXPRESSLY

INLIEU

OFALL

CTHERWARM.NTIES,

EXPRESSED

OR IMPLIED,

INCLUDII{G,ANY

IMPLIED

WARRANTY

OF

MERCHANTABILIry

OFFITNESS

FORA

PARTICULAR

PURPOSE.

;

We

make

no

Other

warranty,

representation

or

guarantee,

nor

isanyone

authorized

to

make

one

on

our

behalf.

We

shallnot

beliable

for

anyconsequential

damage

of

any

kind,

including

loss

or

damage

resulting,

directly

orindirectly,

from

theuse

or

loss

ofuse

of

the

machine.

Without

limiting

the

generality

of

theforegoing,

this

exclusion

from

liability

embraces

the

purchase's

expenses

for

downtime,

damages

forwhich

the

purchaser

may

beliable

toother

persons,

damages

to

property,

and

injury

ordeath

of

any

persons.

This

warranty

shall

not

be

deemed

to

cover

maintenance

parts,

including

but

not

limited

to

blades,

belts,

hoses,

hydraulic

oilorfitters,

forwhich

we

shall

have

no

responsability

or

liability

whatsoever.

f

MER

U.S.A.,

lnc.

207

Lawrence

Avenue

South

San

Fancisco,

California

94080

(650)

872-2200

Other manuals for COMBI 250 V

2

Table of contents

Other IMER Saw manuals