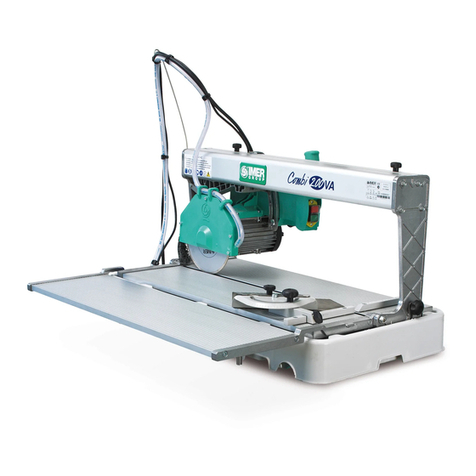

IMER MASONRY 500 Datasheet

ç4jIMER INTERNATIONAL S.p.A.

MASONRY500

Thank-you for purchasinga Masonry 500 from an Imer U.S.A. dealer. Yourdecisionis an intelligentone.

There is no other sawing machine in the world which deliversthe benefitsand features ofthe Masonry350F:

-Extremelyrigid, mig

weldedbarsteelframe.

-5.5H.P. electricmotor.

-Sigle

armforlargerworking space.

-Extremely rigid worktable foraprecise cutting.

At IMER U.S.A.we continuallysearch forwaysto better serve ourcustomers.Should you have an idea orthought to

sharewith usregardingthis productwe wouldappreciatehearingfromyou. Ourmotto is "Tools andServices for the

21stCentury" We look forward todeliveringthe goods.

Thank youagain for your purchase.

MaceT.Coleman, Jr.

President, Imer

USA,Inc.

IMER

WEST

207 LawrenceAvenue

So.SanFrancisco, CA94080

Tel 650-872 -2200

Fax650 -873-6482

2

IMEREAST

221Westhampton Place

Capitol Heights,MD20743

Tel 301 -336-3700

Fax301 -

336- 6681

1.

Carriage locking lever.

2. Spray guard

3. Electric motor

4. Blade aupport

5. waterpump

6. Guide

7. Contactor

8. Worktable

9. Water tank

10. Blade cover

II.Adjuatment crank.

12.Workpiece

13. Blade

14. Frame

15. Earth acrew

16.Pedal.

17. Head atop bolt.

18. Bladeguard.

1!

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Dear

Customer;

Con

gratulationsonyour

choice of

purchase: this IMER saw, the

resultofyears ofexperience,isafully reliable machine andis

equippedwith thelatest technicalinnovations.

/j\-WORKINGINSAFETY

Toworkin completesafety, readthe followinginstructions

carefully.

-ThisOPERATION ANDMAINTENANCEmanualmustbe

kept

onsite

by

the

personincharge, e.g.theSITE

FOREMAN,

andmust

always

beavailableforconsultation.

-

Thismanualistobeconsideredanintegralpart

ofthe

machine,

and

itmustbepreserved

forfuturereference

(EN292/2)throughout

the

machine'snormalworking

life. Ifthe manualisdamagedorlost,a

replacementmay be requested

from thesaw manufacturer

-

Themanualcontains

important

information regarding

sitepreparation,

installation,

machine

use,maintenance

procedures

andrequests

for

spare parts.Nevertheless,

theinstallerand the

operatormust both

haveadequateexperience

and knowledge

ofthemachine priorto

use.

-Toguaranteecompletesafetyoftheoperator, safe operation

and

longlifeof

equipment,

followtheinstructionsinthismanual

carefully,

andobserveallsafety

standards

currently

inforceforthe

prevention

ofaccidents atwork. Use personal protection (safety footwear,

suitable

clothing,gloves,goggles,etc.).

.4'..-Safetyglasses ora

protective visormustbewornatall

times.

/j\-Ear

protection

mustbewornatalltimes.

/j -MAKESURETHAT WARNING SIGNS AREALWAYS

LEGIBLE.

- Itis strictly forbidden tocarry outany form of

modification tothesteelstructure orworkingpartsofthe

machine.

-

IMERINTERNATIONAL declinesall

responsibilityfornon-compliance

with laws andstandards governingtheuseofthis equipment,

in

particular;improperuse,defective power

supply,

lackof

maintenance,

unauthorised

modifications,

andpartial

ortotalfailuretoobservethe

instructionscontainedinthismanual.

IMERINTERNATIONALisentitledto

modifythe

characteristicsofthe

sawing

machineand/orthecontentsofthismanualwithout

necessarily

updatingprevious

machinesand/ormanuals.

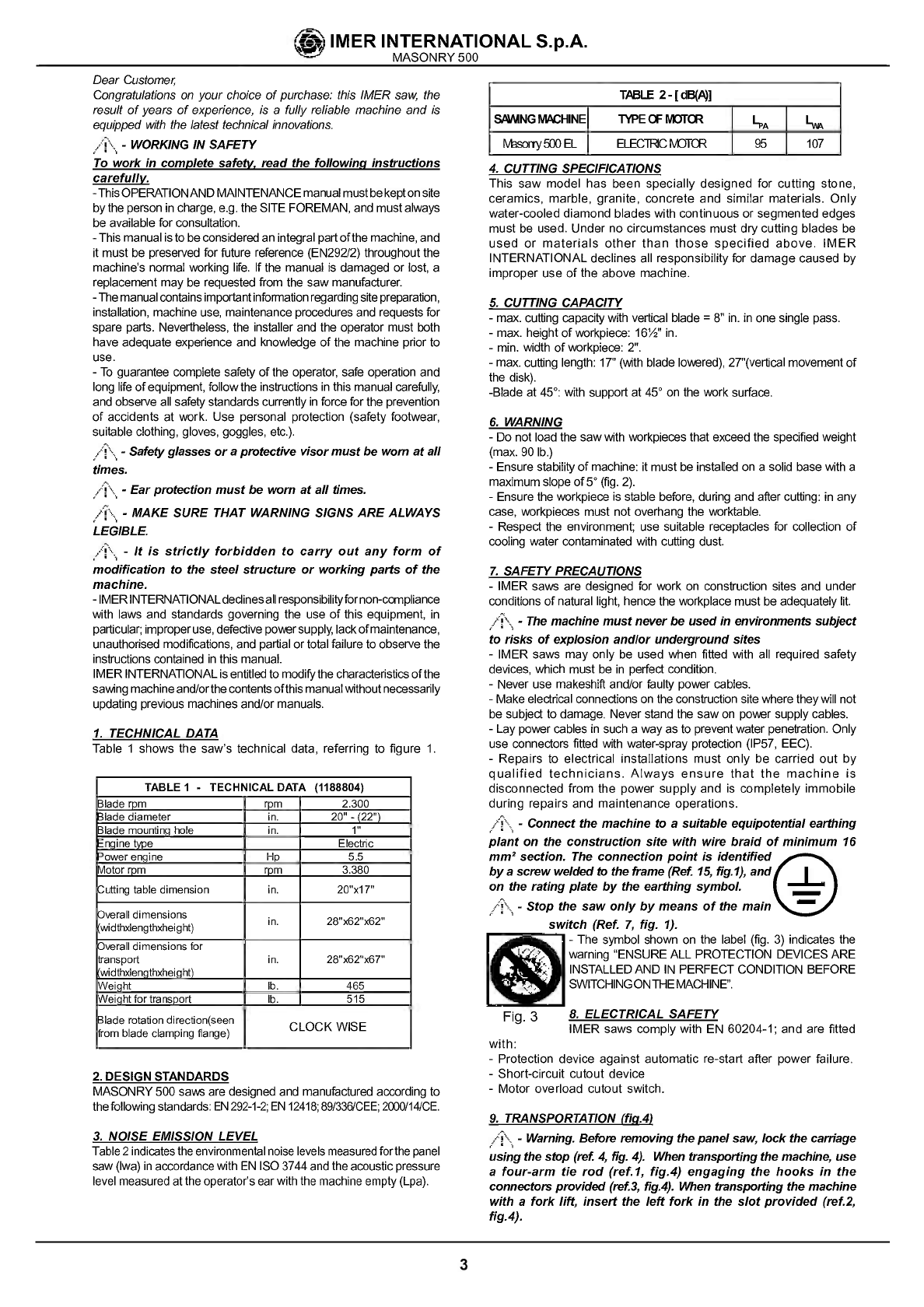

1. TECHNICAL DATA

Table 1 shows thesaw'stechnical data, referring tofigure 1.

TABLEI . TECHNICALDATA (1188804)

llade

rpm rpm 2.300

Blade diameter in. 20"-(22")

Blade mountinghole in. 1"

Enginetype Electric

'owerengine Hp 5.5

otorrpm rpm 3.360

utting

table dimension in. 20"x17"

)veralldimensions

widthslengthxheight) .

in. 2B"x62"x62"

)veralldimensions for

transport

widthslengthxheight) in. 2B"x62"x67"

Weight lb. 465

Weightfortmnsport lb. 515

Blade rotation direction(seen

romblade clampingflange) CLOCKWISE

2.DESIGNSTANDARDS

MASONRY500sawsare

designedandmanufactured

according

to

the

following

standards: EN

292-1-2;

EN12418;89/336/CEE;

2000/14/CE.

3.NOISEEMISSION LEVEL

Table2indicates theenvironmental noiselevelsmeasured forthe

panel

saw(Iwa)

inaccordancewith EN ISO3744andtheacoustic

pressure

levelmeasuredatthe

operator's

earwiththemachine

empty(Lpa).

I Ti4BLE2-[dB(P4]

S6WNGMACHINE TYPEGFIVO1UI LPA Lw,,

Fvhsonysfx)EL ELECTRICFvtJ1CR 95 107

4. CUTTING SPECIFICATIONS

This saw model has been speciallydesigned

forcuttingstone,

ceramics, marble,granite, concreteand similar materials. Only

water-cooled diamond blades with continuous or

segmented edges

must be used. Under nocircumstances must drycutting blades be

used ormaterials otherthan thosespecified above. IMER

INTERNATIONALdeclines allresponsibility for

damage caused by

improper useoftheabove machine.

5. CUTTING CAPACITY

-max.cullingcapacity

withverticalblade

=8"in.inone singlepass.

-max.height

of

workpiece:16Win.

-mm.widthof

workpiece:2".

-

max.cullinglength:17"

(withblade

lowered),27"(vertical

movementof

the disk).

-Bladeat45°: with support

at45° ontheworksurface.

6. WARNING

-Donotloadthesaw withworkpieces

thatexceedthespecifiedweight

(max.

90lb.)

-Ensure

stability

ofmachine:itmust beinstalledonasolid base witha

maximum

slopeof5°

(fig.2).

-Ensurethe

workpiece

isstablebefore,duringandafterculling:inany

case,workpiecesmust not

overhangtheworktable.

-Respecttheenvironment;use suitablereceptacles

forcollection of

coolingwatercontaminatedwith culling dust.

7. SAFETY PRECAUTIONS

-IMERsaws are designedforworkon constructionsites and under

conditionsofnaturallight,

hencethe

workplacemustbeadequately

lit.

-Themachinemustneverbeusedin environments subject

to risks of

explosion

andlor

underground

sites

-IMER saws may only

be used when filledwith all required safety

devices,

whichmustbein perfectcondition.

-Neveruse makeshiftand/orfaultypowercables.

-

Makeelectricalconnectionsontheconstructionsitewhere

theywillnot

besubjecttodamage. Neverstandthesawon powersupplycables.

-Laypower

cablesinsucha

way

asto

prevent

waterpenetration.Only

use connectorsfilled with water-sprayprotection(1P57, EEC).

-Repairs toelectricalinstallationsmust onlybe carriedout by

qualified technicians.

Always ensurethat the machine is

disconnected from thepowersupply

and is completely immobile

during repairs and maintenance operations.

-Connectthemachinetoasuitable

equipotential earthing

planton theconstructionsite with wirebraid ofminimum16

mm2section. Theconnection

point isidentified

by

ascrewwelded totheframe

(Ret15,fig.1),and I

on therating

platebythe

earthingsymbol. __

-Stopthesawonlybymeans ofthemain —

switch (Ref.7, fig. 1).

-Thesymbolshown onthelabel (fig. 3) indicatesthe

waming"ENSUREALL PROTECTIONDEVICESARE

INSTALLEDANDIN PERFECTCONDITIONBEFORE

ISWITCHING ONTHEMACHINE".

Fig. 3 &ELECTRICAL SAFETY

IMER saws comply with EN 60204-1; and arefilled

-Protection device against automatic re-start after power failure.

-Short-circuit cutout device

-Motoroverload cutout switch.

9. TRANSPORTATION

(fig.4)

-Warning. Before removingthe

panelsaw,lockthecarriage

using

the

stop(ret 4,fig.4). Whentransporting the

machine, use

a four-arm tierodfret

1,fig.4) engaging

thehooksinthe

connectors

providedfret3,fig.4).When transporting themachine

withaforklift, inserttheleftforkin theslot

provided fret2,

fig.4).

ctIMER INTERNATIONAL S.p.A.

MASONRY500

with:

3

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

intoposition.

4

IMER INTERNATIONAL S.p.A.

MASONRY500

10. INSTALLATION(flg. 4)

-Liftthemachineoutofitspackageusingslingingequipment

with 4

ropelegs.Fixthehookstotherelative attachments.

-Installthemachineonacompletely

evenandstablesurface.

-Releasethe

carriage

fromtheleverthatsecuresittotheframe.

11. ELECTRICALCONNECTION

/\- Ensurethatthere is an overloadcutoutdevice

fitted up-lineon thepowerline.

-Ensurethatthe mains

voltagecorresponds tothat

specified

forthemachine: 230V/6OHz.Theelectrical power

cable must

be suitably

sizedtoavoid voltagedrops. Cable drumsmustnot

be used.

Connect the machine toan efficient earthing system.

Thesize ofthepower cablewiresmustbe based onoperating

current and length ofthe power line to prevent excessive

voltagedrops (ref.Table 3).

Cables used on construction sitesmustbefittedwith suitable

external sheathing thatis resistant to wear, crushing and

extremeweatherconditions (forexample HO7RN-F).

/\-Allpowersupply installationsmust complywith

CEI 64-8 standards(harmonised

documentCENELEC

HD384).

12.MACHINESTART-UP

Before connecting the machine tothe power supply:

1 -Ensurethatthe metal structure isconnected toanearthing

plantasindicated in Section 7 "Safety Precautions".

2-Ensurethat thetank contains sufficient cooling water.

3-Ensurethatthe

power

circuitcorresponds tothe

requirements

asindicated in Section 11 "Electrical connections"

4-Connect themachine tothe power supply

5-Pressthe black switch (Ref. 7, fig. 1).

/\-Ifrotating direction isopposite tothe arrowon the

guard, stopthe machine andreverse the two

wiresinside thefeedingplug: suchoperation

must be

carriedonbyreliablepersons

6-adjusttheflowofcooling waterbyturning thecocknext to

the blade guard(do notperform cutting without

water).

7-Check thatthedirection ofbladerotation corresponds tothat

indicated by

thearrowonthe blade guard.

8-Ifallisin order, proceed with cutting.

13.EMERGENCYSTOP

/\-Inan emergency,stopthe machine bypressing the

stopcontrolswitch.

/'\,- Themotor isfittedwith an overload cutoutdevice.

Ifthe motor overheats, itwillautomatically

shutdown.

Allowthemotortocooland

press

the blackswitch onthe

overload cutoutdevice torestart

(Ref. 7, fig. 1).

- The motorisprotectedagainstautomaticre-start

afterinterruptions due to power failure. To resume

operation, when powerisre-connected, pressthe black

switchonthe overloadcutoutdevice (Ref. 7,fig. 1).

14.BLADE INSTALLATION (Fig.5)

By

means ofa hexwrench no.10,unscrewthe5screwsthatlock

the

movingblade

guard(ref.3). Use ahexwrenchno.13toremove

thescrewthat locks theflangesonthedisc:thisscrewhasaleft-

handthread (nfl).Removethe mobile

flange(rif.2)

andcheckthat

the

flanges,

discshaft and bladearenot

damaged.

-Neverusewornblades orbladeswithmissingsegments.

/j\-Only usebladesthatare designed

for thenumberof

revolutions indicatedonthe machineratingplate.

-Check thatbladerotation

corresponds

tothatindicated

on the bladeguard.

Centrethebladeagainst

thefixedflange,position

themobile

flange

and tightenthesecuringscrew bymeansofa hexwrenchno.13

(turn clockwise).

Refitthe

moving

blade

guard,tightening

the5screws

(ref.3).

-Ensurethatthebladeguard (ref.3)

islockedsecurely

- WARNING!Anincorrectly installed blade,or a

screw insufficiently tightened can

provoke damagetothe machine orinjury , -.

topersons. .

Notethat the blademust have an -

external diameter of20"in. a central hole

diameterof1"in.andinex. thicknessof118"in. !.-

-Checkthatthe blade tobe usedis

suitable forthe material tobe cut.

/j\ -Donotusebladesforwood! (fig. 6). Fig. 6

15.USE

/\-Leaveaspace of5ft.around themachine toopera-

te in fullsafety.

-Do notallowotherpersons toapproach themachine during

cutting.

-Neverusethemachine infire-riskareas. Sparks cancausefire

or explosions.

-Makesurethat themachine isswitched offbefore positioning

orhandling.

-Alwaysensurethat the bladeisfree ofany contactbefore

start-up.

-Ensurecorrectinstallation ofallprotective devices.

Before starting work, fill thewatertank.

Top upduring operation

whenevernecessary: NB. the pumpsuction hosemust

alwaysremain immersed in water.

-Insert theplug in thepower socket.

- WARNING! Forsafety purposes the removal of

protective

guards

fromthemachine isstrictlyprohibited

The machine is protected against overload: this

protection triggers stopping the machine, afterwhich

thetime necessary

fortheoverloadtocool mustpass

before itispossible

torestartthe machine.

- WARNING!

Alwaysswitchoffthe machine before

carryingoutbladeadjustment.

15.1 VERTICAL MOVEMENT OFTHEDISK.

Toraiseorlower the

cutting wheel, turnthecrank

(ref.11,fig.1)

until thewheel is attherequired height above the

cutting table.

Thewheel canalsobe lowered bypressing the pedal (ref.16,

fig.1); when thepedal isreleased thecutting wheel willreturn to

theposition originally setusing thecrank.

/?\-Ensure that the lockinghandle is tightenedfully

before

starting work.

15.2POSITIONING FOR45°CUTS.

To machine a45° cut, it isnecessary tousethe45° support.

Placethe45°

support onthe

cuttingtableinthepositionrequired,

fixthesupport

tothecarriage bylocking theflywheel provided,

then positionthepiecetobecut,

afterwhich itis possibletostart

themotorandcommence cutting operations

15.3 CUTTING

Forsafe useofthe machine when cutting, pushthe carriage

forwards asthe cut advances, placingyour hands tothetwo

sidesofthecarriage. Never

pushdirectly onthepiecetobecut.

-Checkthat the bladeisalignedwith the cutting

line.

-Place the workpiece on the worktable (ref. 8,fig. 1), resting

firmly against

thestop.

-Starttheengine.

-Waituntilthewaterreachestheblade.

-Begin cutting.

-

Horizontalcuttingmovement iscarriedout

bypullingthe

carriage

towards the blade.

-

Ascutting

thickness

increases,thebladeissubjected

togreater

stress. Toavoid overloading

theengine, the

operator should

continually

checkbladefeed speed. The

speedwillalso depend

on the characteristicsofthe

material being

cut(hardness, toughness etc.).

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

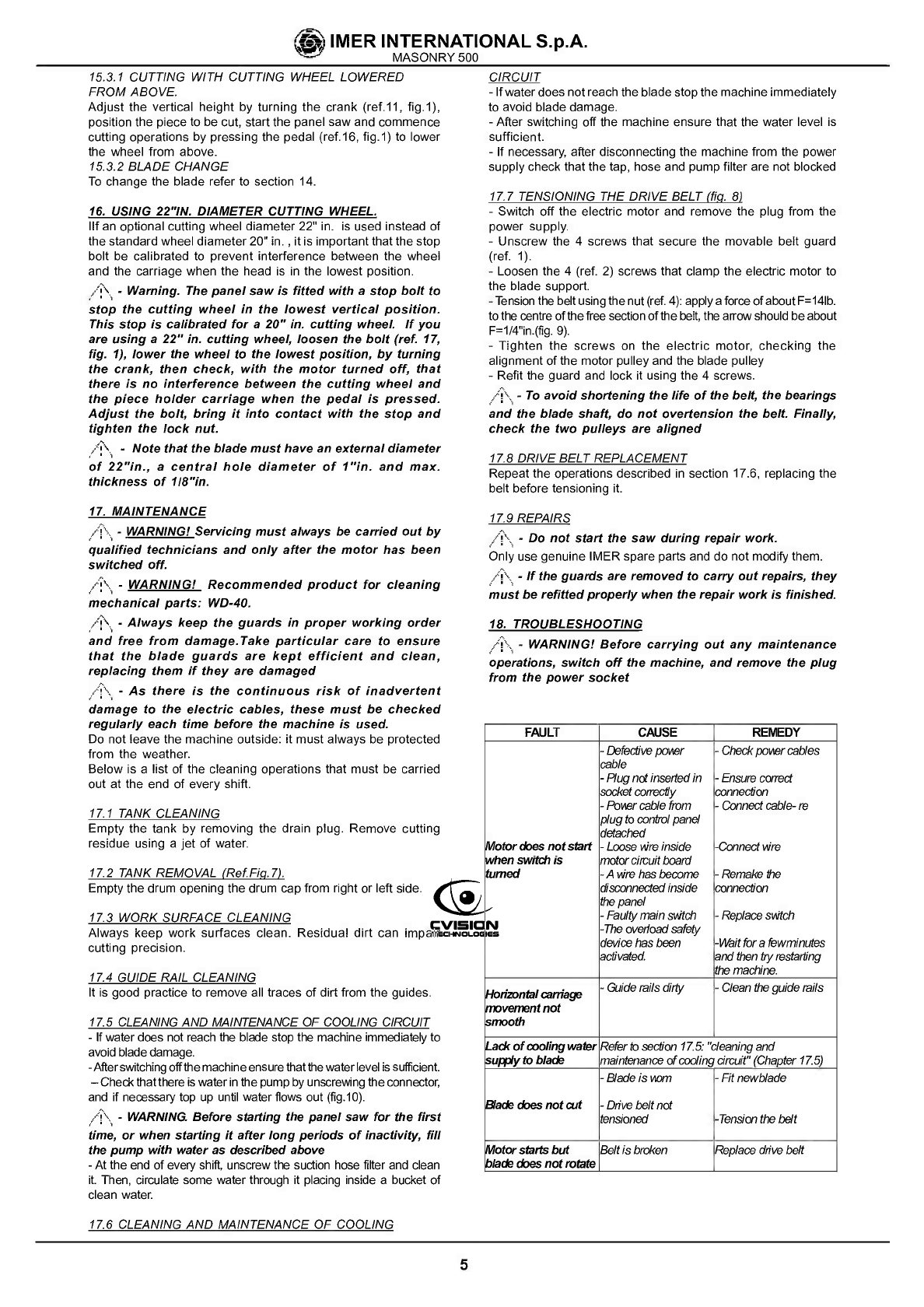

15.3.1 CUTTING WITH CUTTING WHEEL LOWERED

FROMABOVE.

Adjust the verticalheight byturningthe crank (ref.11, fig.1),

positionthepiece

tobecut,

startthepanel saw andcommence

cutting operations bypressing thepedal(ref.16, fig.1)tolower

the wheel from above.

15.3.2BLADECHANGE

Tochange thebladerefertosection14.

16. USING

22"IN.DIAMETER

CUTTING WHEEL.

hfan optional cutting wheel diameter22" in. isusedinstead of

thestandard wheel diameter 20'in., itisimportantthatthe

stop

boltbe calibrated to prevent interference between the wheel

and thecarriage

whentheheadisin the lowest position.

-Warning. The

panel

sawisfittedwitha stopboltto

stopthe cutting wheelin the lowest verticalposition.

This stopiscalibrated fora2O'in. cutting

wheel. If

you

areusing

a22"in.cuttingwheel,loosenthe bolt(ref. 17,

fig. 1), lowerthe wheeltothelowest

position, byturning

thecrank,then check, with the motor turned off, that

there isno interference between the cuttingwheeland

thepiece holder

carriagewhenthepedal is pressed.

Adjust thebolt, bringitintocontactwith the stopand

tightenthelocknut.

- Notethattheblade musthaveanexternal diameter

of22"in., a central hole diameter of 1"in. and max.

thickness of1I8'in.

17.MAINTENANCE

/j\-WARNING! Servicing must

alwaysbecarried outby

qualified technicians andonlyafterthe motorhas been

switchedoff.

-WARNING! Recommended product forcleaning

mechanical

parts: WD-40.

-Alwayskeep the guards

inproper working

order

and freefromdamage.Take particular

care toensure

that the blade guards are keptefficientand clean,

replacing

themifthey aredamaged

/i-As there is the continuous risk ofinadvertent

damage tothe electric cables, thesemustbe checked

regularly

each timebefore the machine isused.

Donotleavethemachine outside: itmust

always

be protected

from the weather.

Below isalistofthecleaningoperations thatmustbe carried

out atthe end ofeveryshift.

Empty the tank byremoving the drain plug. Remove

cutting

residue usinga jet

ofwater.

17.2TANK REMOVAL (Ref.Fig.7).

17.3WORKSURFACE CLEANING

Alwayskeep work surfacesclean. Residual dirt can impair

cutting precision.

17.4 GUIDE

RAIL

CLEANING

Itisgood practice toremove all traces ofdirtfromtheguides.

17.5 CLEANINGAND MAINTENANCEOFCOOLING CIRCUIT

-Ifwaterdoesnotreachtheblade

stopthemachineimmediately

to

avoidblade

damage.

-After

switching

offthemachineensurethatthewaterlevelissufficient

—

Checkthatthereiswaterinthe

pumpbyunscrewing

the

connector,

and ifnecessarytopup untilwaterflows out(fig.10).

- WARNING Beforestarting thepanel

sawforthe first

time,orwhenstarting

itafter

longperiods ofinactivity, fill

the

pump with waterasdescribedabove

-Attheendof

everyshift,

unscrewthe suctionhosefilterand clean

it. Then,circulatesome waterthrough it placing insidea bucketof

clean water.

CIRCUIT

-

Ifwaterdoesnotreach thebladestopthemachine immediately

toavoid blade

damage.

-

Afterswitching offthemachine ensurethat thewaterlevel is

sufficient.

-Ifnecessary,afterdisconnecting themachine fromthepower

supply check thatthe

tap, hoseandpump filterarenotblocked

17.7TENSIONING THEDRIVEBELT(fig. 8)

-Switch offtheelectricmotor and remove the plug from the

power supply.

-Unscrew the 4screwsthat secure the movable beltguard

(ref. 1).

-Loosen the4(ref. 2)screws thatclamptheelectric motorto

the blade support.

-

Tensionthebelt

using

thenut

(ref. 4):apply

aforceofaboutF=141b.

tothecentreofthefreesectionofthe

belt,

thearrowshouldbeabout

F=1/4'in.(fig.9).

-Tighten the screws on the electric motor, checking the

alignment ofthemotor

pulley andtheblade pulley

-Refittheguard and lock itusing the4screws.

-Toavoid

shortening thelifeofthebelt, thebearings

andthe blade shaft,donotovertension the belt.Finally,

checkthetwopulleysarealigned

17.8DRIVEBELTREPLACEMENT

Repeat theoperations described in section

17.6, replacing the

beltbefore tensioning it.

17.9 REPAIRS

/?\-Do notstartthe sawduring repair

work.

Onlyuse

genuine IMER spare parts anddo not

modifythem.

/\-Iftheguards are removedtocarryoutrepairs, they

mustberefitted

properly

whentherepair workisfinished.

18. TROUBLESHOOTING

-WARNING!Before

carryingout anymaintenance

operations,switch offthe machine,andremove the plug

fromthe powersocket

FAULT CAUSE RENEDY

1otorcbesnotstart

i'Menswitchis

turned

-

Defective povter

cable

-

Plugnotinsertedin

socket

correctly

-Povrcablefrom

plugtocontrol panel

detached

-

LooseWreinside

motorcircuitboard

-

Avrehasbecome

disconnected inside

the

panel

-

Faulty

mainsvitch

-Theoverload

safety

devicehasbeen

activated,

-

Check

povier

cables

-

Ensurecotrect

connection

-Connectcable-re

-Connect Wre

-

Remakethe

connection

-

Replace

sii'itch

-Waitforafewminutes

andthen

tiyrestarting

themachine.

Horizontal

movementnot

;mooth

-Guiderails

dirty -

aeanthe

guide

rails

Ladcof

coolingwater

upply

toblade ReIrtosection17.5:'cleaning

and

maintenance of

cooling

circuit"

(Chapter 17.5)

Bladeckesnotwt

-

Bladeiswm

-Dflve beltnot

tensioned

-

Fitnewbiade

-Tension thebelt

ñotorstartsbut

ladecesnotrotateBeltisbroken Replace chivebelt

IMER INTERNATIONAL S.p.A.

MASONRY500

17.1 TANK CLEANING

Emptythedrum opening thedrum cap

fromright

orleftside.

17.6 CLEANING ANDMAINTENANCE OF COOLING

5

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

ç4jIMER INTERNATIONAL S.p.A.

MASONRY500

,1

TAV.2

TAV.1 -45SUPPORT (cod.3210526)

Rif. Cod. GB Note

1 2284859 KNOB I

6— Ti r

13 t3—18

1\

TAV.2-

ASSEMBLYOFMOTOR

a 9 t'e7

16

RIF. COD. GB NOTE

1 3210714 MOTOR 230V/6OHZ

2 3210539 BELTS EXTERNAL

COVER

3 3210570 BELT 560J12

4 3210740 BELTS INTERNAL

COVER

5 3210716 JUNCTIONBOX

6 3210721 CAPACITOR pF8O-450V

7 3203921 BOLT M5X1OZ

8 3210573 PULLEY

9 1222059 BOLT M1OX2O

10 2224220 WASHER 10X40

11 2224380 STOP RING 12X25

12 2223700 SELFLOCKING

NUT M.12

13 2222181 BOLT M 12X30

14 2222076 BOLT M8X25

15 2224140 WASHER 8X18

16 2223923 SELFLOCKING

NUT M.8

17 2222189 BOLT M8X45

7

18 3206170 POMP SWITCH

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

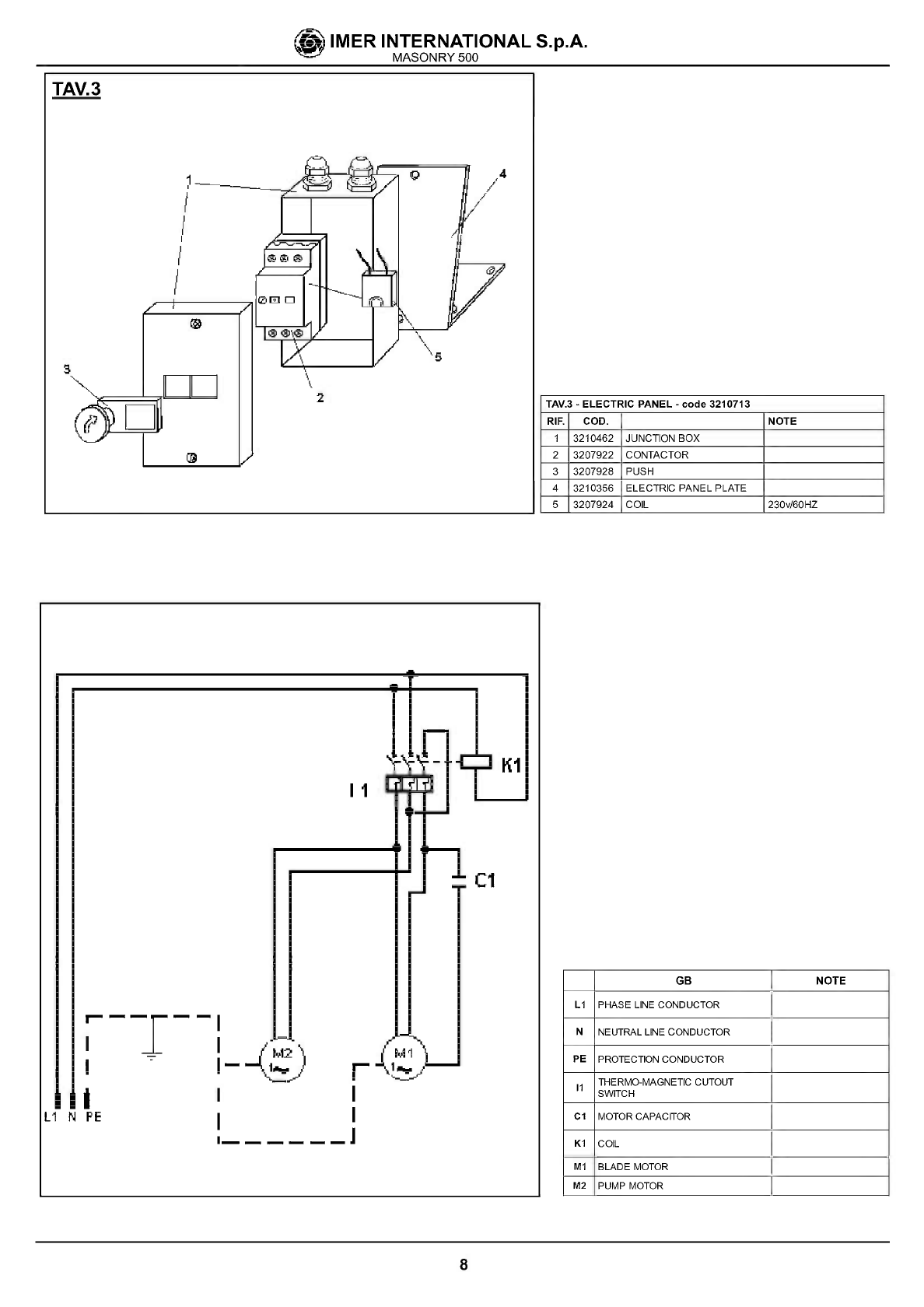

8

GB NOTE

LI PHASE LINE CONDUCTOR

N NEUTRAL LINE CONDUCTOR

PE PROTECTION CONDUCTOR

II THERMO-MAGNETIC CUTOUT

SWITCH

Cl MOTOR CAPACITOR

KI COIL

Ml BLADEMOTOR

M2 PUMPMOTOR

TAV.3

ç4jIMER INTERNATIONAL S.p.A.

MASONRY500

I

/

2 TAV.3

-ELECTRICPANEL-code3210713

RIR COD. NOTE

1 3210462 JUNCTIONBOX

2 3207922 CONTACTOR

3 3207928 PUSH

4 3210356 ELECTRICPANELPLATE

5 3207924 COIL 230v/60H7

is

II

Cl

r-I--I

I I

I

IA N FE

I- r

I I

I———— ——I

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

ç4jIMER INTERNATIONAL S.p.A.

MASONRY500

TAV.4

-MACHINESTRUCTURE

UxiSZ

9

TAV.4-MACHINESTRUCTURE

RIF. COD. GB

3215356 ELECTRIC PANEL PLATE

92 3210530 CUTTING WHEELLH GUARD

48 2224145 WAUHER UxIR Z

NOTE

RIF. COD. GB NOTE

I 3258421 CARRIAGE

2 3215577 SINGLE-PHASECOVER

3 2222550 EOLT 5831 M0X20

4 3254945 REARING E0R-2RS1

5 2223923 SELELOCKINGNUT M.5

U 3257397 WHEEL

7 2222090 ROLT 9737V8x75

U 3216311 GUOE RAN

9 3208442 LEETPENCE

ADHESIVE

16 3208441 RICHTPENCEAOHEUVE

11 3200501 RUBBERCOAITING

12 3210402 WASHER

13 2265675 SHOCKARSORRER

14 3210342 PEDALPIPE

15 3210560 CUTTING HEAD

GROUP

16 3210407 SUPPORT

17 2223929 SELPLOCKINGNUT V10

18 3206965 PLUG

19 2222567 SCREW 5933VSS2U

20 2218406 SPRAYGUARD

21 3210249 PRAME

22 2216270 ADJUSTING ROD PIPE.

23 3210337 KNOB

24 0329 DRUM

25 35428 PLUG

26 6712 WATERPUMP 23SVWSHZ

27 27320 OILSEALRING

28 3 0313 SCREW

29 3 8571 SHAPT

30 3186 NYLONBUSHRG

31 22002 SCREW 0738M6x16

32 2059 SCREW 5739M8X25ZOX.

33 8414 LEVER

34 8422 ONIDMETER

35 7213 IDEEARSUPPORT

36 3208428 TROLLEYSLIDE

37 3210236 GUIDEBARSUPPORTSX

38 2222568 SCREW M4X20Z

W 21 23 03 6 CUTTING WHEELCASING

ADJUSTMENT

48 3209333 KNOB MU

41 3208426 TROLLEYCLAMPING

42 2224536 WASHER

43 2223288 SCREW

44 3209332 CAM

45 2222818 SCREW M4

47

45 3210713 JUNCTION BOX 23SVWOHZ

49 2285585 HANDGRIP

55 3205013 REARING 62002R5

51 3210301 DRCCOVER

52 3232759 OILSEALRING 3NX52X7

53 3204777 INNER PLANGE

54 3204776 OUTER FLANGE

55 3210317 WATERHOSE

56 3210629 REARING 60062R5

57 2218075 VALVE

58 3210322 BLADECOVER

68 3215189 SELPLOCKINGNUT M.28

61 3210572 PULLEY

62 2204655 SUPPORT

64 3210346 PLUG 155x55x3

65 3215278 BLADEGUARDROTATION ROD

66 3215315 SPRING DE56.5

67 3210316 CALLIPERPLATE.

68 3210325 CALLIPERPIN

69 3210319 SPRAYGUARD

78 3210353 TIEROD SCREW IOXUO

73 3210412 FILTERPIPE

74 2228780 SNAP-PIN

75 1222694 SCREW MIS X11S

76 3210345 PULLEY 85X45X3

77 3210323 PULCRUM PIN

78 3210324 PEDALPIN

79 3210483 LOCKING PIPE

85 1224323 WASHER

81 2209400 NYLON RUSHING 3SAP.

82 2228700 SPLITPIN

83 3208329 SPACERRRACKET

85 3210411 SPACERBRACKET

86 2222130 BOLT M16055

97 2223506 NUT D.1U

58 2223650 NUT 0.10

69 2257785 PULLEY

98 3210532 GASKET

91 3210531 CUTTING WHEELRHGUARD

46 2224148 WASHER

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

ONEYEARWARRANTY

Wewarrant totheoriginal purchaser thatthe IMER equipment described herein

(the"equipment") shall befreefrom defectsin material and workmanship under

normaluseandserviceforwhichitwasintendedforaperiod ofone(1)year

from

thedateofpurchaseby

theoriginalpurchaser.

Ourobbligationunderthiswarrantyis

expressely limitedtoreplacingorrepairing,

freeof charge, F.O.B.our designated service facility, such part orparts ofthe

equipmentasourinspectionshalldisclosetobedefective.Partssuchasengines,

motors, pumps,valves,

electricmotors,etc.furnished

byusbutnotmanifactured

by

uswillcarryonly

thewarrantyofthemanifacturer.

Transportationchargesorduties

shallbebornebythepurchaser.

Thisshallbethelimitofour

liabilitywith respect

to

thequalityoftheequipment.

This

warranty

shallnotapplytoanyequipment, orpartsthereof,whichhas been

damaged byreasonofaccident, negligence, unreasonableuse,faultyrepairs, or

which has not been mantained and operated in accordance with our printed

instructionsforour

equipment.Further,

thiswarrantyisvoidiftheequipment,

or

any

ofitscomponents,isalteredormodified inanyway.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSEDOR IMPLIED, INCLUDINGANY IMPLIED WARRANTYOF

MERCHANTABILITYOFFITNESSFORAPARTICULARPURPOSE.

Wemake noother

warranty,representation

or

guarantee,norisanyone

authorized

tomakeoneonourbehalf.Weshall notbeliablefor

anyconsequentialdamageof

anykind, including loss or

damage resulting,directly

orindirectly,

fromtheuseor

loss ofuseofthe machine. Without limiting the generality oftheforegoing, this

exclusionfrom

liabilityembracesthepurchase'sexpenses

for

downtime,damages

forwhichthepurchaser maybeliabletoother

persons,damages toproperty,

and

injury

ordeathof

anypersons.

This

warranty

shallnotbedeemed tocover maintenance parts,including butnot

limitedto blades,belts, hoses, hydraulic oil or

filters, forwhichweshall have no

responsabilityor

liabilitywhatsoever.

IMERU.S.A.,Inc.

207LawrenceAvenue

SouthSan Fancisco, California94080

(650)872-2200

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Other manuals for MASONRY 500

2

This manual suits for next models

1

Table of contents

Other IMER Saw manuals