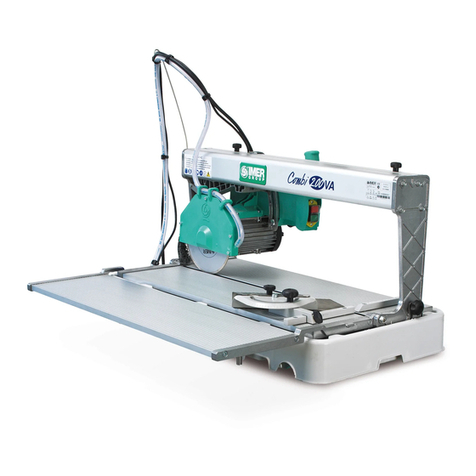

IMER COMBI 250 VA Guide

COMBI 250 VA

SAWING MACHINE

OPERATING, MAINTENANCE, SPARE PARTS MANUAL

IMER WEST

3654, Enterprise Avenue

Hayward, CA 94545

Ph. 510.670.7970

Fax 510.783.4255

IMER EAST

221 Westhampton Place

Capitol Heights, MD 20743

Ph. 301.336.3700

Fax 301.336.6687

IMER U.S.A. Inc.

Toll Free: 800.275.5463

www.imerusa.com

2015/09 - R05

Cod. 3226143

IMER U.S.A. Inc.

COMBI 250 VA

2

Dear Customer,

Congratulations on your choice of purchase: IMER saws are the result

of years of experience and are equipped with all the latest technical

innovations.

- WORKING IN SAFETY

To work in complete safety, read the following instructions care-

fully.

To work in complete safety, read the following instructions carefully be-

fore using the machine.

To work in complete safety, read the following instructions carefully be-

fore using the machine.

This OPERATION AND MAINTENANCE manual must be kept on site

by the person in charge, e.g. the SITE FOREMAN, and must always be

available for consultation.

The manual is to be considered integral part of the machine and must

be kept for future reference (EN 12100-2) until the machine is disposed

of. If the manual is damaged or lost, a replacement may be requested

from the manufacturer.

The manual contains important information regarding site preparation,

machine use, maintenance procedures, and requests for spare parts.

Nevertheless, the installer and the operator must both have adequate

experience and knowledge of the machine prior to use.

To guarantee complete safety of the operator, safe operation and long

life of equipment, follow the instructions in this manual carefully, and

observe all safety standards currently in force for the prevention of ac-

cidents at work (use of safety footwear and suitable clothing, helmets,

gloves, goggles etc.).

- Make sure that all signs are legible.

- It is strictly forbidden to carry out any form of modification to

the steel structure or working parts of the machine.

IMER INTERNATIONAL declines all responsibility for failure to com-

ply with laws and standards governing the use of this equipment, in

particular; improper use, defective power supply, lack of maintenance,

unauthorised modifications, and partial or total failure to observe the

instructions contained in this manual.

IMER INTERNATIONAL reserves the right to modify features of the saw

and contents of this manual, without the obligation to update previous

machines and/or manuals.

1. TECHNICAL DATA

Technical data are stated in table 1 and electrical specifications in table

2.

Table 1 - TECHNICAL DATA

Model Combi 250 VA

Max. blade diameter 10 inches

Diamond Blade hole diameter 5/8 inches

Single phase 115V/60Hz motor power 1.3 kW

Max. blade rotation speed 3.400 rpm

Cutting table dimensions 850x500 mm

Length of 90° cuts (thickness= 10mm)

Length of cuts from above

550 mm

600 mm

Maximum cut depth with single stroke

Maximum cut depth with two stroke

66 mm

105 mm

Water pump flow rate 13 L/1’

Water tank capacity 36 L

Machine dimensions 1050x565x480 mm

Packed machine dimensions 1090x610x525 mm

Weight with packaging 45.5 Kg

Table 2

Feature Motor (115V/60Hz)

Power (kW) 1.3

Rated voltage (V) 115

Frequency (Hz) 60

Absorbed current (A) 14.4

Number of poles 2

rpm 3400

Service type S6 40%

Insulation category F

Protection category IP55

Capacitor (μF) 110 (Ø 50x120)

2. DESIGN STANDARDS

Combi 250 VA saws have been designed and manufactured according

to the following standards: UNI EN 12418:2001; EN 12100-1/2:2005;

EN 60204-1:2006.

3. SOUND PRESSURE LEVEL AND VIBRATIONS

Table 3 shows the sound pressure level measured loadless at the ope-

rator’s ear (LpA) and of the vibrations transmitted during operation.

Table 3

Model Type of motor LpA Aeq

Combi 250 VA Electric 86 dB 2.57 m/s2

4. GENERAL SAW DESCRIPTION

4.1 General description

The Combi 250 VA is a saw comprising the following main sub-groups:

• cutter head (ref.A, fig.1)

• runner guide and arms (ref.B, fig.1)

• cutting tables and heads (ref.C, fig.1)

• water collection tank (ref.D, fig.1)

• frame (ref.E, fig.1)

The cutting head is mounted on a reinforced aluminium profile and is

equipped with horizontal and vertical movement facilities. The alumi-

nium profile is hinged onto die-cast arms (ref.F, fig.1) and the entire

unit can rotate through 45° (fig.2) by means of the relative handwheels

(ref.G, fig.2).

The machine is supported by a special metallic frame. There is a

shockproof plastic tank between the machine and the frame. The water

immersion pump is mounted below the cutting surfaces on a special bra-

cket and supplies a water distributor inside the blade guard for cooling

the cutting blade during operation.

The high resistance plastic handle (ref.H, fig.2), is equipped with the

main ON-OFF switch on the operator side to facilitate saw activation

and shutdown.The raised position of the red OFF button on the handle is

designed to facilitate shutdown of the machine in the event of an emer-

gency. The motor capacitor is located in a protected position inside the

handle.

The saw is fitted with a guard to guarantee optimal safety during opera-

tion and to protect the user during cutting cycles.

A valve is mounted above the blade guard to adjust the flow rate of water

delivered to the cutting blade.

4.2 Processable materials

This saw has been designed for cutting the following materials: ceramic

tiles, masonry and stone in general with maximum dimensions com-

patible with the length, cutting depth and dimensions of the surfaces

specified in table 1.

Maximum weight of processable materials: 25 kg.

4.3 Unsuitable material

Materials unsuitable for this machine are all those not specified in pa-

ragraph 4.2.

In any event, before using the saw with materials other than as specified

by the manufacturer for this saw model, contact IMER INTERNATIONAL

S.p.A.

- Use of this machine with workpieces outside the specified

dimensions is strictly prohibited and constitutes a hazard for the

operator.

IMER U.S.A. Inc.

COMBI 250 VA

3

5. OPERATION SAFETY

- Before using the saw, ensure that all protection devices are

fitted.

- Never use the saw in environments subject to the risk of

explosions or fire.

The saw is not fitted with specific lighting and therefore the workplace

must be sufficiently lit for this purpose (min. 300 lux).

The power lines must be laid to prevent any possible damage.

Ensure that the electrical connection is protected against the risk of wa-

ter penetration in connectors. Use exclusively connectors and couplings

equipped with water spray protection.

Never use inadequate or makeshift electrical lines or cables without

earthing; if in doubt consult a specialised technician.

Repairs to the electrical circuit must be performed exclusively by specia-

lised personnel. Disconnect the machine from the power supply before

performing maintenance or repairs.

6. GENERAL SAFETY WARNINGS

Note that this machine has been designed to ensure optimal performan-

ce and maximum safety: however the operator must also guarantee this

level of safety by paying special attention to the machine throughout all

work phases.

1. Ensure that an efficient earthing system is installed.

2. Work only with all protection devices fitted correctly and in effi-

cient working order.

3. Remove rings, watches, bracelets or ties before using the ma-

chine; these elements constitute a serious hazard to the operator.

Also ensure that sleeves are tight around the wrists, hair is tied

back and robust footwear is used.

4. Always use personal protection devices such as safety goggles,

suitably sized gloves, ear muffs or plugs and hair caps when ne-

cessary.

5. Never cut workpieces that have dimensions or weight that are

not suited to machine i capacity as specified by the manufacturer

(see point 4.2)

6. Always keep your hands away from the work areas when the

machine is running. Before taking any action to remove a piece

from close to the disc, stop rotation by pressing the stop button.

7. Keep the machine clean: general cleaning (and the work surfa-

ces in particular) represents an important safety factor.

8. Always stop the machine and disconnect from the power supply

before cleaning or removing any protection device (for maintenan-

ce or disassembly purposes). If water jets are used for cleaning,

never point jets directly at the power supply unit or electric motor.

9. Use genuine diamond blades as recommended by the manufac-

turer to ensure optimal performance of the machine.

10. Use exclusively water-cooled continuous rim blades suited to

the material to be cut.

11. Never dry cut material or cut when cooling water levels are low.

12. Never use blades over the rotation speed specified by the ma-

nufacturer.

13. Do not use reduction rings to adapt the hole of the disc on the

flange. Only use discs with hole corresponding to the flange sup-

plied with the machine (1" or 7/8").

14. Never use diamond blades that are chipped or deformed.

15. The instructions in this manual are aimed at machine users

(operators, maintenance engineers).

7. SAFETY DEVICES

The Combi 250 VA has been constructed taking into account current

harmonised European safety standards.

According to machine directive 98/37/EEC all safety devices have been

installed with the aim of safeguarding the operator.

7.1 Guards and safety devices

The machine is equipped with fixed guards, secured by means of screws

and protections that prevent access to moving or dangerous parts.

All fixed guards, covers, shields fixed by means of screws have been

envisaged to protect the operator (maintenance engineers, technicians

and others) from possible accidents cause by electrical discharge or

moving mechanical parts.

Therefore use of the machine with guards removed or modified in any

way is strictly prohibited.

- Before performing maintenance or repairs to the machine,

turn it off via the main switch and disconnect from the power sup-

ply to prevent inadvertent start-up and isolate all machine electri-

cal circuits.

8. MACHINE INSTALLATION

8.1 Positioning

The machine must be placed on a smooth surface that is at least as

large as the tank, with the saw on the relative stand.

- Ensure that the stand is positioned on the relative inserts on

the tank base and thus secured.

In the event of moving the saw, take care to secure the head by means

of the fixing knobs (ref.L, fig.1) and carry the machine by means of the

handles on the tank (ref.I, fig.1) after disconnecting the power supply.

- Always remove the plug from the mains power before mo-

ving the machine.

8.2 Stand assembly

The stand is supplied disassembled. Firstly, join the two parts of each

leg making sure that the inner and outer holes are aligned. Join the two

legs fitting the safety catches (ref.3-4, fig. 6), tighten the screws and

self-locking nuts with the spanner provided (ref.6, fig.6) taking care to

allow rotation of the legs.

8.3 Lifting and handling

The Combi 250 VA saw weights 33 Kg and can be moved by means of

the side handles on the tank (ref.I, fig.1).

- Always empty the tank before moving the machine.

8.4 Side roller assembling (optional kit p/n 1188166)

The side roller table is supplied with side supports already assembled.

First of all it’s necessary to fit such supports

inside the proper seats housed alongside the saw up to the stop. Now

lower the side roller table up it’s levelled to the saw’s table (fig.7).

To fit the central support it’s necessary to reverse the screw fitting side

of the stand which is aside the side roller table (ref.8, fig.7). Then place

the support, fitting it inside the screw and tighten it so to hold the table.

Then tighten the nut.

IMER U.S.A. Inc.

COMBI 250 VA

4

9. ELECTRICAL CONNECTION

- Ensure that voltage corresponds to machine dataplate spe-

cifications.

The power supply line must be equipped with current overload protec-

tion (e.g. thermal cutout) and protection against indirect contact (e.g.

residual current circuit breaker).

Connect the machine to an efficient earthing system.

The size of the power cable wires must be based on operating current

and length of the power line to prevent excessive voltage drops (table

4).

Table 4

Model Type of motor Cable (mm²)

1.5 2.5 4.0

Combi 250 VA 115 V

14.4 A 0 ÷ 12 13 ÷ 20 21 ÷ 32

Cable

length (m)

Connect the saw plug to the mains and tighten the mechanical retainer

ring with IP67 protection rating.

The saw is now ready for operation.

10. MACHINE USE

10.1 Operation

The correct side for the operator is shown in fig.4 ref.X.

Fill the water tank to the maximum level (approx. 36 litres).

Connect the machine to the power mains and start as described in pa-

ragraph 10.

Open the valve (ref.N, fig.1) and ensure sufficient flow of cooling water

to the diamond blade.

10.2 Cutting

Rest the material to be cut on the cutting table against the stopper. De-

fine the required inclination using the goniometer. To adjust the cutting

head height, loosen the handwheel (ref.O, fig.3), position the head at

the required height, then fully tighten the handwheel. Make sure that

handwheels for sloped cutting (ref.G, fig.2) are firmly tightened. Start the

sawing machine as described in paragraph 10. To proceed with cutting,

press the piece to be cut on the table with your hand and move the cutter

head gripping the handle and drawing it towards you. If the feed speed

is too fast in relation to the thickness and hardness of the material the

blade might stop turning. In this case, release the disk as quickly as

possible moving the cutter head away from you until the disk recovers

its nominal rotation speed. Resume cutting, adjusting the feed speed

according to the characteristics of the material.

10.3 Angled cuts

Loosen the handwheels (ref.G, fig.2), set the cutting head at the requi-

red angle, retighten the handwheels, and proceed as described in the

point above.

- Ensure that the tank is kept full during all work phases and in

the event of prolonged work intervals replace water regularly and

remove all processing residue.

10.4 Laser pointer

The machine is fitted with a laser pointer that reproduces the cutting line

on the piece being machined. The track of light indicates the trajectory

of the diamond disk during the feed motion. Making the required cutting

profile coincide with the laser profile, it is possible to ensure the highest

accuracy of the operation.

Cuts at right angle with one side of the piece being machined do not re-

quire tracing beforehand: in fact it will suffice to make sure that the side

of reference is in contact with the stopper on the resting surface. Likewi-

se, using the goniometer, cutting at predefined inclinations is possible.

The laser light will indicate the actual position of the cut.

The laser pointer is activated when the machine is connected to the

electric mains.

The pointer is aligned with the disk and must not be moved from its

initial position.

- The pointer used emits a low power laser light, but it is in any

case advisable to avoid looking directly at the emitter itself.

11. MAINTENANCE

11.1 Premise

Routine maintenance operations can also be performed by non-speciali-

sed personnel provided that all safety standards specified in the relative

sections of this manual are observed at all times.

11.2 Machine cleaning

The machine should be cleaned exclusively when it is stationary.

- All power switches must be set to “0” and plugs must be

disconnected from the mains.

1. Never use compressed air; this could cause infiltration of dust or re-

sidue in enclosed parts.

2. Ensure that the cooling water nozzles are not obstructed.

3. Above all the cooling water in the tank must be changed every day.

4. Do not use detergents or lubricants.

11.3 Cleaning the tank

Clean the tank in the event of build-up of sediment on the base, or at le-

ast once a day. Failure to clean the tank could impair operation of the im-

mersion pump used for circulation of the diamond blade cooling water.

To clean the tank, disassemble from the machine, lock the head, hold it

by the arms and rinse with a direct water jet (this is to avoid direct con-

tact of the water with electrical parts), the proceed with manual cleaning

using cloths or brushes.

Take care not to damage cables when replacing the machine on the tank

Take care not to damage the pump when placing the machine on the

surface

11.4 Cleaning the cooling water supply circuit

At regular intervals (or when the flow rate of the blade cooling water is

reduced) clean the cooling water supply circuit. To do this, disassemble

the delivery nozzle (ref.P, fig.1) located inside the blade guard and clean

in water.

Periodically clean the cooling water delivery line between the pump and

valve and blade guard using water.

11.5 Blade replacement

The diamond blade is made of material that may be damaged when

subject to high temperatures, and therefore must be cooled during the

work phases.

To replace the blade, proceed as follows:

1. Block axial movement of the cutting head by means of the handwhe-

els (ref.L, fig.1).

2. Disassemble the front guard (ref.P, fig.1).

3. Loosen the locknut by rotating clockwise (left thread), using a 19 mm

wrench.

4. Move the cutting head forward slightly and incline to remove the blade

from its seat.

5. Ensure that there are no foreign objects between the fixing flange and

diamond blade. During disassembly, avoid use of tools that could dent

or deform the flange.

6. Insert the new blade proceeding in reverse order of the operation

described at point 4. Take special care to ensure correct direction of

rotation of the diamond blade.

7. Tighten the blade locknut fully down by rotating anticlockwise (left

thread), to a torque of 40 Nm.

- Always disconnect the power plug before changing the disk.

11.6 Repairs

Repairs to the electrical installation must be performed exclusively by

specialised personnel. Use exclusively original IMER spare parts; modi-

fications to parts are strictly prohibited. The special design of the Combi

250 VA ensures that no other maintenance other than as specified abo-

ve is required.

Ensure that the contacts of the power plug and plug-switch assembly

are efficient. If oxidation is detected, clean immediately

- In the event of activation of the RCCB, check the machine

and arrange for repairs if necessary exclusively by specialised

personnel.

11.7 Waste disposal

As regards disposal of processing waste observe all current legislation

in the country of use.

IMER U.S.A. Inc.

COMBI 250 VA

5

12. RESIDUAL RISKS AND SAFETY SIGNS

Although the sawing machine has been manufactured fully in complian-

ce with current regulations, residual risks exist that cannot be eliminated

and involve the use of appropriate individual protection devices. Ade-

quate warning signs fitted on the machine point out both the risks and

the behaviour to be followed.

NOISE RISK

Ear protection must be worn

RISK OF INJURY TO THE HANDS

Safety gloves must be worn

RISK OF INJURY TO THE EYES

Eye protection must be worn

ABNORMAL USE RISK

Reading the manual before use is compulsory

Cutting with water is compulsory

DANGER OF CUTTING

DANGER OF ELECTROCUTION

DANGER OF LASER BEAM

Please be reminded that checking the use of IPDs is delegated to the

employer.

13. TROUBLESHOOTING

- CAUTION!!! All maintenance operations must be performed

exclusively with the machine switched off, with the selector set to

“0” and the power plug disconnected from the mains.

Trouble Causes Remedies

The motor does not

start when the start

switch is pressed

Current does not reach

the supply line

Check the line *

The socket and plug

are not connected

properly

Restore correct

connection

The differential switch

is off

Turn the differential

switch on

The power cable from

the plug to the panel

is cut off

Change the cable *

An electric wire inside

the motor terminal strip

is cut off

Restore the connection *

An electric wire inside

the panel is cut off

Change the switch *

The start switch is

faulty

Change the switch *

Cooling water fails

to reach the blade

Low water level in tank Restore the water level

Pump filter clogged Clean the pump filter

Current fails to reach

the pump

Check the pump

electrical supply *

Pump failure Change the pump *

The blade does

not cut

Blade fitted in the

opposite direction to

that of rotation

Remove the blade

and reposition it in the

direction shown on the

blade label

Worn blade Change the blade

* Operation to be carried out by an electrician

IMER U.S.A. Inc.

COMBI 250 VA

6

A

B

C

E

D

F

I

L

L

N

P

FIG. 1

IMER U.S.A. Inc.

COMBI 250 VA

7

FIG. 2

G

H

M

FIG. 3

O

FIG. 4

X

IMER U.S.A. Inc.

COMBI 250 VA

8

26

15

23

19

14

22

16

11

13

5

4

9

10

17

18

7

6

20

21

2

3

8

12

1

24

25

IMER U.S.A. Inc.

COMBI 250 VA

9

TAV. 1 - MACHINE STRUCTURE

REF. CODE DESCRIPTION NOTES

1 3210055 TANK

2 3226064 R.H. SURFACE

3 3226265 L.H. SURFACE

4 3226070 REAR SIDE

5 3226069 FRONT SIDE

6 3226359 REAR ARM

7 3226357 FRONT ARM

8 3234381 SLIDEWAY

9 3226073 RIGHT FENCE

10 3226074 LEFT FENCE

11 3210071 T-NUT

12 3210099 BOLT TEFR 6X25

13 3210576 WASHER D.8,4X17X1,5

14 2235429 CAP

15 2222545 BOLT TCEI 5931 M6X30

16 3204865 KNOB M6

17 3226087 WASHER D.10,5X17X1,5

18 3226088 BUSHING

19 2223920 NUT 7474 M10

20 3226747 BOLT TTDE 5732 8X40

21 3210069 MILLIMETRED STRIP

22 2284866 KNOB M8

23 2222584 BOLT TSPEI 5933 M6X25

24 3210070 ROD

25 3226083 BRACKET

26 2222449 BOLT TC 6954 3.5X19

IMER U.S.A. Inc.

COMBI 250 VA

10

FIG. 6

TAV. 2 - COMPLETE FRAME

REF. CODE DESCRIPTION NOTES

1 3210641 EXTERNAL TRESTLE ELEMENT

2 3210645 INTERNAL TRESTLE ELEMENT

3 3207193 RIGHT RABBET

4 3207194 LEFT RABBET

5 1222030 BOLT TE 8.8 5737 M8X60 Z

6 2223923 NUT 7473 M8

7 2224204 WASHER 6593 D.8X24 Z

8 3210646 RUBBER COAITING

9 3206205 TERMINAL

1

2

5

6

7

79

3

4

8

Stand Complete

3210080

IMER U.S.A. Inc.

COMBI 250 VA

11

3226358 TAV. 3 - COMPLETE GONIOMETER

REF. CODE DESCRIPTION NOTES

1 3230617 GONIOMETER SUPPORT

2 3230616 GONIOMETER

3 3226360 SLIDING ROD

4 2224140 WASHER 6593 D.8X18

5 3207939 HANDWHEEL M8X30

6 3211381 HANDWHEEL M8X30

7 3223279 HANDWHEEL M6X20

8 3230638 SPACER

9 2222511 BOLT TCEI 5931 M8X25

10 3231271 BAR

9

4

5

6

7

1

2

3

8

10

6

Complete

3226358

IMER U.S.A. Inc.

COMBI 250 VA

12

TAV. 4 - BLADE PROTECTION MOTOR

ASSEMBLY

REF. CODE DESCRIPTION NOTES

1

L000034

MOTOR

2 3230255 ENGINE SUPPORT

3 3210087 SPRING

4 3211935 BLADE GUARD

5 3210043 SPACER BRACKET

6 3210238 INNER FLANGE

7 1193782 BLADE

8 3210046 OUTER FLANGE

9 3211933 BLADE GUARD

10 2224535 WASHER

11 2222587 BOLT TSPEI 5933 M8X20

12 3204399 BOLT TCEI 5931 M5X25

13 3207884 COCK

14 3209060 BOLT TE 8.8 5737 M6X35

15 2222001 BOLT TE 8.8 5737 M4X20

16 2223352 NUT 5588 D.5

17 2223920 NUT 7474 M10

18 2223926 NUT 7473 M4

19 3210050 SPRAY SHIELD

20 3210053 NUT 5588 M12 Z SX

21 2222540 BOLT TCEI 5931 M6X20

22 2224380 WASHER 6592 D.12X25

23 2223280 NUT 5588 M6

24 2223924 NUT 7473 M6

25 3230251 BUSHING GFM-1012-6

26 3230250 GOUPILLE

27 3230644 FAN COVER

7

15

21

23

16

17

18

22

10

11

12

13

14

2

5

6

8

19

20

9

4

1

24

3

25

26

27

3234385 Fan

IMER U.S.A. Inc.

COMBI 250 VA

14

8

14

5

1

3

15

2

13

4

7

911

12

10

17

19

18

27

24

21

22

23

26

25

20

16

6

TAV. 5 - ELECTRIC PANEL

REF. CODE DESCRIPTION NOTES

1 3227467 JUNCTION BOX

2 3210114 GASKET

3 3210231 COVER

4

3231055

CAPACITOR

5 3210233 SWITCH

6 3209340 LEAKAGE PROTECTION

7 3225596 GASKET

8 3233422 WATER PUMP

9 3226095 CABLE GLAND LOCKING RING PG 16

10 3226101 CABLE GLAND GROMMET PG 16

11 3226098 CABLE GLAND LOCKING RING PG 11

12 3226100 CABLE GLAND GROMMET PG 11

13 3210116 BOLT TCTC 4,2X16

14 2222540 BOLT TCEI 5931 6X20

15 3210096 BOLT TTCQ 5732-65 M8X60

16 2284866 HANDWHEEL 180-40-M8

17 3224630 PLUG + ELECTRIC CABLE

18 3227508 CABLE CLAMP PG 9

19 3227487 CABLE GLAND NUT PG 9

20 3227481 SUPPORT

21 3227483 ADJUSTMENT BLOCK

22 3227489 CABLE GLAND NUT M20x1.5

23 3228250 LASER

24 3207155 BOLT TC PH 7687 M4X10

25 3227482 COVER

26 3228251 POWER SUPPLY

27 2222424 BOLT TC PH 6954 4.2X9.5

Water Hose

2242365

IMER U.S.A. Inc.

COMBI 250 VA

14

WIRING DIAGRAM

REF. DESCRIPTION

S1 CONTROL SWITCH

C1 CAPACITOR

PE EARTHING CABLE

N NEUTRAL LINE CABLE

L1 PHASE LINE CONDUCTOR

M1 BLADE MOTOR

M2 PUMP MOTOR

ID CURRENT CIRCUIT BREAKER

L1 NPE

M1

M2

11

S1

U<

I d

C1

IMER U.S.A. Inc.

COMBI 250 VA

15

TAV. 6 - CARRIAGE

REF. CODE DESCRIPTION NOTES

1 3210031 CARRIAGE

2 3210032 CAM

3 3207393 SPACER BRACKET

4 3204945 BEARING 608 2RS1

5

3207525 WHEEL ASSEMBLY with Bearing

6 3210627 RING

7 3210036 BOLT TCEI 5931 M5X16

8 3210622 SPACER BRACKET

9 2222114 BOLT TE 5737 M8X90

10 2223923 NUT 7473 M8

11 3210028 CARRIAGE BLOCK

12 3210105 BOLT TSP PH M5X12

13 3210029 BLADE GUARD

14 2222000 BOLT TE 5739 M5X16

14

9

10

4

3

5

11

13

1

2

7

12

8

6

IMER U.S.A. Inc.

COMBI 250 VA

16

3

2

1

4

678

5

FIG. 7

COD.1188166 TAV. 7 - SIDE ROLLER

REF. CODE DESCRIPTION NOTES

1 3226145 SUPPORT

2 3226146 SUPPORT

3 3226066 SIDE ROLLER

4 3226233 SUPPORT

5 3210646 RUBBER COAITING

6 2284866 HANDWHEEL M8X30

7 2224204 WASHER 6593 D.8X24 Z

8 1222030 BOLT TE 8.8 5737 M8X60 Z

Screw

2222607

Complete

1188166

IMER U.S.A. Inc.

COMBI 250 VA

17

ONE YEAR WARRANTY

We warrant to the original purchaser that the IMER equipment described herein (the

"equipment") shall be free from defects in material and workmanship under normal use

and service for which it was intended for a period of one (1) year from the date of purchase

by the original purchaser.

Our obbligation under this warranty is expressely limited to replacing or repairing, free of

charge, F.O.B. our designated service facility, such part or parts of the equipment as our

inspection shall disclose to be defective. Parts such as engines, motors, pumps, valves,

electric motors, etc. furnished by us but not manifactured by us will carry only the warranty

of the manifacturer. Transportation charges or duties shall be borne by the purchaser. This

shall be the limit of our liability with respect to the quality of the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been damaged

by reason of accident, negligence, unreasonable use, faulty repairs, or which has not been

mantained and operated in accordance with our printed instructions for our equipment.

Further, this warranty is void if the equipment, or any of its components, is altered or modi-

fied in any way.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRES-

SED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OF

FITNESS FOR A PARTICULAR PURPOSE.

We make no other warranty, representation or guarantee, nor is anyone authorized to

make one on our behalf. We shall not be liable for any consequential damage of any kind,

including loss or damage resulting, directly or indirectly, from the use or loss of use of the

machine. Without limiting the generality of the foregoing, this exclusion from liability em-

braces the purchase's expenses for downtime, damages for which the purchaser may be

liable to other persons, damages to property, and injury or death of any persons.

This warranty shall not be deemed to cover maintenance parts, including but not limited

to blades, belts, hoses, hydraulic oil or filters, for which we shall have no responsability or

liability whatsoever.

IMER U.S.A. Inc.

221 Westhampton Place

Capitol Heights, MD 20743

Ph. 301.336.3700

Fax 301.336.6687

Toll Free: 800.275.5463

www.imerusa.com

Other manuals for COMBI 250 VA

1

Table of contents

Other IMER Saw manuals