IMER COMBI 250 V Guide

OPERATING, MAINTENANCE, SPARE PARTS

MANUAL

SAWING MACHINE

6/2002-R1

- Cod. 3210213 -

IMER U.S.A. Inc.

207, Lawrence Avenue

South San Francisco, California 94080

(650) 872-2200 IMER EAST

221 Westhampton Place

Capitol Heights, MD 20743

Tel 301 - 336 - 3700

Fax 301 - 336 - 6681

IMER WEST

207 Lawrence Avenue

So. San Francisco, CA 94080

Tel 650 - 872 - 2200

Fax 650 - 873 - 6482

COMBI 250 V

2

IMER U.S.A. Inc.

Dear Customer,

Congratulations on your choice of purchase: IMER saws are

the result of years of experience and are equipped with all the

latest technical innovations.

- WORKING IN SAFETY.

To work in complete safety, read the following instructions

carefully before using the machine.

To work in complete safety, read the following instructions

carefully before using the machine.

This OPERATIONAND MAINTENANCE manual must be kept on

site by the person in charge, e.g. the SITE FOREMAN, and

must always be available for consultation.

The manual is to be considered integral part of the machine

and must be kept for future reference until the machine is

disposed of. If the manual is damaged or lost, a replacement

may be requested from the manufacturer.

The manual contains important information regarding site

preparation, machine use, maintenance procedures, and

requests for spare parts.

Nevertheless, the installer and the operator must both have

adequate experience and knowledge of the machine prior to

use.

To guarantee complete safety of the operator, safe operation

and long life of equipment, follow the instructions in this

manual carefully, and observe all safety standards currently in

force for the prevention of accidents at work (use of safety

footwear and suitable clothing, helmets, gloves, goggles etc.).

- Make sure that all signs are legible.

- It is strictly forbidden to carry out any form of

modification to the steel structure or working parts of

the machine.

IMER INTERNATIONAL declines all responsibility for failure to

comply with laws and standards governing the use of this

equipment, in particular; improper use, defective power

supply, lack of maintenance, unauthorised modifications, and

partial or total failure to observe the instructions contained in

this manual.

IMER INTERNATIONAL reserves the right to modify features of

the saw and contents of this manual, without the obligation to

update previous machines and/or manuals.

1. TECHNICAL DATA

Technical data are stated in table 1 and electrical

specifications in table 2.

F e a tu r e 11 5 /6 0 H z

P o w e r (k W ) 1 .1

R a te d vo lta g e (V ) 11 5

F re q u e nc y (H z) 6 0

A b s o rb e d c urre nt 1 4 .4

N um b e r o f p o le s 2

rp m 3 4 0 0

S e rvic e typ e S 6 4 0 %

Ins ula tio n c a te g o ry F

P ro te c ti o n c a te g o ry IP 5 5

C a p a c ito r (µ F ) 11 0 (Ø 5 0 x1 2 0 )

2. DESIGN STANDARDS

The saws have been designed and manufactured according

to the following european standards: EN 292-1-2; EN 60204-

1;EN 12418.

3. NOISE EMISSION LEVEL

Table 3 specifies the sound emission levels measured on the

saw (Lwa) in accordance with EN ISO 3744 and the sound

pressure level measured at the ear of the operator under no

lload conditions (LPA) .

TABLE 3

SAWING MACHINE TYPE OF MOTOR LPALWA

CM250 V ELETRIC 70 85

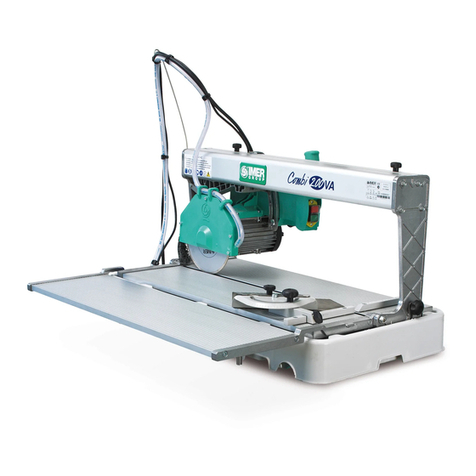

4. GENERAL SAW DESCRIPTION

4.1

General description:

The Combi 250 V is a saw comprising the following main sub-

groups :

- cutting head (ref. A fig.1).

- sliding guide (ref. B fig.1).

- water collection tank (ref. C fig.1).

- frame (ref. D fig.2).

- cutting surface (ref. F fig.2).

- stand (ref. G fig.5).

The cutting head is mounted on a reinforced aluminium profile

and is equipped with horizontal and vertical movement

facilities.The aluminium profile is hinged onto sheet steel arms

(ref.H fig. 5) and the entire unit can rotate through 45° ( fig. 6)

by means of the relative handwheels (ref.L fig. 7).

The cutting surfaces are positioned on the tubular frame of the

saw which is placed on the tank constructed in impact-

resistant plastic.

The water immersion pump is mounted below the cutting

surfaces on a special bracket and supplies a water distributor

inside the blade guard for cooling the cutting blade during

operation.

The high resistance plastic handle (ref.M fig. 6), is equipped

with the main ON-OFF switch on the operator side to facilitate

saw activation and shutdown.The raised position of the red

OFF button on the handle is designed to facilitate shutdown of

the machine in the event of an emergency. The motor

capacitor is located in a protected position inside the handle.

The saw is fitted with a guard to guarantee optimal safety

during operation and to protect the user during cutting cycles.

A valve is mounted above the blade guard to adjust the flow

rate of water delivered to the cutting blade.

4.2 Processable materials:

This saw has been designed for cutting the following

materials: ceramic tiles, masonry and stone in general with

TEC HN ICAL DATA - Table 1

Model COMBI 250 V

Max. diamond blade diameter 10 inches

Diamond blade hole diameter 1 inches

Single phase motor (115V 60Hz )

output 1.1 Kw

Max. blade rotation speed (115V

60Hz) 3.400 rpm

Worktop dimensions 500x840 mm

90° cut length (th=16mm) 660mm

Length of cuts from above 785mm

Maximum cut depth w ith single

stroke 66 mm

Maximum cut depth w ith two strokes 95 mm

Water pump flow rate 10 L/min

Water tank capacity 42 L

Machine dimensions 1040x560x640mm

Packed machine dimensions 1050x570x660mm

Weight w ith packaging 41 Kg

COMBI 250 V

3

IMER U.S.A. Inc.

maximum dimensions compatible with the length, cutting depth

and dimensions of the surfaces specified in Table 1.

Maximum weight of processable materials: 25 kg.

4.3

Unsuitable material

:

Materials unsuitable for this machine are all those not specified

in paragraph 4.2.

In any event, before using the saw with materials other than

as specified by the manufacturer for this saw model, contact

IMER INTERNATIONAL S.p.A.

-

Use of this machine with workpieces outside the

specified dimensions is strictly prohibited and constitutes

a hazard for the operator.

5. OPERATION SAFETY

- Before using the saw, ensure that all protection

devices are fitted.

- Never use the saw in environments subject to the

risk of explosions, fire or underground.

The saw is not fitted with specific lighting and therefore the

workplace must be sufficiently lit for this purpose.

The power lines must be laid to prevent any possible damage.

Never stand the saw on the power supply cable.

Ensure that the electrical connection is protected against the

risk of water penetration in connectors. Use exclusively

connectors and couplings equipped with water spray

protection.

- Never use inadequate or makeshift electrical lines or cables

without earthing; if in doubt consult a specialised technician.

- Repairs to the electrical circuit must be performed

exclusively by specialised personnel. Disconnect the machine

from the power supply before performing maintenance or

repairs.

6. GENERAL SAFETY WARNINGS

Note that this machine has been designed to ensure optimal

performance and maximum safety: however the operator must

also guarantee this level of safety by paying special attention

to the machine throughout all work phases.

1. Ensure that an efficient earthing system is

installed.

2. Work only with all protection devices fitted

correctly and in efficient working order.

3. Keep the machine clean: general cleaning

(and the work surfaces in particular) represents an

important safety factor.

4. Always stop the machine and disconnect from

the power supply before cleaning or removing any

protection device (for maintenance or disassembly

purposes).

If water jets are used for cleaning, never point jets

directly at the power supply unit or electric motor.

5. Remove rings, watches, bracelets or ties before

using the machine; these elements constitute a serious

hazard to the operator.

Also ensure that sleeves are tight around the wrists,

hair is tied back and robust footwear is used.

6. Never cut workpieces that have dimensions or

weight that are not suited to machine i capacity as

specified by the manufacturer (see point 4.2)

7. Always use personal protection devices such

as safety goggles, suitably sized gloves, ear muffs or

plugs and hair caps when necessary.

8. Use original diamond blades as recommended

by the manufacturer to ensure optimal performance of

the machine.

9.

Always keep hands well away from the working

zone while the machine is running; before removing

workpieces from the blade area, always press the stop

pushbutton to shut down rotation.

10. The instructions in this manual are aimed at

machine users (operators, maintenance engineers).

11. Never use diamond blades that are chipped or

deformed.

12. Never use blades over the rotation speed

specified by the manufacturer.

13. Use exclusively water-cooled continuous rim

blades suited to the material to be cut.

14. Never dry cut material or cut when cooling

water levels are low.

15. Ensure that the machine, with or without stand,

is placed on a stable surface with a maximum

inclination of 5°.

7. SAFETY DEVICES

The COMBI 250 V has been constructed taking into account

current harmonised European safety standards.

According to machine directive 98/37/EEC all safety devices

have been installed with the aim of safeguarding the operator.

7.1 Guards and safety devices

The machine is equipped with fixed guards, secured by

means of screws and protections that prevent access to

moving or dangerous parts.

All fixed guards, covers, shields fixed by means of screws

have been envisaged to protect the operator (maintenance

engineers, technicians and others) from possible accidents

cause by electrical discharge or moving mechanical parts.

Therefore use of the machine with guards removed or

modified in any way is strictly prohibited.

Before performing maintenance or repairs to the

machine, turn it off via the main switch and disconnect

from the power supply to prevent inadvertent start-up

and isolate all machine electrical circuits.

8. MACHINE INSTALLATION

8.1 Lifting and handling

The Combi 250 V saw weights 39 Kg and can be moved by

means of the side handles on the tank (ref.N fig.5).

Always empty the tank before moving the machine.

8.2 POSITIONING.

The machine must be placed on a smooth surface that is at

least as large as the tank, with the saw on the relative stand.

-Ensure that the stand is positioned on the relative

inserts on the tank base and thus secured.

The correct side for the operator is as shown in Fig.3 position

X.

In the event of moving the saw, take care to secure the head

by means of the fixing knobs (ref.O, L fig.7) and carry the

machine by means of the handles on the tank (ref.N fig.5)

after disconnecting the power supply.

Always remove the plug from the mains power before

moving the machine.

8.3 STAND ASSEMBLY

The stand is supplied pre-assembled. Before use complete

assembly by inserting the foot (ref.T fig.5) in the stand frame

and tightening the screw and nut (ref.U fig.5).

COMBI 250 V

4

IMER U.S.A. Inc.

9. ELECTRICAL CONNECTION

- Ensure that voltage corresponds to machine

dataplate specifications

.

Connect the machine to an efficient earthing system.

The size of the power cable wires must be based on

operating current and length of the power line to prevent

excessive voltage drops (ref.Table 4).

C om bi250 V - Ta b. 4

C ab le len gth (m ) V115

I= 14.4 A 0 ÷ 12 13 ÷ 20 21 ÷ 32

C ab le (m m ²) 1 .5 2.5 4

-Ensure that the electric line has a suitable

differential overload switch(RCD)(GFCI-USA).

Connect the saw plug to the mains .

- The saw is now ready for operation.

11. SAW START-UP

Connect the mains power cable to the plug on the electrical

panel.

Then start the saw by means of the switch on the handle

(ref.

P fig.6) , comprising two buttons: green for start, red for

stop.

The switch is fitted with low voltage protection; in the event

of accidental power failure, press the green button again to

resume operation.

In the event of an emergency, press the red pushbutton to

shut down the machine and disconnect the plug from the

power mains.

THERMAL CUTOUT PROTECTION:

- The electric motor is protected against overload

by a thermal cutout; in the event of overheating this

device shuts down the motor.

Cool the motor and restart by means the main switch

on the handle (ref.P fig. 6).

12 . MACHINE USE

Operation

The correct side for the operator is shown in fig. 3 ref X.

Fill the water tank to the maximum level (approx. 42 litres).

Connect the machine to the power mains and start as

described in paragraph 11.

Open the valve (ref.V fig.7) and ensure sufficient flow of

cooling water to the diamond blade.

Cutting

Place the material to be cut on the cutting surface against the

fence at the required angle using a protractor.

Adjust the height of the cutting head by means of the

handwheel (ref. R fig. 6).

Ensure that the handwheels for angled cuts (ref. L fig. 7)

and tightened fully down.

Start the saw as described in paragraph 11.

Proceed with cutting moving the saw head by means of the

handle.

In the event of blade rotation shutdown due to excessive

force, free the disk by moving it forwards and wait for the

saw to reach normal operating speed before resuming

operation.

Angled cuts

Loosen the handwheels (ref.L fig. 7), set the cutting head at

the required angle, retighten the handwheels, and proceed

as described in the point above.

Ensure that the tank is kept full during all work phases and in

the event of prolonged work intervals replace water

regularly and remove all processing residue.

Press the workpiece by hand onto the cutting surface.

Apply sufficient pressure on the handle to move the cutting

head without blocking the blade.

13 . Maintenance

13.1 Premise

Routine maintenance operations can also be performed by

non-specialised personnel provided that all safety standards

specified in the relative sections of this manual are observed

at all times.

13.2 Machine cleaning

The machine should be cleaned exclusively when it is

stationary.

- All power switches must be set to “0” and plugs

must be disconnected from the mains.

♦

Never use compressed air; this could cause infiltration of

dust or residue in enclosed parts

.

♦

Ensure that the cooling water nozzles are not obstructed

.

♦

Above all the cooling water in the tank must be changed

every day

.

♦

Recommended product for cleaning and lubricating the

mechanical parts of the saw: WD40

13.3 Waste disposal

As regards disposal of processing waste observe all current

legislation in the country of use.

13.4 Repairs

Repairs to the electrical installation must be performed

exclusively by specialised personnel. Use exclusively

original IMER spare parts; modifications to parts are strictly

prohibited. The special design of the COMBI 250 V ensures

that no other maintenance other than as specified above is

required.

Ensure that the contacts of the power plug and plug-switch

assembly are efficient. If oxidation is detected, clean

immediately

13.5 Cleaning the tank

Clean the tank in the event of build-up of sediment on the

base, or at least once a day. Failure to clean the tank could

impair operation of the immersion pump used for circulation

of the diamond blade cooling water.

13.6 Blade replacement

The diamond blade is made of material that may be damaged

when subject to high temperatures, and therefore must be

cooled during the work phases.

To replace the blade, proceed as follows:

1.Block axial movement of the cutting head by means of the

handwheels (ref. O fig. 7).

2. Disassemble the front guard (ref.D fig.4).

3. Loosen the locknut by rotating clockwise (left thread),

using a 19 mm wrench.

4. Move the cutting head forward slightly and incline to

remove the blade from its seat.

5 . Ensure that there are no foreign objects between the

fixing flange and diamond blade. During disassembly, avoid

use of tools that could dent or deform the flange.

6 . Insert the new blade proceeding in reverse order of the

operation described at point 4. Take special care to ensure

correct direction of rotation of the diamond blade.

7. Tighten the blade locknut fully down by rotating

anticlockwise (left thread), to a torque of 40 Nm.

13.7 Cleaning the cooling water supply circuit

At regular intervals (or when the flow rate of the blade

cooling water is reduced) clean the cooling water supply

circuit. To do this, disassemble the delivery nozzle (ref. S fig.

4) located inside the blade guard and clean in water.

Periodically clean the cooling water delivery line between the

pump and valve, (ref.V fig. 7) and blade guard using water.

Other manuals for COMBI 250 V

2

This manual suits for next models

1

Other IMER Saw manuals

Popular Saw manuals by other brands

Scheppach

Scheppach Special Edition HS 720 Translation from original manual

Haussmann

Haussmann X-pert JT2503RN instruction manual

Hilti

Hilti DSH 900 operating instructions

Norton

Norton TR 230 GL Operating instructions and spare parts list

Makita

Makita 5402 instruction manual

EINHELL

EINHELL TE-CC 1825 U Original operating instructions