IMER Combi 200 Installation and operation manual

&20%,

(1188072 - 230V 50Hz) / (1188074 - 110V 50Hz)

manuale uso manutenzione (1 - 5)

manuel utilisation entretien (6 - 10)

Operating,maintenance, manual (11 - 15)

Handbuch für Bedienung, Wartung (16 - 20)

manual de uso, mantenimiento (21 - 25)

ricambi - pieces de rechange - spare parts - ersatzteile – recambios (26)

,0(5,17(51$7,21$/6S$

53036 POGGIBONSI (SIENA) Loc. SALCETO

,7$/,$

tel.: 0577 983300 - fax: 0577 983304

&RG5

COMBI 200: Operating and Maintenance Manual

___________________________________________________________________________________________________________________

11

*HQHUDOLQIRUPDWLRQ

,QWURGXFWLRQ

Dear Customer, congratulations on your purchase: the

&20%,

tile/stone

cutter is ideal for cutting tiles, thresholds and every kind of slab or fired tile.

This

86($1'0$,17(1$1&(

manual must be kept by the

6,7(0$1$*(5

within the building site, so it is always available for consultation. The manual is

to be considered part of the machine and must be kept for future reference

(EN292/2) for the whole machine life. If it is damaged or mislaid, a new copy

can be requested from the manufacturer. To guarantee the safety of the

operator, the safety of machine functioning and a long life for the machine, the

instructions in the manual must be respected, together with the safety and work

accident prevention regulations as per current legislation. Suitably safe

equipment must be used (safety shoes, gloves as per

'35,WDOLDQ'HFUHH

'35DQG'/,WDOLDQ/DZ

).

When writing to or telephoning your Agent or

,0(5,17(51$7,21$/ 6S$

for any reason involving the machine, always supply the following details:

1. machine model

2. serial number

3. voltage and frequency

4. period of use - number of working hours

5. type of disk used

5HFRPPHQGDWLRQVIRUDVVLVWDQFH

When compiling this manual, we kept in due consideration all the adjustment

and service operations which are part of normal maintenance.

We recommend that no repairs or operations are carried out which are not

indicated in this manual.

All operations which require parts to be dismantled must only be carried out by

qualified personnel.

,QWURGXFWLRQWRXVH

Before beginning machining with the tile/stone cutter, read this instructions

manual carefully to understand the machine, its uses and any possible counter-

indications.

The machine must be used exclusively for the uses hereby specified, use it as

recommended in this manual and do not try to tamper with it or force it, or to

use it for purposes not mentioned.

,0(5 ,17(51$7,21$/ 6S$

declines all responsibility in the case of non

observance of the laws which regulate the use of such equipment, in particular:

improper use, power supply anomalies, neglect of maintenance, unauthorised

modifications, partial or total non observance of the instructions contained in

this manual.

,W LV IRUELGGHQ WR FDUU\ RXW PRGLILFDWLRQV RI DQ\ NLQG RQ WKH

PDFKLQHVPHWDOVWUXFWXUHRUHOHFWULFDOV\VWHP

,GHQWLILFDWLRQ

The machine is marked by the captions punched on the metal plate on the

upper part of the machine (Fig.1.1-A).

'(6&5,37,212)&$37,216381&+('217+(0(7$/3/$7(

Type Machine model

No. Serial number

Year Year of manufacture

Volt Electrical voltage in Volts

Hz Electrical frequency in Hz

Kg Weight

Amp. Electrical absorption in Amps

rpm Number of revs. per minute of the disk

kW Nominal power

External diameter of disk

Disk hole diameter

$

Fig.1.1

Fig.1.2

'HVFULSWLRQ

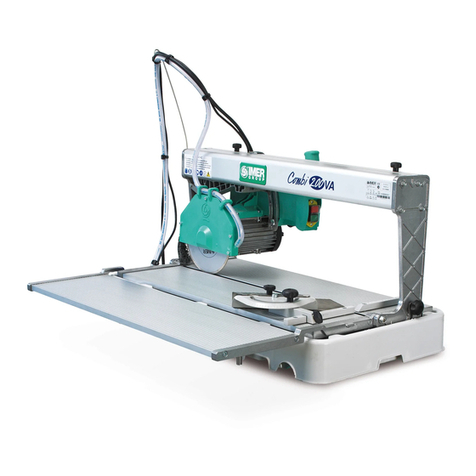

&20%,

(Fig.1.2) is a small tile/stone cutter designed and manufactured by

IMER INTERNATIONAL

Spa

for cutting tiles, ceramics and stone in general.

The fundamental qualities of the machine are accuracy, reliability and lightness

which combine to make it a unique machine.

0DWHULDOVZKLFKFDQEHFXW

The machine can cut the following materials: ceramic tiles and stone in general

with the dimensions specified in section 1.6.1.

0DWHULDOVZKLFKFDQQRWEHFXW

The machine can only cut the materials mentioned in section 1.5.1. Using the

machine with other materials is forbidden.

♦In any case, before carrying out machining different from those

envisaged by the manufacturer or machining of materials different

from those for which the machine was manufactured, we

recommend that you contact

,0(5,17(51$7,21$/6S$

8VH RI WKH PDFKLQH ZLWK SDUW GLPHQVLRQV EH\RQG WKRVH IRU

ZKLFKWKH PDFKLQHZDV PDQXIDFWXUHGLV DEVROXWHO\IRUELGGHQ

DQGGDQJHURXVIRUWKHRSHUDWRU

7HFKQLFDOFKDUDFWHULVWLFV

6WDQGDUG&20%,FKDUDFWHULVWLFV

7(&+1,&$/'$7$

'LDPHWHURIWKHGLDPRQGGUHVVHGGLVN

mm 200

'LDPRQGGUHVVHGGLVNKROH

mm 25.4

&XWWLQJVXUIDFHGLPHQVLRQV

mm 650x420x20

8QLWVL]HOHQJWK[ZLGWK[KHLJKW

mm 775x520x360

8QLWVL]HIRUWUDQVSRUW

mm 805x530x370

0DFKLQHZHLJKWQHW

Kg 24

:HLJKWIRUWUDQVSRUWJURVV

Kg 27

&XWWLQJOHQJWKVS PP

&XWWLQJOHQJWKVS PP

mm 430

430

0D[LPXPFXWWLQJGHSWK

0D[LPXPFXWWLQJGHSWK

mm 40

20

:DWHUSXPSFDSDFLW\ /¶

11

7DQNFDSDFLW\ /

23

COMBI 200: Operating and Maintenance Manual

____________________________________________________________________________________________________________________

12

7(&+1,&$/'$7$

9ROWDJH

V230 110

)UHTXHQF\

Hz 50 50

0RWRUSRZHU

kW 0.37 0.37

0RWRUVSHHG

rpm 2830 2800

'LDPRQGGUHVVHGGLVNVSHHG

rpm 2830 2800

$EVRUEHGFXUUHQW

A2 4

'HVLJQVWDQGDUGV

&20%,,0(5

was designed and manufactured by applying the following

standards:

,(&(1(1'35

&RQVXOWLQJWKLVPDQXDO

The following is a description of the various types of symbol which will be seen

when reading this manual.

1RWHVV\PERO

♦

The notes highlight information which is particularly useful for correct machine

functioning.

6DIHW\ZDUQLQJV\PERO

∆

Failure to observe the safety warnings may lead to injury, both for the operator

and other persons.

'DQJHUVLJQDOV\PERO

The danger signal indicates situations of special danger where the operator

risks serious injuries.

5HIHUWRLOOXVWUDWLRQV

When the text refers to an illustration, for example: " ... (Fig.

&

) ...", refer to

part

&

in figure number

Some illustrations are included in the context,

while others are annexed.

The

&((8523($1&21)250,7<PDUN

confirms that the machine has

been designed according to and complies with European Community

requirements and regulated by precise Legal Standards. (DIR. 89/392/EEC -

91/368/EEC)

*HQHUDOVDIHW\ZDUQLQJV

Remember that this machine has been manufactured to offer, as well as better

performance, maximum safety: however, it is the operator who must guarantee

this safety, by taking the necessary precautions in all work phases. The

operator is advised to:

(QVXUHWKDWWKHHDUWKLQJXQLWLVVXLWDEOH

2QO\ZRUNZLWKDOOWKHJXDUGVLQSODFHDQGZRUNLQJFRUUHFWO\

.HHSWKHPDFKLQH FOHDQWKHJHQHUDOFOHDQLQJ RIWKHPDFKLQH

DQG LWV ZRUN VXUIDFHV LQ SDUWLFXODU LV DQ LPSRUWDQW VDIHW\

IDFWRU

6WRS WKH PDFKLQH FRPSOHWHO\ EHIRUH FOHDQLQJ LW RU EHIRUH

UHPRYLQJ DQ\ JXDUG IRU PDLQWHQDQFH RU UHPRYDO RI DQ\

FRPSRQHQW WXUQ WKH PDLQV VZLWFK WR ]HUR DQG GLVFRQQHFW

WKHSOXJ,IWKHPDFKLQHLVFOHDQHGZLWKZDWHUMHWVGRQRWVSUD\

ZDWHUGLUHFWO\RQWKHSRZHUVXSSO\XQLWRUHOHFWULFDOPRWRU

5HPRYH ULQJV ZDWFKHV EUDFHOHWV DQG WLHV H[SHULHQFH KDV

VKRZQ WKDW WKHVH DQG RWKHU REMHFWV FDQ OHDG WR DFFLGHQWV ,Q

DGGLWLRQ PDNH VXUHVOHHYHV DUH FORVHG WLJKWO\ RQ WKH ZULVWV

NHHSKDLUWLHGEDFNDQGXVHUREXVWIRRWZHDU

'RQRWPDFKLQHSLHFHVZKLFKDUHEH\RQGWKHVL]HVXLWDEOHIRU

WKHFKDUDFWHULVWLFVUHFRPPHQGHGE\WKHPDFKLQHPDQXIDFWXUHU

6HHSRLQW

7LJKWHQVFUHZVEROWVDQGULQJQXWVIRUHDFKLQVWUXPHQWWRWKH

WRUTXH HQYLVDJHG ZLWKRXW H[FHHGLQJ WKH QRUPDO YDOXHV DQG

ZLWKRXWXVLQJOHYHUVRUKLWWLQJWKHVSDQQHUV

$OZD\V XVH WKH SHUVRQDO SURWHFWLRQV DFFLGHQW SUHYHQWLRQ

JODVVHV ZKLFK FRQIRUP ZLWK VWDQGDUGV VXLWDEO\ VL]HG

FXVWRPLVHG JORYHV HDU PXIIV RU HDUSOXJV DQG KDLU QHWV LI

QHFHVVDU\

8VH WKH RULJLQDO WRROV UHFRPPHQGHG E\ WKH PDQXIDFWXUHU WR

HQVXUHPD[LPXPPDFKLQHSHUIRUPDQFH

$OZD\VNHHSWKHKDQGVIDUIURPWKHPDFKLQLQJDUHDVZKHQWKH

PDFKLQHLVUXQQLQJ%HIRUHUHPRYLQJDQ\SDUWV QHDUWKHGLVN

VWRSWKHGLVNURWDWLQJE\SUHVVLQJWKHVWRSSXVKEXWWRQ

7KHLQVWUXFWLRQVFRQWDLQHGLQWKLVPDQXDODUHIRUWKHXVHUVRI

WKHPDFKLQHRSHUDWRUVPDLQWHQDQFHSHUVRQQHO

1HYHUXVHFUDFNHGRUGHIRUPHGFXWWLQJGLVNV

1HYHUXVHWKHGLVNVDWDVSHHGKLJKHUWKDQWKDWLQGLFDWHGE\WKH

PDQXIDFWXUHU

2QO\XVHFRQWLQXRXVFURZQGLVNVRIDW\SHVXLWDEOHIRU

WKHPDWHULDOWREHFXW

6DIHW\GHYLFHV

&20%,

was designed in line with safety standards established at a

European level.

The safety devices, as per machine directive

((&

were designed with

utmost importance given to the safety of the operator.

Safety and accessibility are combined perfectly in

&20%,

; the operator is

fully protected, without any risks.

*XDUGVDQGVDIHW\GHYLFHV

The machine is fitted with fixed guards secured with fixing screws and guards

which prevent access to the moving and dangerous parts. All the fixed guards,

covers and screens secured with screws have been designed to protect the

operators (maintenance personnel, technicians, etc.) from injuries caused by

electrical discharges and moving mechanical parts.

Therefore, there is no envisaged use of the machine where the guards have

been modified or removed from the positions which they have been designed

for.

∆

%HIRUH FDUU\LQJ RXW DQ\ PDFKLQH PDLQWHQDQFH RU UHSDLUV WKH

PDFKLQHPXVWEHWXUQHGRIIDWWKHPDLQVVZLWFKDQGWKHPDLQV

SOXJ PXVW EH GLVFRQQHFWHG VR WKDW QRERG\ FDQ WXUQ RQ WKH

PDFKLQHXVLQJWKHPDLQVVZLWFK

0DFKLQHLQVWDOODWLRQ

/LIWLQJDQGXQORDGLQJ

Given its small size and lightness (only 24 Kg), Combi 200 can be lifted and

unloaded manually by the operator using the handles on the container tank.

$OZD\VHPSW\WKHWDQNEHIRUHPRYLQJWKHPDFKLQH

3RVLWLRQLQJ

Put the machine in the most suitable position, bearing in mind the electrical

connections. The space required for use and maintenance is shown in the

diagram below (Fig.2.2).

♦When moving the machine on the site, always take care to secure

the head with the lever (Fig. 3.1-G) and lift the machine with the

handles on the tank (Fig. 2.2/A-A).

$OZD\V GLVFRQQHFW WKH SRZHU VXSSO\ SOXJ EHIRUH PRYLQJ WKH

PDFKLQH

Fig.2.2

The machine may be supplied on an optional support stand (code 118.76.00)

as shown below (Fig.3.1/I).

%

$

Fig.2.2/A

♦Make sure that the stand is positioned on the supports on the

bottom of the tank.

&RQQHFWLQJWKHPDFKLQHWRWKHPDLQVSRZHUVXSSO\

Check that the mains power supply unit to which the machine is connected has

an earth connection as envisaged by current standards, and that the socket is

operating correctly.

COMBI 200: Operating and Maintenance Manual

___________________________________________________________________________________________________________________

13

♦Remember that there must be an overload protection upstream of

the mains power supply unit which can guarantee the safety of all

the conductors from short circuiting and overload.

(QVXUHWKDWWKHHOHFWULFOLQHKDVDVXLWDEOHGLIIHUHQWLDORYHUORDG

VZLWFK 5&' *)&,86$ ,0(5 PD\ VXSSO\ GLIIHUHQWLDO

RYHUORDGVZLWFKNLWV

230V-50Hz code 1187628

110V-50Hz code 1187629

Note the power installed (see machine identification plate) to dimension the

section of cable for the electric wiring, considering a maximum current capacity

of 4

$PPð

for lengths no higher than

PHWHUVRU

2

$PPð

for lengths between

DQGPHWHUV

7KHPDFKLQHPXVWEHFRQQHFWHG

WRWKHHTXLSRWHQWLDOHDUWKXQLW

LQ WKH EXLOGLQJ VLWH 7KH FRQQHFWLRQ SRLQW LV WKH VFUHZ

LQGLFDWHGZLWKWKHOHWWHU%LQ ILJ$SRVLWLRQHGRQ WKHUHDU

DUPPDUNHGZLWKDSODWHDQGDQHDUWKV\PERO

∆

7KHVHFWLRQRIWKHHDUWKFDEOHZKLFKLV\HOORZJUHHQVKRXOGEH

WKH VDPH DV WKH VHFWLRQ RI WKH OLQH FRQGXFWRUV RU DW OHDVW

FRQIRUPZLWKFXUUHQWOHJLVODWLRQDQGWHFKQLFDOVWDQGDUGVLQWKH

FRXQWU\LQZKLFKWKHPDFKLQHLVXVHG

∆

%HIRUH PDNLQJ WKH FRQQHFWLRQ FKHFN WKDW WKH PDLQV YROWDJH

DQGIUHTXHQF\FRUUHVSRQGWRWKHPDFKLQHVSHFLILFDWLRQV6HH

PDFKLQHLGHQWLILFDWLRQSODWH

∆

7KHSRZHUVXSSO\OLQHVLQWKHZRUNDUHDPXVWEHSRVLWLRQHGWR

HQVXUH WKDW WKH\ DUH QRW GDPDJHG DQG WKDW ZDWHU GRHV QRW

SHQHWUDWHWKHFROOHFWRUV 2QO\XVH FROOHFWRUVDQG DWWDFKPHQWV

ILWWHGZLWKZDWHUMHWSURWHFWLRQV 'RQRWSODFHWKH PDFKLQHRQ

WKHSRZHUVXSSO\OLQHV6XLWDEOHSURWHFWLRQPXVWEHDGRSWHG

∆

'R QRW XVH D WHPSRUDU\ PDFKLQH FRQQHFWLRQ WKH RSHUDWLRQ

PXVWEHFDUULHGRXWE\VSHFLDOLVHGSHUVRQQHO(QVXUHWKDWWKH

DWWDFKPHQWIRUWKHSRZHUVXSSO\FDEOHLQ WKHSOXJVZLWFKXQLW

KRXVLQJLVVWDEOH

∆

7KHZRUNDUHD PXVWUHVSHFW DFFLGHQWSUHYHQWLRQ DQGVHFXULW\

GHYLFHVWDQGDUGV

0DLQUHTXLUHPHQWVRIWKHHOHFWULFDOFDELQHWV

The motor is driven by pressing the push-button on the handle (Fig.3.3/A).

0DLQUHTXLUHPHQWVRIWKHHOHFWULFDOPRWRUV

Electric motor

characteristics 230V-50Hz 110V-50Hz

Power (Kw) 0.37 0.37

Nominal voltage (V) 230 110

Frequency (Hz) 50 50

Number of poles 2 2

R.p.m. 2830 2800

Isolation class S6 S6

Protection grade IP55 IP55

Type of mechanical

casing 63 B14 63 B14

Capacitor (µF) 14(D.36x65) 43(D.36x90)

0DFKLQHQRLVHOHYHO

,QWURGXFWLRQ

Protection from machine noise (

/SD

symbol) in the workplace has been

designed to meet the requirements of

$UWFRPPDRI/HJDO'HFUHHQR

RI

.

3URORQJHG H[SRVXUH WR QRLVH DERYH

G%$

PD\ GDPDJH

KHDOWK,WLVWKHUHIRUHUHFRPPHQGHGWKDWDSSURSULDWHSURWHFWLRQ

PHDVXUHVHJHDUPXIIVSOXJVHWFDUHWDNHQ

1RLVHHPLVVLRQPHDVXUHPHQWDVSHU

,62

VWDQGDUG

0DFKLQLQJ

&HUDPLFVWLOHVVWRQHLQJHQHUDO

)XQFWLRQLQJFRQGLWLRQ

,62%,6

VWDQGDUGDQGUHODWLYHDSSHQGLFHV

1RLVHOHYHO G%PHDVXUHG

0DFKLQHXVH

*HQHUDOGHVFULSWLRQ

Once the machine installation has been completed, machining can begin.

&20%,

consists of a stainless steel cutting surface. The 0.37 kW motor

and the cutting head (work unit) are fitted on a steel bar tilted at 45° to ensure

high cutting precision. The tile/stone cutter is placed on a tank, in plastic shock-

proof material, which contains water. The tank can be easily removed for

cleaning. There is a cooling pump immersed in the tank under the work table

which supplies the water jet for cooling the cutting disk.

&20%,

can be used for 90 degree vertical cutting and 45 degree tilted

cutting.

For vertical cutting, the pieces must have a maximum length of 430 mm and a

maximum thickness of 40 mm. For 45 degree tilted cutting, the pieces must

have a maximum length of 430 mm and a maximum thickness of 20 mm.

*

)

' &

%

(

$ +

,

Fig.3.1

The machine consists of a mobile cutting part (Fig.3.1-A), a fixed machine

support frame (Fig.3.1-B), a disk cooling tank (Fig.3.1-C) and an adjustment

unit (Fig.3.1-E).

The machine is fitted with protection devices to guarantee maximum functioning

safety (Fig.3.1-D).

)XQFWLRQLQJ

&20%,

functions as follows:

1. The piece to be machined is placed against the fence (Fig. 3.3 -E)

of the work surface with the required angle using the protractor

(Fig.3.1-E);

2. Select the cutting angle, vertical (Fig.3.1) or tilted at 45° (Fig.3.3); to

move the operating head to the fence, simply release the securing

knob (Fig.3.1-F) (Fig.3.2-A) for the operating head angle setting,

then secure the clamping knob again;

A

B

Fig.3.2

3. Turn the clamping knob for the operating head angle setting

(Fig.3.1-G);

4. Start up the machine using the maintained push-button near the

handle (Fig.3.3-A).

♦Make sure the tank is full of water during operations.

5. Press the piece against the table by hand

♦Apply a suitable pressure for the piece to be cut so that the motor is

not overloaded (motor under normal operating conditions

6. Move the operating unit and begin the cut; if the motor stops due to

overloading, retract the disk from the workpiece and allow the motor

to reach working speed before re-starting the cut.

The cut must be made near the fences on the work table.

♦If the 45° and 90° cuts are incorrect, adjust the screws on the two

arms (Fig. 3.3.-F).

COMBI 200: Operating and Maintenance Manual

____________________________________________________________________________________________________________________

14

'

%

$

)

&

(

Fig.3.3

2SHUDWLQJXQLW

The operating unit consists of the following:

1. A sliding unit guided by wheels on bearings (Fig.3.3-B and Fig.3.1-

A);

2. An electric motor (Fig.3.3-C);

3. A cutting unit consisting of a cutting disk (Fig.3.1-D);

4. A maintained push-button (Fig.3.3-A);

5. A cutting disk guard (Fig.3.1-H);

6. A handle (Fig.3.3-D);

7. An operating head clamping knob (Fig.3.1-F);

8. A safety knob (Fig.3.1-G);

0DLQWHQDQFH

,QWURGXFWLRQ

The normal operations for ordinary maintenance can be carried out by non

specialised personnel provided they observe the safety indications listed in the

previous and following paragraphs.

0DFKLQHFOHDQLQJ

The machine must

RQO\

be cleaned when the machine is at a standstill.

7KHSRZHUVXSSO\VZLWFKHVPXVWEHWXUQHGWRWKH

SRVLWLRQ

DQGWKHSOXJVGLVFRQQHFWHGIURPWKHPDLQVSRZHUVXSSO\

♦Do not used compressed air: this would send dust and residuals

into the most inaccessible corners of the machine.

♦Check that the cooling liquid nozzles are not blocked.

♦We recommend that the cooling water in the tank is changed every

day.

♦Do not use detergents or lubricants which may harm the materials of

which the machine is made.

'LVSRVDORIZDVWHPDWHULDOV

To dispose of the waste materials produced by the machine, current legislation

must be observed.

5HSDLUV

Repairs of the electrical systems must only be carried out by specialised

personnel. The spare parts to be used for mechanical repairs must be original

,0(5,17(51$7,21$/6SD

parts and they should not be modified in any way.

No further maintenance is required for the special structure of

&20%,

.

Check that the plug and plug-switch unit contacts are not damaged. If they are

oxidised, clean them immediately.

&OHDQLQJWKHWDQN

Clean the tank every time that sediment forms on the bottom, or at least once a

day. Failure to clean the tank could create problems for the immersion pump

which circulates water for cooling the cutting disk. To clean the tank, remove it

from the machine, secure the head, take it by the arms and wash it down with

direct water jets (this operation prevents direct contact of the electric parts and

the water jets), then clean it by hand with cloths or brushes.

♦Pay attention to the cable when replacing the machine on the tank.

♦Pay attention to the pump when releasing the machine and placing

it on the table.

5HSODFLQJWKHPRWRU

If you have to dismantle the electric motor, take care when re-fitting it on the

fixing plate.

∆

5HILW WKH HOHFWULFPRWRU XVLQJ WKHVDPH EROWV FRG

7DE$DQGZDVKHUVFRG7DE$VRWKDWEROWV

ZLWKWKHLQFRUUHFWGLPHQVLRQVGRQRWGDPDJHWKHPRWRU

5HSODFHPHQWRIWKHGLVN

The diamond-dressed disk is manufactured in special material for cutting the

materials described above and must be cooled with water during the work

phase.

To replace the disk, the following procedure must be followed:

1. Secure the axial slide of the operating head with the lever.

2. Dismantle the front guard.

3. Loosen the securing nut by turning it in a clockwise direction (left

hand thread), using a 10 mm spanner.

4. Remove the disk by first moving it and then tilting it slightly to extract

it from its housing.

♦When removing the disk, ensure that the cooling water jet nozzle is

not bent.

5. Insert the new disk, by carrying out the operations described in point

4 in reverse order, paying particular attention to the rotation direction

of the disk.

6. Secure the disk nut correctly by turning it in an anti-clockwise

direction (left hand thread), ensuring that there is a torque of 1.8

Kgf.m

$WWHQWLRQZKHQUHDVVHPEOLQJWKHGLVNIODQJHFKHFNWKDWWKHUH

DUHQRIRUHLJQERGLHVEHWZHHQWKHWLJKWHQLQJIODQJHDQGWKH

GLVN:KHQFOHDQLQJWKHIODQJHGRQRWXVHWRROVZKLFKPD\

DOWHUWKHVKDSHRIWKHIODQJH

([WUDRUGLQDU\PDLQWHQDQFH

After a work period of approximately one year, check that the operating unit is

stable; if not, carry out the following operations to stabilise it:

1. Release the two nuts (Fig.4.1-A);

2. Press down on the operating unit (near the plate)

3. First push the right wheel in a diagonal direction towards the inside

$

$

$

Fig.4.1

4. Secure the wheel nut by pressing it.

5. Do the same with the left wheel.

COMBI 200: Operating and Maintenance Manual

___________________________________________________________________________________________________________________

15

$SSHQGL[

The appendix contains the diagrams for the various units present in the

machine and the reference drawings. This section also contains the

documentation for the components installed in the machine and referred to in

the manual.

:LULQJGLDJUDPV

For wiring, the operator must consult the diagrams below

,

S1 Control switch

C1 Capacitor

X1 Disk motor connector

PE Overload line conductor

N Neutral line conductor

L1 Phase line conductor

M1 Disk motor

M2 Pump motor Fig.5.1

3UREOHPVFDXVHVVROXWLRQV

:$51,1*$OOWKHPDLQWHQDQFHRSHUDWLRQVPXVWEHFDUULHGRXWZKHQWKHPDFKLQHKDVEHHQVWRSSHGE\WXUQLQJWKHVHOHFWRUWR³´DQG

GLVFRQQHFWLQJWKHSRZHUVXSSO\

3UREOHP &DXVH 6ROXWLRQ

When the start switch is pressed, the motor does

not start −No mains voltage.

−The plug and socket are not connected

properly.

−The power supply cable is disconnected

from the cabinet.

−An electric wire inside the motor terminal

board is disconnected.

−An electric wire inside the cabinet is

disconnected.

−The mains switch is faulty.

−Check the mains.

−Reset the correct connection.

−Replace the cable.

−Contact an electrician for assistance.

−Contact an electrician for assistance.

−Change the switch.

No cooling water for the disk. −Consult machine cleaning, section 4.2 ,and tank cleaning, section 4.5

The disk does not cut. −Incorrect disk rotation direction.

−Worn disk.

−Dismantle the disk and reposition it in the

direction indicated on the disk label.

−Fit a new disk.

COMBI 200: ricambi - pieces de rechange - spare parts - ersatzteile - recambios

___________________________________________________________________________________________________________________

27

Fig.7.1/A

COMBI 200: ricambi - pieces de rechange - spare parts - ersatzteile - recambios

____________________________________________________________________________________________________________________

28

Fig.7.1/B

7$9$.

5LI &RGLFH , ) *% ' ( 1RWH

1 2223570 DADO ECROU NUT MUTTER TUERCA 5588 M8

2 2224140 RONDELLA RONDELLE WASHER BEILAGSCHEIBE ARANDELA Ø 8x18

3 3206312 FASCETTA COLLIER CLAMP SCHELLE ABRAZADERA

4 2223920 DADO ECROU NUT MUTTER TUERCA 7474 M10

5 3206385 PROTEZIONE

QUADRO PROTECTEUR

TABLEAU CABINET GUARD SCHUTZ

SCHALTTAFEL PROTECCIÓN CUADRO

6 3207397 RUOTA ROUE WHEEL RAD RUEDA

7 3207394 DISTANZIALE ENTRETOISE SPACER DISTANZSTÜCK ESPESOR

8 3206744 PIASTRA SUP.

MOTORE PLAQUE SUP.

MOTEUR MOTOR SUPPORT

PLATE MOTORTRAGPLATTE PLANCHA SUP. MOTOR

9 2222516 VITE VIS SCREW SCHRAUBE TORNILLO 5931 M8X70

10 3207118 BLOCCAGGIO

BRACCIO BLOCAGE BRAS ARM CLAMP ARMVERRIEGELUNG DISP. BLOQUEO BRAZO

11 3207393 DISTANZIALE ENTRETOISE SPACER DISTANZSTÜCK ESPESOR

12 1193848 DISCO CERAMICO DISQUE CÉRAMIQUE TILE DISK KERAMIKSCHEIBE DISCO CERÁMICO

13 3206409 CARTER CARTER GUARD SCHUTZHAUBE CUBIERTA

14 2222021 VITE VIS SCREW SCHRAUBE TORNILLO TEFR M6x16

15 1222013 VITE VIS SCREW SCHRAUBE TORNILLO 5737 M6X45

16 3208759 VITE SINISTRA VIS GAUCHE SCREW SCHRAUBE MIT

LINKSGEWINDE TORNILLO IZQUIERDO 5739 M6X20SX

17 3206377 FLANGIA BRIDE FLANGE FLANSCH BRIDA

18 3206376 FLANGIA BRIDE FLANGE FLANSCH BRIDA

19 3205941 TUBO

REFRIGERAZIONE TUBE

REFROIDISSEMENT COOLING TUBE KÜHLWASSERSCHLAU

CH TUBO REFRIGERACIÓN

20 3205985 PARASPRUZZI PARES-EAU SPLASH GUARD SPRITZSCHUTZ PROTECC. CONTRA

SALPICADURAS

21 2224340 ROSETTA RONDELLE WASHER BEILAGSCHEIBE ARANDELA 6592 Ø10x20

22 2223655 DADO M 10 BASSO ECROU M 10 BAS M 10 LOW NUT MUTTER M 10 FLACH TUERCA M 10 BAJA 5589 M10

23 2225749 FASCETTA

AUTOSERRANTE COLLIER À AUTO-

SERRAGE SELF-LOCKING CLAMP SELBSTSICHERNDE

SCHELLE ABRAZADERA CON

AUTOBLOQUEO

24 3206231 PROTEZIONE

PARASPRUZZI PARES-EAU SPLASH GUARD SPRITZSCHUTZ PROTECCIÓN CONTRA

SALPICADURAS

25 2224530 ROSETTA RONDELLE WASHER BEILAGSCHEIBE ARANDELA 6592ø6x12.5

26 2223924 DADO M 6 ECROU M 6 M 6 NUT MUTTER M6 TUERCA M 6 AUTOBL. M 6

27 3207076 ROSETTA NYLON RONDELLE NYLON NYLON WASHER NYLONRING ARANDELA NYLON NYLON Ø10,5X21X1

28 2224531 ROSETTA RONDELLE WASHER BEILAGSCHEIBE ARANDELA 6593 Ø6x18

29 3206085 VOLANTINO VOLANT HANDWHEEL HANDRAD VOLANTE

30 2222540 VITI VIS SCREWS SCHRAUBEN TORNILLOS 5931 M6X20

32 3205972 GUIDA DI

SCORRIMENTO GUIDE DE

COULISSEMENT SLIDING GUIDE GLEITFÜHRUNG GUÍA DE

DESLIZAMIENTO

43 3206121 BATTUTA DESTRA BUTÉE DROITE RIGHT FENCE RECHTER ANSCHLAG TOPE DERECHO

44 3206122 BATTUTA SINISTRA BUTÉE GAUCHE LEFT FENCE LINKER ANSCHLAG TOPE IZQUIERDO

COMBI 200: ricambi - pieces de rechange - spare parts - ersatzteile - recambios

___________________________________________________________________________________________________________________

29

7$9$.

46 3207058 PIANO DESTRO TABLE DROITE RIGHT TABLE RECHTER TISCH SUPERFICIE DERECHA

47 3207059 PIANO SINISTRO TABLE GAUCHE LEFT TABLE LINKER TISCH SUPERFICIE

IZQUIERDA

48 3206164 PERNO PIVOT PIN ZAPFEN PERNO

49 3205943 TAPPO BOUCHON PLUG VERSCHLUSS TAPÓN

50 3207075 GRANO VIS SANS TÊTE SET SCREW GEWINDESTIFT PRISIONERO 5923 M8X20

51 3207074 GRANO VIS SANS TÊTE SET SCREW GEWINDESTIFT PRISIONERO 5923 M8X40

53 2222146 VITE VIS SCREW SCHRAUBE TORNILLO 5739 M10x30

54 2225142 GRANO VIS SANS TÊTE SET SCREW GEWINDESTIFT PRISIONERO 5927 M6X10

55 2288825 ADESIVO PRESA

TERRA ADHÉSIF PRISE

TERRE EARTH SOCKET

ADHESIVE LABEL SCHILD ERDE ADHESIVO TOMA

TIERRA

57 2223923 DADO

AUTOBLOCCANTE ECROU DE SÉCURITÉ SELF-LOCKING NUT SELBSTSICHERNDE

MUTTER TUERCA CON

AUTOBLOQUEO M.8

58 2292365 TUBO ANTIGELO TUBE ANTIGEL ANTI-FREEZE TUBE SCHLAUCH

FROSTSCHUTZ TUBO ANTIHIELO

59 3206580 BRACCIO BRAS ARM ARM BRAZO

60 3207055 SUPP. ANT. SUPPORT AVANT FRONT SUPPORT LAGER VORN SOPORTE DELANTERO

61 3207052 SUPP. POST. SUPPORT ARRIÈRE REAR SUPPORT LAGER HINTEN SOPORTE TRASERO

62 3208449 SUPP. POMP. SUPPORT POMPE PUMP SUPPORT LAGER PUMPE SOPORTE BOMBA

64 2222004 VITE VIS SCREW SCHRAUBE TORNILLO M8x35

65 2225748 FASCETTA COLLIER CLAMP SCHELLE ABRAZADERA

66 3205934 VASCA CUVE TANK WANNE DEPÓSITO

67 3207116 ADESIVO BATTUTA

SINISTRA ADHÉSIF BUTÉE

GAUCHE LEFT FENCE

ADHESIVE LABEL SCHILD LINKER

ANSCHLAG ADHESIVO TOPE

IZQUIERDO

68 3207117 ADESIVO BATTUTA

DESTRA ADHÉSIF BUTÉE

DROITE RIGHT FENCE

ADHESIVE LABEL SCHILD RECHTER

ANSCHLAG ADHESIVO TOPE

DERECHO

69 2241570 CHIAVE CLÉ SPANNER SCHLÜSSEL LLAVE

70 3205980 GONIOMETRO GONIOMÈTRE PROTRACTOR GONIOMETER GONIÓMETRO

71 3206384 CARTER RUOTE CARTER ROUES WHEEL GUARD SCHUTZABDECKUNG

RAD CÁRTER RUEDAS

72 3206381 BLOC. TEST. BLOCAGE TÊTE HEAD CLAMP VERR. KOPFT. DISP. DE BLOQUEO

CABEZAL

73 3205988 SUP. GONIOMETRO SUPPORT

GONIOMÈTRE PROTRACTOR

SUPPORT HALTERUNG

GONIOMETER SOP. GONIÓMETRO

74 3204945 CUSCINETTO ROULEMENT BEARING LAGER RODAMIENTO 608-2RS1

75 3207073 ANELLO BAGUE RING RING ANILLO

77 3213097 ANELLO BAGUE RING RING ANILLO

79 2216277 GUARNIZIONE IN

GOMMA GARNITURE EN

CAOUTCHOUC RUBBER SEAL GUMMIDICHTUNG JUNTA DE GOMA

81 3207129 DADO ECROU NUT MUTTER TUERCA 5589 M8

82 3213111 SCATOLA FKL 63-71 BOÎTIER FKL 63-71 FKL 63-71 BOX DOSE FKL 63-71 CAJA FKL 63-71

83 3203540 GUARNIZIONE

MORSETTIERA GARNITURE BORNIER TERMINAL BOARD

SEAL DICHTUNG

KLEMMENLEISTE JUNTA REGLETA DE

CONEX.

84 3213114 PIASTRA AL PORTA

MICRO PLAQUE AIUMINIUM

PORTE-MICRO MICROSWITCH

HOLDER ALUMINIUM

PLATE

AL-PLATTE

MIKROHALTERUNG PLANCHA AL

SUJETAMICRO

85 3213115 MICROINTERRUTTOR

E 1NO MICRO-

INTERRUPTEUR 1 NO 1NO MICROSWITCH MIKROSCHALTER 1

NO MICROINTERRUPTOR

1NO

86 3213116 PULSANTE NEUTRO

BIANCO BOUTON NEUTRE

BLANC WHITE NEUTRAL

PUSH-BUTTON NEUTRALER

DRUCKTASTER WEISS PULSADOR NEUTRO

BLANCO

87 1283910 PRESSACAVO SERRE-FILS CABLE CLAMP KABELKLEMME APRIETACABLE PG 9

88 3203822 FERMACAVO BC CAVALIER CÂBLE BC BC CABLE CLAMP KABELHALTER BC APRIETACABLE BC

89 3203120 FERMACONDENSATO

RE CAVALIER

CONDENSATEUR CAPACITOR CLAMP KONDENSATORSCHEL

LE SUJETACONDENSADO

R

90 1283982 DADO PER

PRESSACAVO ECROU POUR SERRE-

FILS CABLE CLAMP NUT MUTTER FÜR

KABELKLEMME TUERCA PARA

APRIETACABLE PG 9

91 3207243 VOLANTINO VOLANT HANDWHEEL HANDRAD VOLANTE

100 3207978 GONIOMETRO COMPL. GONIOMÈTRE GONIOMETER WINKELMESSER GONIÓMETRO

7$99+=$.

5LI &RGLFH , ) *% ' ( 1RWH

31 3213117 CONDENSATORE CONDENSATEUR CAPACITOR KONDENSATOR CONDENSADOR MF 14 V450

52 3206411 TARGHETTA DATI

TECNICI PLAQUE CAR.

TECHNIQUES TECHNICAL DATA

PLATE LEISTUNGSSCHILD PLACA DATOS

TÉCNICOS

56 3208443 POMPA POMPE PUMP PUMPE BOMBA

63 3206071 SPINA FICHE PLUG STECKER CLAVIJA

76 3213090 MOTORE COMPLETO MOTEUR COMPLET COMPLETE MOTOR MOTOR MOTOR COMPLETO KW 0,37

78 3213108 QUADRO ELETTRICO TABLEAU

ÉLECTRIQUE ELECTRIC PANEL SCHALTTAFEL CUADRO ELÉCTRICO

80 3207128 TARGHETTA ADESIVA PLAQUE ADHÉSIVE ADHESIVE PLATE KLEBESCHILD PLACA ADHESIVA

7$99+=$.

5LI &RGLFH , ) *% ' ( 1RWH

31 3213119 CONDENSATORE CONDENSATEUR CAPACITOR KONDESATOR CONDENSADOR MF 43 V250

52 3206412 TARGHETTA DATI

TECNICI PLAQUE CAR.

TECHNIQUES TECHNICAL DATA

PLATE LEISTUNGSSCHILD PLACA DATOS

TÉCNICOS

56 3206270 POMPA POMPE PUMP PUMPE BOMBA

63 3204782 SPINA FICHE PLUG STECKER CLAVIJA

76 3213091 MOTORE COMPLETO MOTEUR COMPLET COMPLETE MOTOR MOTOR MOTOR COMPLETO KW 0,37

78 3213109 QUADRO ELETTRICO TABLEAU

ÉLECTRIQUE ELECTRIC PANEL SCHALTTAFEL CUADRO ELÉCTRICO

80 3207130 TARGHETTA ADESIVA PLAQUE ADHÉSIVE ADHESIVE PLATE KLEBESCHILD PLACA ADHESIVA

Other manuals for Combi 200

1

This manual suits for next models

2

Other IMER Saw manuals