Pag. 7

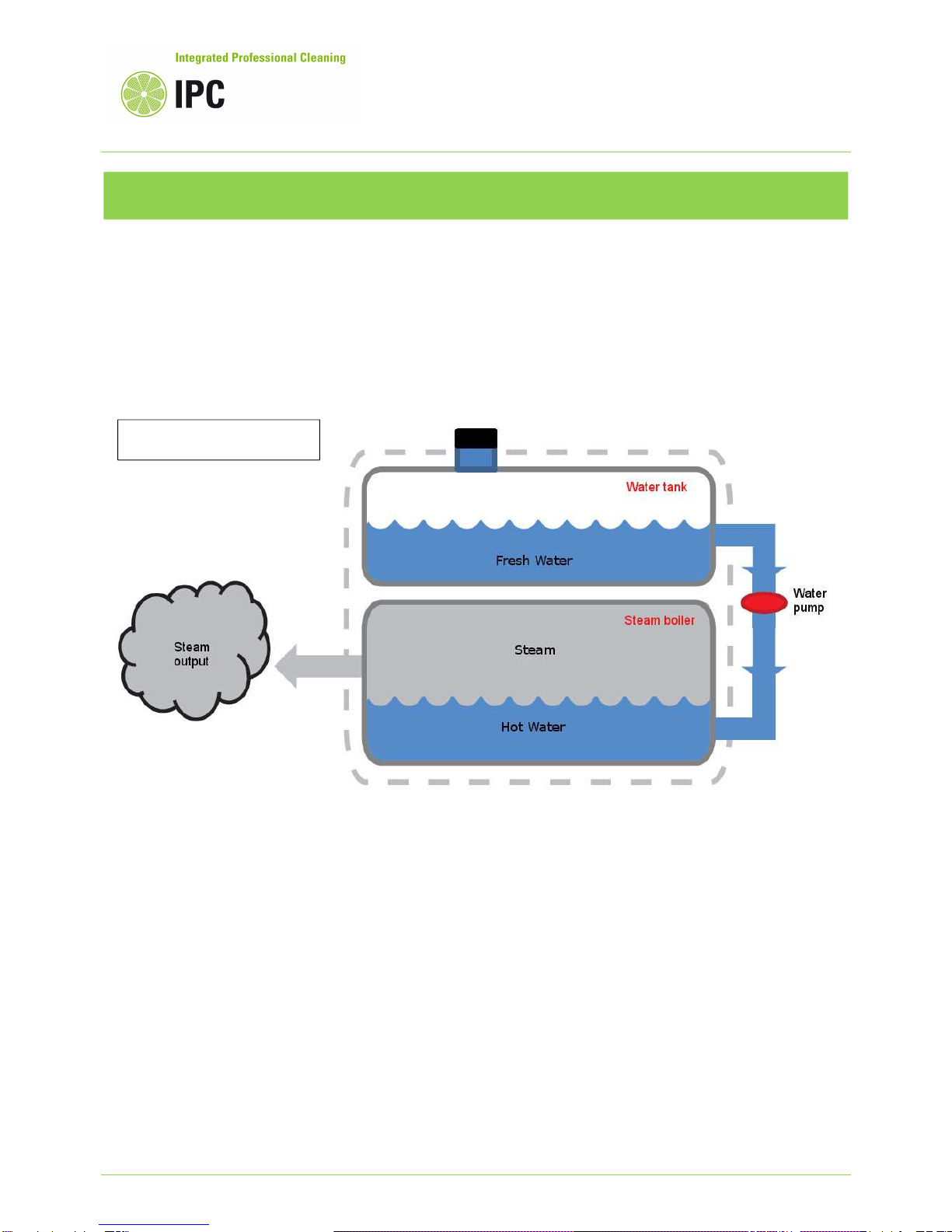

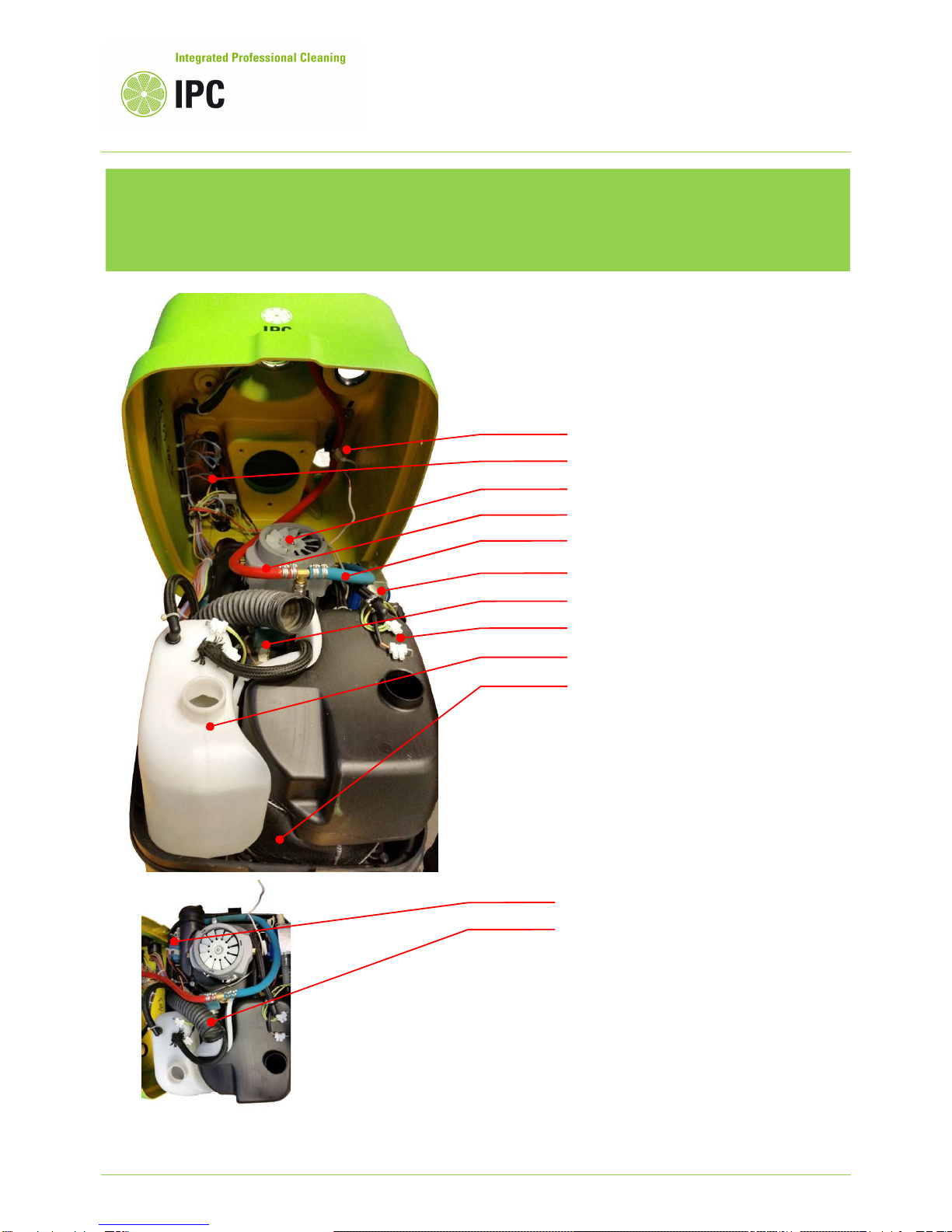

Water tank – the water tank has a capacity of 1,5 liters and is provided with electrodes that thanks to the

water conductivity, detect the water level into the tank.

The electrodes sensor is connected to the electronic board and in case the tank is empty, the water

pump that refills the boiler is deactivated and the red lamp on the machine (water lack) is on.

Water to be used for the steam generator cannot be demineralized water, since the water level detection

is done by electrodes that measure the water own conductivity.

Water pump to refill the boiler – the water pump brings the water from the water tank into the boiler,

this in order to compensate the discharge of steam and keep the boiler at its maximum efficiency of

steam production.

The water pump is powered by the electronic card and is activated when the electrodes sensor inside of

the boiler, detect a low water level.

The water pump functioning is fully automatic.

Steam Boiler – The steam boiler has a volume capacity of 1,5 liters and is provided with resistor having

a power of 2kW to generate the steam.

The resistor are two, each is 1Kw and they can be activated separately by the two switches at the top of

the machine.

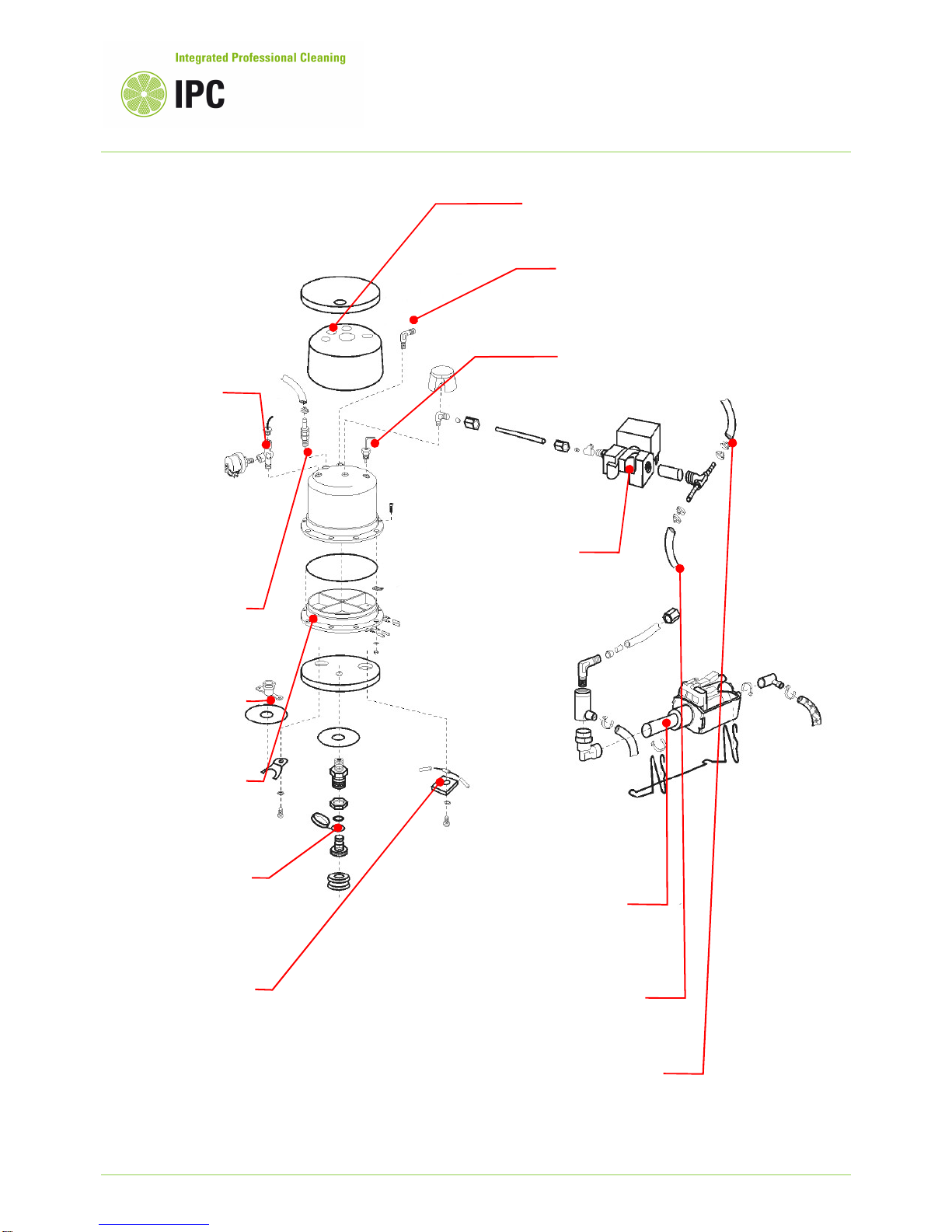

Here following the boiler breakdown view and the functioning description of the boiler elements.

Electrode for the boiler water level control – This electrode is connected to the electronic board and

detects the water level into the boiler. When low water level is detected, the sensor activates, trough the

electronic card, the water feeding pump that supplies the water into the boiler so restoring the proper

level.

The level detection is possible because the tap water has inside impurities (salts and minerals) so is

weakly conductive, for this machine is not possible to feed the boiler with demineralized water.

Pressure – switch – since the pressure and the temperature of the steam are linked each other and are

proportional, by checking the pressure we can determine the steam temperature.

The pressure switch 5,5 bar, will keep the pressure and the temperature, inside of the boiler, constant,

this by activating or deactivating the heating elements through the electronic board.

Safety valve 7 bar – The safety valve will avoid overpressure conditions into the boiler, keeping safely

the pressure to a maximum of 7 bar in case of boiler malfunctioning.

Safety thermostat – The safety thermostat is a safety component that switches off the boiler in case the

temperature is over than 165°C.

Thermal-Amperometric sensor – This safety element checks the temperature and the current draw to

the heating elements.

This intervenes switching off the heating elements if for some reasons they are powered without having

water into the boiler.

Steam EV – The steam electro-valve controls the delivery of steam at the outlet and is controlled by the

switches placed on the hand grip.