6

SerenadeTM Conference Collection - Column/Panel Base Table

Assembly Instructions

Column/Panel Base Table

Assembly

Column Leg & Modesty Panel

Assembly

Note: A fully assembled table

is heavy. The assembly of the

table should be performed at the

final location where table will be

used. Carefully unpack and place

components on a soft surface

(i.e. carpet, packaging foam or

cardboard) to avoid damage.

Note: Panel base table assemblies

are not shown in this instruction

but the assembly is same.

Note: Sightline tables have longer

and shorter column/panel legs.

Longer legs are assembled under

the wider section of the table top

and the shorter legs are assembled

under the narrower section of the

table top.

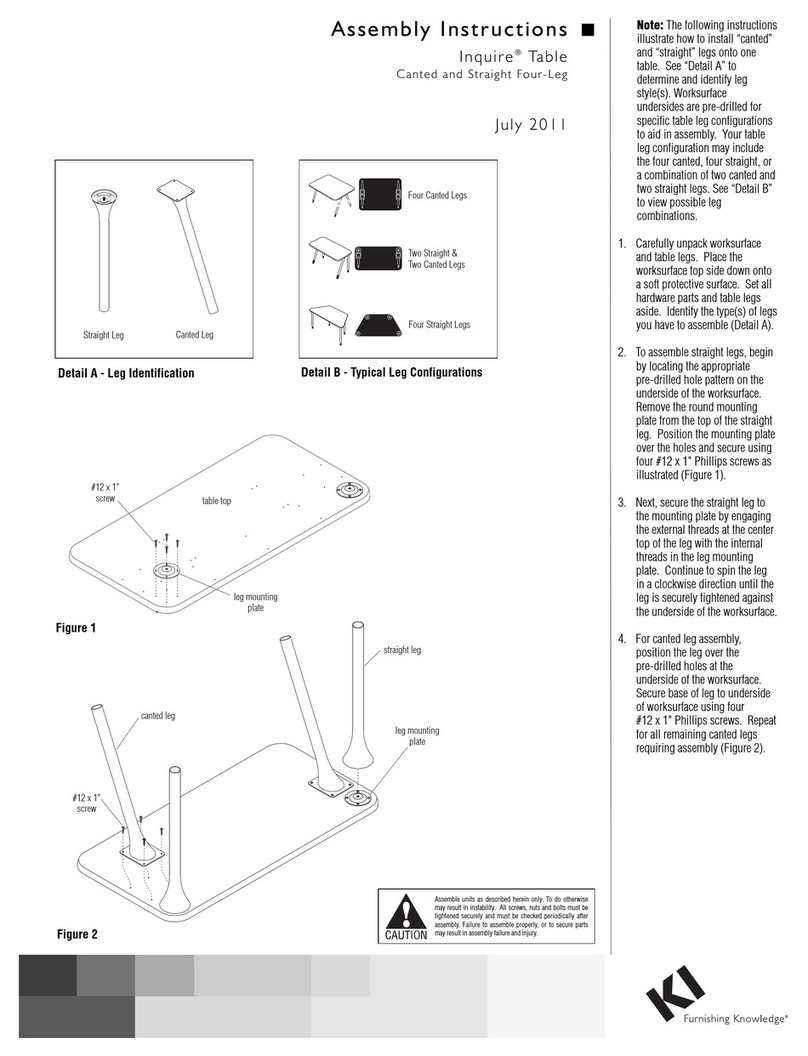

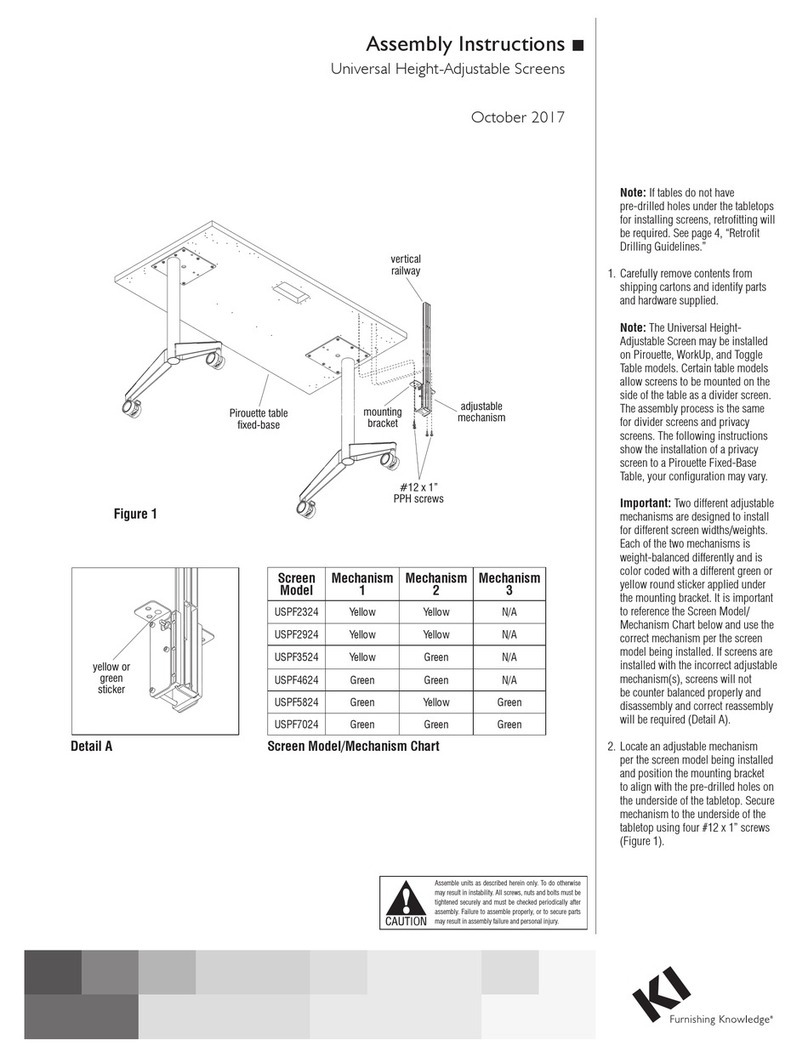

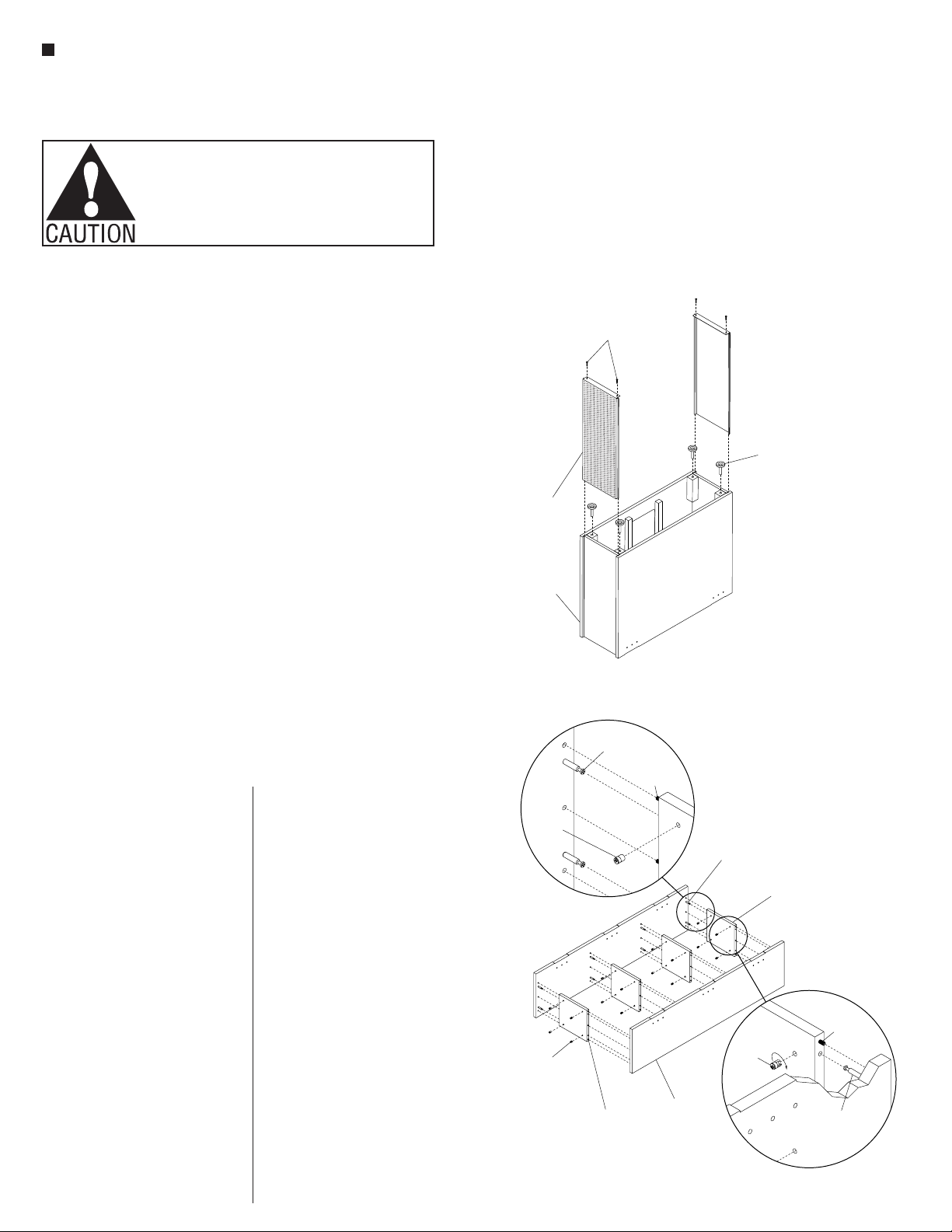

1. Rotate pre-assembled column leg

onto its top (Figure 1).

2. Slide two perforated inserts into the

slots from the bottom of the column

leg and secure using four #6 x 1/2”

screws (Figure 1).

3. Insert the four leveling glides into

the glide blocks of the column leg

(Figure 1).

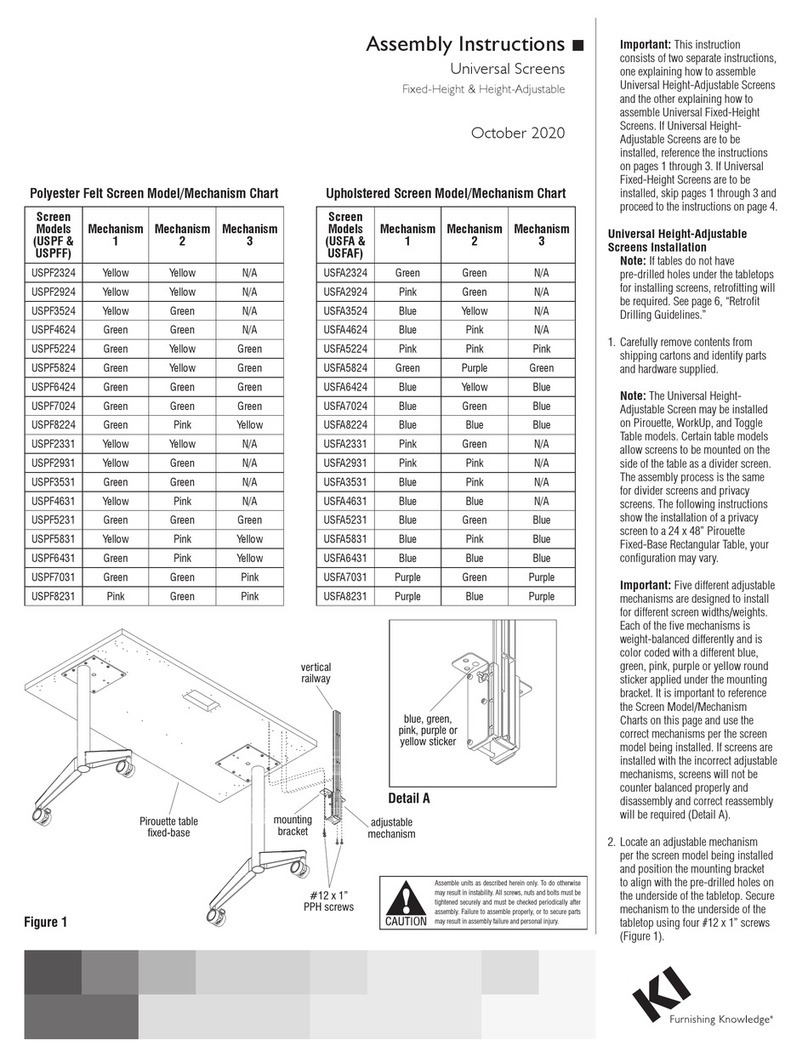

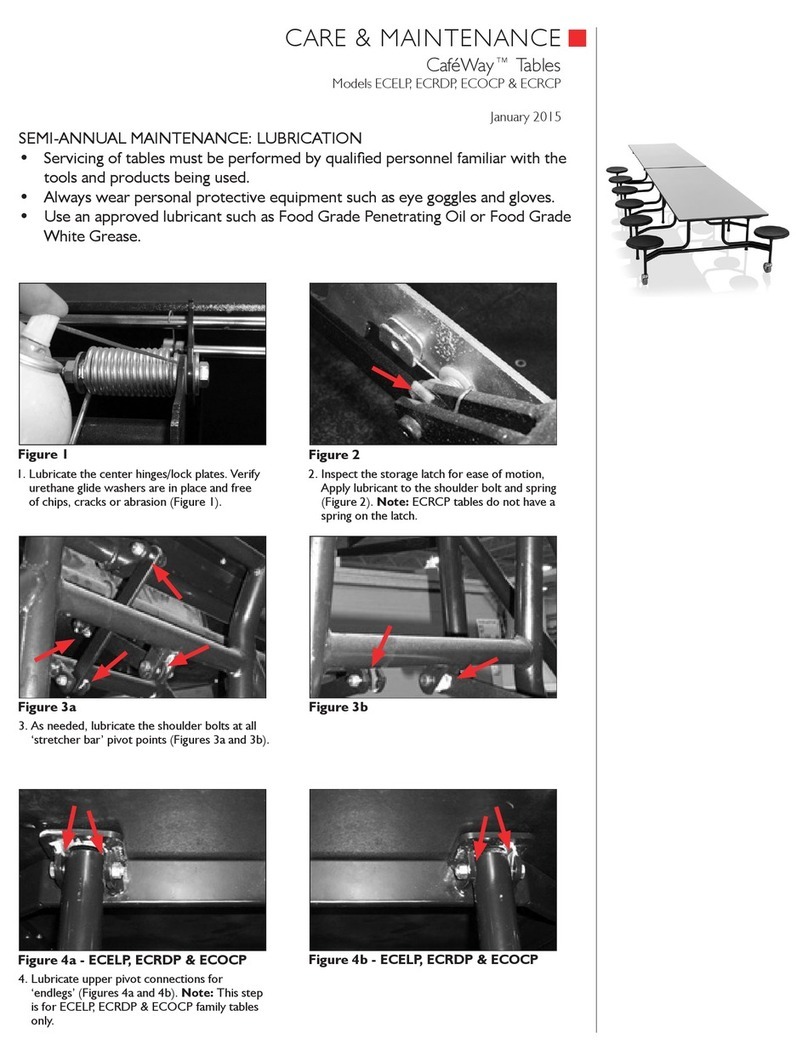

Note: Modesty panels come

with three or four cross supports

depending on the length of the

modesty panel. The modesty panel

shown in this assembly has four

cross supports (Figure 2).

4. Locate the modesty panels. As

illustrated, twist in two shoulder pin

screws into the pre-drilled holes

of the modesty panel (Figure 2 &

Detail A). Repeat step to install the

remaining shoulder pin screws into

the modesty panels.

5. Locate the cross supports. As

illustrated, insert six 8mm dowel

pins into the pre-drilled holes on

both the side edges of the cross

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

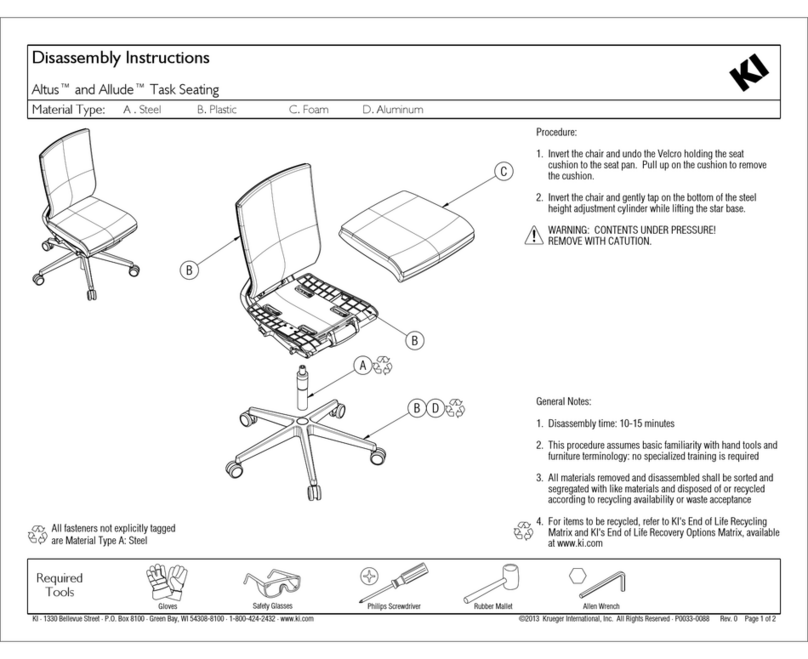

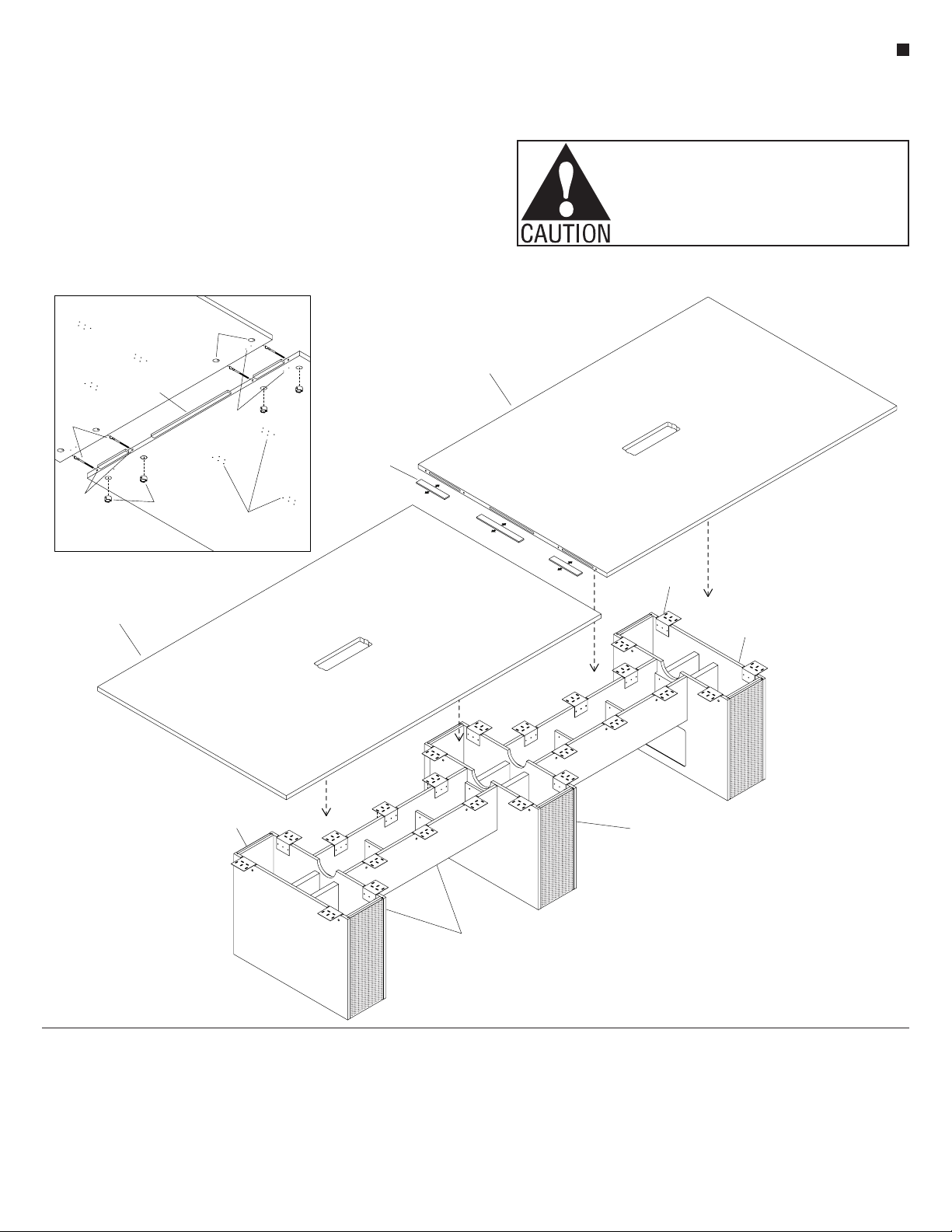

Figure 2

Figure 3

modesty panel

beam assembly

end

column

leg

#10 x 2"

pan head

screw

pre-drilled

/ " dia

1

8

pilot holes

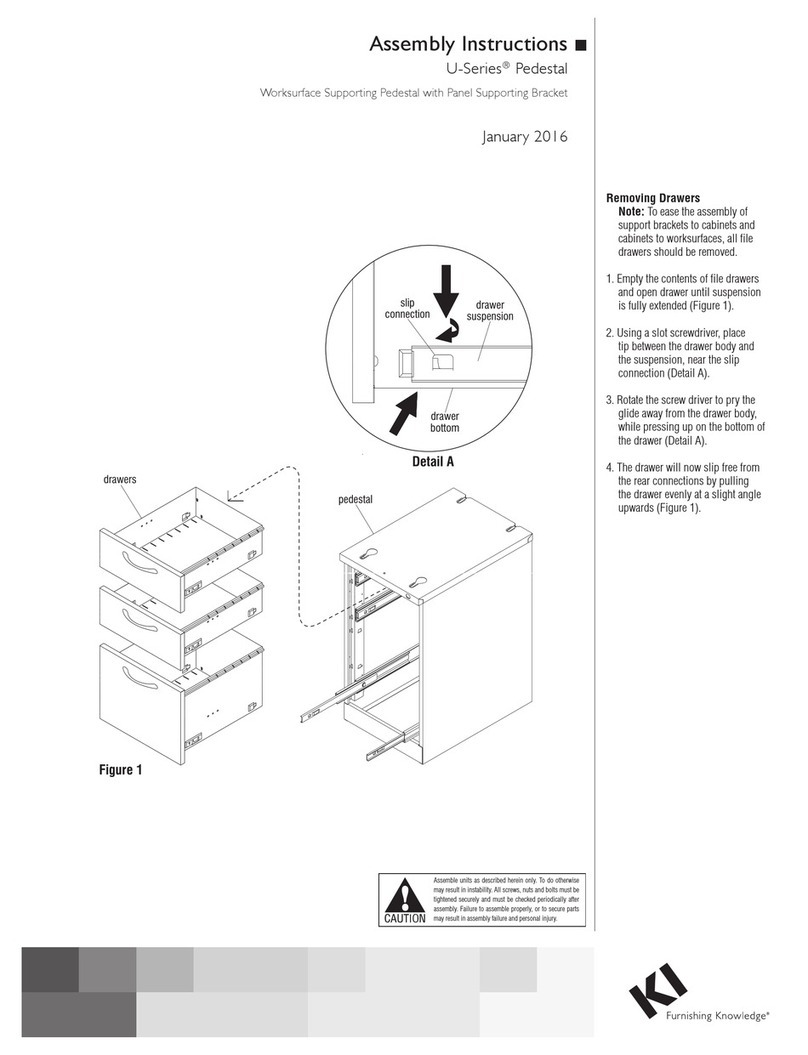

Figure 4

table

bracket

table base

assembly

cross

support

shoulder

pin screw

mini fix

cam

8mm

dowel pin

modesty

panel

Detail A

shoulder

pin screw 8mm

dowel

pin

mini fix

cam

mini fix

cam

8mm

dowel

pin

shoulder

pin screw

Detail B

end

column

leg

end

column leg

Figure 1

end

column

leg

perforated

insert

#6 x / "

1

2

screws

leveling

glide

Figure 2

Figure 3

modesty panel

beam assembly

end

column

leg

#10 x 2"

pan head

screw

pre-drilled

/ " dia

1

8

pilot holes

Figure 4

table

bracket

table base

assembly

cross

support

shoulder

pin screw

mini fix

cam

8mm

dowel pin

modesty

panel

Detail A

shoulder

pin screw 8mm

dowel

pin

mini fix

cam

mini fix

cam

8mm

dowel

pin

shoulder

pin screw

Detail B

end

column

leg

end

column leg

Figure 1

end

column

leg

perforated

insert

#6 x / "

1

2

screws

leveling

glide

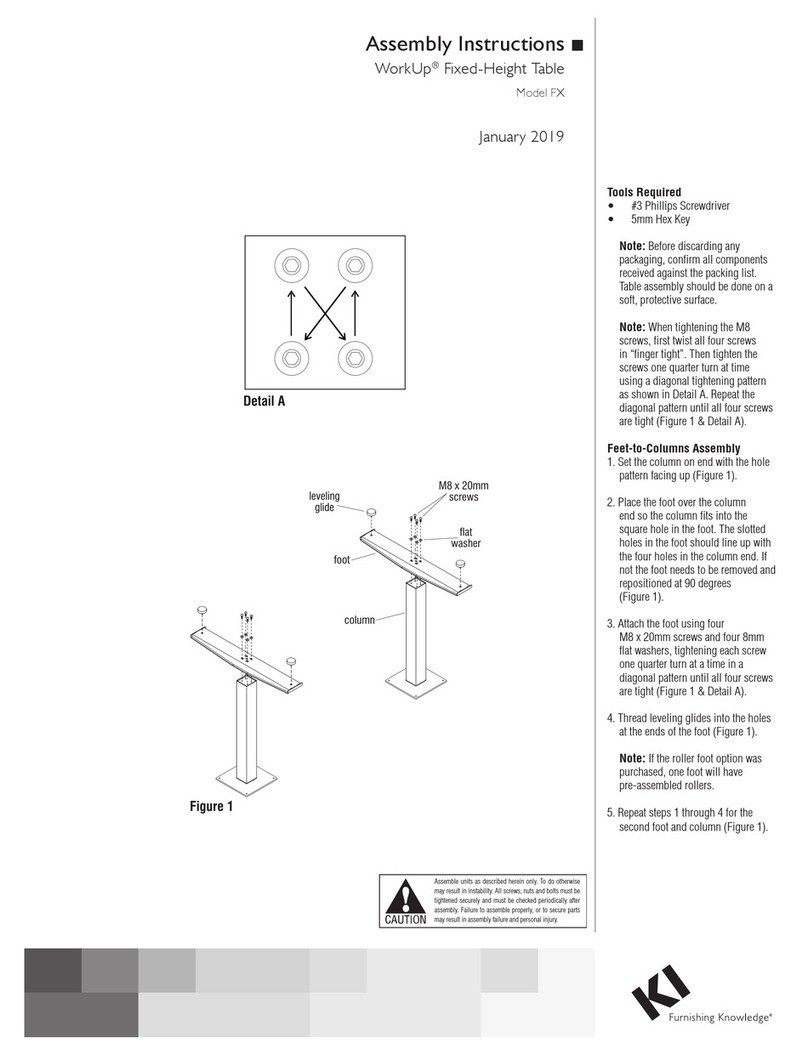

#10-32 x 1 / "

1

4

screw

support. Then, insert four mini fix

cams into the cross support. Make

sure the openings on the mini fix

cams face towards the outside

edge so that when assembled the

shoulder pin screws can be fully

inserted into the mini fix cams

(Figure 2 & Detail B).

6. Locate the first modesty panel

to assemble the cross supports.

Align and position the dowels and

mini fix cam holes on each cross

support to the first modesty panel.

Make sure the cross supports are

fully seated against the modesty

panel (Figure 2).

7. Then align and position the

shoulder pin screws and dowel

holes on the second modesty

panel to the mini fix cam holes

and dowels on the cross supports.

Make sure the modesty panel

is fully seated against the cross

supports (Figure 2).

8. Rotate clockwise all mini fix cams

to engage each shoulder pin screw

which will tighten and secure

the modesty panels to the cross

supports (Figure 2).