7

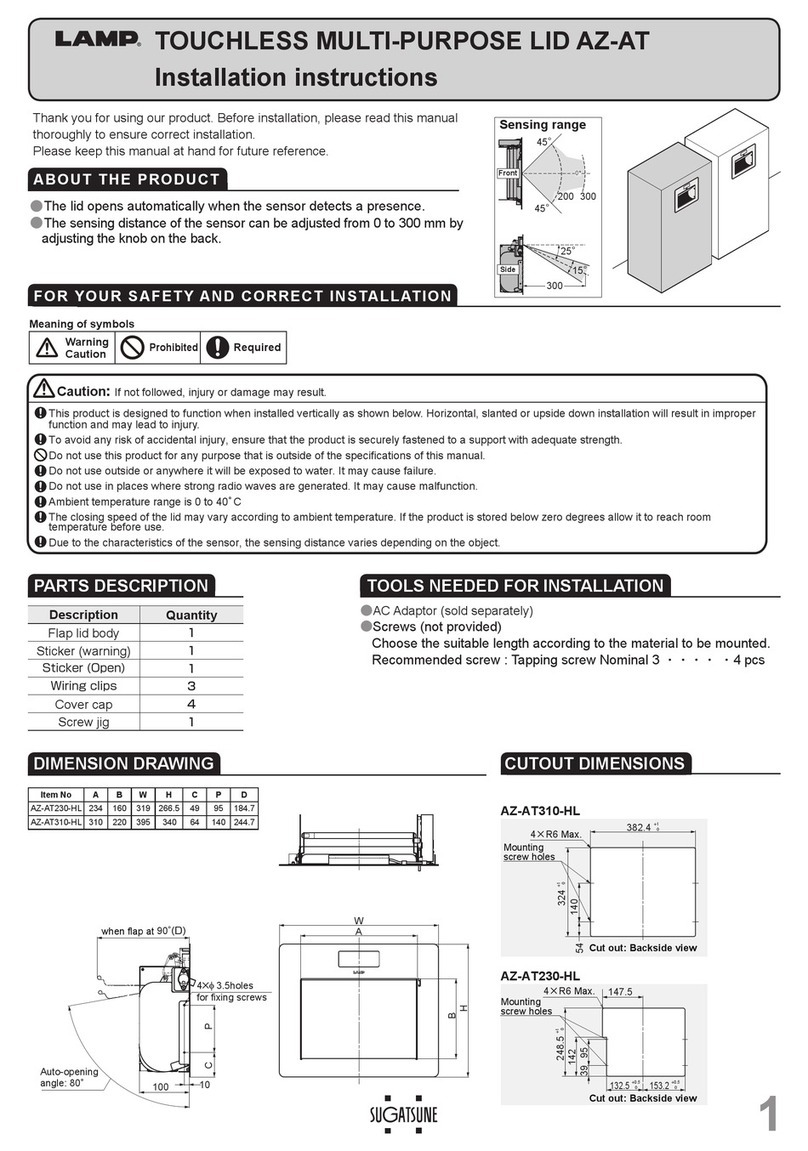

PERIODICAL

INSPECTION

・Clean the inside of the track.

・Check the upper and lower space of the door. If necessary, correct the space.

Trouble Checkpoint Solution

Door stops during soft

closing.

&KHFNLIGRRUERWWRPFRQWDFWVWKHÀRRU

9HULI\WKDWWKHWUDFN¿[LQJVFUHZVDUHQRWORRVHQHG

Then, adjust the door height such that the clearance between the door

ERWWRPDQGÀRRULVPP

Check if upper track is set horizontally. Using a level gauge, reset upper track horizontally.

Check if mohair seal is installed. Reduce the friction between mohair and door.

The door doesn‘t close

softly.

Check if trigger is installed. Install trigger to correct position.

Check if door is closed by excessive force. Do not close door by excessive force as it may damage soft closer.

The position of the trigger catcher in page 3 section

may become dislocated. (It is hidden as installed

in upper track.)

6ORZO\PRYHWKHGRRUWRZDUGVWKHOHDGLQJHGJHWKHQSXVKWKHGRRU¿UPO\

Repeat this action on the opposite side as well.

If it is still not improved, check the status of the trigger catcher in section .

Abnormal noise during

operation Check if door bottom contacts the floor or floor

guide

9HULI\WKDWWKHWUDFN¿[LQJVFUHZVDUHQRWORRVHQHG

Then, adjust the door height such that the clearance between the door

ERWWRPDQGÀRRULVPP

Check track rollers for aluminum dust. Remove the track and pull out the roller. Then, clean the roller.

Check for loose screws retaining the upper track. Tighten the screw.

Heavy door operation Check if door bottom contacts the floor or floor

guide

9HULI\WKDWWKHWUDFN¿[LQJVFUHZVDUHQRWORRVHQHG

Then, adjust the door height such that the clearance between the door

ERWWRPDQGÀRRULVPP

Door starts to move. Check if the upper track is set horizontally. Using a level gauge, reset the upper track horizontally.

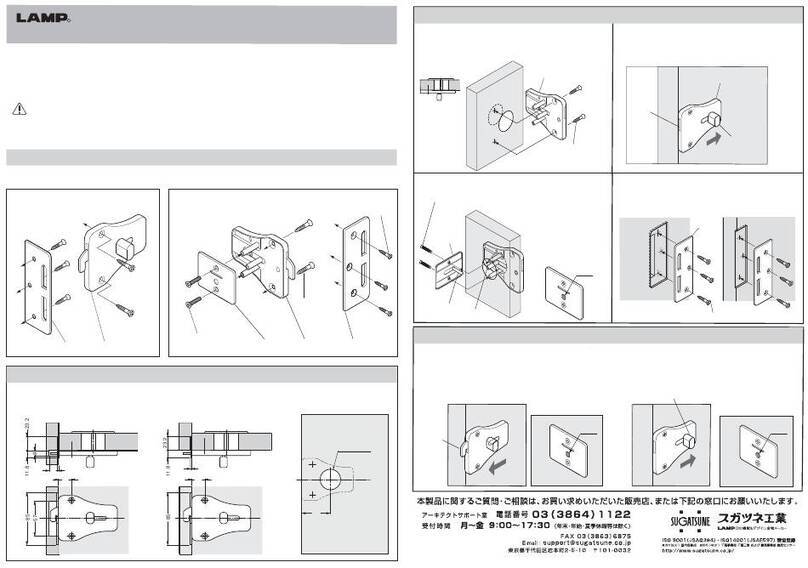

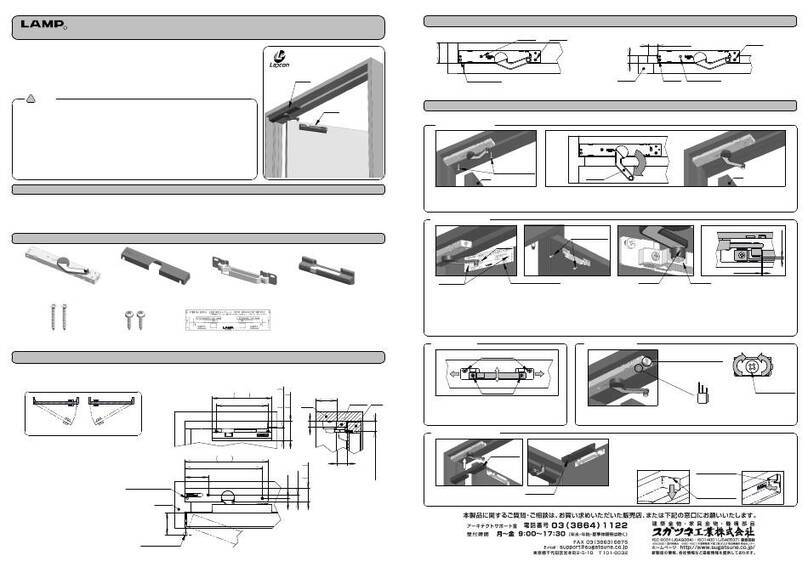

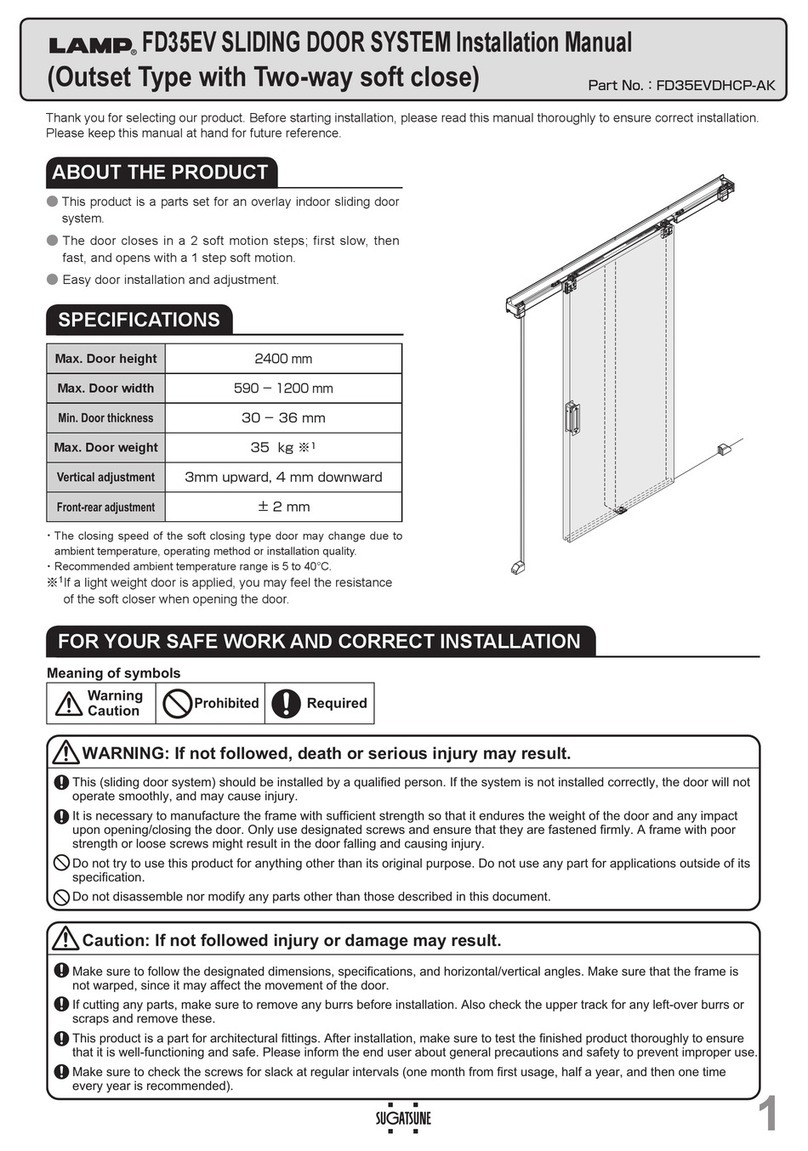

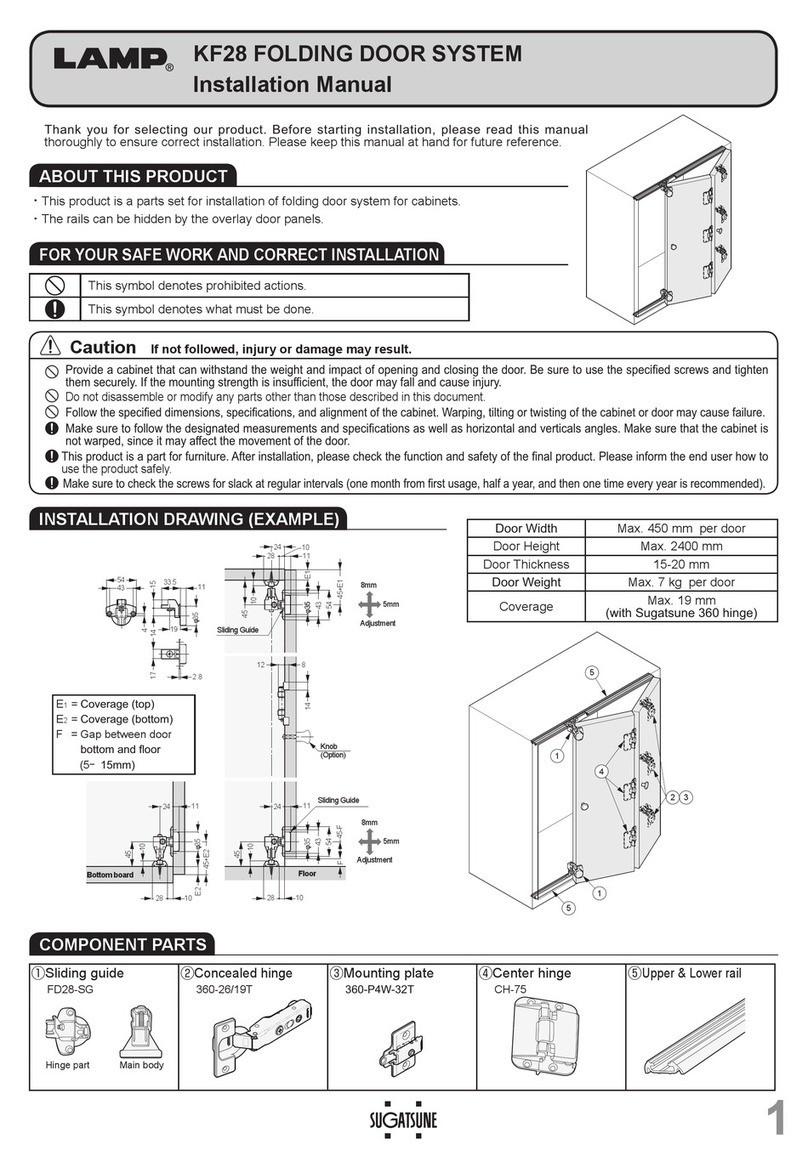

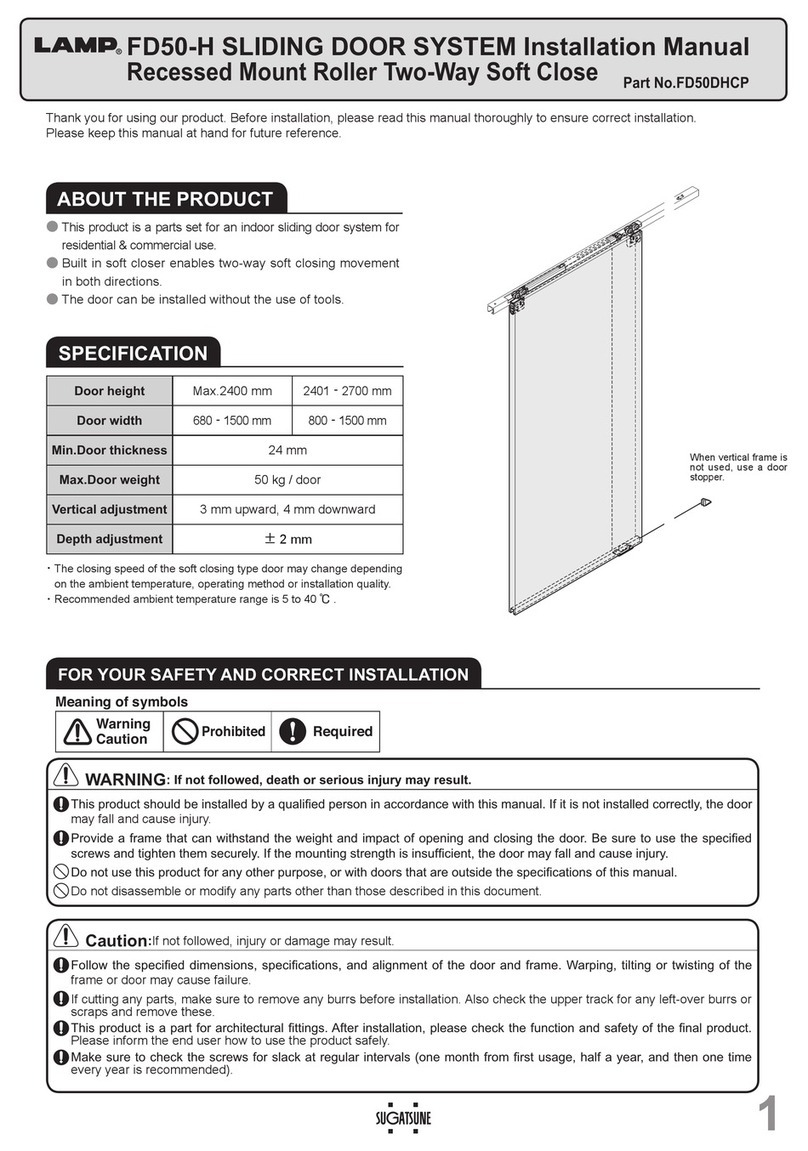

Appendix4Trigger positions

361

30

187.5

Door widthAvailable opening width

187.5

Available opening width Door width

30

30

!

Door must be stopped

by bumper block and

door stopper.

!

Door must be stopped

by bumper block and

door stopper.

Reference line for leading edge

(Leading edge when the door is

closed)

⑩

Door stopper(floor mount)

(Sold separately)

⑩

Door stopper(floor mount)

(Sold separately)

Trigger Trigger

Leading edge when the door

is fully opened

Crimped trigger

Reference line for trailing edge

(Trailing edge when the door is

opened)

Standard installation

Upper track installed inside door jamb

⑦

Bumper block

(Sold separately)

Special fit

(e.g.) No vertical frame and stop

with door stopper and bumper block.

Door width

−361

⑦

Bumper block

(Sold separately)

361 Door width

−361

TROUBLESHOOTING