42016.080755-4

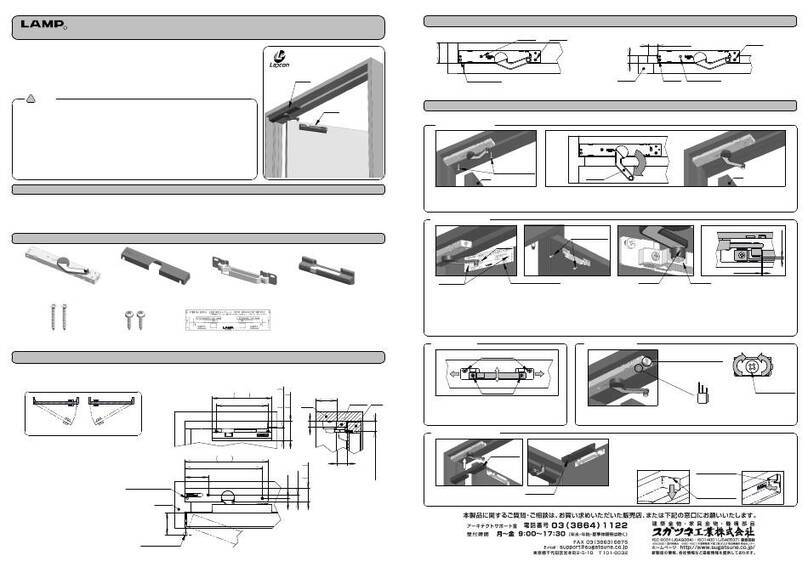

HANGING THE DOOR AND ADJUSTMENT

2

Upper roller

(casing)

Upper roller

(main unit)

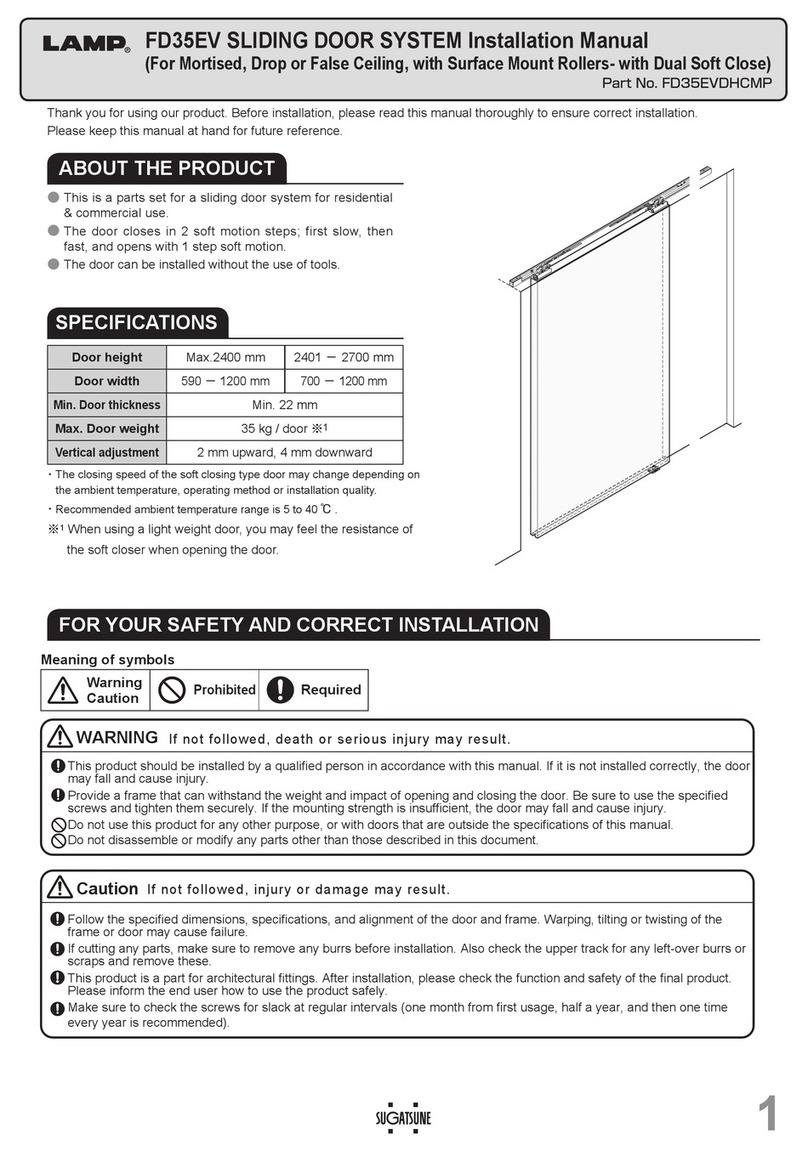

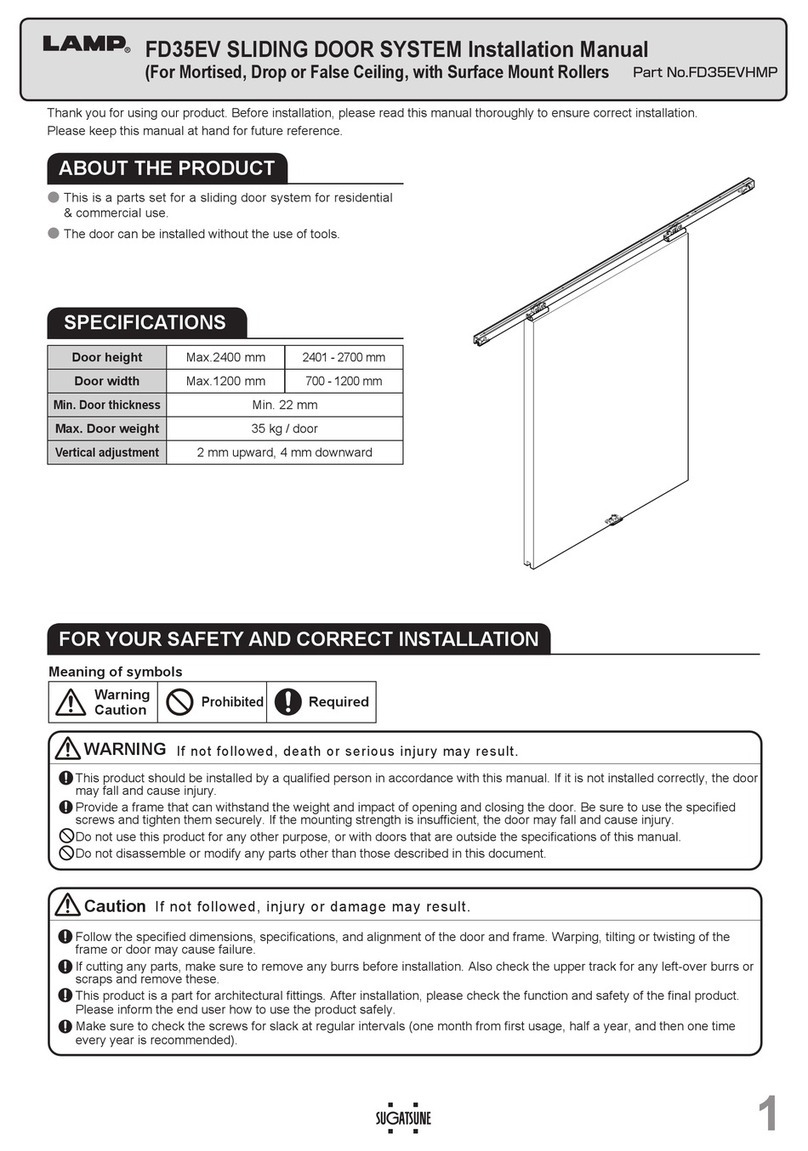

2. Door installation (top)

Insert upper roller main unit into door side casing, and push in lower end of

upper roller until “click” sound is heard.

Confirm that the lever is positioned at the mark on upper roller (main unit), as shown.

Ensure that roller main unit is securely attached to the casing.

Floor guide Lever

上

下上

下

Mark

Lever

Lever Mark

1. Door installation (bottom)

Put a 10mm support under the door. Insert the floor guide in the

groove, and then hang the door.

Correct lever position Incorrect lever position

右左

上

下

Vertical position adjust screw

9

3

4

When removing the door

Use a 10mm support under the door. Then pull out the upper

roller main unit from the door while raising the lever.

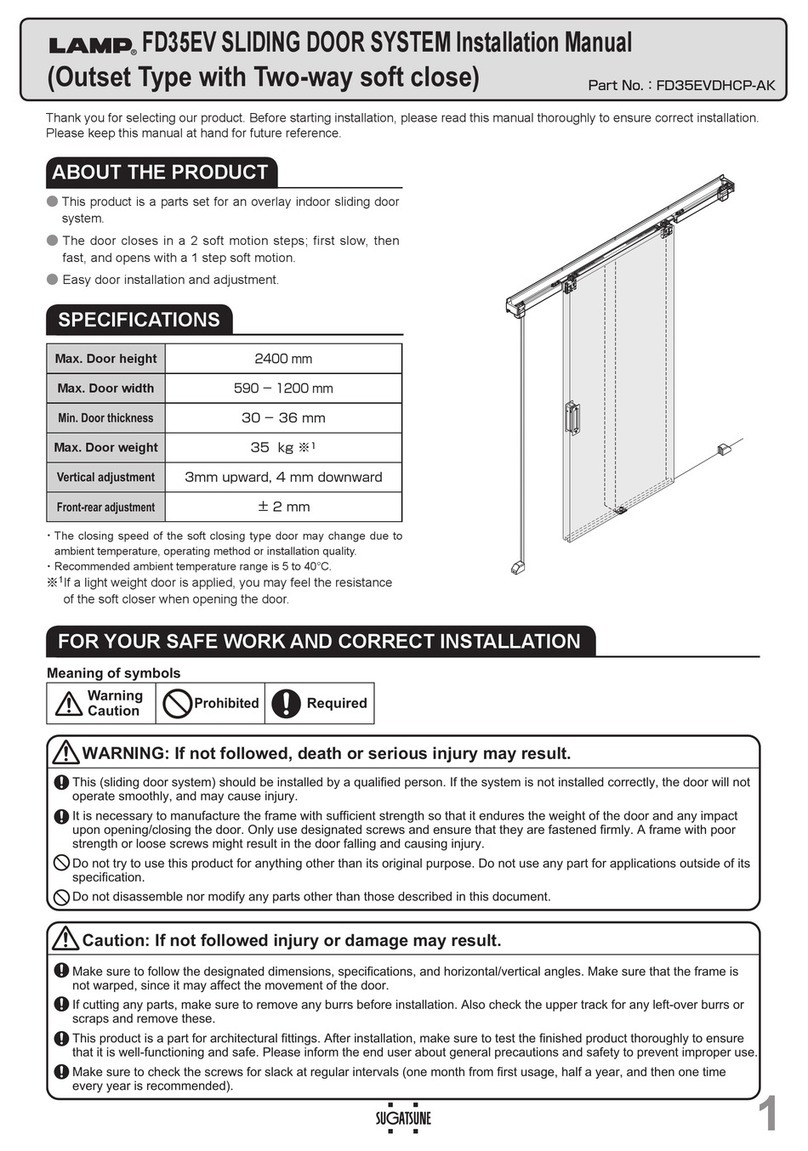

4. Adjusting door position

Adjust door such that door is parallel to upper track with 10mm clearance between door and floor.

Do not turn adjustment screw more than adjustment range.

To avoid damage on the adjustment screw, do not use motor screw driver.

5. Fixing jump prevention nut

With spanner 12, tighten dual soft closer and upper roller

jump protect nuts until they will contact to main unit.

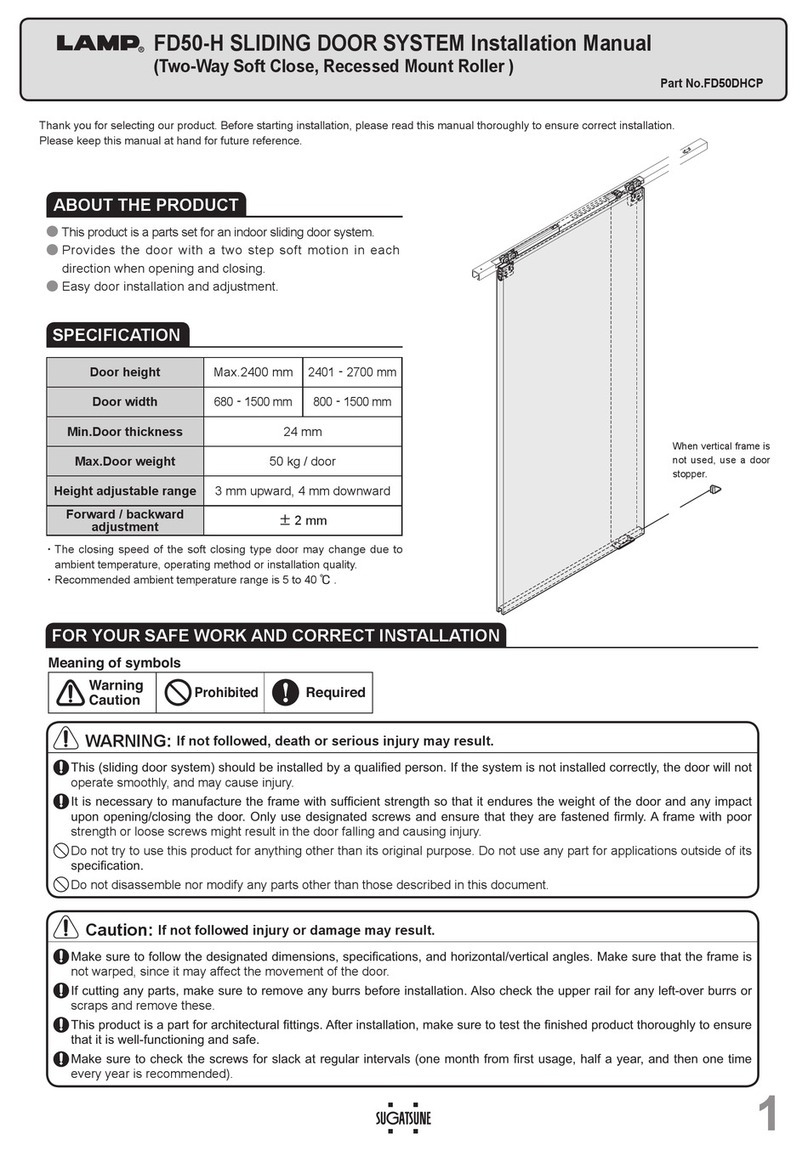

When vertical frame is not

used, install door stopper,

without fail.

Use door stopper of “Option 1”.

Door stopper

22

右左

上

下

Forward / backward adjustment screw

Clockwise =Raise

Counterclockwise=Lower

Lever

Trigger

Tighten

&RQÀUPDWLRQRIVOLGLQJGRRUFORVHURSHUDWLRQ

Slowly move the door toward door head, and confirm that sliding door closer

starts its function at approx. 115mm before full-close position. And, carry out

similar confirmation for door tail direction.

When closer is not working correctly, take remedy according to “Troubleshooting”.

Do not close the door with excessive force. It may cause damage or malfunction

of soft close mechanism.

Vertical

adjustment range: 7mm

Forward / backward

adjustment range: 4mm

PERIODICAL INSPECTION

・Clean inside of track.

・Check upper space and lower space of the door. If necessary, correct the space.

Trouble Check Solution

Door stops during soft

closing

Check if door bottom contacts with floor. Confirm that track fixing screws are not loosened. Then, adjust door height

such that clearance between door bottom and floor becomes 10 mm.

No soft closing Check if trigger is installed. Install the trigger to correct position.

Check if hook lock is used. Depending upon specification of hook lock,soft closer may not be able to close

the door. Please contact us.

Abnormal noise during

operation

Check if door touches other parts. Provide necessary space between door and adjacent objects.

Check track rollers for aluminum dust. Remove the track and pull out the roller. Then, clean the roller.

Check for loose screws retaining the upper track. Tighten the screw.

Heavy door operation Check if door touches adjacent parts. Correct door position to avoid contact to other objects.

Adjust position of floor guide or stopper.

Check if door is warped. Use the door without warp.

Door does not move. Check track retaining screws for looseness. Roller touches the screw.

Retighten screws to free the roller.

Door starts to move. Check if the upper track is set horizontally. Using a level gauge, reset upper rail horizontally.

TROUBLESHOOTING

)LQDOFRQÀUPDWLRQ

&RQÀUPWKDWDOOVFUHZVDUHVHFXUHO\WLJKWHQHG$QGFRQÀUPWKDWDOOVFUHZVDUHXVHGZLWKRXWPLVWDNH