4

SUGATSUNE KOGYO CO.,LTD

Tokyo, JAPAN

SUGATSUNE KOGYO (UK) LTD

Reading, UK

Phone: +44 118 9272 955

SUGATSUNE EUROPE GmbH

Dusseldorf, GERMANY

Phone: +49 211 53812900

SUGATSUNE SHANGHAI Co., LTD

Shanghai, CHINA

Guangzhou, CHINA

SUGATSUNE KOGYO INDIA PRIVATE LIMITED

Mumbai, INDIA

SUGATSUNE AMERICA, INC

California, USA

Chicago, USA

Phone: +1 312 461 1081

SUGATSUNE CANADA, INC.

Phone: +1 514 312 5267

2017.10 0516-6

Trouble Check Point Remedy

Door stops during soft

closing &KHFNLIGRRUERWWRPFRQWDFWVZLWKÀRRU Confirm that

track

fixing screws are not loosened. Then, adjust door height

VXFKWKDWFOHDUDQFHEHWZHHQGRRUERWWRPDQGÀRRUEHFRPHVPP

No soft closing Check if door stops before door stopper. Close the door completely. This will reset the function.

Check if trigger is installed. Install the trigger to correct position.

Check if door is closed with excessive force. Do not close the door with excessive force. It prevents suitable function

causing trouble. Use normal operating force.

Abnormal noise during

operation Check if door contacts to other parts. Provide necessary space between door and adjacent objects.

Check inside of upper track for existence of foreign

matter such as aluminum dust. Remove dust or foreign matter.

Check track rollers for existence of dust or aluminum powder.

Remove the

track

and pull out the roller. Then, clean the roller.

Check for loosened screws retaining the upper

track.

Tighten the screw.

Heavy door operation Check if door contacts to other parts. Provide necessary space between door and adjacent objects.

Check if door is warped. Use the door without warp.

Door starts to move. Check

track

retaining screws for looseness. Tighten the screw.

Door does not move. Check the upper

track

if it is set horizontally. Using a level gauge, reset upper

track

horizontally.

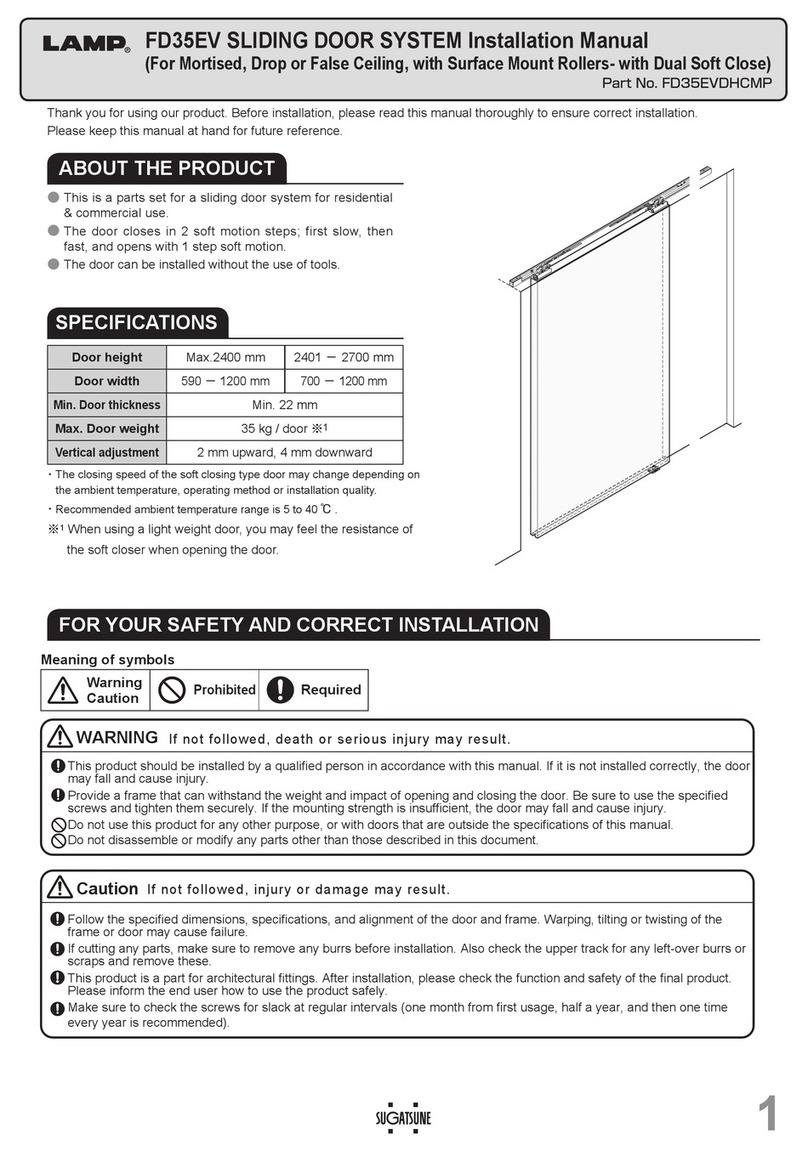

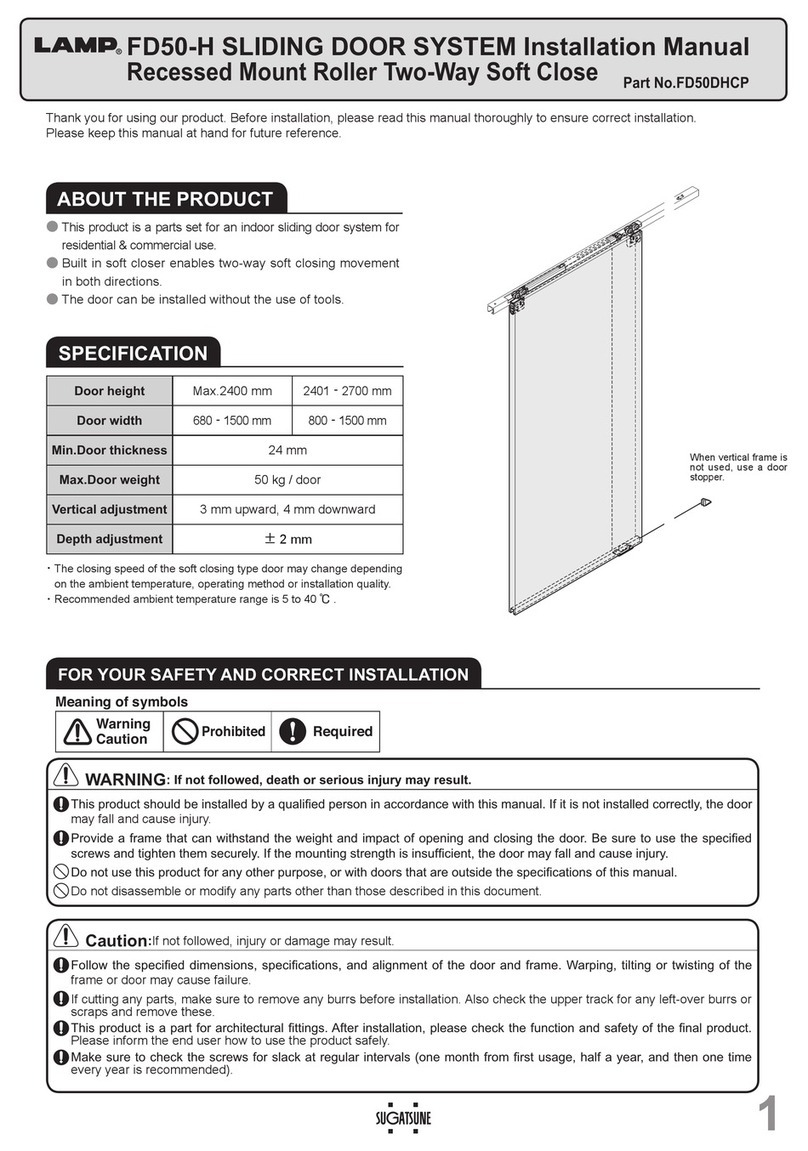

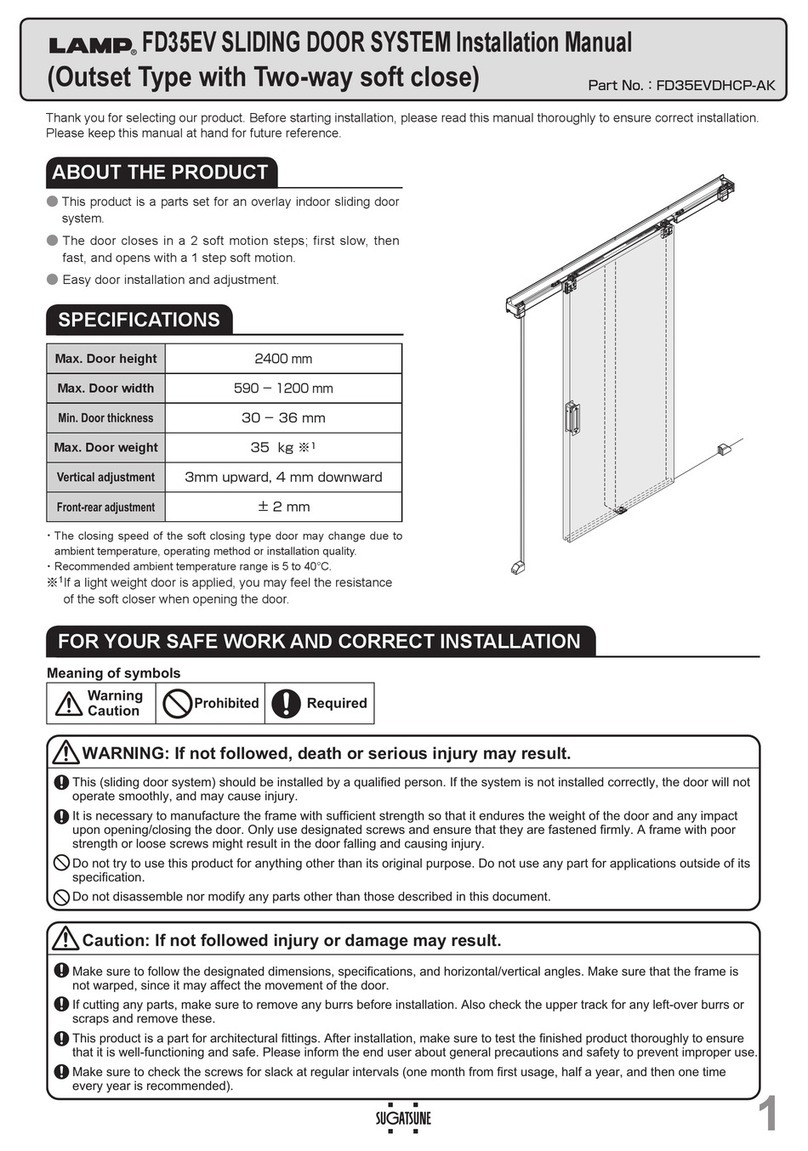

&RQ¿UPLQJ7ZRZD\6RIW&ORVHU2SHUDWLRQ

(1)

6ORZO\PRYHWKHGRRUWRZDUGGRRUKHDGDQGFRQ¿UPWKDWVOLGLQJGRRU

closer starts its function at approx. 115 mm before full-close position.

$OVRFRQ¿UPWKDWWKHGRRUFORVHUVWDUWVLWVIXQFWLRQDWDSSUR[

115 mm before full-open position.

If the closer is not working correctly, check the Troubleshooting section.

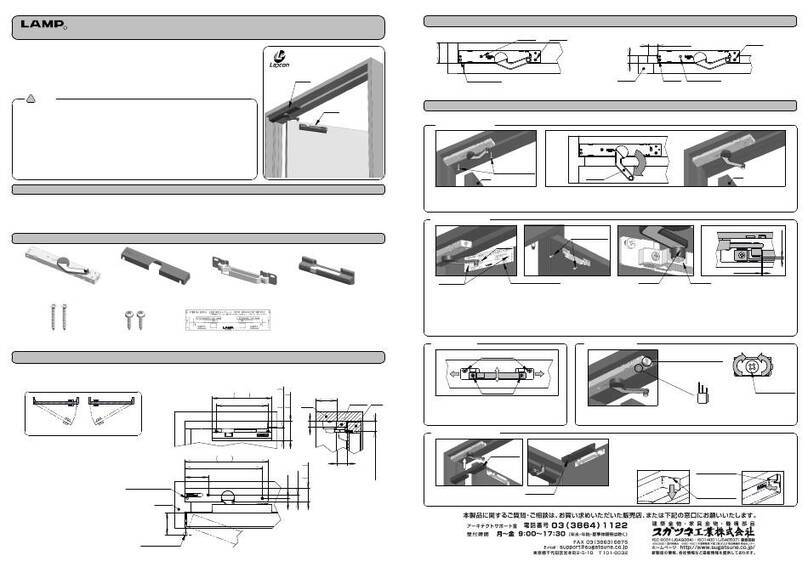

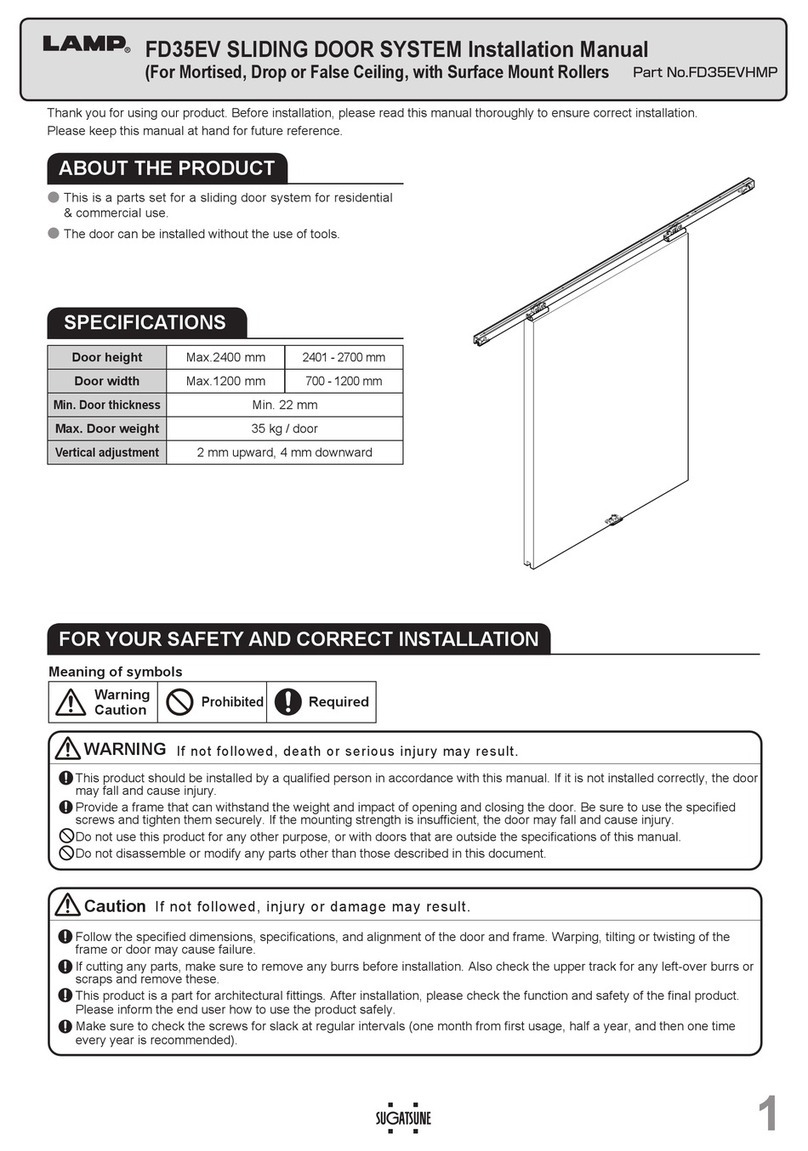

3. Adjusting Door Position

approx 115mm approx 115mm

Frame Frame

Trigger 1

Two-way soft closer

Upper roller

Trigger 2

Leading edge Trailing edge

TROUBLESHOOTING

Periodical

Inspection ・Clean inside of track.

・Check upper space and lower space of the door. If necessary, correct the space.

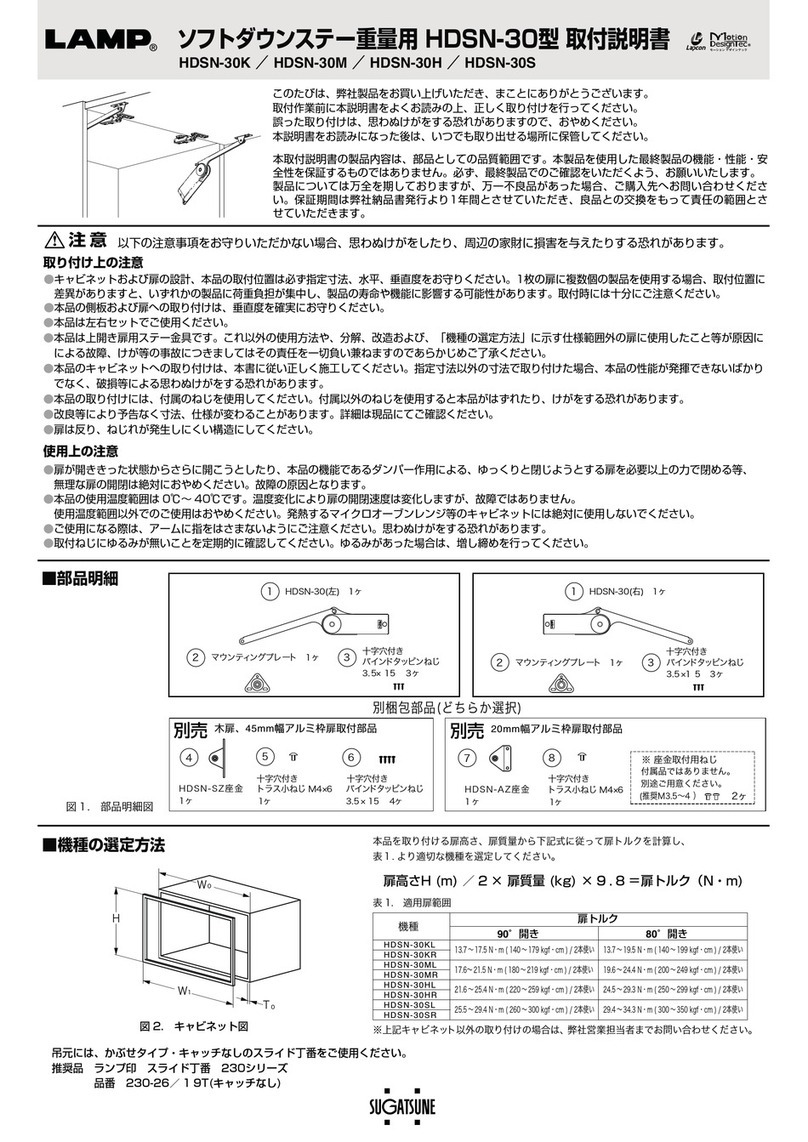

1

2

34

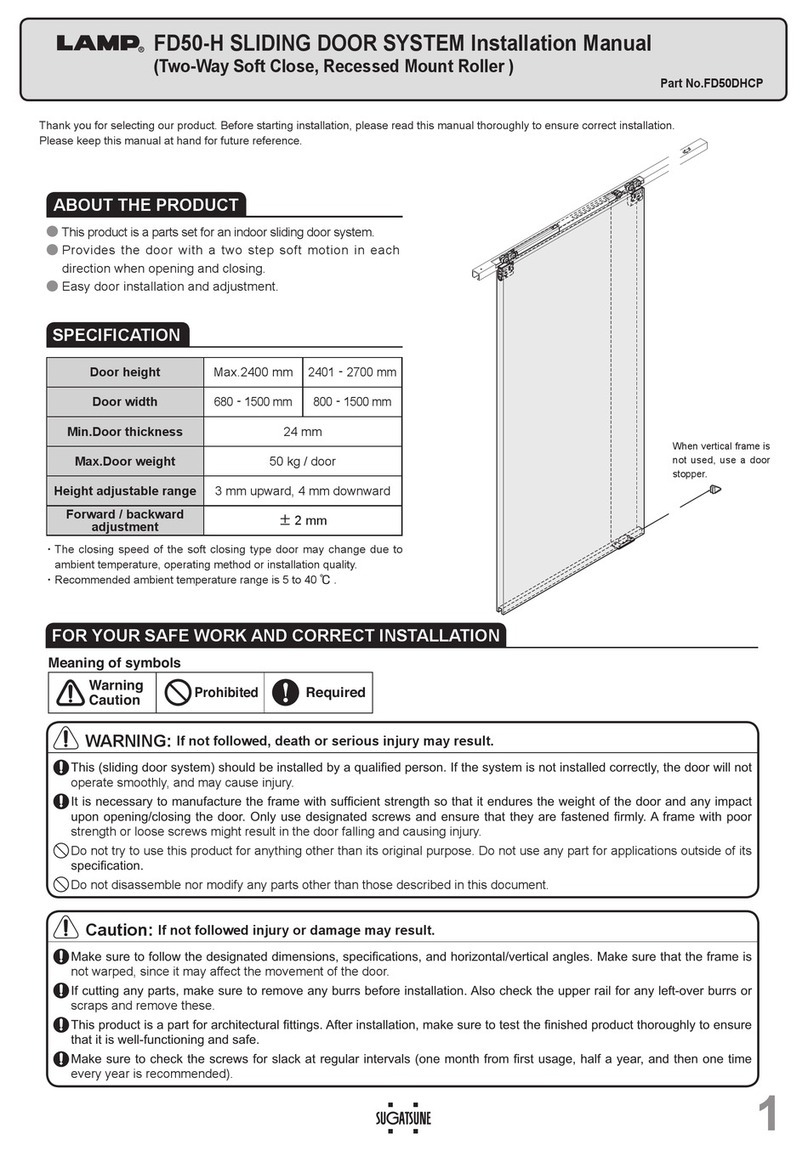

Remove holder

Bracket

Upper roller①③ Holder

Vertical adjustment

range: 8mm

Adjust door such that door is parallel to upper track

with 8mm clearance between door and floor.

Bracket

M8 Hanger bolt

Down Raise

Fix holder

Do not turn adjustment screw

more than adjustment range.

Bracket

Upper roller①③ Holder

Ensure that hanger bolt head

is in straight position.

10

Confirm that the pawl

of shaft support holder

catches opposite side of

the holder.

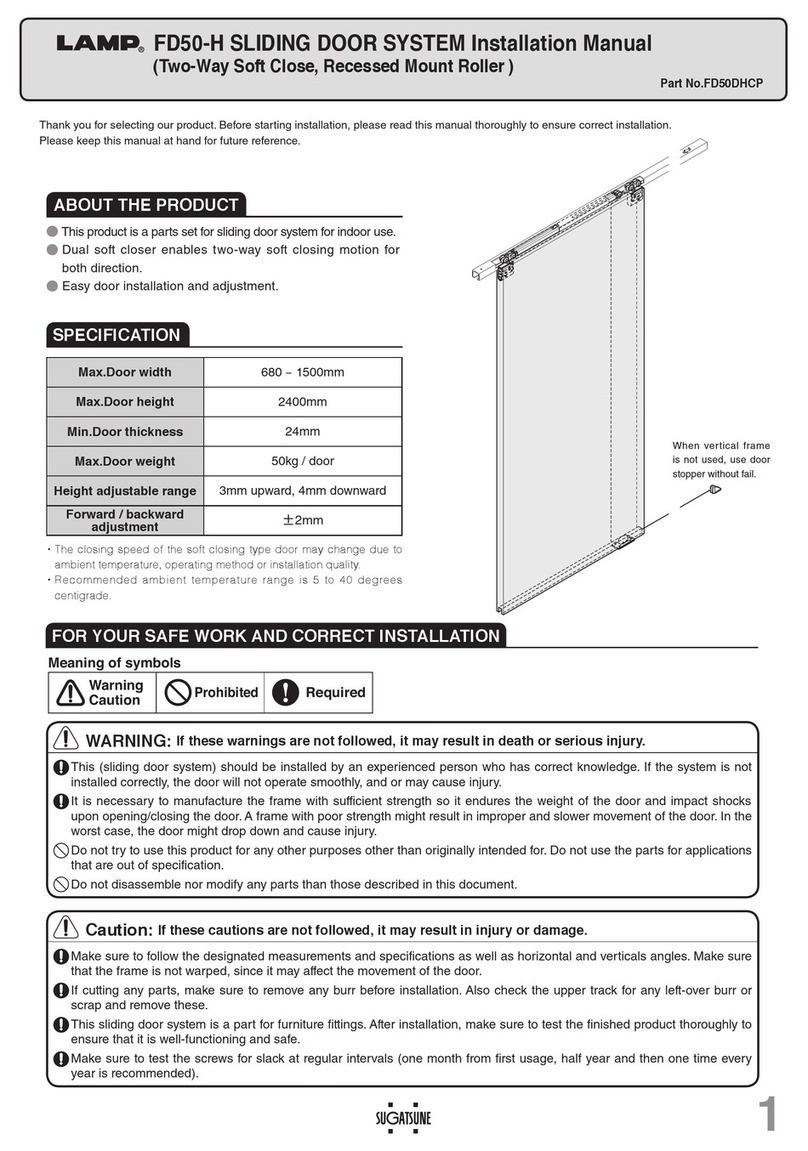

■Installing Door Stopper (Floor)

Make sure to install the Door stopper (floor) when vertical frame

is not used.

■How to Remove Door

(1)Put a support under the door.

(2)Pull out the Holder.

(4)Remove the door from the Floor guide.

⑨Floor door stopper (Optional)

(3)Pull out the Upper roller

from the Bracket.

Holder

Upper roller

①③ Bracket