TABLE OF CONTENTS

Section/Title Page

169603 3RevisionB

INTRODUCTION........................................................................................................................................................2

GENERAL SAFETY ..................................................................................................................................................4

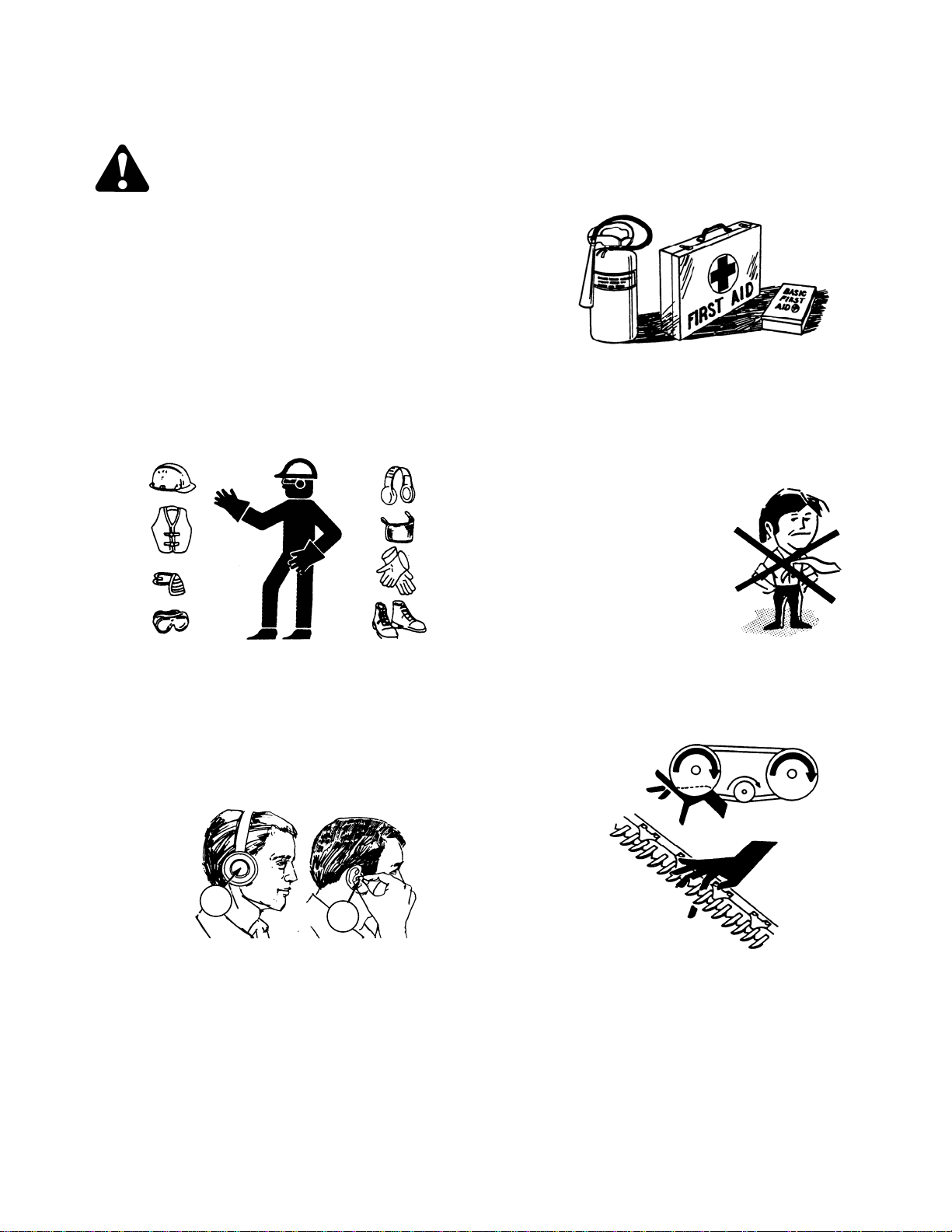

RECOMMENDED TORQUES ...................................................................................................................................6

A.GENERAL..........................................................................................................................................6

B.SAE BOLTS.......................................................................................................................................6

C.METRIC BOLTS................................................................................................................................6

D.HYDRAULIC FITTINGS.....................................................................................................................7

CONVERSION CHART .............................................................................................................................................9

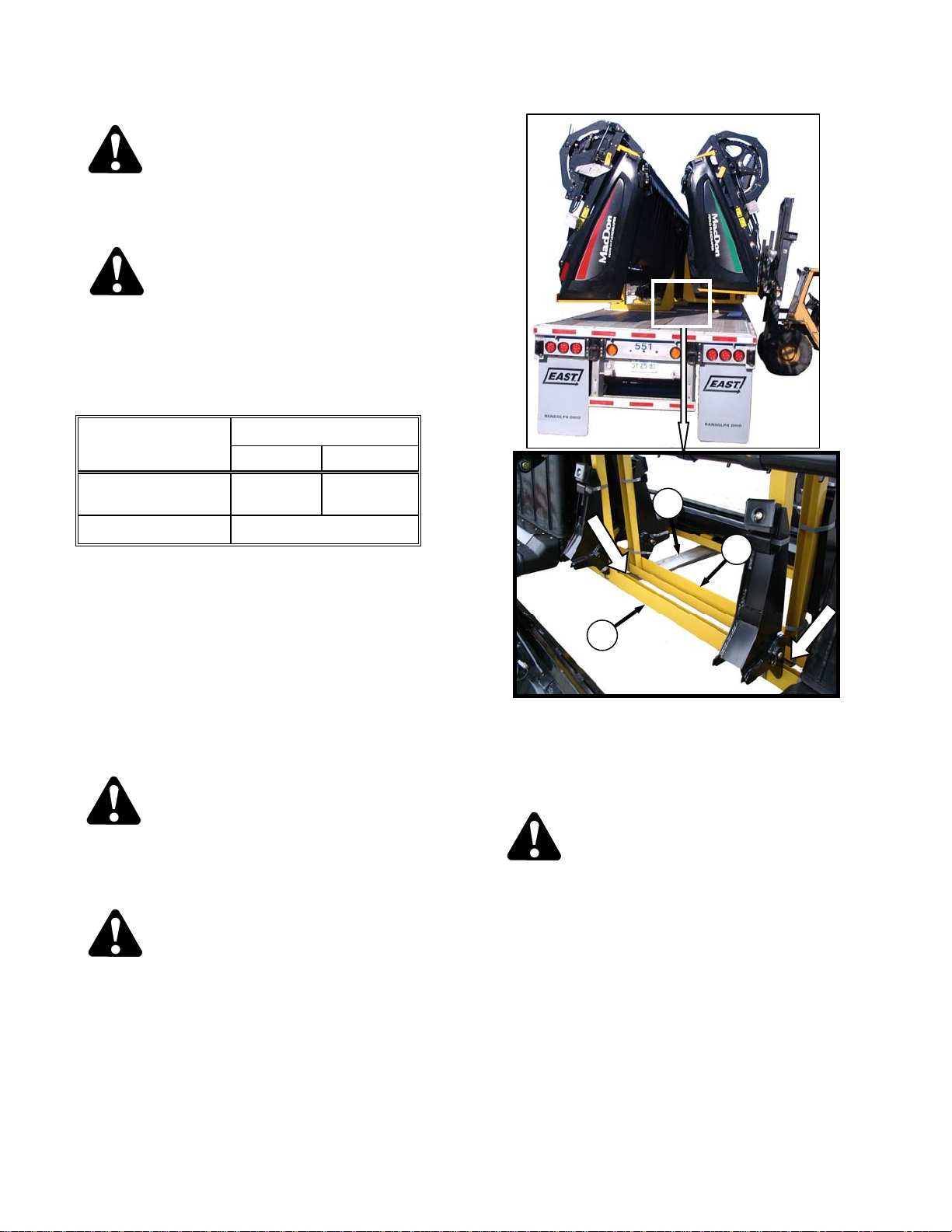

STEP 1. UNLOAD HEADER..................................................................................................................................10

STEP 2. LOWER HEADER....................................................................................................................................11

A.SINGLE REEL HEADERS...............................................................................................................11

B.DOUBLE REEL HEADERS.............................................................................................................12

STEP 3.REMOVE SHIPPING SUPPORTS.......................................................................................................13

STEP 4.INSTALL REEL LIFT CYLINDERS .....................................................................................................15

STEP 5.ATTACH TO WINDROWER ................................................................................................................18

STEP 6.CONNECT CENTER-LINK ..................................................................................................................20

STEP 7.CONNECT HYDRAULICS...................................................................................................................22

STEP 8.ATTACH CAM ARMS..........................................................................................................................24

STEP 9.INSTALL CROP DIVIDERS.................................................................................................................25

STEP 10.TRIM DRAPER DEFLECTORS...........................................................................................................26

STEP 11.ADJUST TRANSPORT LIGHTS..........................................................................................................26

STEP 12.INSTALL OPTIONS.............................................................................................................................26

STEP 13.ADD BALLAST....................................................................................................................................27

STEP 14.PRE-DELIVERY INSPECTION............................................................................................................28

A.TIRE PRESSURE (Transport and Stabilizer Wheel Options).........................................................28

B.WHEEL BOLT TORQUE (Transport and Stabilizer Wheel Options) ..............................................28

C.SICKLE DRIVE BOX .......................................................................................................................28

D.SICKLE DRIVE BELT TENSION.....................................................................................................29

I.NON-TIMED DRIVE: SK and DK..............................................................................................29

II.TIMED DRIVE: DK....................................................................................................................29

E.REEL CENTERING.........................................................................................................................30

F.DRAPER TENSION.........................................................................................................................31

G.SKID SHOE SETTINGS..................................................................................................................32

H.HEADER LEVELLING.....................................................................................................................32

I.REEL TINE TO CUTTERBAR CLEARANCE..................................................................................33

J.DRAPER SEAL................................................................................................................................35

K.ENDSHIELDS..................................................................................................................................36

L.LUBRICATE HEADER.....................................................................................................................38

M.MANUALS .......................................................................................................................................41

STEP 16.RUN-UP THE HEADER.......................................................................................................................42

STEP 17.POST RUN-UP CHECKS.....................................................................................................................43

A.KNIFE ..............................................................................................................................................43