Docking alternatives

SMO 40 can be connected with other products from

NIBE in several different ways, some of which are shown

below (accessories may be required).

Further option information is available at www.nibe.eu

and in the respective assembly instructions for the ac-

cessories used. See page 55 for a list of the accessories

that can be used with SMO 40.

Installations with SMO 40 can produce heating and

hot water. Cooling can also be produced, but it de-

pends on the heat pump that is used.

On cold days of the year when the access to energy

from the air is reduced the additional heating can

compensate and help to produce heat. The additional

heating is also good to have as assistance if the heat

pump ends up outside its working range or if it has

been blocked for any reason.

NOTE

The heating medium side and the hot water

side must be fitted with the necessary safety

equipment in accordance with the applicable

regulations.

This is the outline diagram. Actual installations

must be planned according to applicable

standards.

Explanation

SMO 40AA25

Outdoor sensor1)

BT1

Temperature sensor, hot water charging1)

BT6

Temperature sensor, hot water top1)

BT7

Temperature sensor, external supply line1)

BT25

Room sensor1)

BT50

Temperature sensor, external supply line

after electric heater

BT63

Temperature sensor, external return line1)

BT71

Circulation pump, Heating mediumGP10

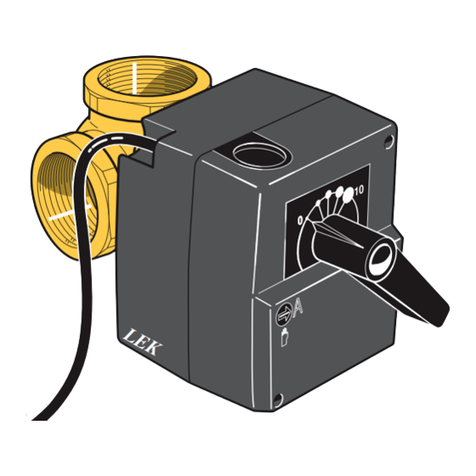

Reversing valve, Hot water/Heating medi-

um2)

QN10

Pool system 1 to 2CL11 to 12

Unit box with accessory card2)

AA25

Temperature sensor, pool2)

BT51

Exchanger, poolEP5

Circulation pump, poolGP9

Particle filter, poolHQ4

Three way valve, pool2)

QN10

Trim valveRN10

Additional heatEB1

Expansion vesselCM5

Immersion heaterEB1

Safety valveFL10

Auxiliary relay/Contactor2)

KA1

Trim valveRN11

Shut-off valveQM42 to 43

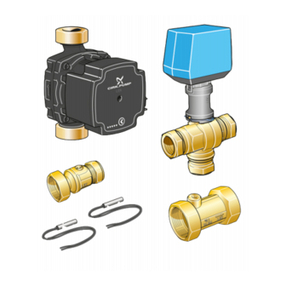

Heat pump systemEB101 to

104

Unit box with accessory card2)

AA25

Temperature sensor, return line3)

BT3

Temperature sensor, condenser supply

line3)

BT12

Heat pumpEB101 to

104

Safety valveFL10

External circulation pump, climate systemGP10

Charge pump2)

GP12

Particle filter3)

HQ1

Drain valve, Heating mediumQM1

Shut-off valve, Heating medium, FlowQM31

Shut off valve, Heating medium, ReturnQM32

Shut-off valveQM43

Non-return valveRM11

Climate system 2 to 3EP21 to 22

Unit box with accessory card2)

AA25

Temperature sensor, heating medium

supply2)

BT2

Temperature sensor, heating medium re-

turn2)

BT3

Circulation pump2)

GP20

SMO 40Chapter 4 | Pipe connections10