Perma STAR CONTROL User manual

Other Perma Lubrication System manuals

Perma

Perma FUTURA 120 User manual

Perma

Perma STAR VARIO User manual

Perma

Perma Classic 120 User manual

Perma

Perma STAR VARIO User manual

Perma

Perma STAR VARIO User manual

Perma

Perma FLEX 60 User manual

Perma

Perma NOVA 125 User manual

Perma

Perma FLEX PLUS Series User manual

Perma

Perma FLEX Series User manual

Perma

Perma PRO LINE User manual

Perma

Perma STAR VARIO Owner's manual

Perma

Perma PRO 500 Quick guide

Perma

Perma CLASSIC User manual

Perma

Perma PRO 250 Manual

Perma

Perma CLASSIC Series User manual

Perma

Perma Star Control Time User manual

Perma

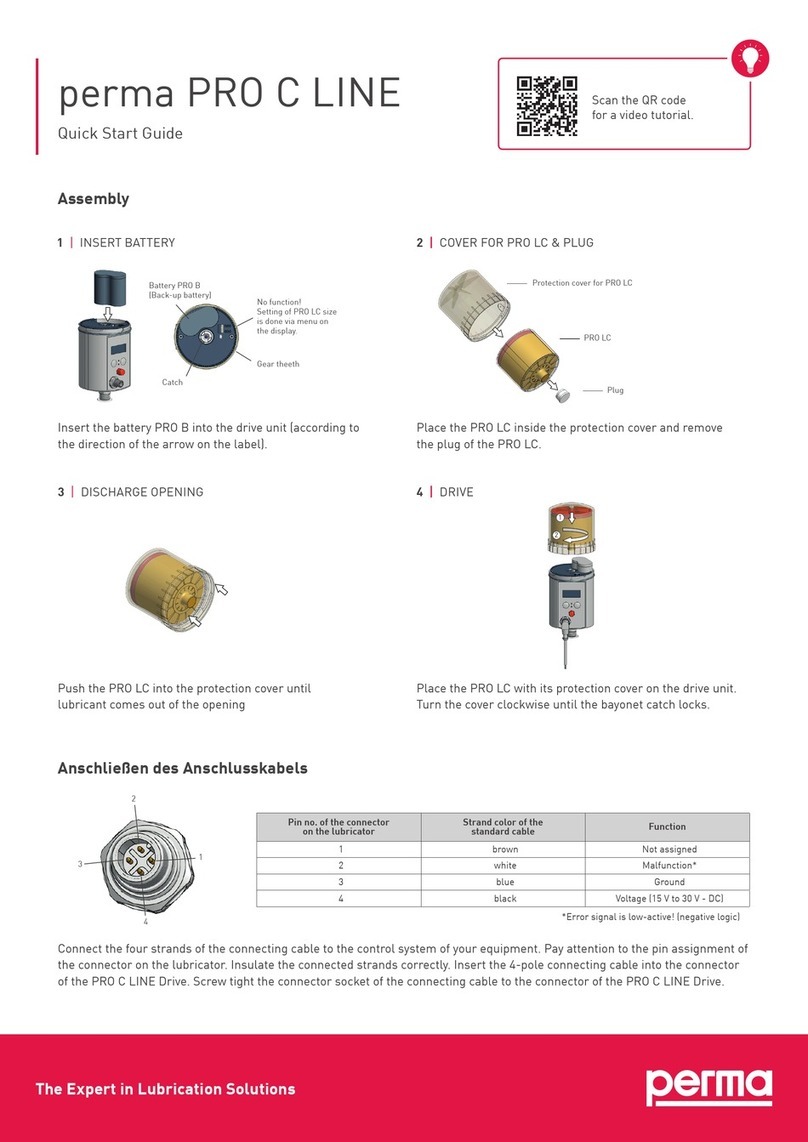

Perma PRO C LINE User manual

Perma

Perma ECOSY 5 Quick guide

Perma

Perma STAR VARIO User manual

Perma

Perma FUTURA Manual

Popular Lubrication System manuals by other brands

Groeneveld

Groeneveld Multiline AC Series installation manual

MATO

MATO eHybrid-Greaser 230V operating instructions

Timken

Timken M-Power 300 installation instructions

MEMOLUB

MEMOLUB HPS instructions

IMI

IMI norgren Micro-Fog L68C Installation & maintenance instructions

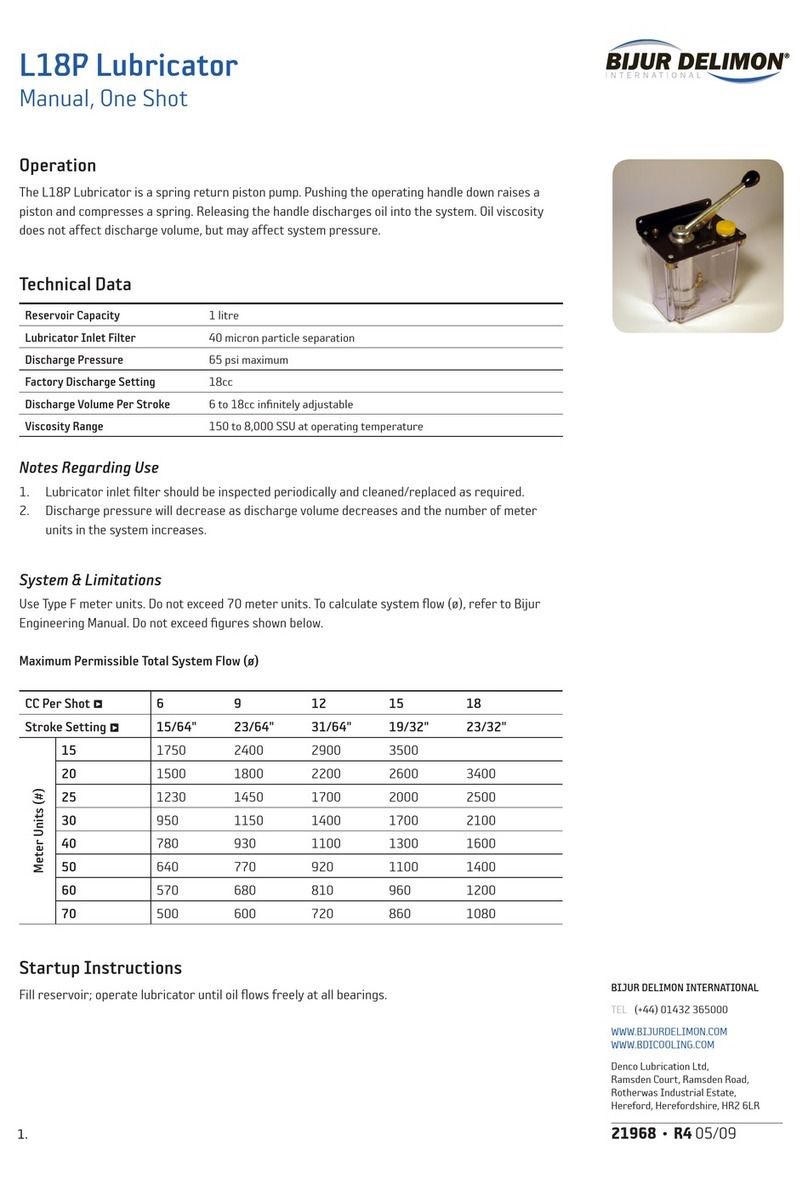

Bijur Delimon

Bijur Delimon L18P manual