PI L-306 Series User manual

Other PI Valve Positioner manuals

PI

PI M-403 DG Series User manual

PI

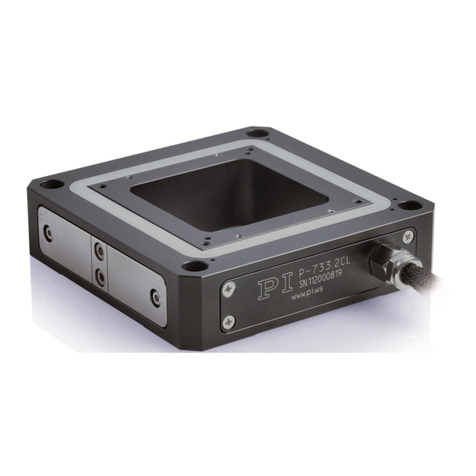

PI P-73 Series User manual

PI

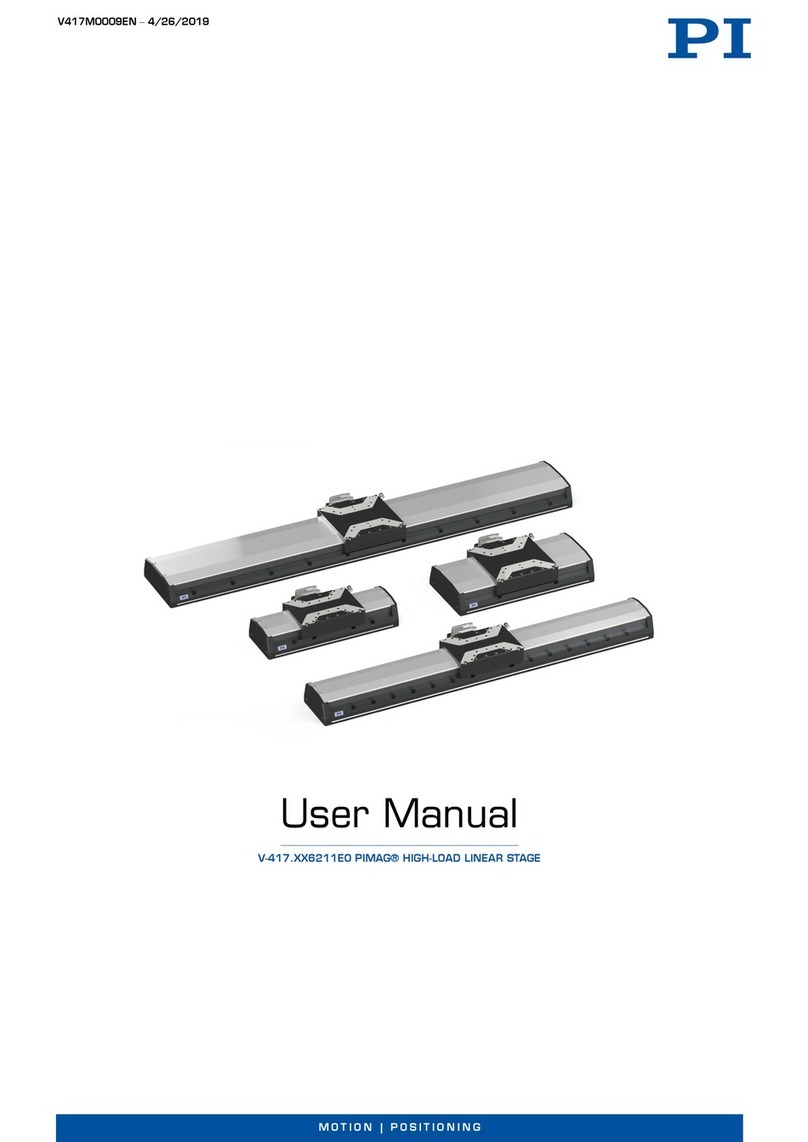

PI PIMAG V-417.6211E0 Series User manual

PI

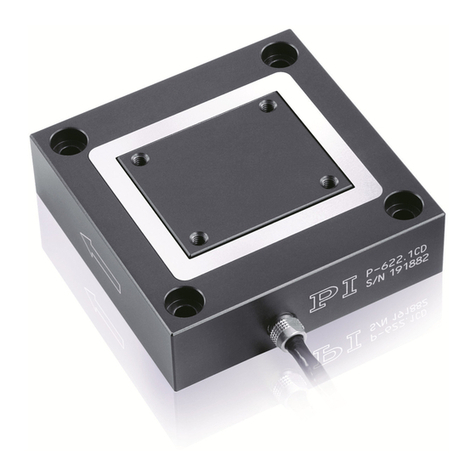

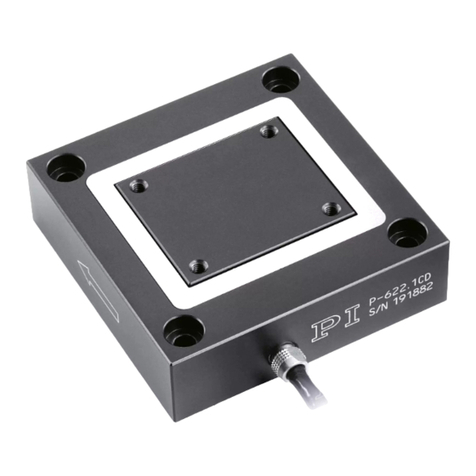

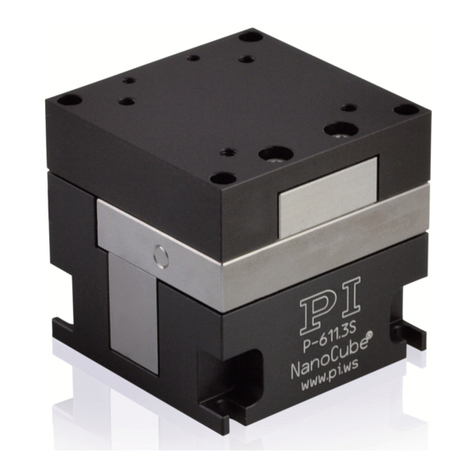

PI P-62 Series User manual

PI

PI P-54 Series User manual

PI

PI P-611 Series User manual

PI

PI PIMAG V-417.6025E0 Series User manual

PI

PI NEXACT Stage N-565 Series Manual

PI

PI P-611 Series User manual

PI

PI Q-Motion Q-632 Manual

Popular Valve Positioner manuals by other brands

Westlock

Westlock Quantum 2800 Installation & operating instructions

Samson

Samson 3730-0 Mounting and operating instructions

Samson

Samson TROVIS 3730-3 Mounting and operating instructions

ESCO Technologies

ESCO Technologies ETS LINDGREN 2302-001 user manual

SMC Networks

SMC Networks IP8000 manual

Samson

Samson FOUNDATION 3730-5 Mounting and operating instructions

Samson

Samson TROVIS SAFE 3731-3 Mounting and operating instructions

Flowserve

Flowserve Logix 3400MD User instructions

halstrup-walcher

halstrup-walcher HIPERDRIVE instruction manual

ABB

ABB TZIDC Commissioning instructions

Samson

Samson FOUNDATION 3730-5 Mounting and operating instructions

halstrup-walcher

halstrup-walcher PS*3**DP series instruction manual