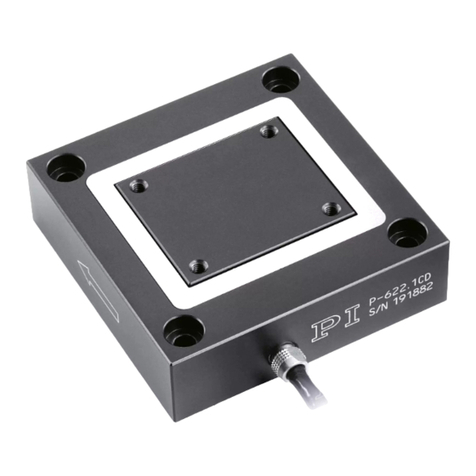

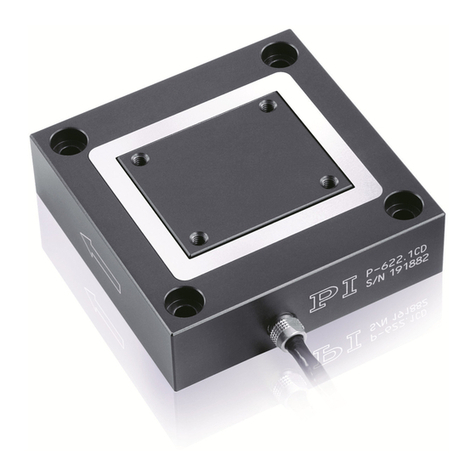

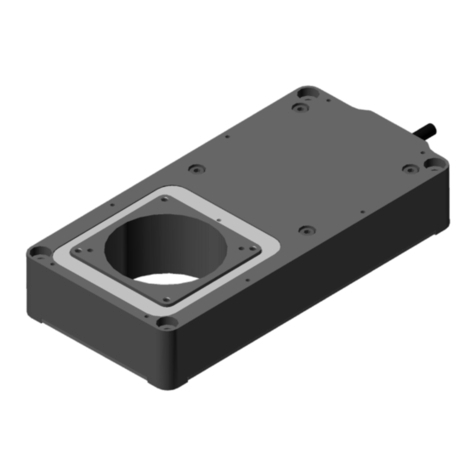

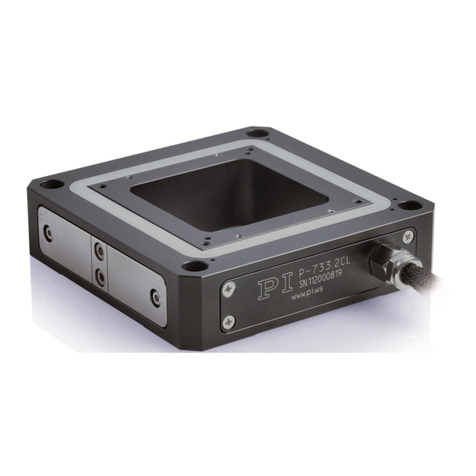

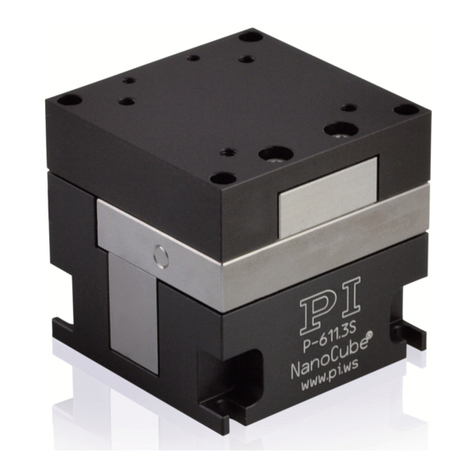

6 Version: 3.2.0 PZ82E P-5x7/P-5x8 Positioners

The P-5x7/P-5x8 is driven by piezo actuators. Temperature changes and compressive stress can

induce charges in piezo actuators. Piezo actuators can remain charged for several hours after

disconnecting the electronics. Touching or short-circuiting the contacts in the P-5x7/P-5x8's

connector can lead to minor injuries from electric shock. The piezo actuators can be destroyed

by an abrupt contraction.

Do not open the P-5x7/P-5x8.

Discharge the positioner's piezo actuators before installing:

Connect the positioner to the switched-off PI electronics equipped with an internal

discharge resistor.

Do not pull the plug connector out of the electronics during operation.

Positioners with D-sub plug connector:

Touching the contacts in the plug connector can lead to an electric shock (max. 130 V DC) and

minor injuries.

Do not touch the contacts in the plug connector.

Use screws to secure the positioner's connector against being pulled out of the

electronics.

If a protective earth conductor is not or not properly connected, dangerous touch voltages can

occur on the P-5x7/P-5x8 in the case of malfunction or failure of the system. If there are touch

voltages, touching the P-5x7/P-5x8 can result in minor injuries from electric shock.

Connect the P-5x7/P-5x8 to a protective earth conductor (p. 18) before starting.

Do not remove the protective earth conductor during operation.

If the protective earth conductor has to be removed temporarily (e.g., in the case of

modifications), reconnect the P-5x7/P-5x8 to the protective earth conductor before

restarting.

Mechanical forces can damage or misalign the P-5x7/P-5x8.

Avoid impacts that affect the P-5x7/P-5x8.

Do not drop the P-5x7/P-5x8.

Do not exceed the maximum permissible stress and load capacities according to the

specifications (p. 37).

Do not touch any sensitive parts (e.g., motion platform) when handling the

P-5x7/P-5x8.

The P-5x7/P-5x8 is maintenance-free and achieves its positioning accuracy as a result of the

optimal alignment of mechanical components and piezo actuators. Loosened screws cause a

loss in positioning accuracy.

Loosen screws only when instructed in this manual.

Do not open the P-5x7/P-5x8.