8.USE WARNINGS

3

9.ELECTRICCONNECTION

B

A

B

We recommendfollowingtheindications belowinorderto alwaysworkinsafetyconditions.

·All theoperations must becarriedoutcomplyingstrictlywiththesafetyrulesof the

countrywherethedeviceisto beinstalled.

·ItisSTRICTLYFORBIDDENto smokeduringtheinstallationoradjustmentoperations of

thecuttingunit.

·TheCustomerundertakesto complywithandmakehisstaffobservealltherulesand

regulationsinforceconcerningsafety,preventionof accidentsandhealthinthework

place.Therefore,theCustomerassumestheresponsibilitytostrictlyfollowalltherulesand

regulations inforce,as wellasthespecialprovisionsinforceinsportandpublicinstallations

theCustomerdeclaresto knowafterreceivingall therelativenecessaryinformation.

·Thecuttingunitworksalsowithoutitssafetyprotectivedevice.Thisprotective

devicemustNEVERbe removed.

·Alwayscheck theresistanceofthematerialto becutandthekindofbladewhichisbeingused.

·TheCustomershallequiphisownpersonnelwithalltheindividualsafetyprotectionsfor

theexecutionoftheworks,aswellaswiththeoneswhichmightbeprescribedbythe

Manufacturerduetospecificdangerconditionsoftheplantoroftheareawherethe

personnelmust work.

·Donot makeanyadjustmentwhilethebladeisworkingorwhiletheelectricplugis

connected.

·Always payattentionto theelectriccablepositiontopreventitfrom beingcutordamaged

bytheblade.

·ItisallowedtoassemblecuttingunitGRT12 onmachinesO.E.M.onconditionthattheir

originalstructureisnot modified.Otherwise,theinterventionmust becertifiedbyRasor®.

Firstlymakesurethatthelinesareabletofeedthecuttingunitcorrecltly,in

compliancewiththesafetyrules (forthefeaturerequiredseepar.5).

Wesuggestinstallingamagnetothermicsafetydevicebeforethecuttingunitandcheck

thatthegroundcircuitiseffective.Beforeworkingonthefeedingcablepulltheplugout.

Checkthatelectricconnectionsandprotectionscorrespondtothedrivingforceandthe

platedatavalues (voltageandcurrent),requiredbythedifferentelectriccircuits.Byreferring

totheCEI11-27/1standardall theworkscarriedoutbymeansofelectriccurrentmustbe

performedbyastaff,whohasbeenprovidedwithallthedevicesrequiredbytheabove-

mentionedstandard.Fortheworkscarriedoutundervoltage,itisnecessarythatthe

employercertifiesthesuitability, againstformativeprocesses.

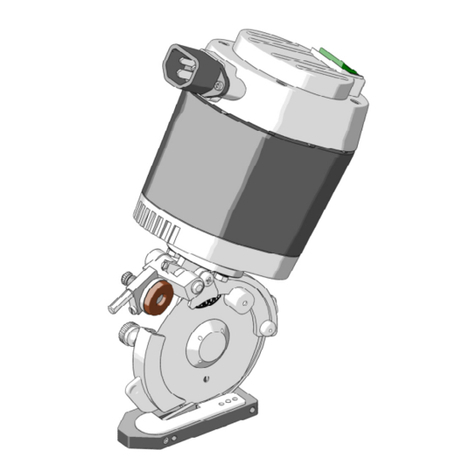

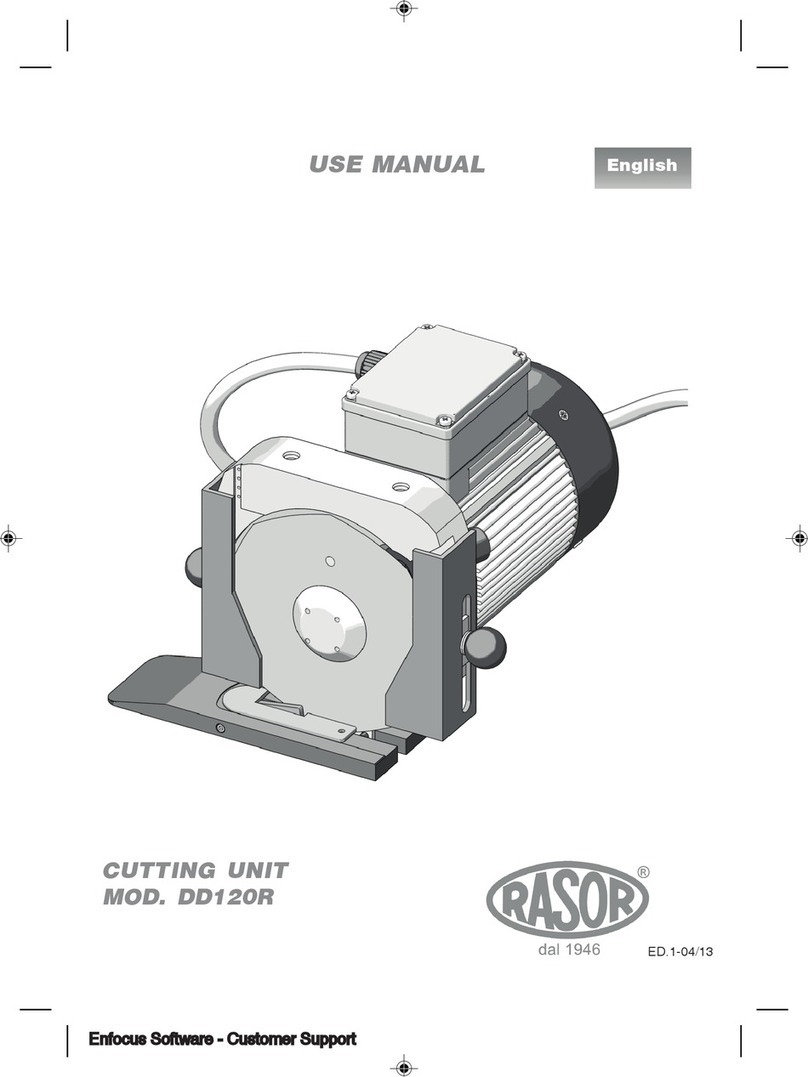

Thecuttingunit GRT12issuppliedwithelectriccable connected

totheconnectorblocklocated besidethemotor.Theuser

mustconnectthecuttingunittothemains (thecablecomplies

withtheCEI 20-22 III Standard).Neverchangethelengthof

thecablesupplied.Ifitisnecessary,usealongercableand

replacetheonesupplied.Toconnectthenewcable openthe

cover“A”byunscrewingthe 4cross-slottedscrews “B”(see

picture3).Connectthephasecabletotheterminalboard.

Theminimum sectionof theconnectingcablesmustbe

determinedbytheoperatorinchargeoftheinstallation.We

recommendto usesafetycablesandsocket IMQapproved.

Checktheconnectionbyenabling thecuttingunitandverify

therotationdirection.Thecuttingunitis provided withearthing

WARNING

Enfocus Software - Customer Support

EN

24